Floating drilling platform and construction method thereof

A drilling platform and floating technology, which is applied in the direction of floating buildings, barges/barges, etc., can solve the problems such as the inability to position and punch the steel casing, the geographical restrictions are large, and the anchoring is difficult to locate, so as to improve the drilling operation. Efficiency, small geographical conditions, and the effect of improving construction safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

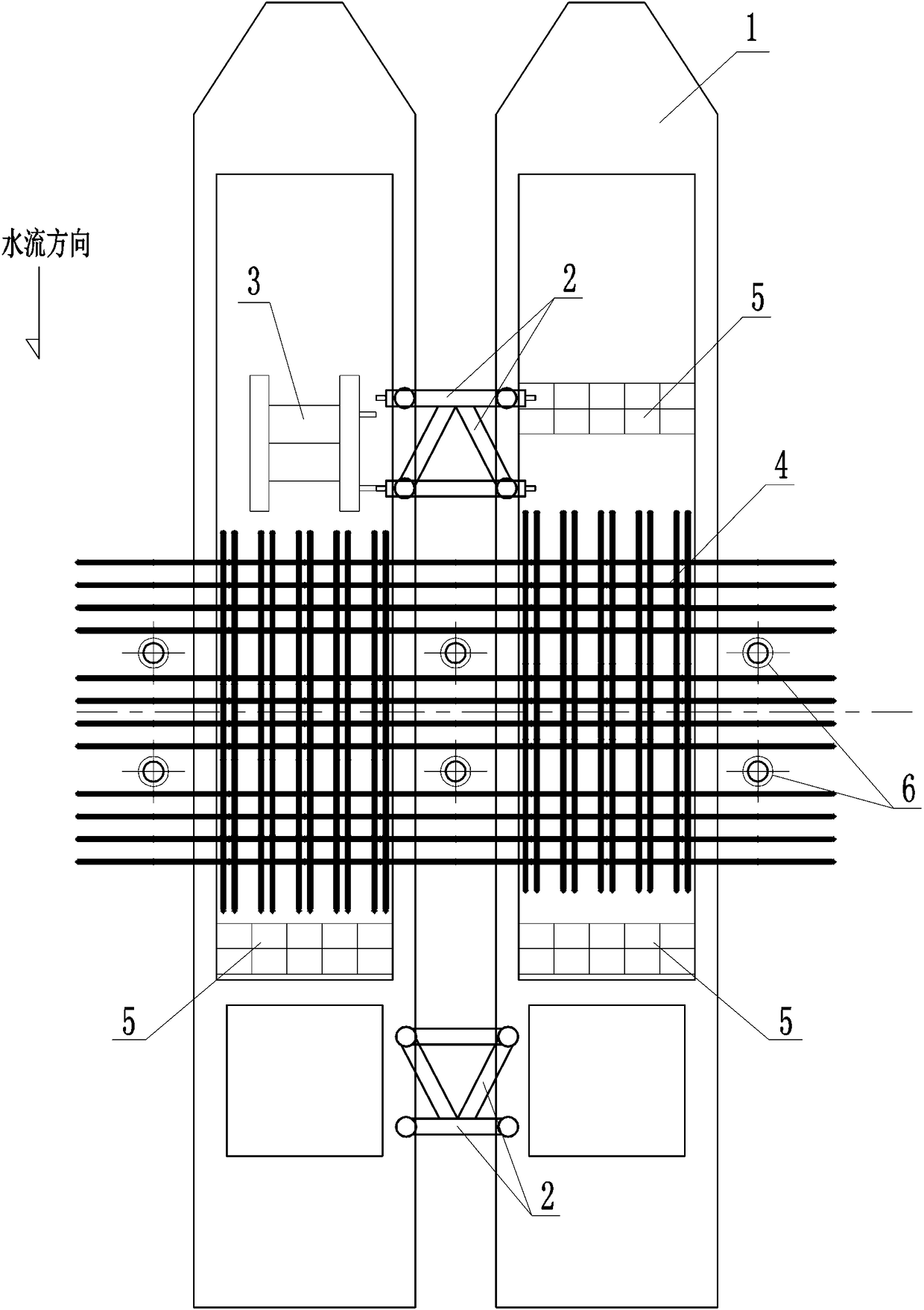

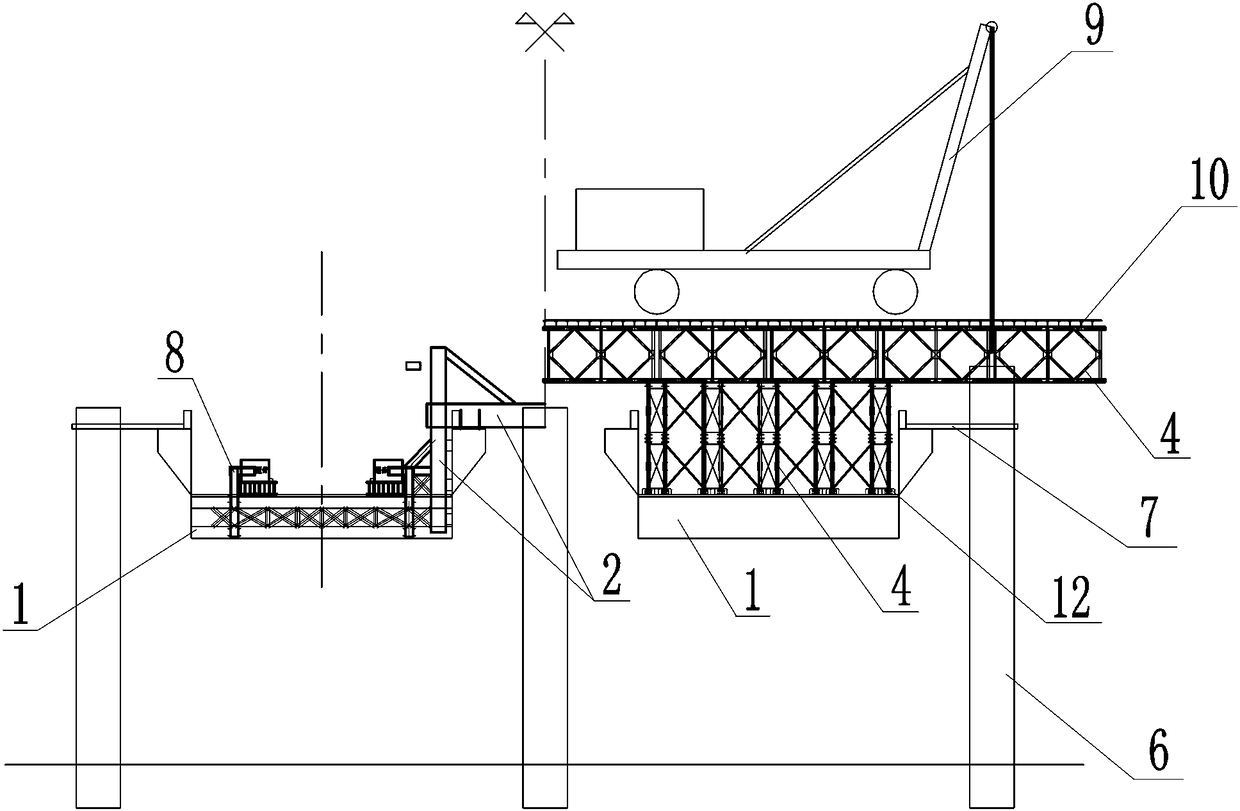

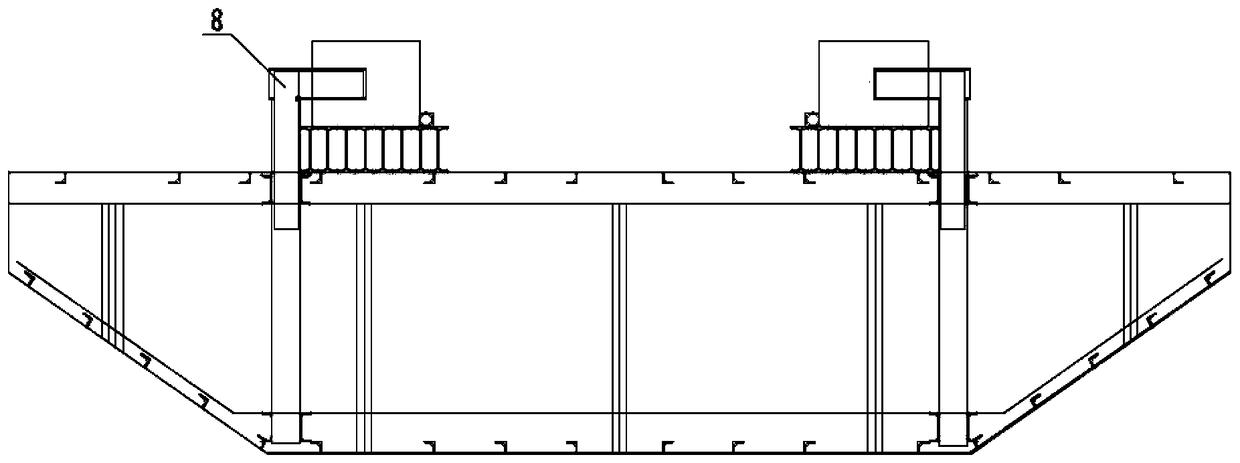

[0036] see Figure 1-5 , a kind of floating drilling platform, it includes the semi-storage barges 1 that are interconnected with each other by connecting cross-links 2, the interior of the cabin of the semi-storage barges 1 is provided with a load-bearing distribution beam 4, and the top of the load-bearing distribution beam 4 A platform surface 10 is provided; a crawler crane 3 is provided on the top of one of the semi-storage barges 1 , and a drilling rig 9 for drilling is provided on the platform surface 10 at the top of the other half-storage barge 1 . By adopting the above-mentioned floating drilling platform, the fast moving and positioning of the floating drilling platform can be realized, and the drilling operation efficiency of the platform can be improved.

[0037] Further, a counterweight 5 for maintaining the balance of the half-storage barge 1 is placed on the half-storage barge 1 . The level of the two half-storage barges 1 can be adjusted through the counterwe...

Embodiment 2

[0046] Adopt the construction method of the floating drilling platform described in any one of claims 1-9, it is characterized in that it comprises the following steps:

[0047] Step1: Connect the bow and stern of the two semi-storage barges 1 into a whole using the connecting system horizontal link 2, and the section steel of the connecting system horizontal link 2 is welded firmly with the keel of the semi-storage barge 1;

[0048] Step2: Install a crawler crane 3 on one of the semi-storage barges 1. The crawler crane 3 is laid with section steel and steel plate, and the crawler is fixed with the limit device 8, which is firmly connected with the cabin keel;

[0049] Step3: The other half of the barge 1 uses the counterweight 5 to level the platform, uses the Bailey beam base 11 to level the platform surface 10, and assembles Bailey beams on the Bailey beam base 11 to form a load-bearing distribution beam 4. Lay horizontal distribution beam steel and steel panels to form the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com