A mems microstructure four-axis vibration device with piezoelectric ceramics as the excitation source

A piezoelectric ceramic and vibration excitation device technology, applied in the field of MEMS microstructure four-axis vibration excitation device, can solve the problems of large parallelism error, inflexibility, increase in measurement result error, etc., and achieve accurate preload force data. , The adjustment process is smooth, and the effect of reducing the shear force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

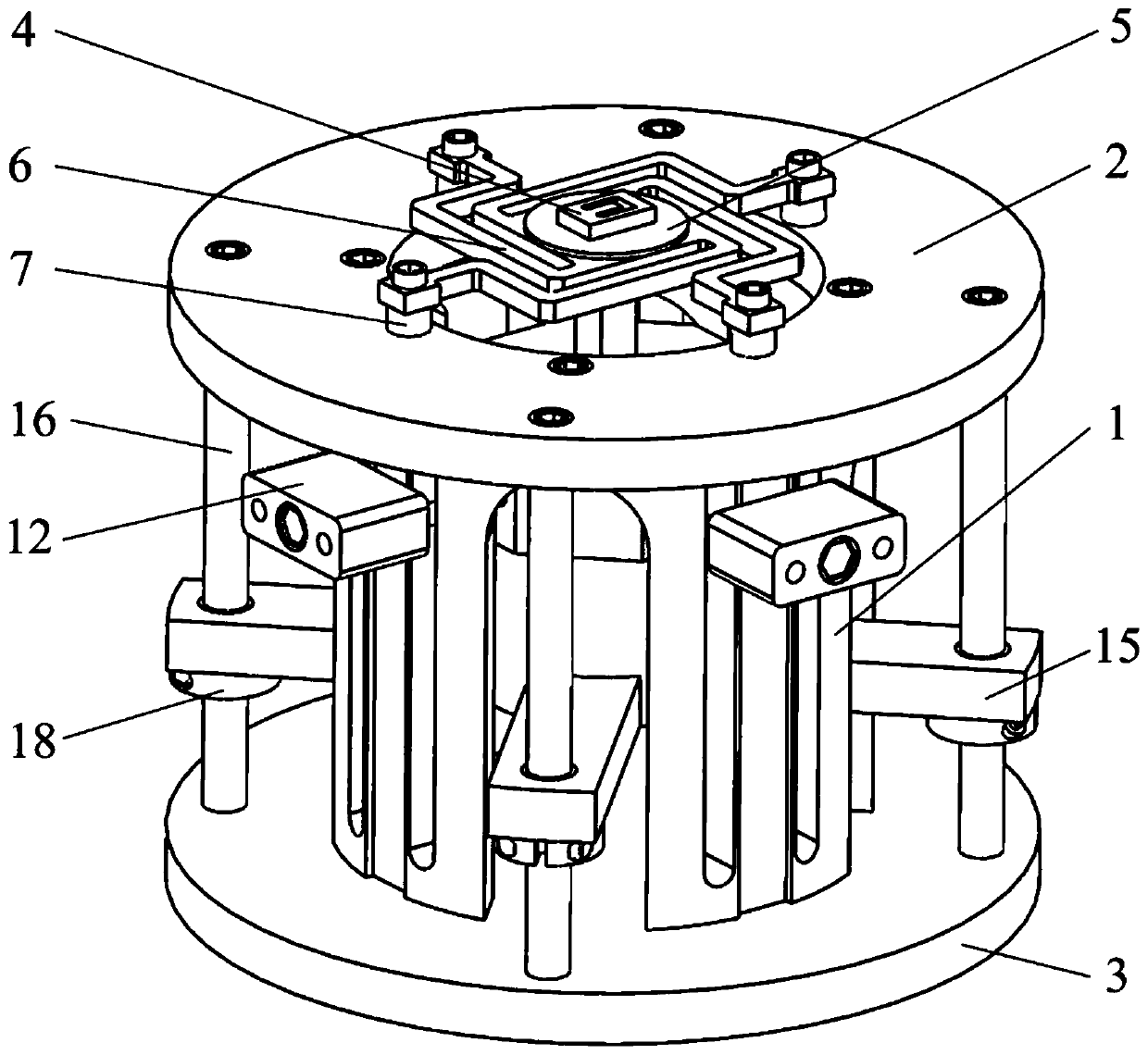

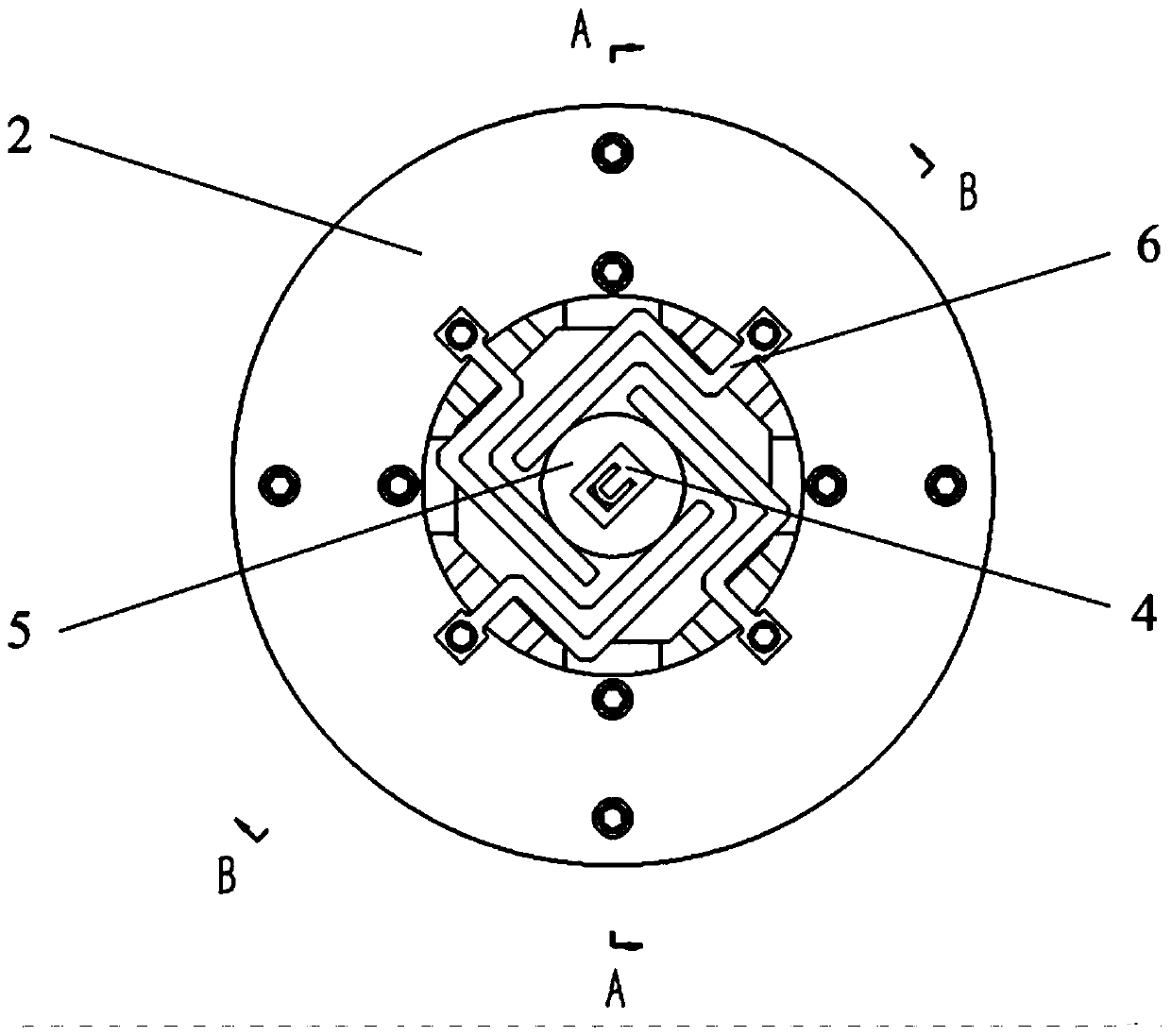

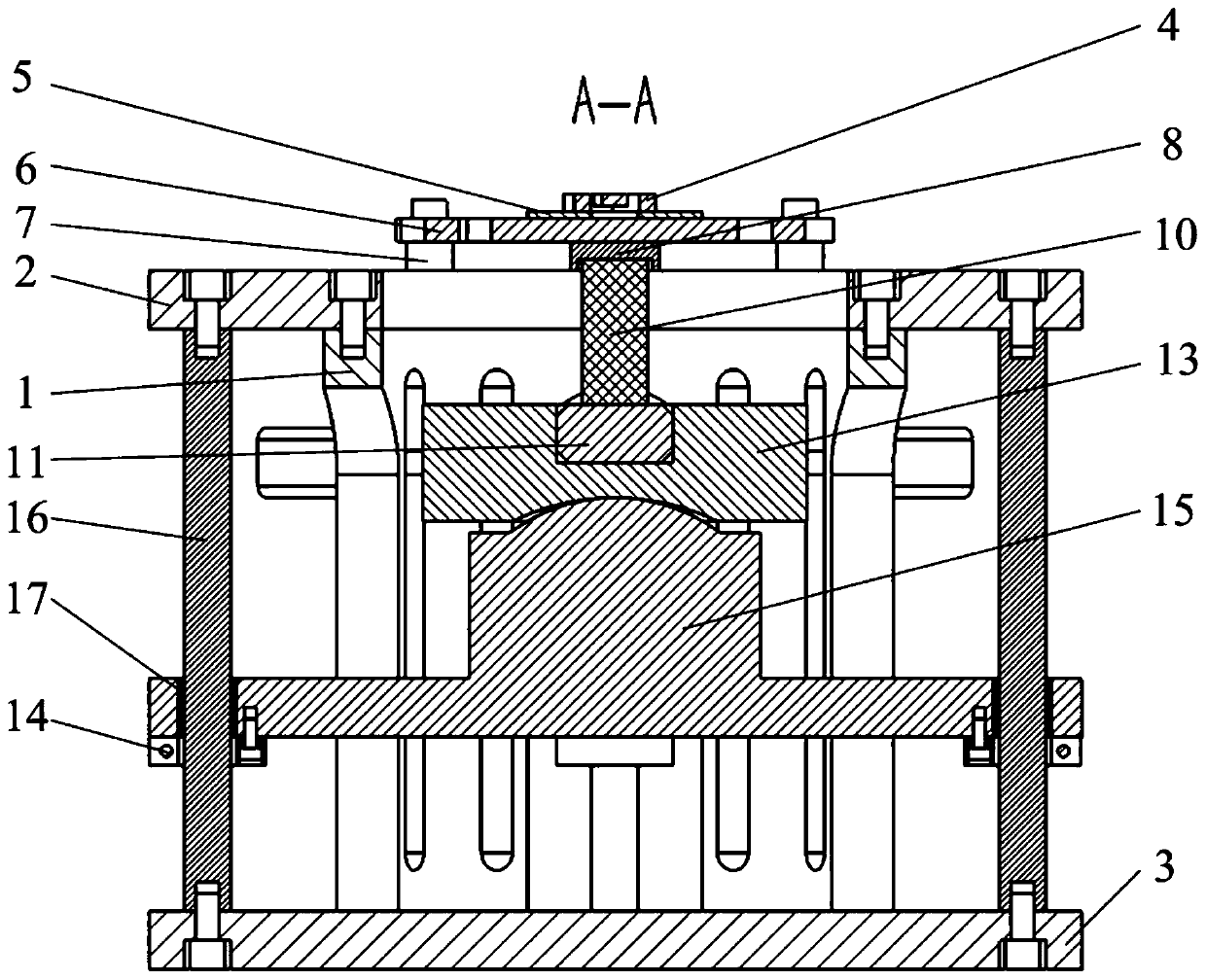

[0041] Such as Figure 1 to Figure 8 As shown, the present invention relates to a MEMS microstructure four-axis vibration device using piezoelectric ceramics as an excitation source, including a hollow sleeve 1, and stacked piezoelectric ceramics 10, a pressure sensor and a pressure sensor are arranged in the sleeve 1. 11 and a movable base composed of an upper coupling block 13 and a lower coupling block 15, an elastic support 6 and a MEMS microstructure 4 are arranged on the sleeve 1.

[0042] An annular top plate 2 and a bottom plate 3 with equal outer diameters and larger than the outer diameter of the sleeve are respectively fixed by screws on the top and bottom of the sleeve 1 , and the MEMS microstructure 4 is mounted on the annular top plate 2 through elastic supports 6 . The elastic support includes a square base plate 602 and four support arms 601 uniformly distributed around the circumference, each support arm 601 is composed of a first connecting arm 6011, a second...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com