High-concentration dust pregrading device and method

A grading device and high-concentration technology, which is applied in separation methods, chemical instruments and methods, and separation of dispersed particles, can solve the problems of increasing the processing burden of post-stage dust collectors and increasing the intermediate links of recovery, so as to improve the comprehensive purification efficiency , The effect of reducing the burden of purification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

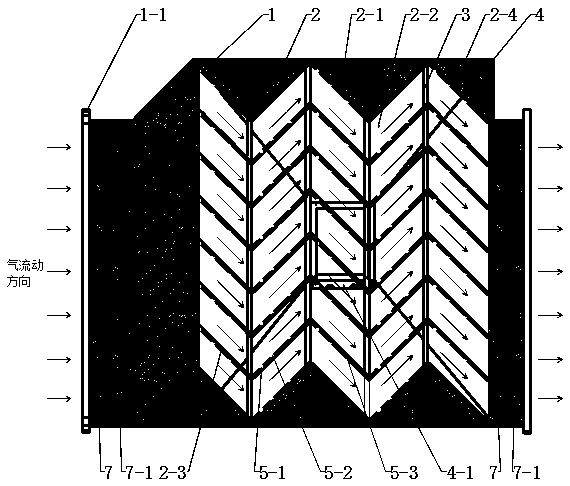

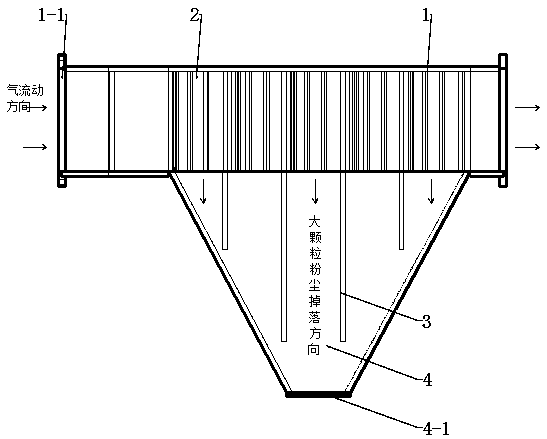

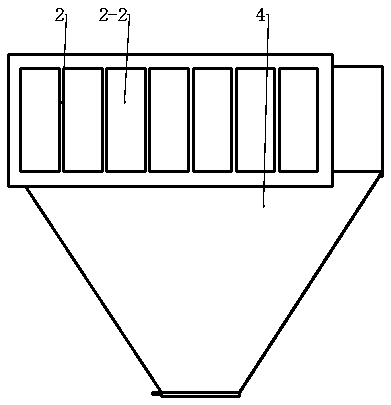

[0028] as attached figure 1 - As shown in -3, a high-concentration dust pre-classification device 10 is located between the gas collection hood suction pipeline 6 and the purification equipment, including a pipeline 1, a baffle plate 2, a baffle plate 3, a dust collector 4 and a dust collector Groove 5; the baffle plate 2 is arranged in the pipeline 1, and a plurality of relatively independent flow channels are formed in the pipeline 1, and the side of the baffle plate 2 is provided with a dust-reducing groove 5; the dust collector 4 is arranged on the side of the flow channel Below, and along the flow direction of the airflow, there are multiple baffles 3 from the baffle 2 to the bottom of the dust collector 4, and the baffles 3 are arranged at the bends of the baffles to form a Multiple spaced and connected spaces.

[0029] The pipeline 1 is a rectangular parallelepiped structure with air inlets and air outlets at both ends. The height of the inner diameter of the pipeline ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com