Gear-driven type crushing device for preparing herba dendrodii officinalis microcrystal powder

A Dendrobium candidum, gear-driven technology, applied in the field of crushing devices, can solve the problems of low crushing efficiency, uneven crushing, incomplete crushing, etc., and achieve the effect of improving the effect and fine crushing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The technical solution of this patent will be further described in detail below in conjunction with specific embodiments.

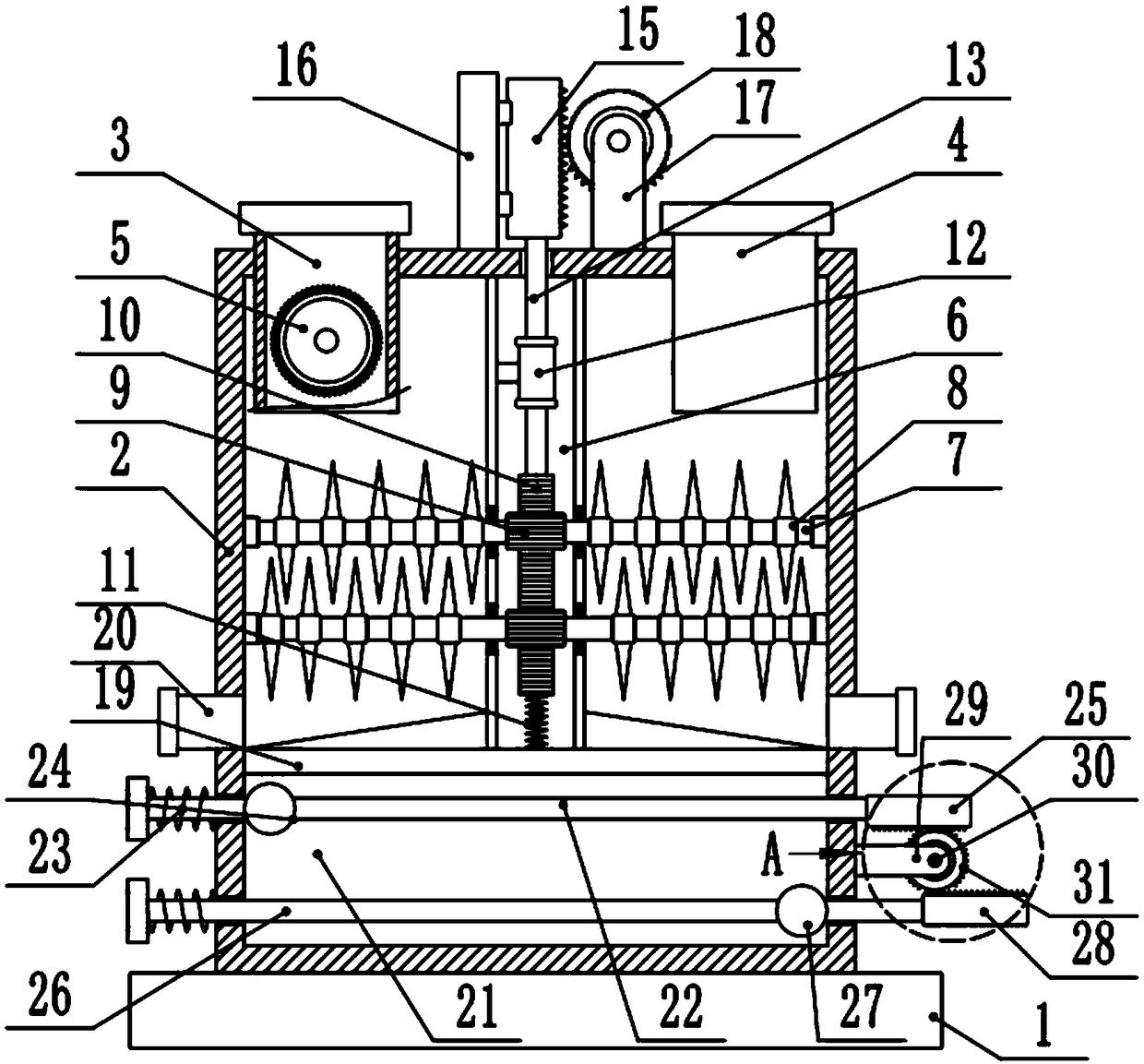

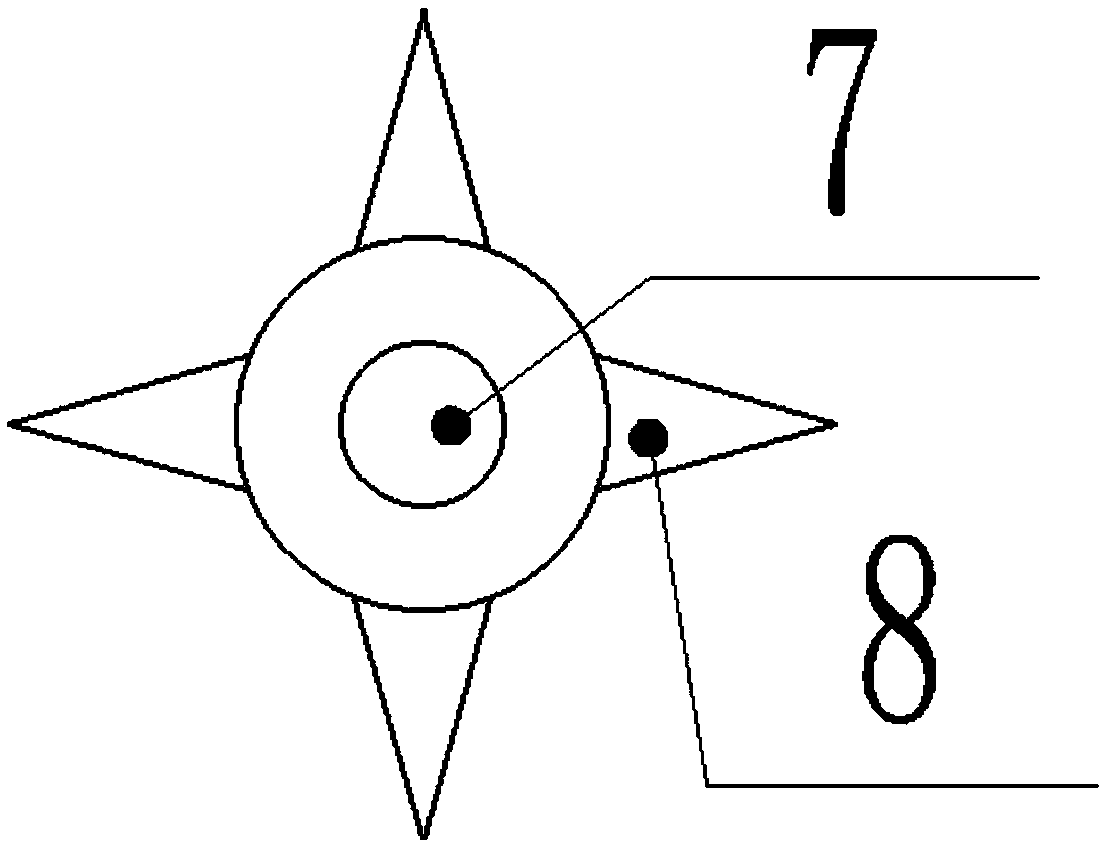

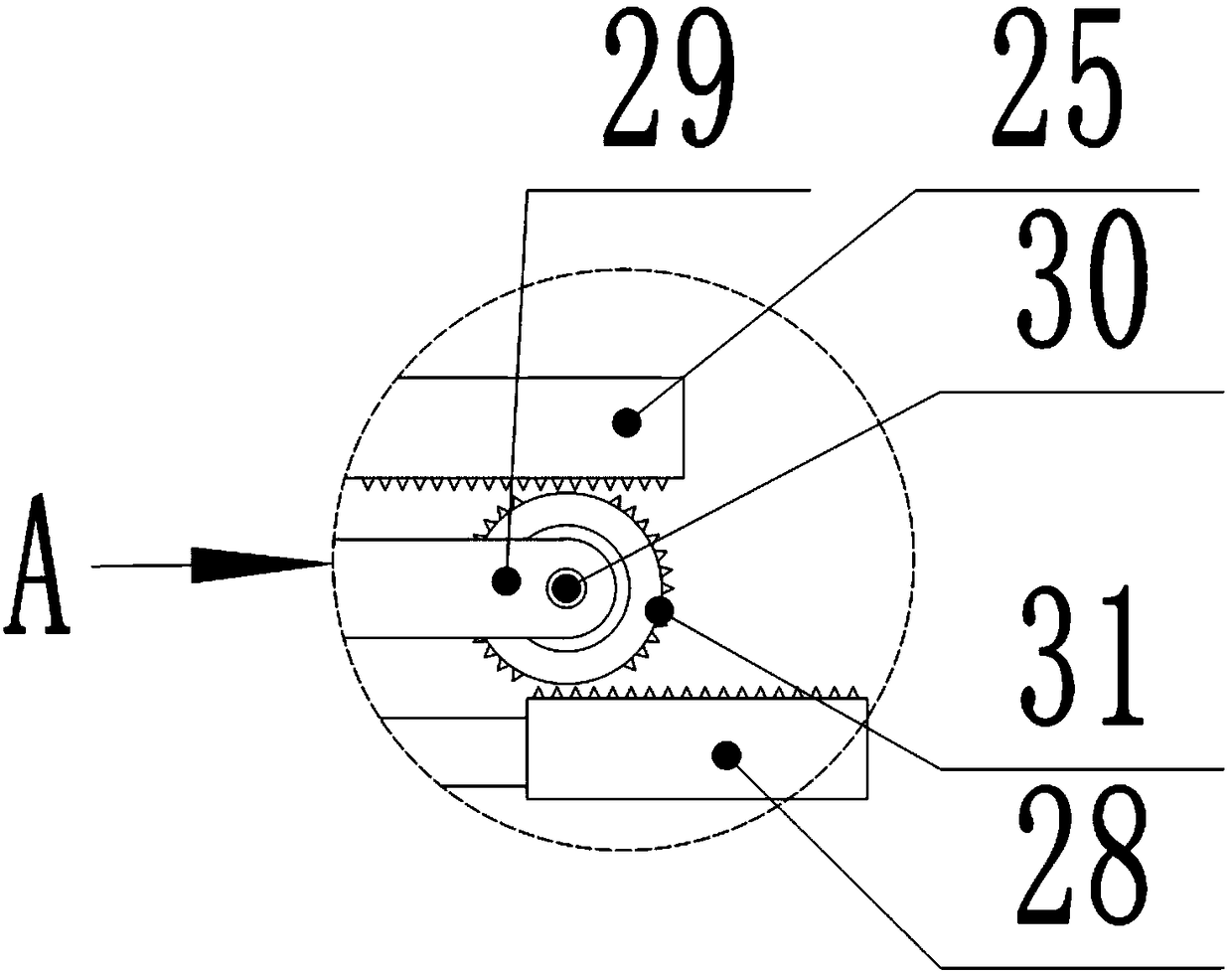

[0021] see Figure 1-3 , a gear-driven dendrobium candidum microcrystalline powder preparation crushing device, including a base 1, a crushing box 2, a crushing wheel 5, a crushing blade 8, a first drive motor 17, a left impact ball 24 and a right impact ball 27, the base 1 is provided with a crushing box 2, and the crushing box 2 and the base 1 are fixedly connected by bolts. The left and right sides of the crushing box 2 are respectively provided with a left feed port 3 and a right feed port 4, and the left feed port Both the mouth 3 and the right feeding port 4 are embedded with feeding pipes, and a crushing wheel 5 is installed inside the feeding pipe. The crushing wheel 5 is driven by an external drive device. The center position inside the box 2 is provided with a first device cavity 6 through a sealing plate in the vertical direction, and a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com