Funnel part drawing die for aircraft engine

A technology for aircraft engines and drawing dies, applied in engine components, forming tools, manufacturing tools, etc., can solve problems such as deficiencies, irreparable processing, and difficulty in the drawing process, so as to increase the drawing effect and increase the processing qualification rate. And the effect of yield and increasing processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

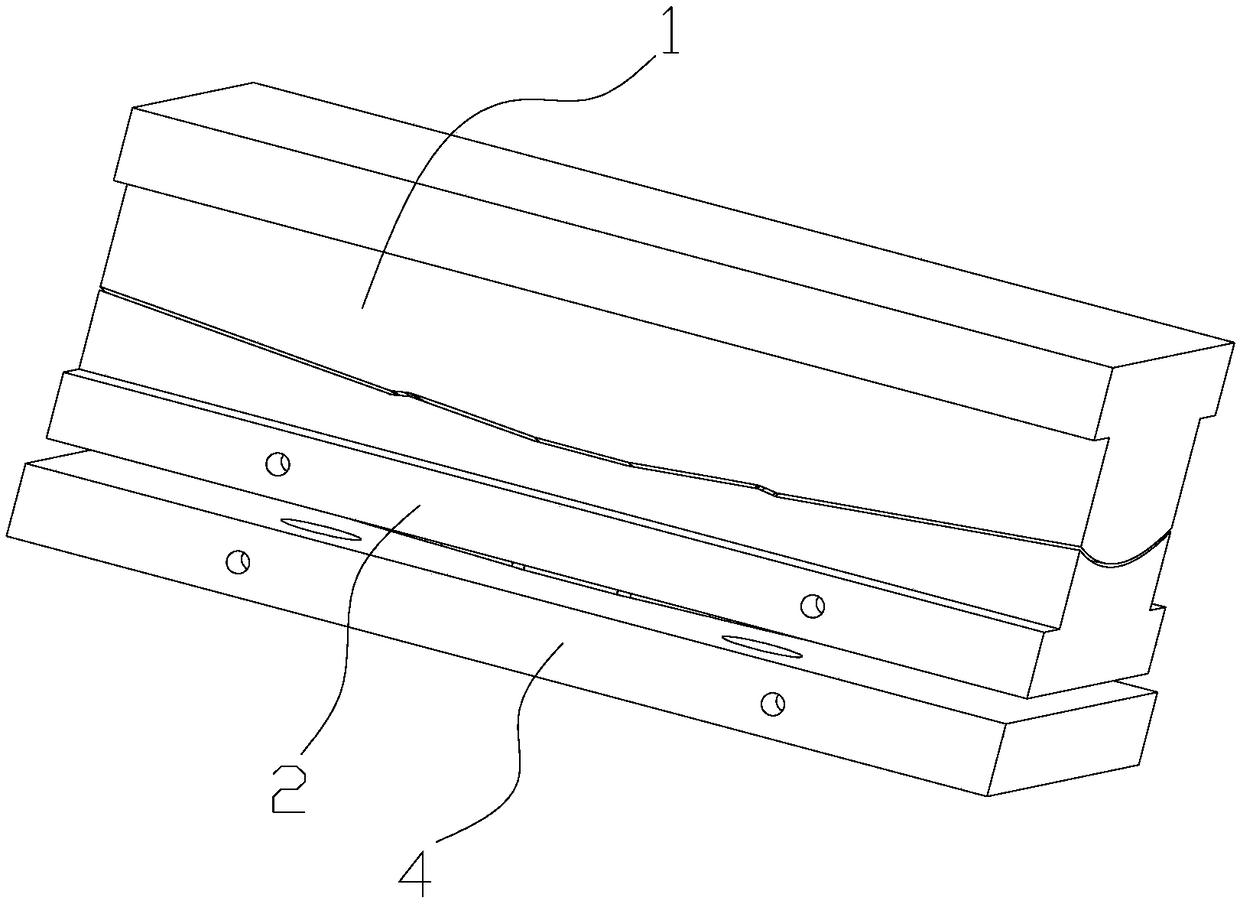

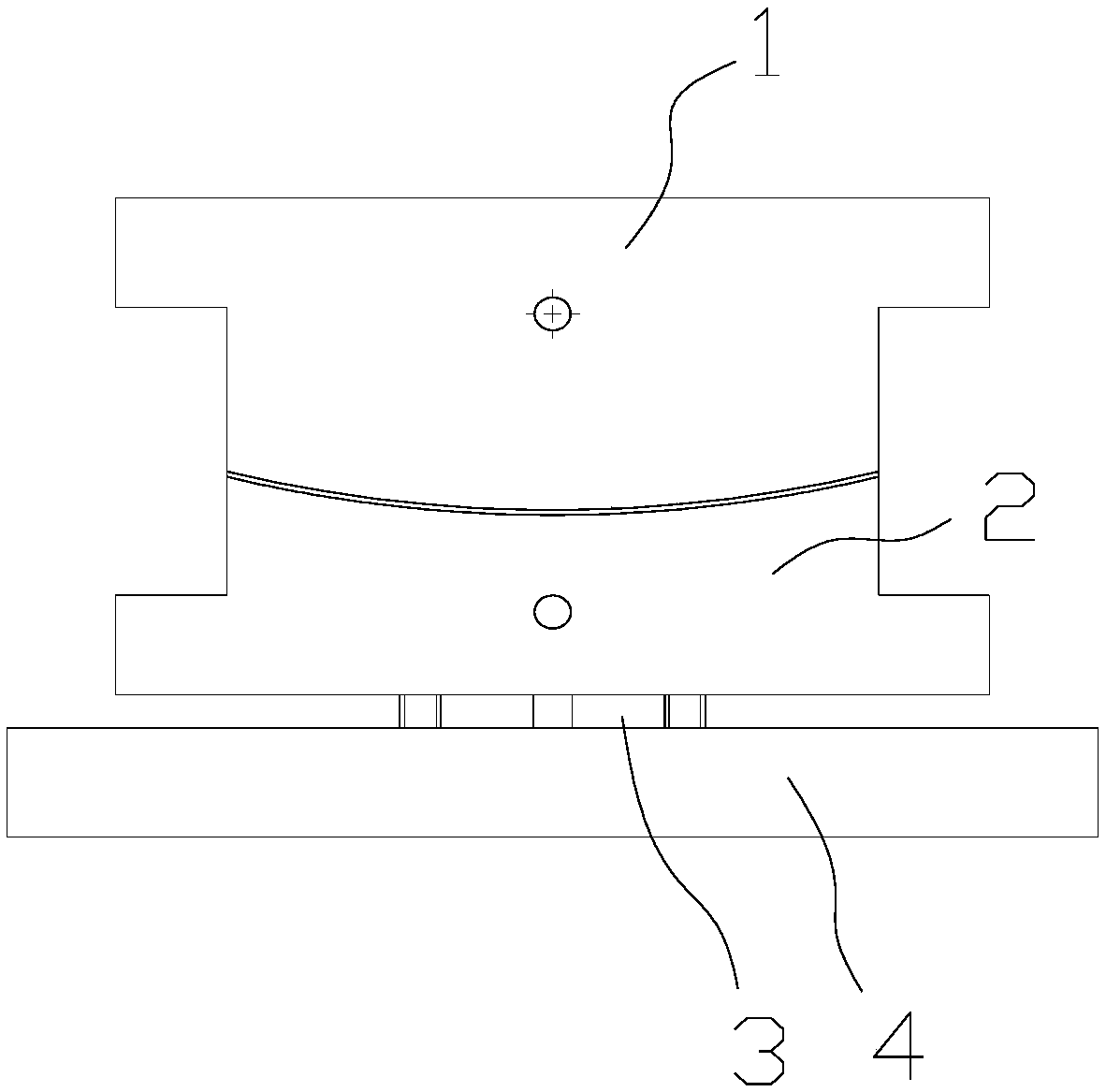

[0039] Such as Figure 1-5 , a drawing die for a funnel part of an aircraft engine, comprising:

[0040] Die 1 (such as Figure 4 );

[0041] Blankholder 2 (such as Figure 5), the blank holder 2 can cooperate with the die 1, and the inner wall of the blank holder 2 matches the opening of the total inner wall of the die 1 (the upper surface of the blank holder 2 has a second pressing surface 9. The lower surface of the die 1 is equipped with a first pressing surface 8, the first pressing surface 8 and the second pressing surface 9 fit together to clamp the blank);

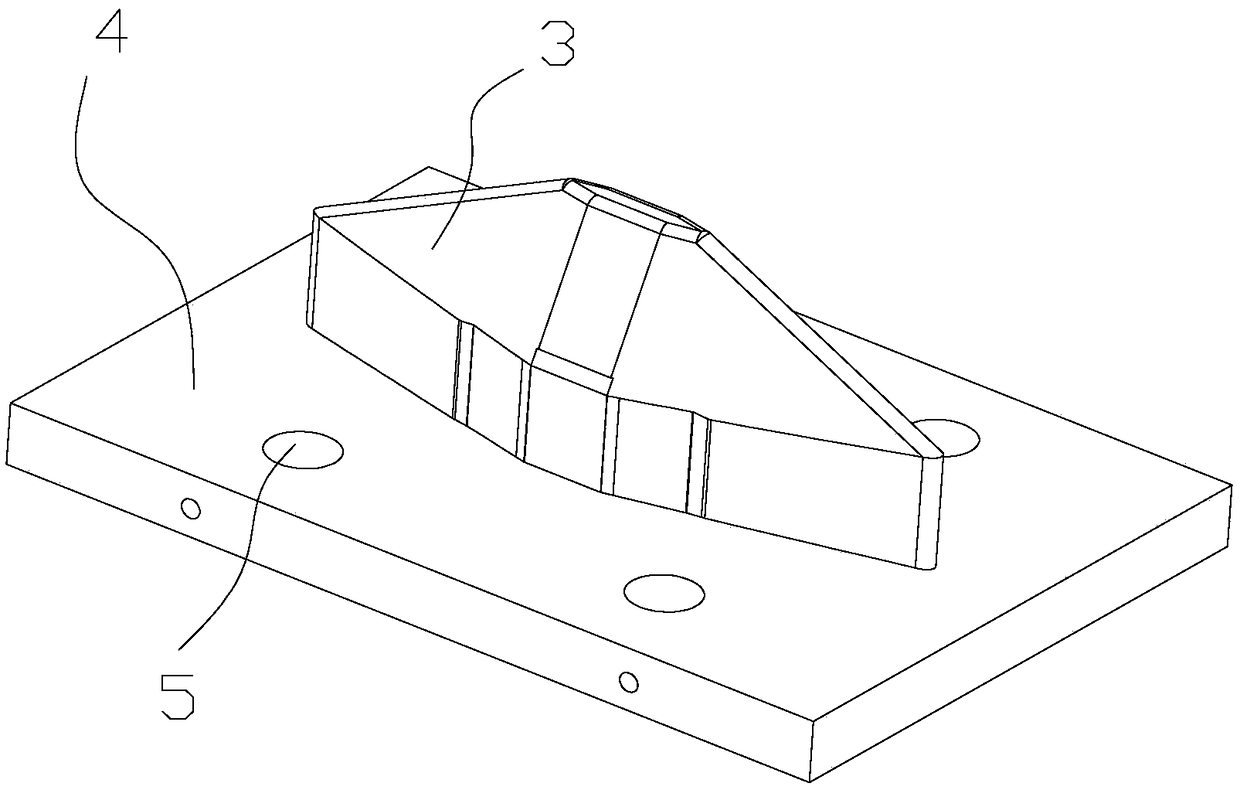

[0042] Punch 3 (such as image 3 ), the punch 3 can pass through the blankholder 2 while matching the total inner wall of the die 1;

[0043] The die 1 is provided with more than two sub-inner walls 6 corresponding to a single funnel part, all of the sub-inner walls 6 are arranged oppositely and connected to each other with their parts corresponding to the tail ends of the funnel parts, and all of the sub-inne...

Embodiment 2

[0048] In this embodiment, the difference from Embodiment 1 is that a lifting device is provided between the support structure 4 and the bottom of the blank holder 2 (not shown in the figure, the lifting device is a hydraulic mechanism).

[0049] This embodiment also discloses a method for processing the funnel part of the aircraft engine, which includes the steps of:

[0050] A. Pick the material, check the surface of the material without pits, scratches and other defects, and check whether the thickness is correct;

[0051] Process the received 450X280mm material into a combined blank (by cutting, brush oil on the surface of the material before cutting to prevent metal splashes during the cutting process, after cutting, grind the edge of the combined blank and remove the edge The ablation layer of the ablation layer, and at the same time use alcohol to clean the oil stain on the surface of the combined blank), the combined blank is formed by symmetrically connecting the sing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com