Miniature grabbing device based on van der waals force and grabbing method of miniature grabbing device

A grabbing device, micro-sized technology, applied in the direction of transportation and packaging, conveyor objects, etc., can solve the problems of unfavorable large-scale promotion, small adhesion force, small applicability range, etc., to achieve reliable adhesion and easy desorption , a wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

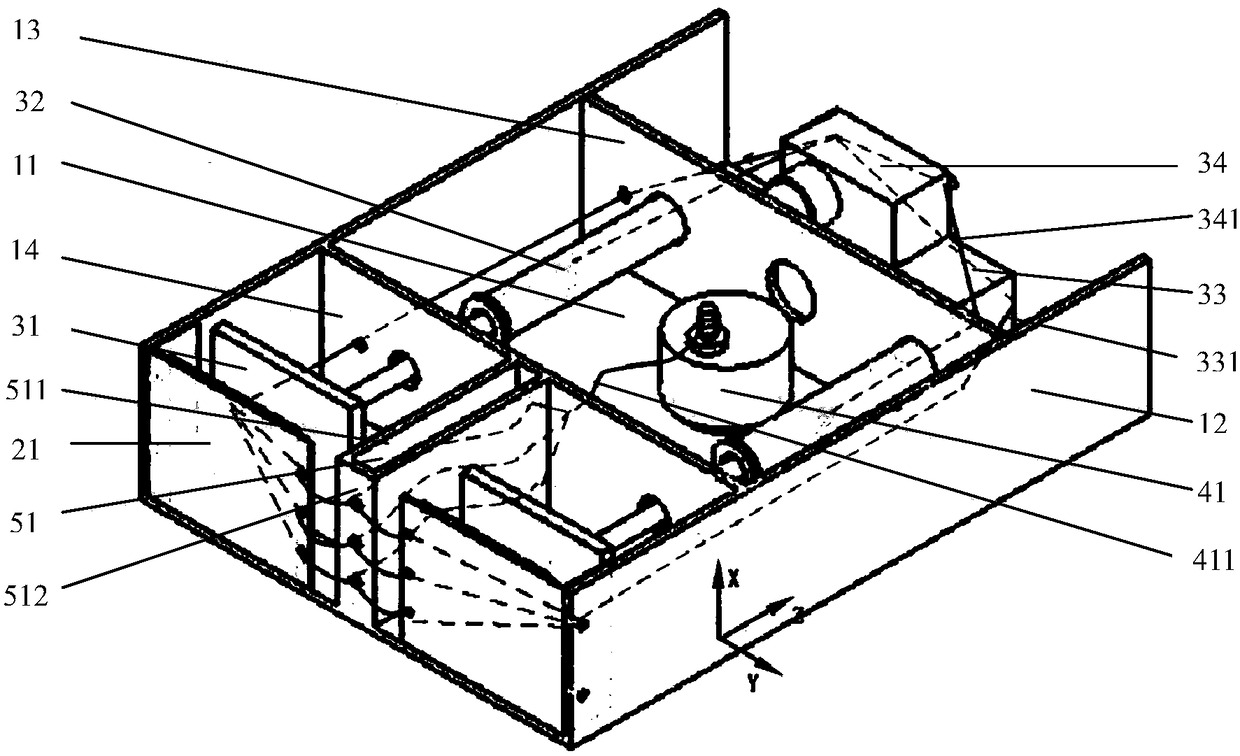

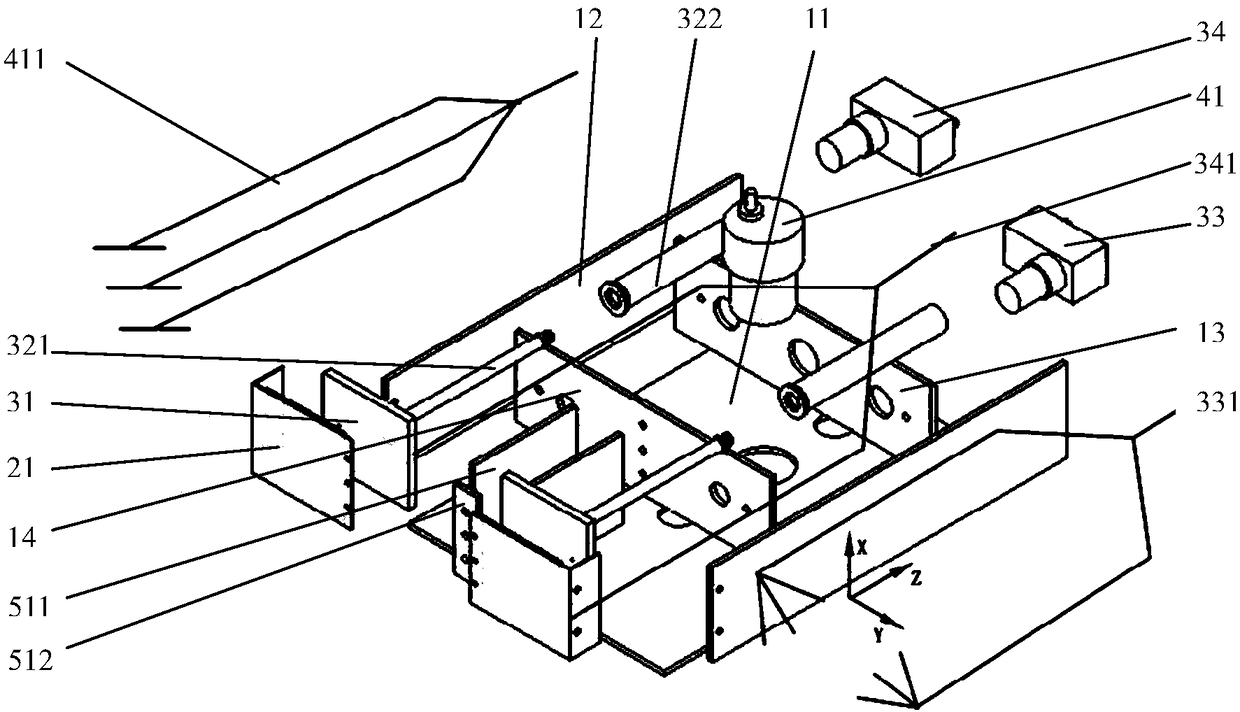

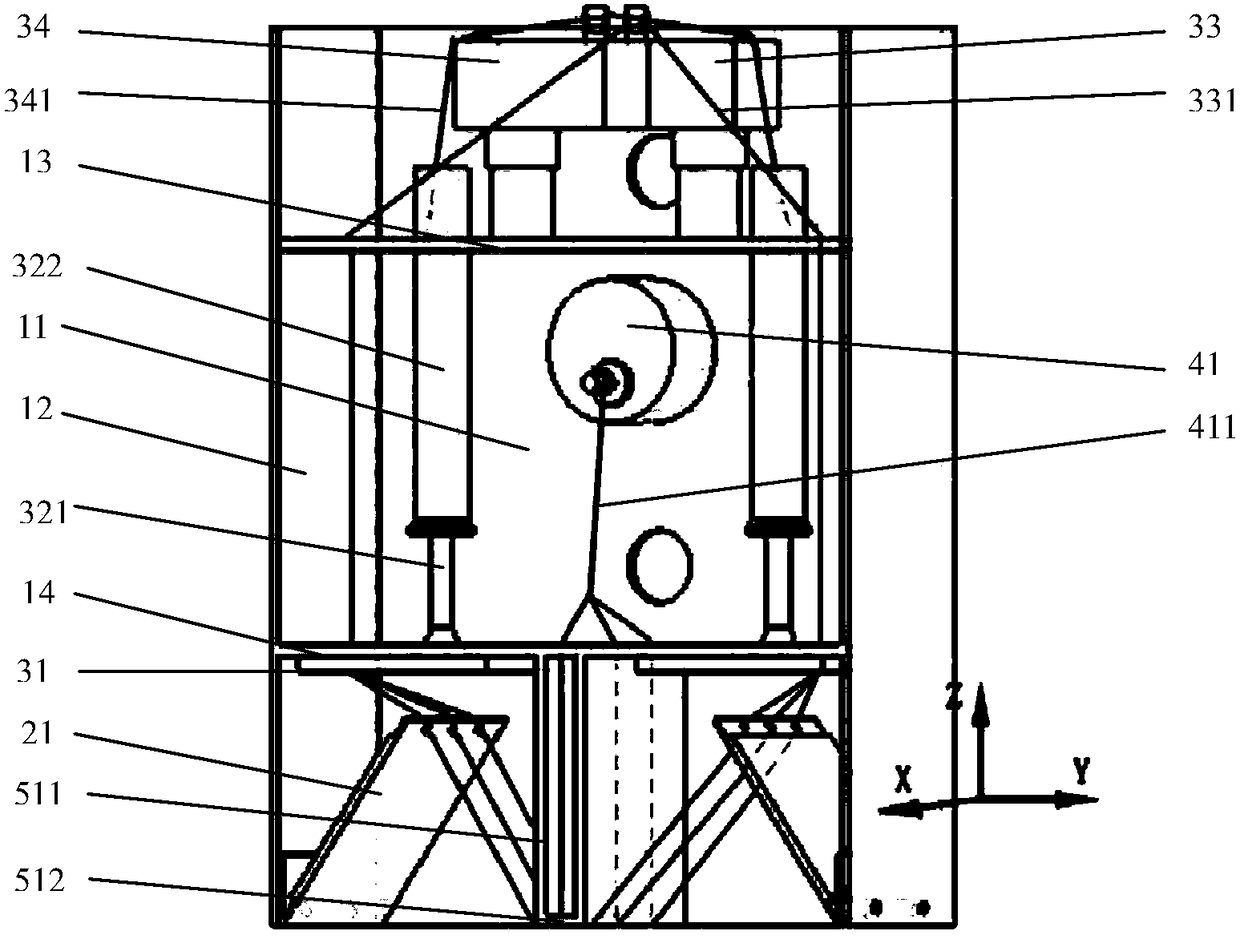

[0035] Such as figure 1 and 2 As shown, the grabbing device includes a supporting fixed frame, as well as a bionic adhesive material and an adhesion-detachment control system arranged in the supporting fixed frame; the supporting fixed frame is constructed of a plexiglass plate, including a bottom plate 11, which is installed on the Two longitudinal vertical plates 12 on both sides of the base plate and the first transverse plate 13 and the second transverse plate 14 installed on the plane of the base plate 11, the vertical plate, the base plate and the transverse plate are perpendicular to each other; the middle part of the lower surface of the second transverse plate 14 is installed The U-shaped frame body 51 includes two vertical plates 511 and a horizontal plate 512 at the bottom, and the vertical plates 511 and the horizontal plate 512 are fixed to the bottom plate 11 through L-shaped connecting pieces.

[0036] One side of the biomimetic adhesive material 21 is vertical...

Embodiment 2

[0045] The structure of this device is substantially the same as that provided in Embodiment 1, but the telescopic rod 32 is driven by an internal motor, that is, the top of the inner rod 321 is provided with a motor, and the inner wall of the sleeve 322 is provided with threads, and the inner rod 321 passes through the motor and the sleeve 322. The inner thread cooperates to drive the inner rod 321 to move up and down.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com