Waste slag grabbing equipment

A kind of equipment and waste residue technology, which is applied in the field of waste residue grabbing equipment, can solve the problems of inability to grasp waste residue more accurately, difficulty in adjusting the position of the grab bucket, and inconvenient operation of waste residue grabbing, and achieves simple structure, novel design, and convenient The effect of grabbing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

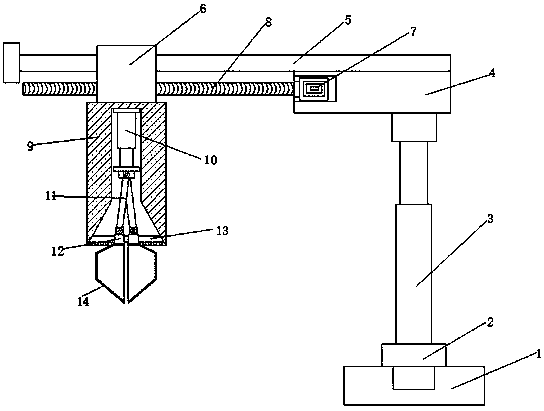

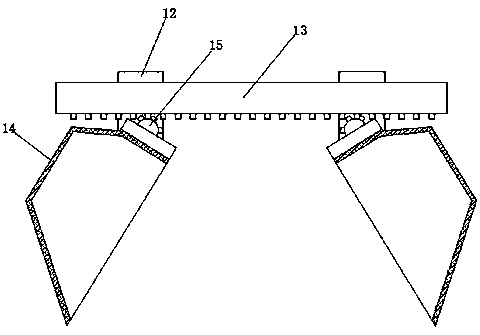

[0019] refer to Figure 1-2 , a waste grabbing device, including a base 1, a rotary table 2 is arranged above the base 1, a servo motor is installed inside the base 1, the output shaft of the servo motor is connected to the rotary table 2, and the servo motor is controlled by an electrical connection The chassis, the top of the rotating table 2 is connected with a lifting column 3, the lifting column 3 is vertically arranged, and the top of the lifting column 3 is provided with a lifting plate 4, and the top of the lifting plate 4 is horizontally provided with a horizontal movement guide rod 5, and the horizontal movement guide rod 5 is socketed with a moving block 6...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com