Screw rod driven swinging type waterborne coating and powder mixing device

A water-based paint and mixing device technology, which is applied in the direction of shaking/oscillating/vibrating mixers, mixers, mixing methods, etc., can solve the problems of affecting the mixing effect of paint, the precipitation of paint in the mixing box, and the lack of mixing effect, so as to avoid paint Precipitation or stratification, increase the flow rate, improve the effect of mixing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

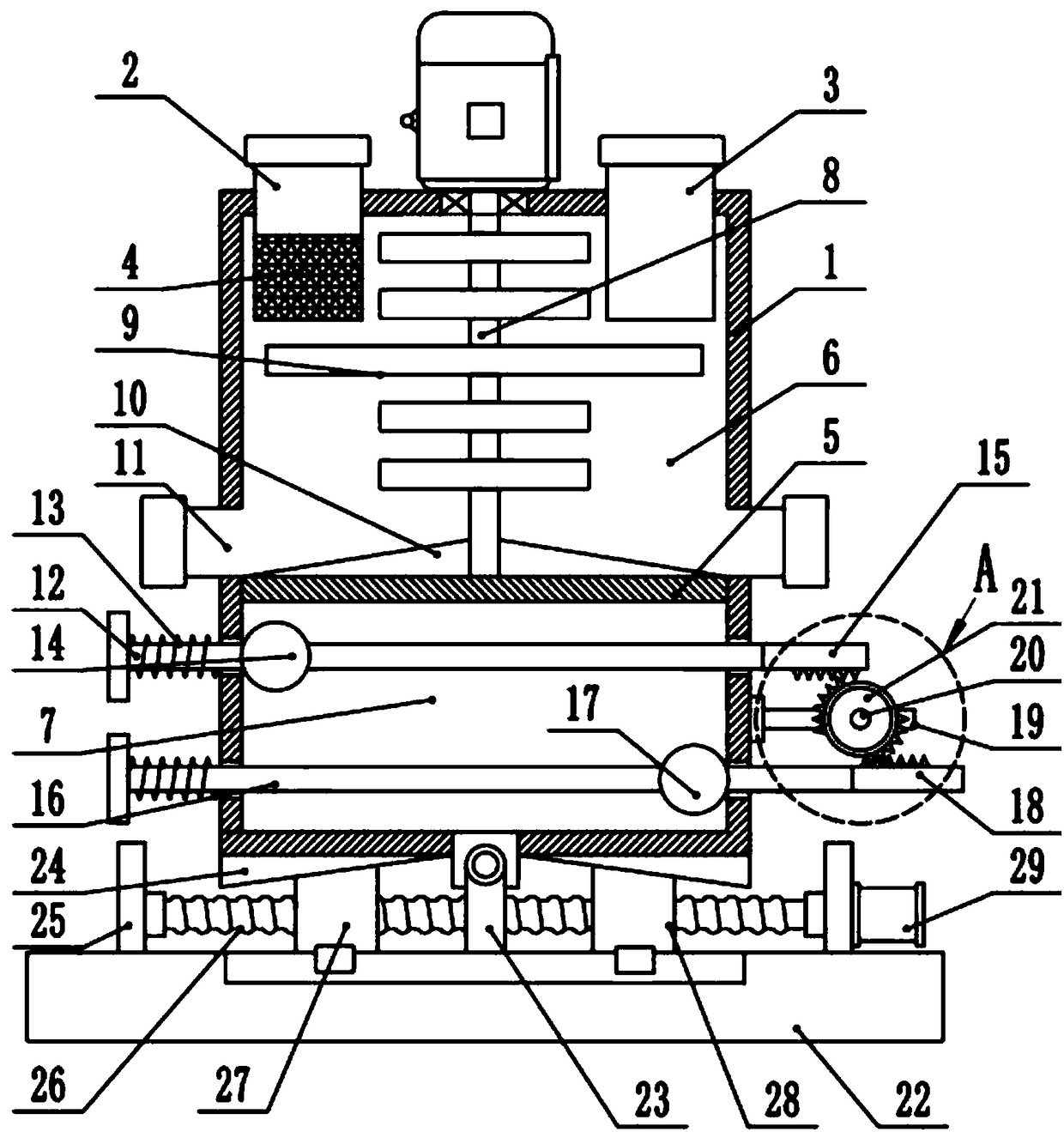

[0020] The technical solution of this patent will be further described in detail below in conjunction with specific embodiments.

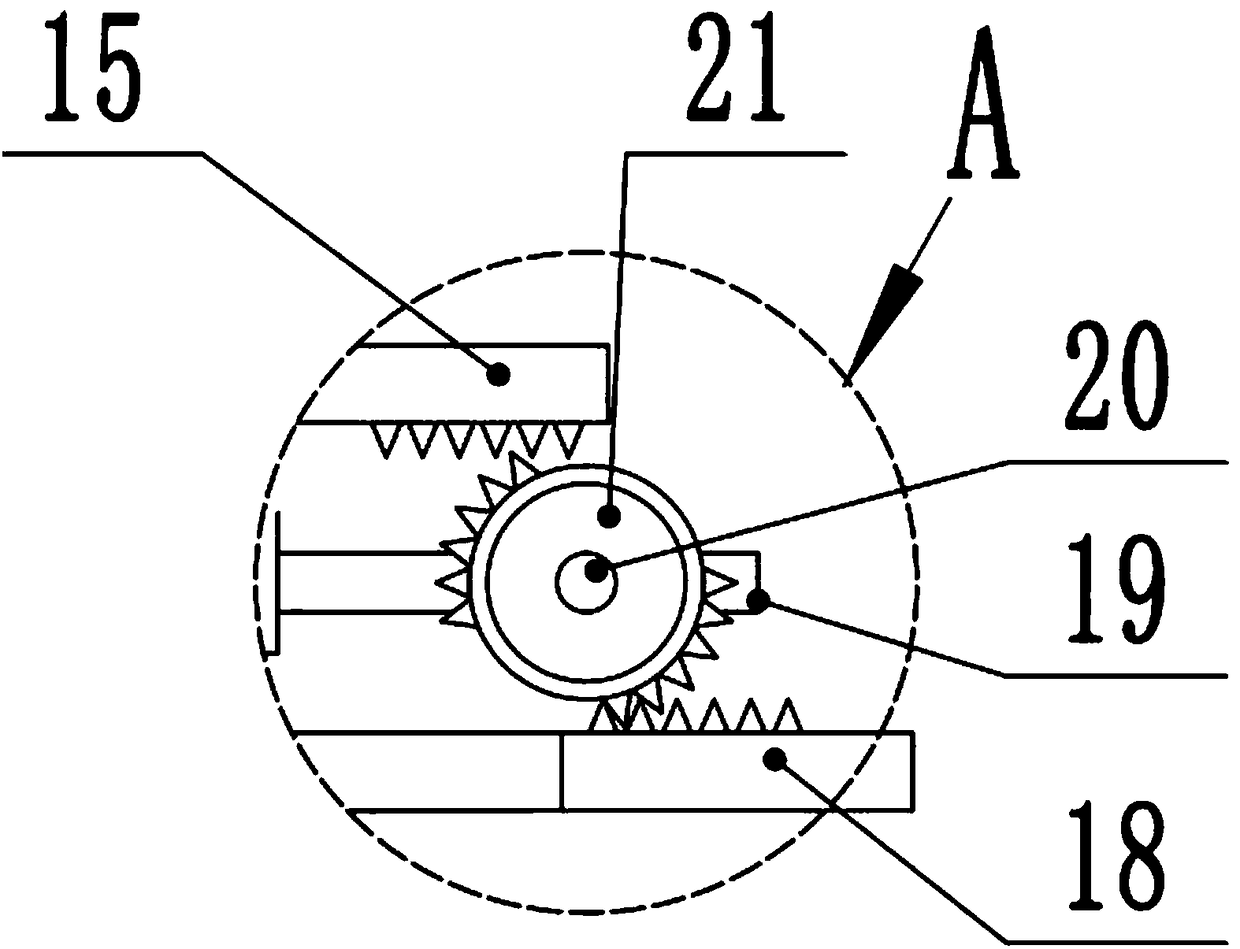

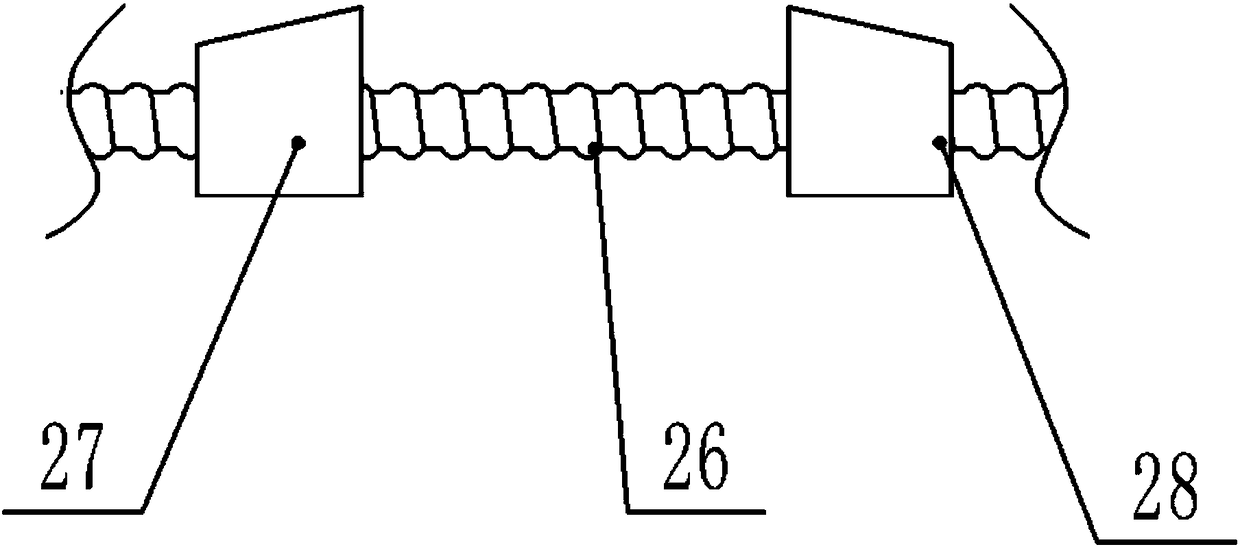

[0021] see Figure 1-3 , a screw drive swing type water-based paint and powder mixing device, including a mixing box 1, a first drive motor 8, a left impact ball 14, a right impact ball 17, a second drive motor 20, a special-shaped gear 21 and a base 22, The upper side of the mixing box 1 is symmetrically opened with a first feed port 2 and a second feed port 3, the first feed port 2 is used to add water-based paint, the second feed port 3 is used to add powdery paint, and the first feed port 3 is used to add powdery paint. The mouth 2 is provided with a filter screen 4 inside, and the filter screen 4 is used to filter the water-based paint. The inside of the mixing box 1 is horizontally fixed with a middle partition 5, and the middle partition 5 divides the inside of the mixing box 1 into a mixing chamber 6 and a mixing chamber 6. The impact cham...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com