Lubricating oil production mixing device capable of preventing lubricating oil from adhering to inner wall

A technology of mixing device and lubricating oil, applied in mixers, mixers, dissolving and other directions with rotary stirring devices, can solve the problems of low mixing efficiency, accompanied by impurities, increased waste, etc., to improve practicability and avoid sticking inner wall effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

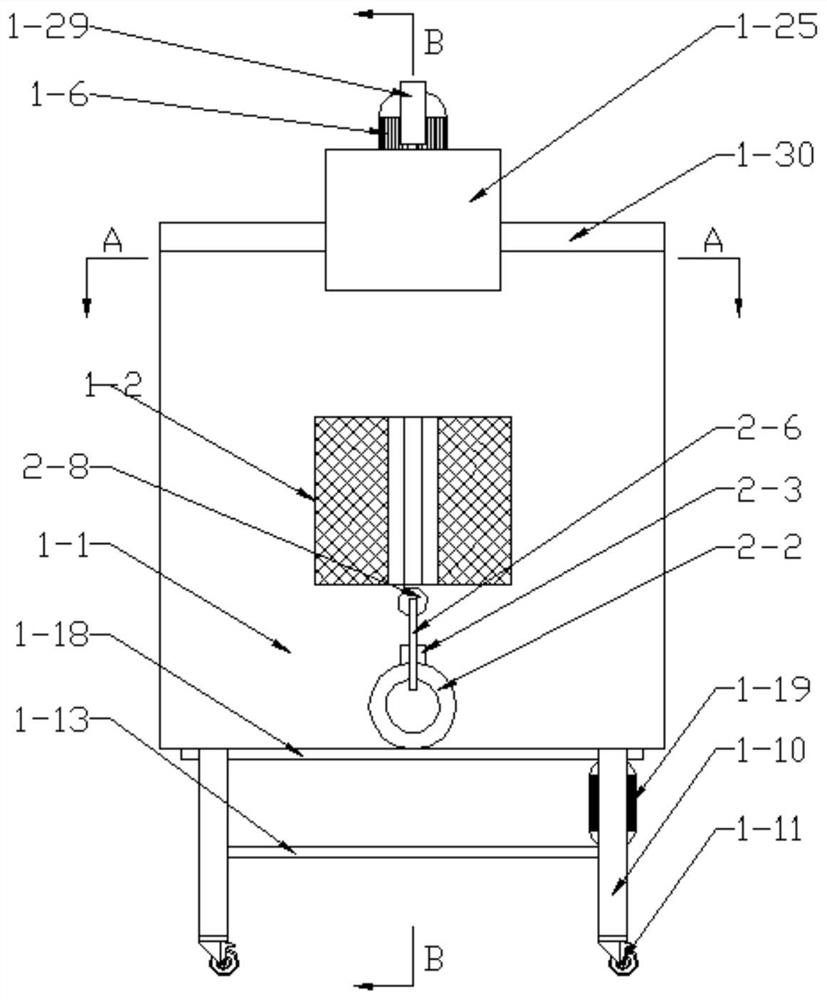

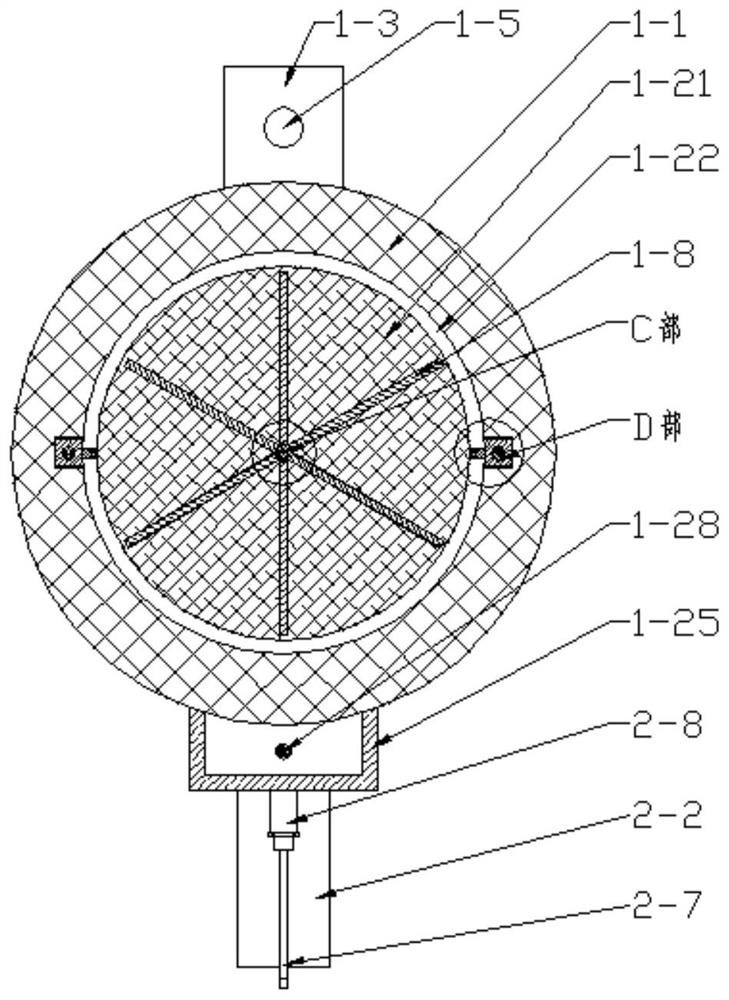

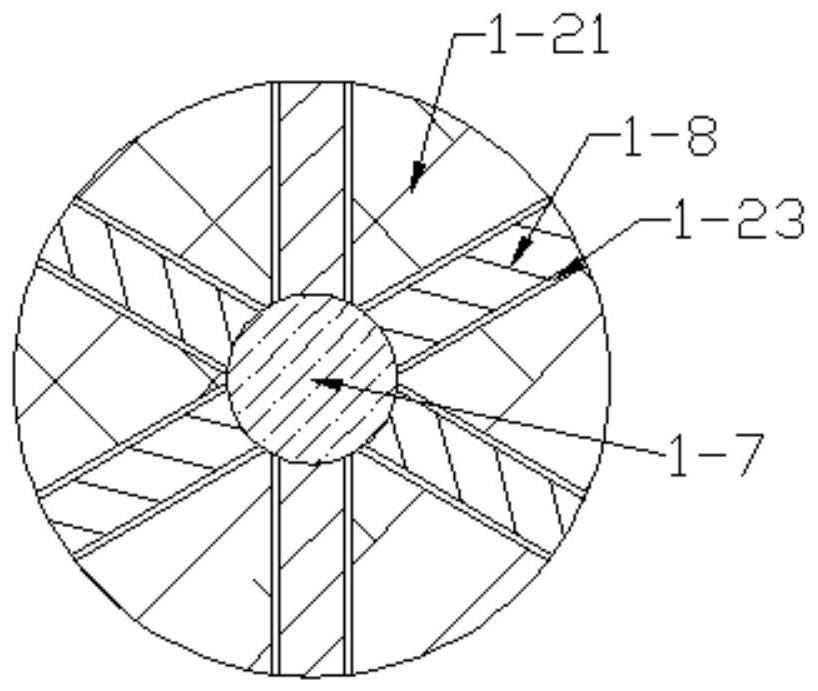

[0026] The present invention will be further described below in conjunction with the accompanying drawings.

[0027] see as Figure 1 to Figure 7As shown, the technical solution adopted in this specific embodiment is: it includes a mixer main body 1 and a discharge mechanism 2; the mixer main body 1 includes a tank body 1-1, an observation window 1-2, and a support plate 1-3 , No. 2 support plate 1-4, No. 1 electric push rod 1-5, No. 1 motor 1-6, rotating shaft 1-7, stirring frame 1-8, stirring net 1-9, supporting feet 1-10, universal wheel 1-11, handle 1-12, No. 3 support plate 1-13, screw nut 1-15, screw rod 1-16, gear 1-17, chain 1-18, No. 2 motor 1-19, slider 1- 20. No. 1 scraper 1-21, feed pipe 1-24, feed hopper 1-25, limit ring 1-26, No. 2 scraper 1-27, No. 1 connecting rod 1-28, rubber handle 1-29 and the cover body 1-30; the opening of the front ring wall of the tank body 1-1 is embedded with an observation window 1-2, and the observation window 1-2 helps to observe ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com