Method and equipment for producing transfer belt for image forming apparatus, and transfer belt for image forming apparatus

The technology of an imaging device and a manufacturing method is applied in the fields of manufacturing a transfer belt for an imaging device and the transfer belt for a device and an imaging device, and can solve the problems of difficulty in obtaining a surface layer with a small thickness and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

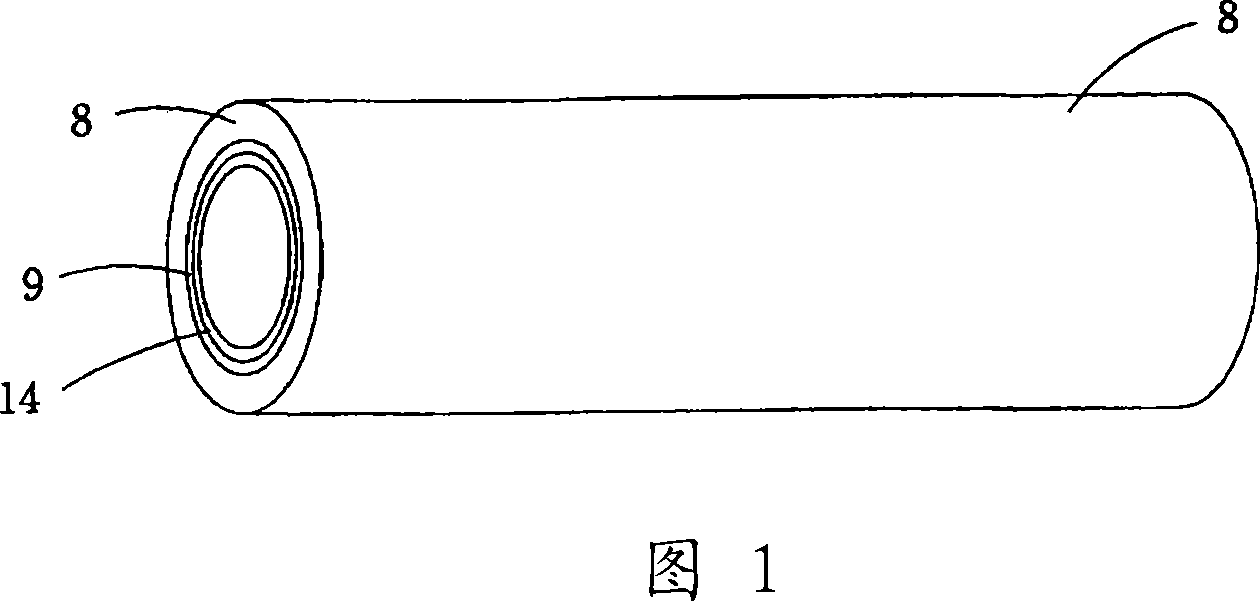

[0161] This embodiment is the insertion of a second composite layer, prepared by forming an elastomer layer on the outer surface of the bottom layer, into the inner side of the first composite body, the first composite layer being formed on the inner side of the surface layer. Prepared by forming an adhesive layer and using a core to bond the two layers.

[0162] First, as shown in FIG. 1, PTFE (melting point: 327° C., thermal decomposition point: 400° C.) is coated on the inner surface of the steel outer pipe 8 by a dip coating method, and sintered at 380° C. to obtain a surface layer 9 , the steel outer tube 8 has a 1.76×10 -5 / °C coefficient of thermal expansion and has a mirror-polished inner surface.

[0163] Then, THV polymer (melting point: 120° C., thermal decomposition point: 400° C.) was dissolved in butyl acetate, a film was formed on surface layer 9 by dip coating, and dried to obtain adhesive layer 14 . The adhesive layer 14 is then heated at a temperature above...

no. 2 approach

[0174] This embodiment relates to a pressure-sensitive adhesive layer comprising a fluorine-containing polymer constituting the surface layer.

[0175] As shown in FIG. 1, PFA (350J dispersion, particle size 0.2 μm, manufactured by du Pont de Nemours & Co.) (melting point 295° C.) was coated by dip coating on the inner surface of the steel outer pipe 8, and the Sintering at 380°C to obtain the surface layer 9, the steel outer tube 8 has a 1.76×10 -5 / °C coefficient of thermal expansion, and has a mirror-polished inner surface.

[0176] Then, a THV polymer (THV220, manufactured by Sumitomo 3M Co.) (melting point: 120°C, thermal decomposition point: 400°C) was dissolved in butyl acetate to form a film on the surface layer 9 by dip coating, and dried, Thus, the adhesive layer 14 is obtained. The adhesive layer 14 is then heated at a temperature above the melting point of PFA and THV, ie 350° C., thereby causing it to adhere to the skin layer 9 . Others The method was carried o...

no. 3 approach

[0182] This embodiment also relates to an adhesive layer comprising a fluoropolymer constituting the surface layer.

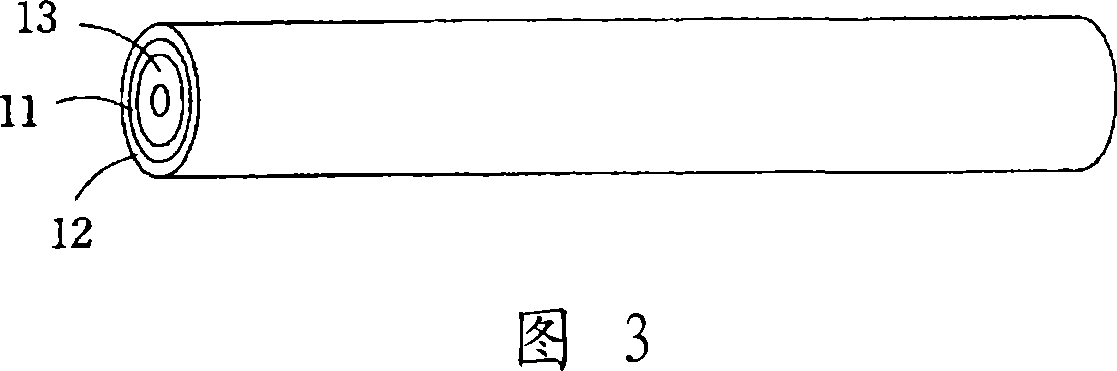

[0183] In order to form the adhesive layer, powdery PFA (340J, particle size 0.2 μm, manufactured by du Pont de Nemours & Co.) for forming the skin layer was preliminarily added to the THV polymer in an amount of 60 parts with respect to 100 parts of THV polymer. (THV220, manufactured by Sumitomo 3M Co.), and THV polymer was dissolved in butyl acetate. Others The method was performed in the same manner as in the second embodiment, thereby obtaining a transfer belt for an image forming apparatus.

[0184] The thus-obtained transfer belt for image forming apparatus comprises: on a 60 μm thick base layer (polyimide), a 200 μm thick elastic layer (ionically conductive polyurethane), a 3 μm thick adhesive layer (THV) and a 5 μm thick (PFA), and a transfer belt for an image forming apparatus having excellent surface resistivity, toner release properties, and non-sta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com