Grinding separating device and sand mill

A separation device and grinding disc technology, applied in the grinding field, can solve problems such as low work efficiency, difficult discharge of finished products, uneven product particles, etc., and achieve the effect of improving grinding efficiency, improving product discharge efficiency, and avoiding material blockage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

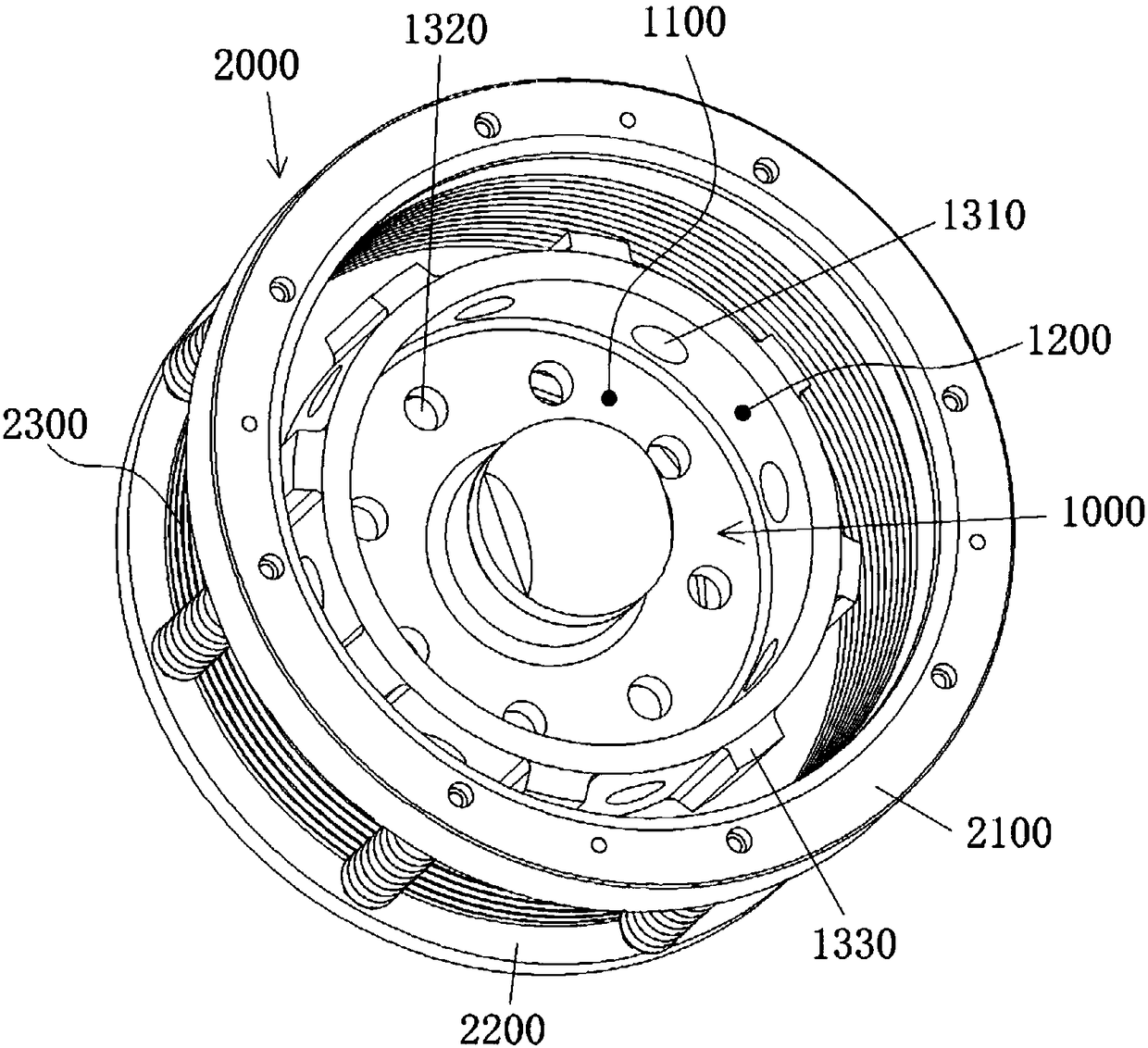

[0042] refer to figure 1 with figure 2 , in this embodiment, a grinding and separating device is proposed, including a grinding disc 1000 and a separating assembly 2000 .

[0043] Wherein, the grinding disc 1000 is used to stir the raw materials so that the raw materials are ground by the grinding media to obtain finished products, and the separation assembly 2000 is used to separate the finished products from the raw materials.

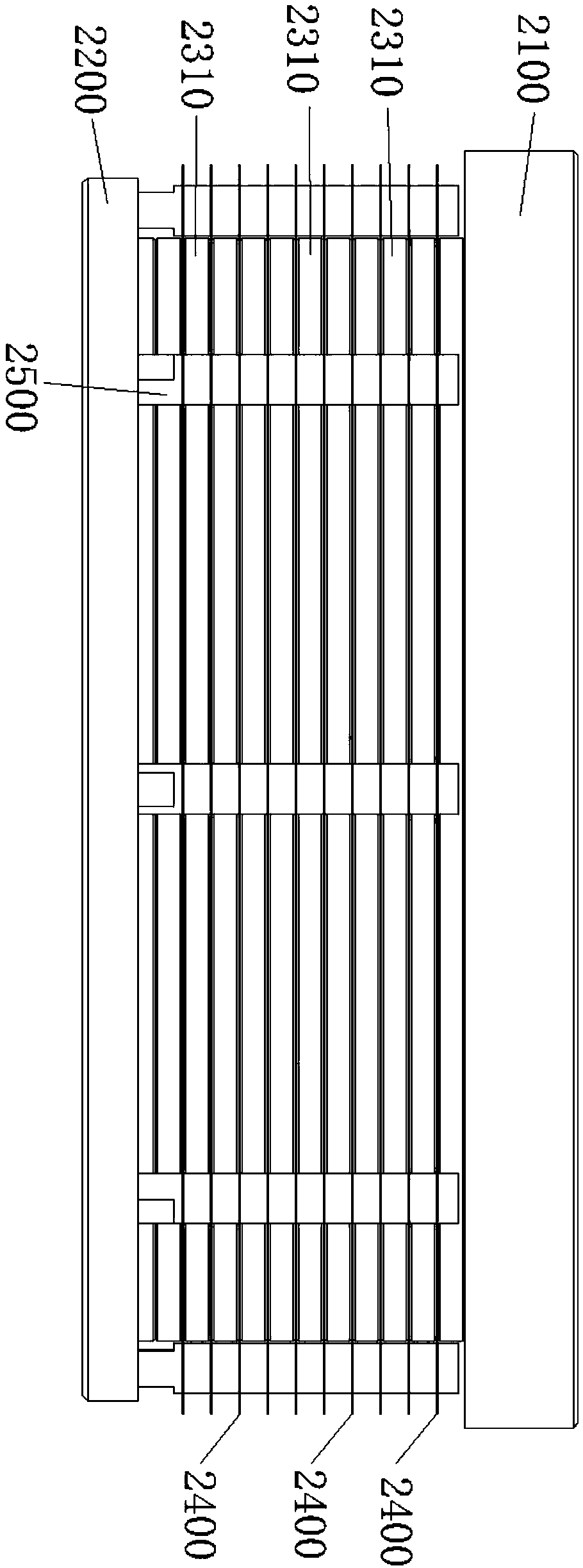

[0044] The separation assembly 2000 includes a first mount 2100 , a second mount 2200 and a separation part 2300 . Wherein, the separation part 2300 is located between the first mounting base 2100 and the second mounting base 2200 .

[0045] The first mounting base 2100 is parallel to the second mounting base 2200, and both are fixedly connected.

[0046] The separation part 2300 is composed of several separation rings 2310 whose axis lines are collinear, and the separation rings 2310 are all located between the first mounting seat 2100 and the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com