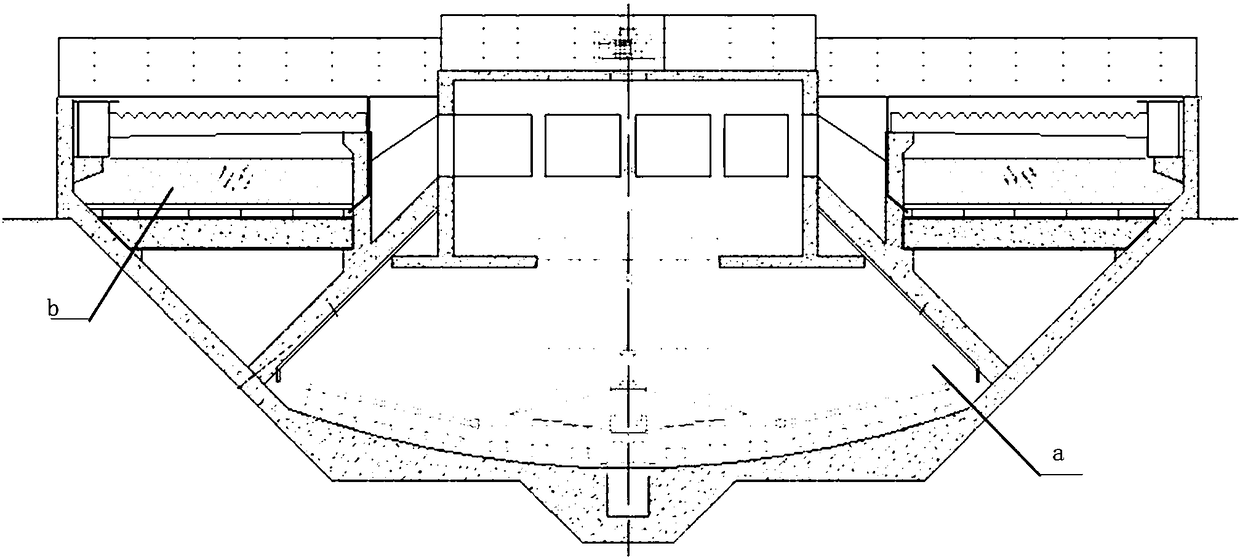

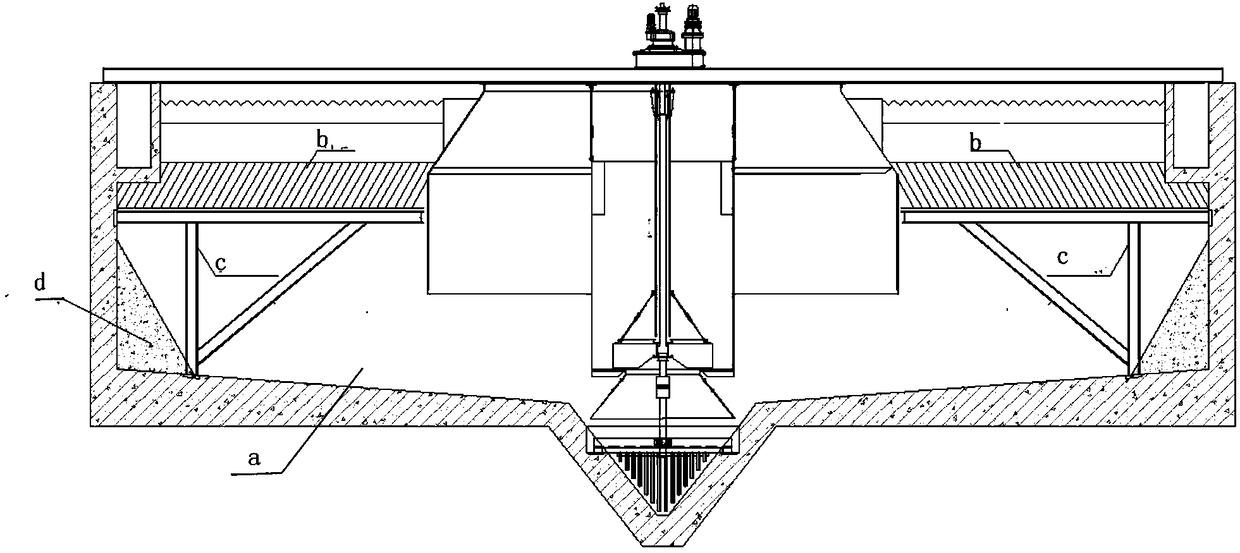

Mechanical stirring and clarifying tank with novel oblique pipe support frames

A technology of mechanical stirring and clarifier, which is applied to the feeding/discharging device of the sedimentation tank, the sedimentation tank, chemical instruments and methods, etc., which can solve the problem of affecting the flow state in the tank, poor stability of the support structure, and reducing the residence time of the clarifier, etc. problems, to achieve the effect of ensuring processing capacity and efficiency, reducing civil work workload, structural stability and high strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

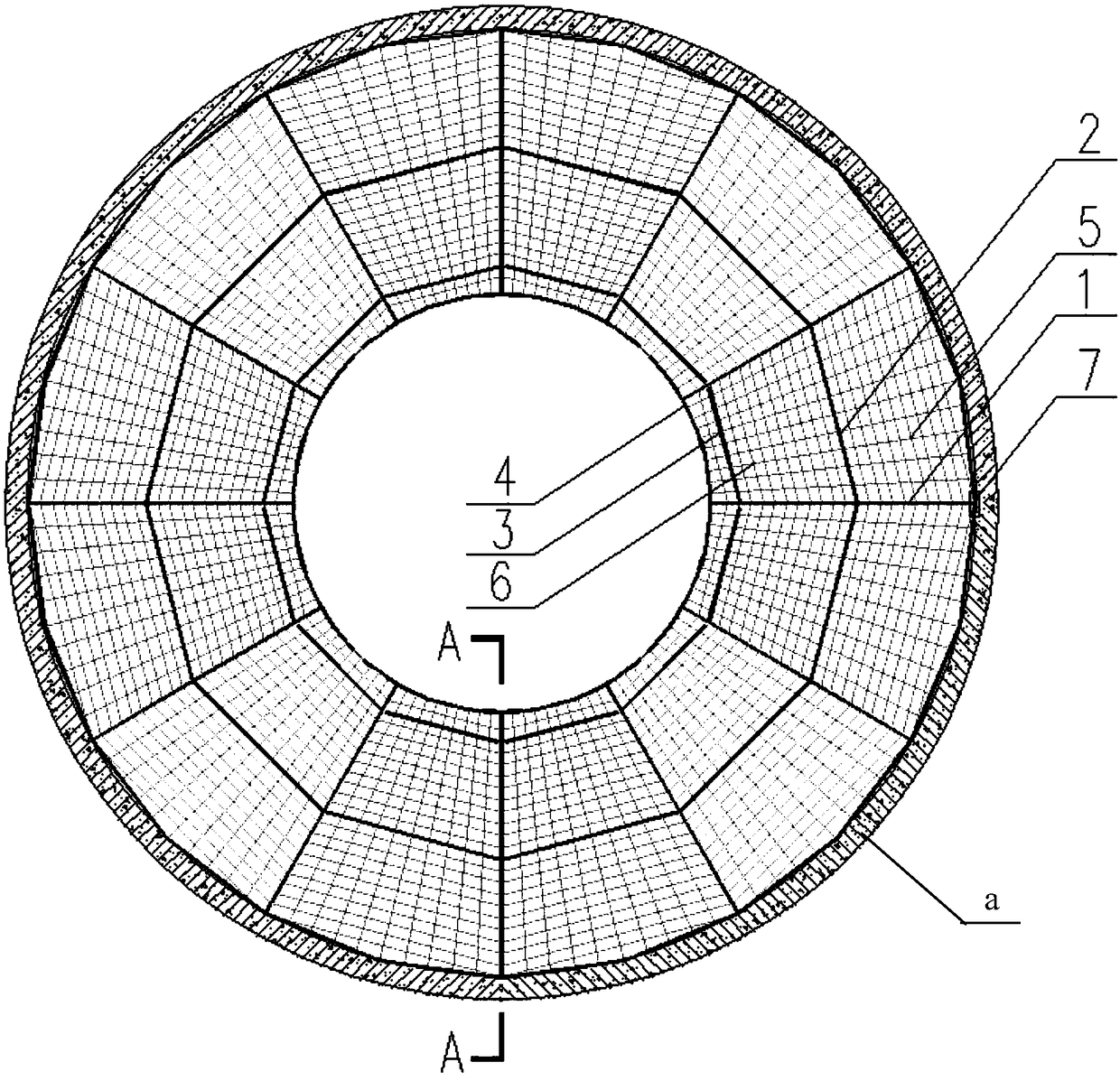

[0044] The inclined pipe support among the present invention comprises support 1, main crossbeam 2, auxiliary crossbeam 3, edge banding beam 4, cover plate 5, cover plate 6 and buried iron 7, and support 1 is radially arranged in circular pool body, and buried The iron 7 is connected with bolts, and the number of support 1 for each clarifier is more than 6. The support 1 is composed of a horizontal beam 8, a diagonal brace 9, a vertical web bar 10, a diagonal web bar 11 and a connecting block 12. The horizontal beam 8 and the diagonal brace 9 are connected with the buried iron 7 on the pool wall by bolts; the diagonal brace 9 and the horizontal beam 8 are connected by bolts on the side close to the center of the pool; Steel, vertical web bar 10, diagonal web bar 11 are respectively connected with the connecting block 12 welded on the buried iron 7, the horizontal beam 8 and the diagonal brace 9 with bolts. Both ends of the vertical web bar 10 and the diagonal web bar 11 have ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com