Full-automatic solid sensor in-vivo injector

A solid sensor, fully automatic technology, applied in the field of medical devices, can solve the problems of inconvenient, unsafe, inconvenient disassembly, etc., achieve the effect of simple assembly, improve the accuracy of measurement, and improve the success rate of assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

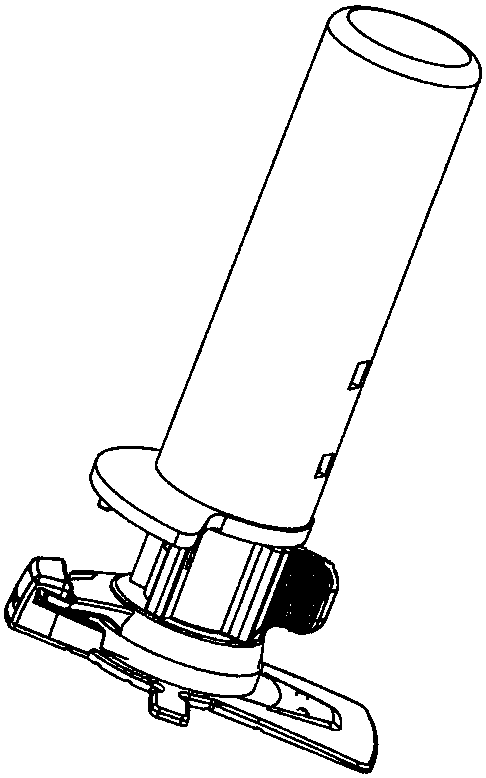

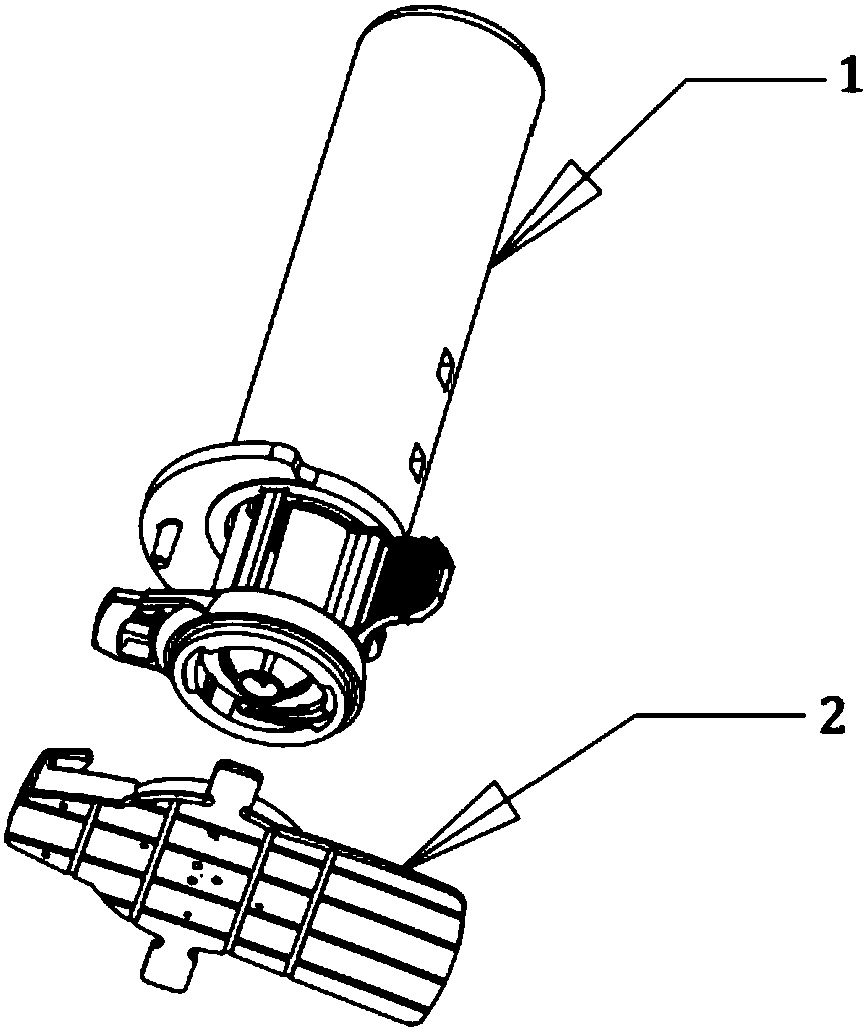

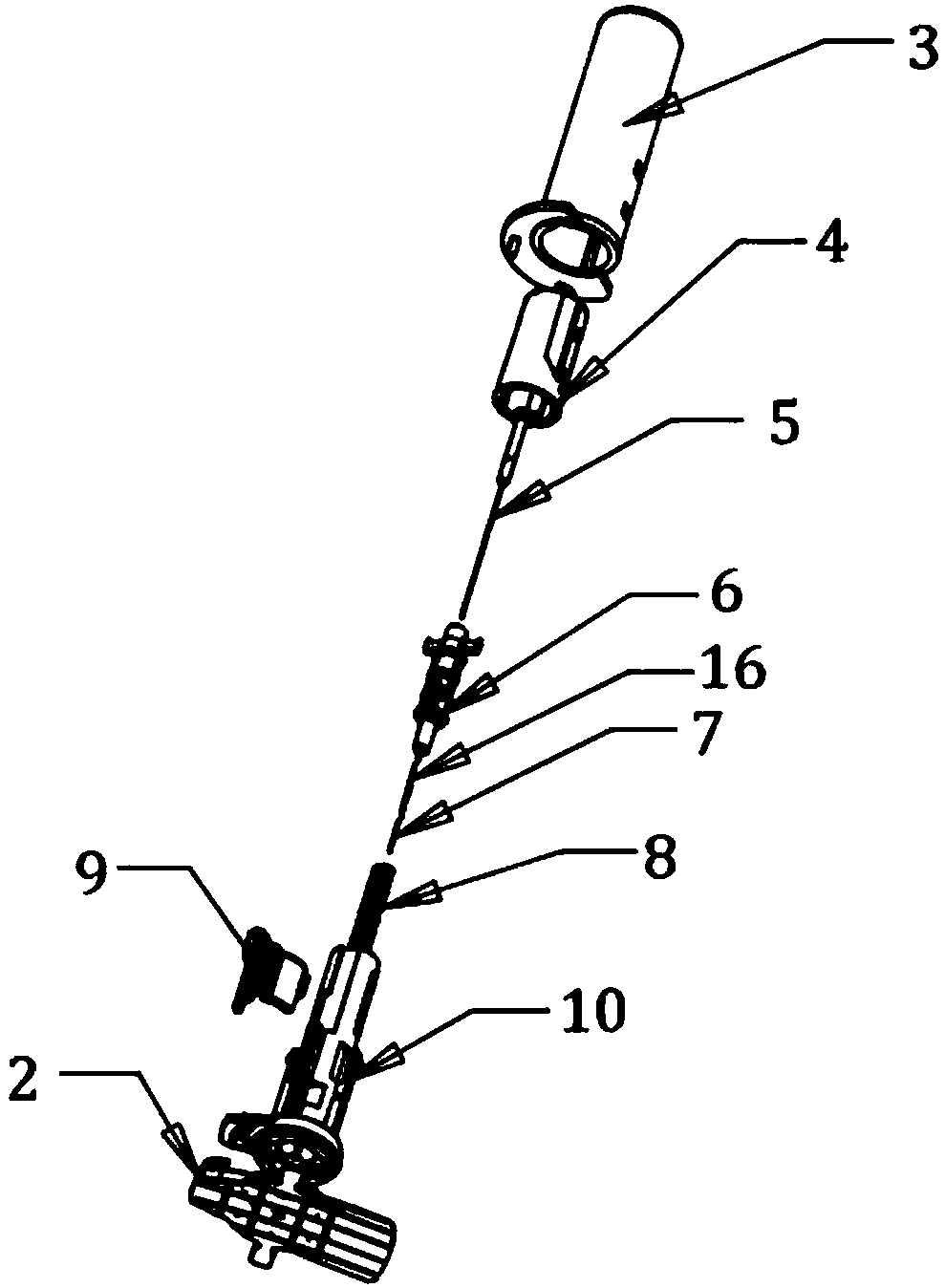

[0026] As shown in Figure 1, the syringe of this embodiment includes: a syringe part 1, a sensor fixing part 2, an outer sleeve 3, a pusher 4, a push needle assembly 5, a syringe assembly 6, a solid sensor 7, a compression spring 8, such as image 3 The shown safety lock 9, the base 10, the fixed push pin assembly 11, the step 12, the inclined surface 13, the limit step 14, and the limit groove 15, wherein: the outer sleeve 3 is connected with the base 10 through a hook, and the safety lock 9 are respectively in contact with the outer sleeve 3 and the base 10 to ensure that when the syringe is not activated, it will not cause false triggering due to misoperation, such as Figure 6 shown.

[0027] The hollow needle 16 of the syringe assembly 5 is provided with a solid sensor 7 inside, and the solid push pin of the push pin assembly 5 restricts the solid sensor 7 in the needle tube as Figure 4 location shown.

[0028] The positions of the syringe assembly 6 and the push pin a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com