Patents

Literature

45results about How to "Accurate Preload Data" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

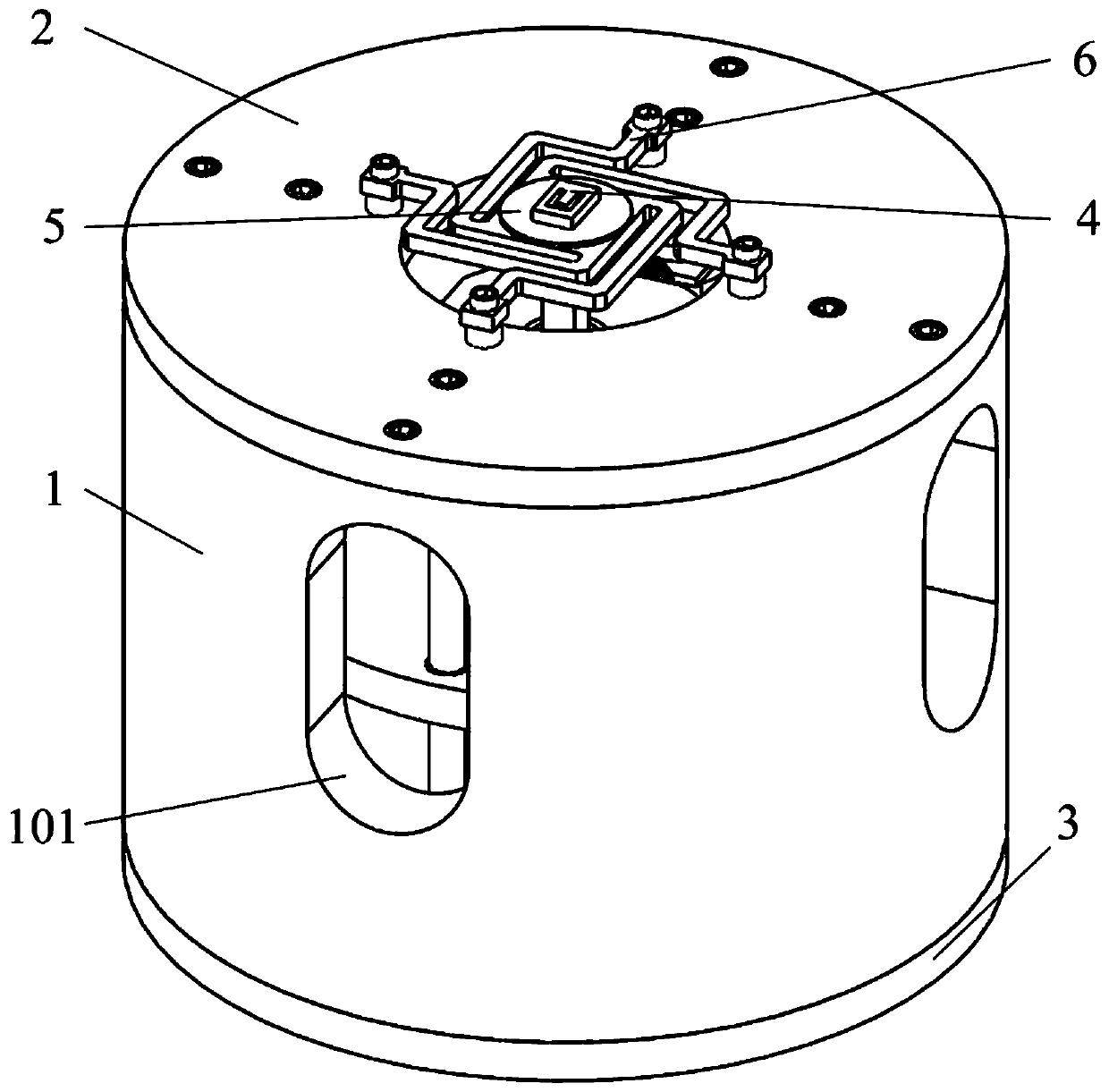

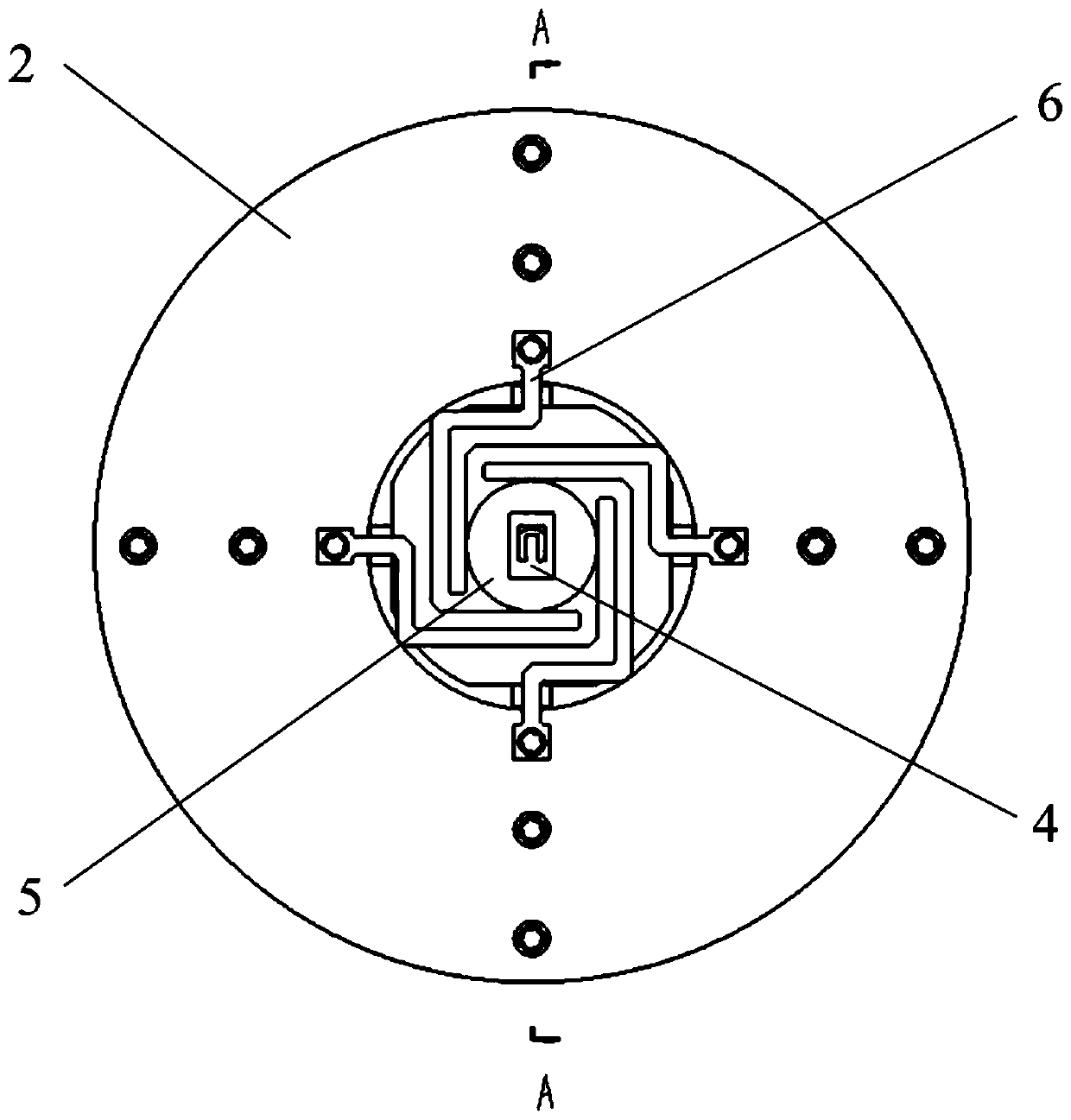

Four-axis type piezoelectric ceramic excitation device for testing dynamic characteristics of MEMS microstructure

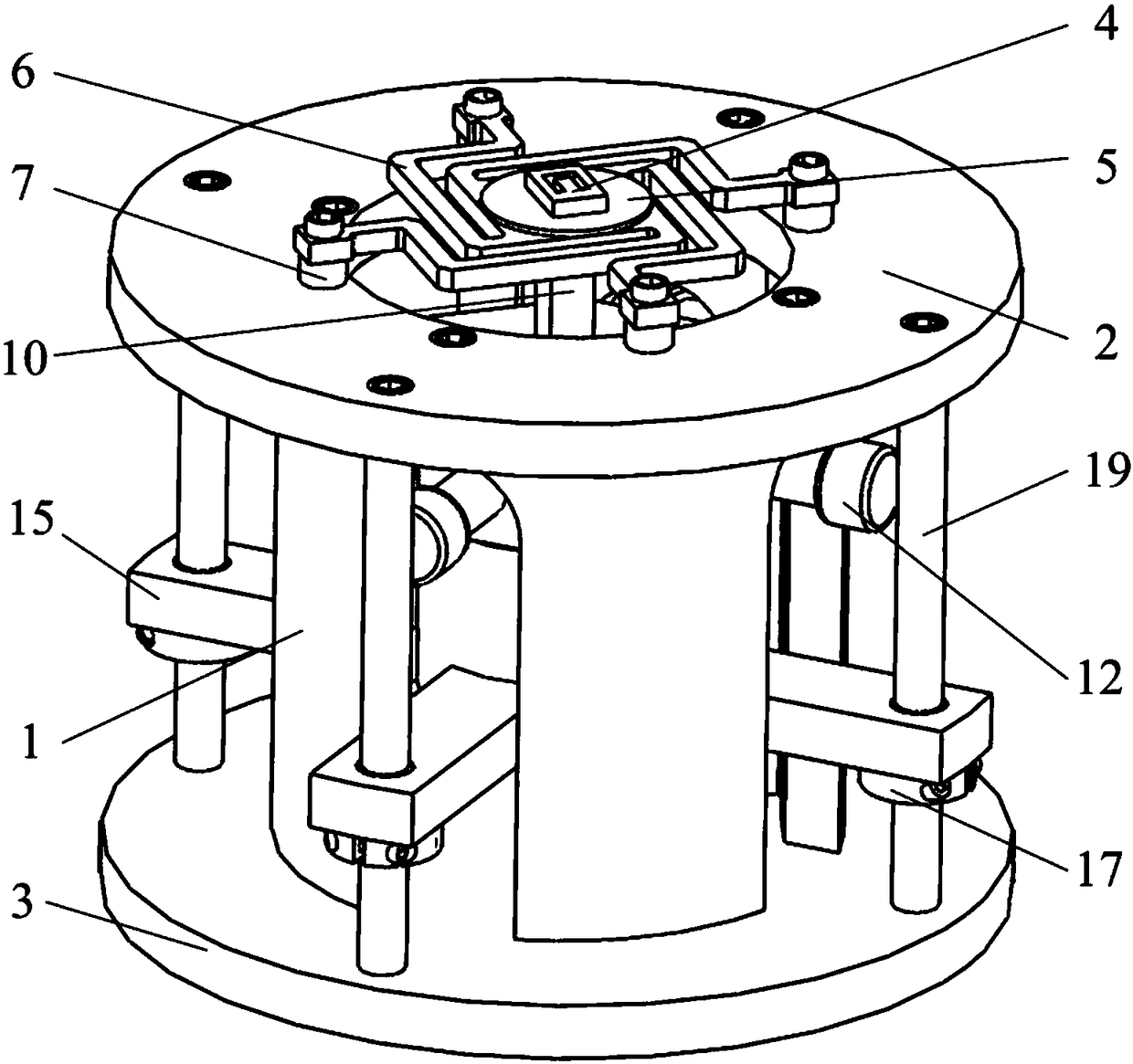

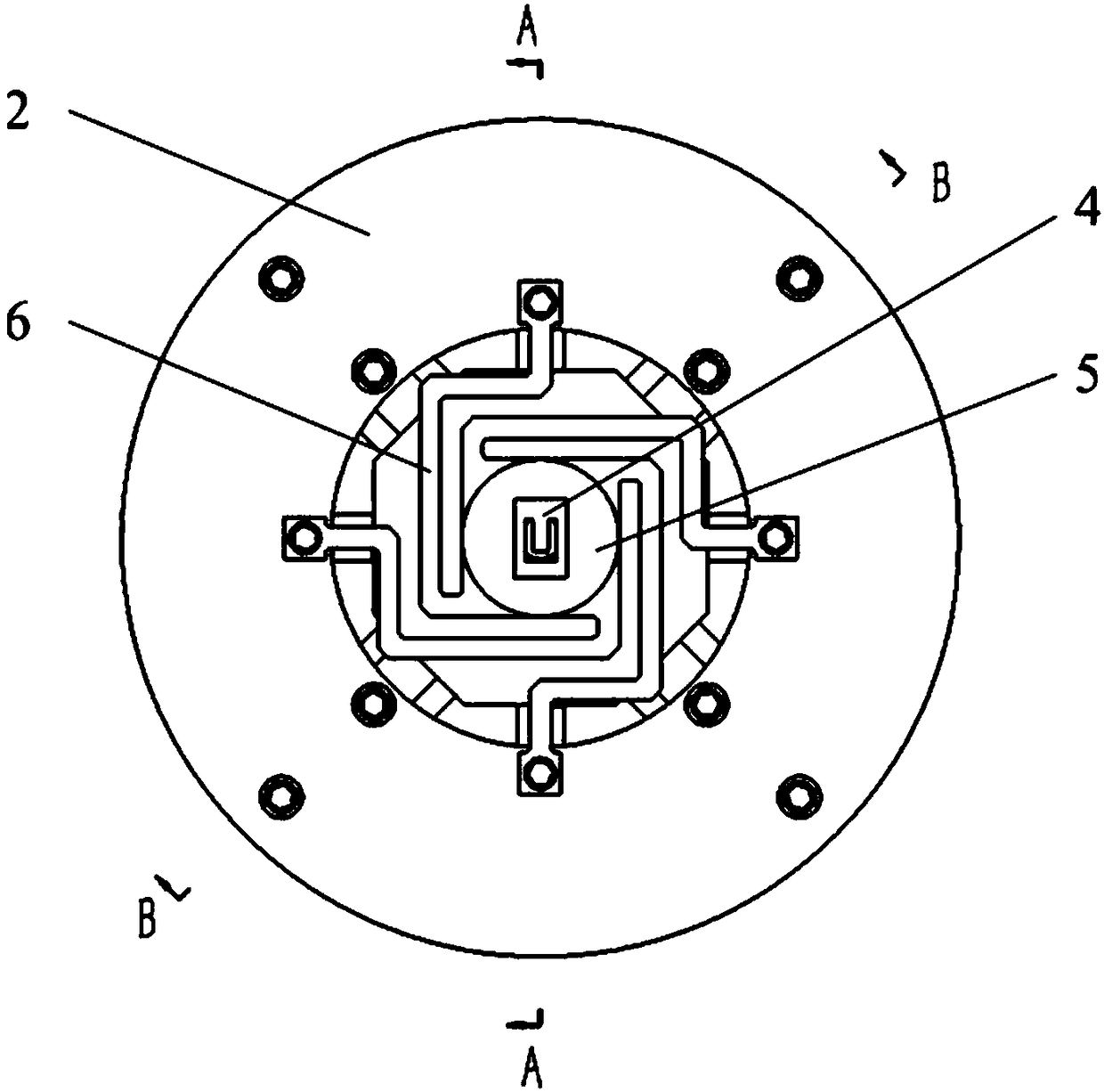

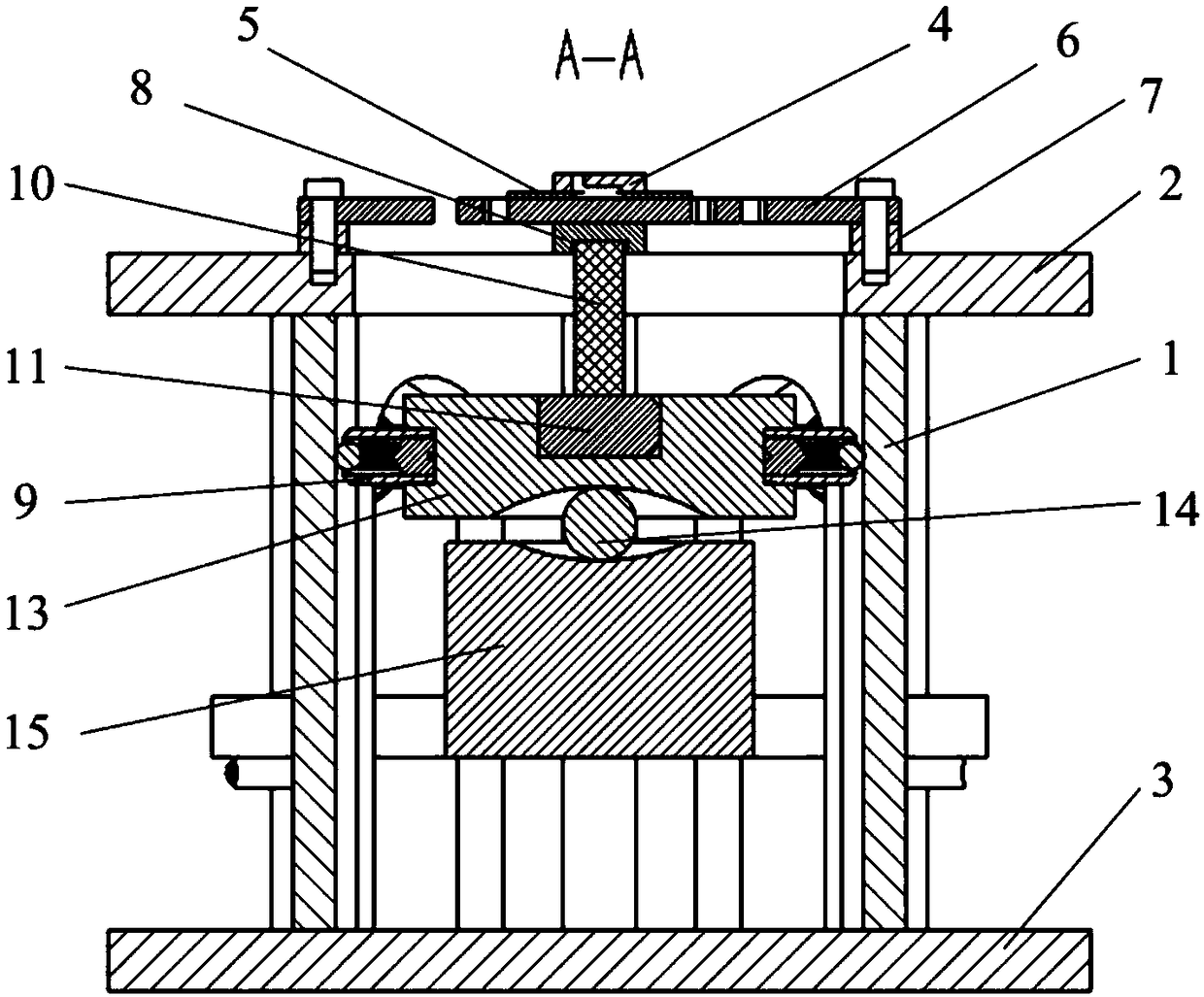

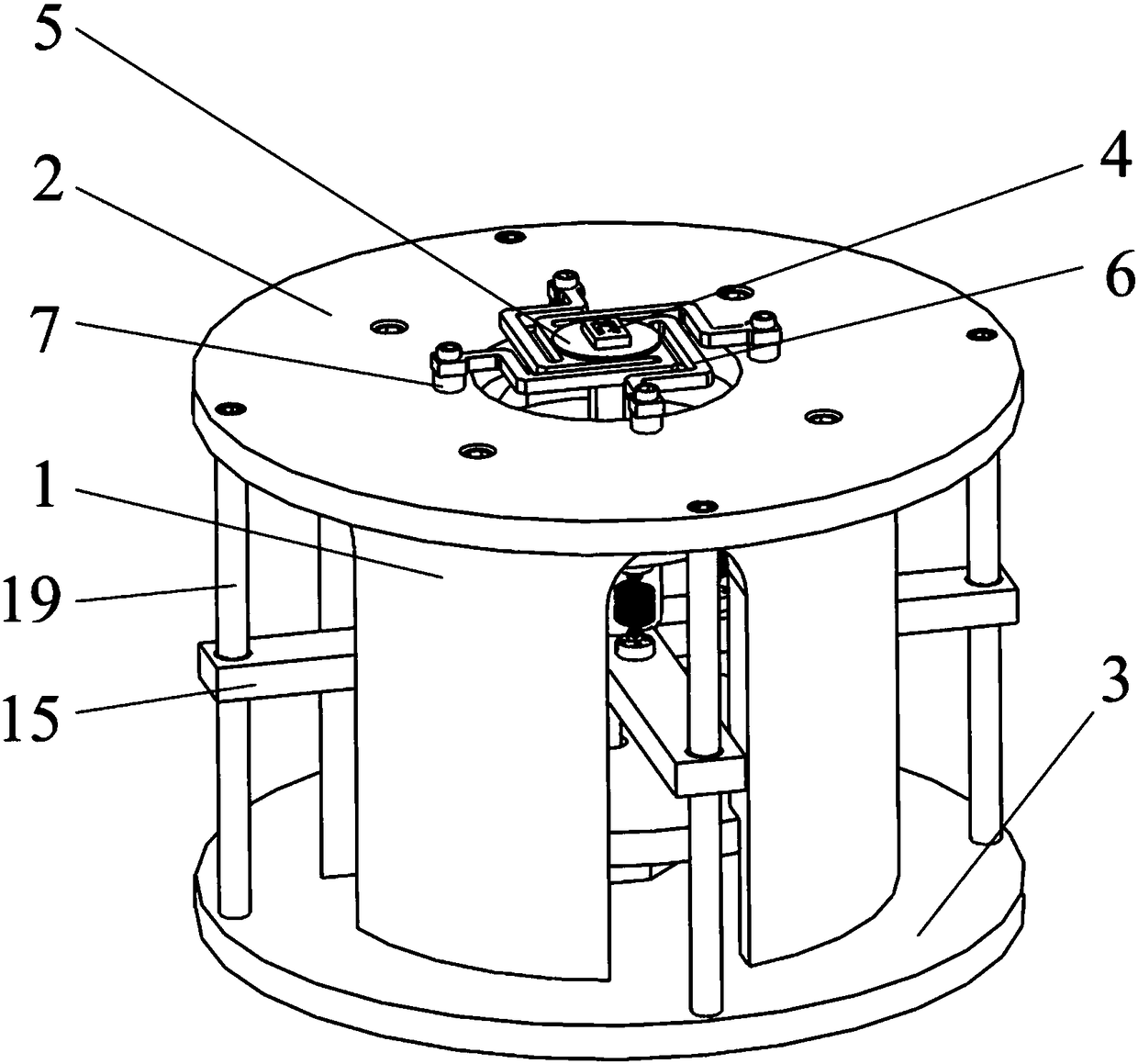

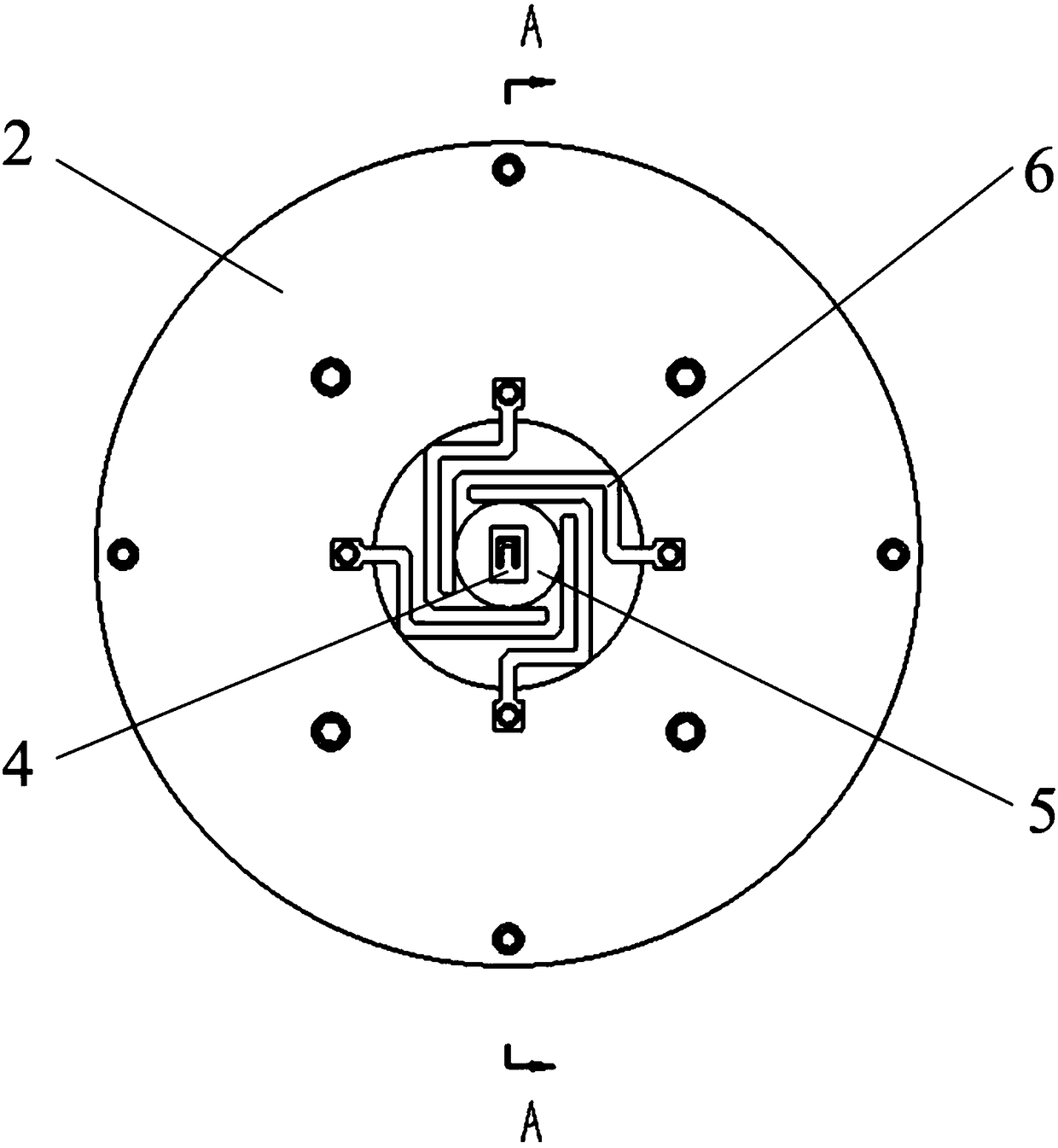

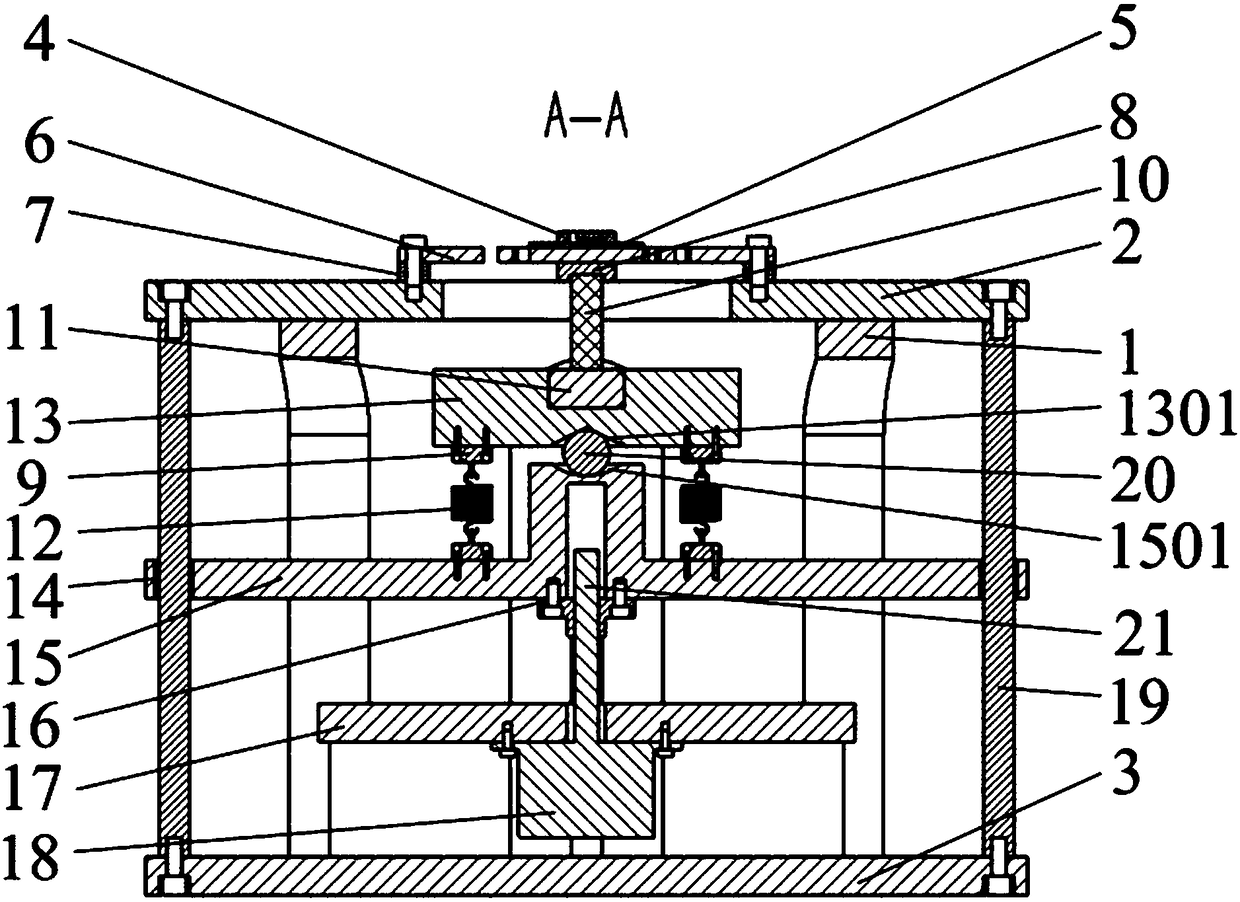

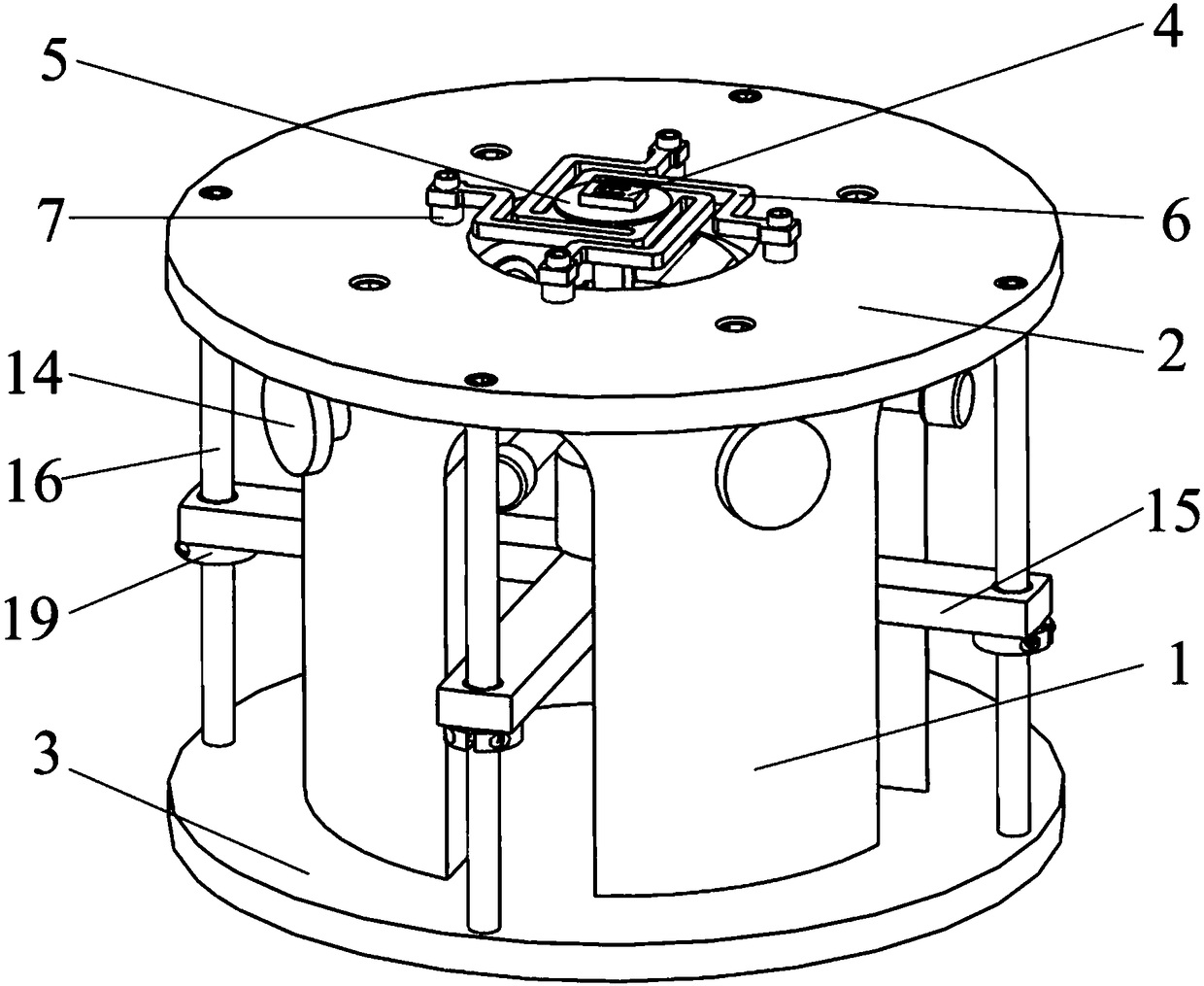

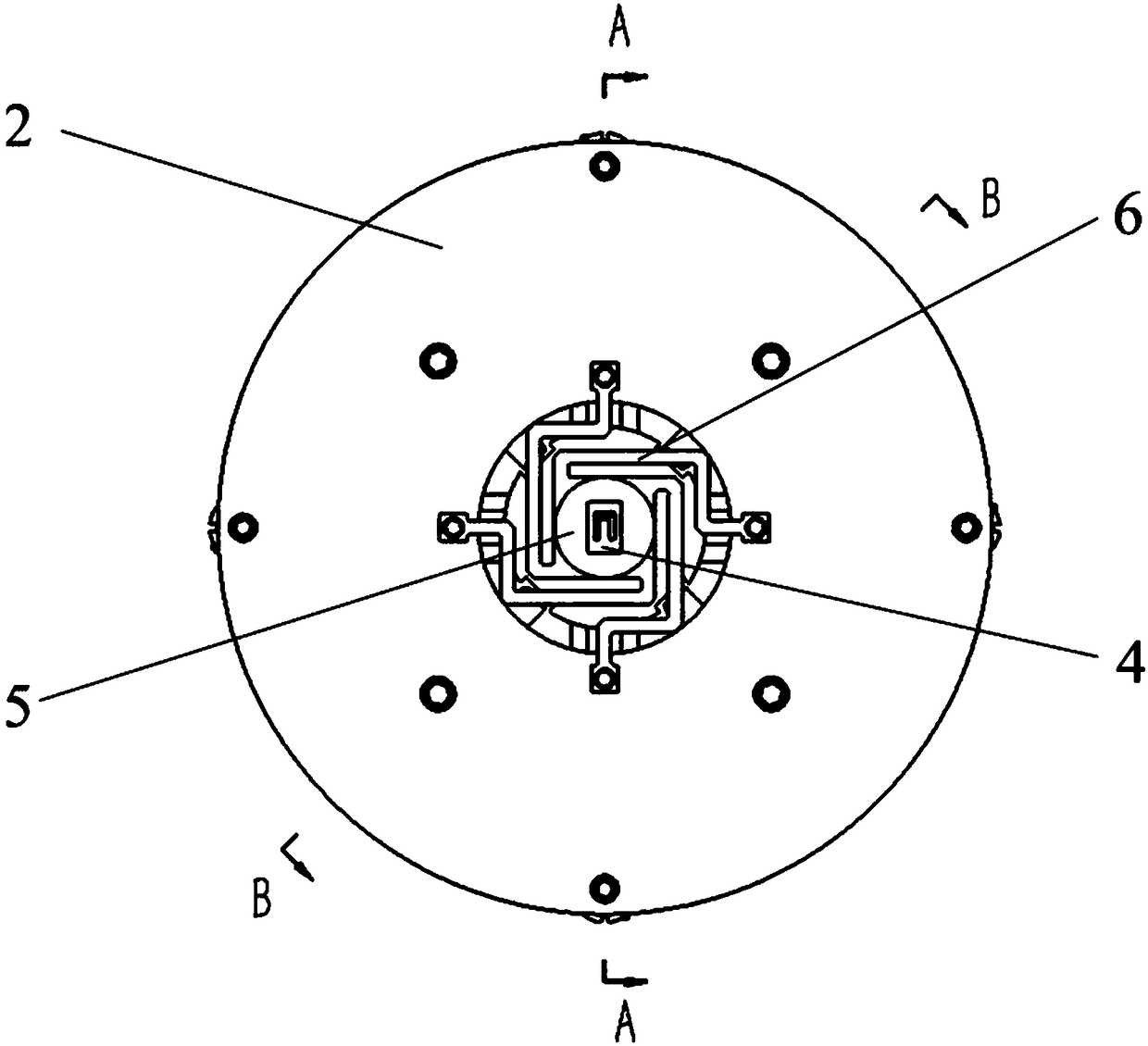

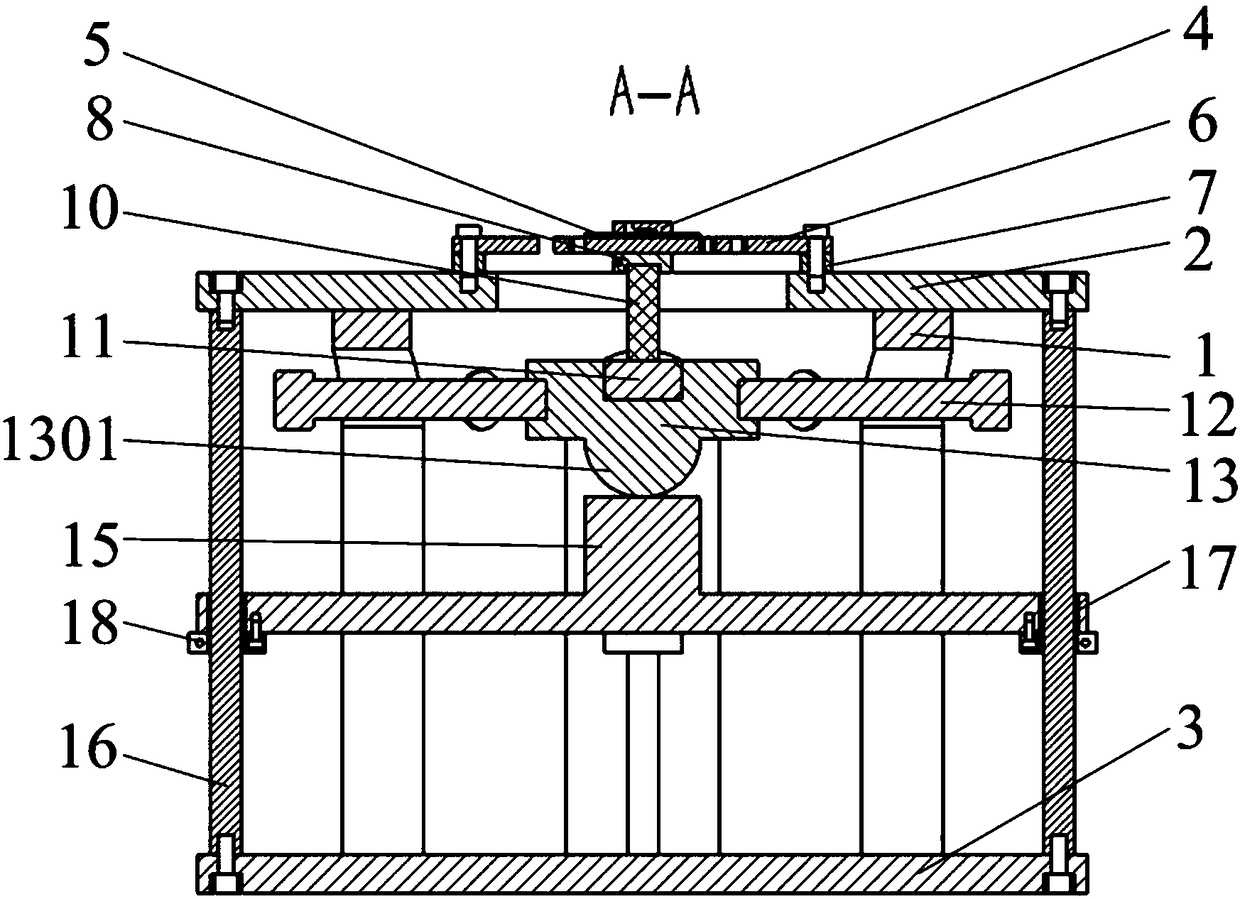

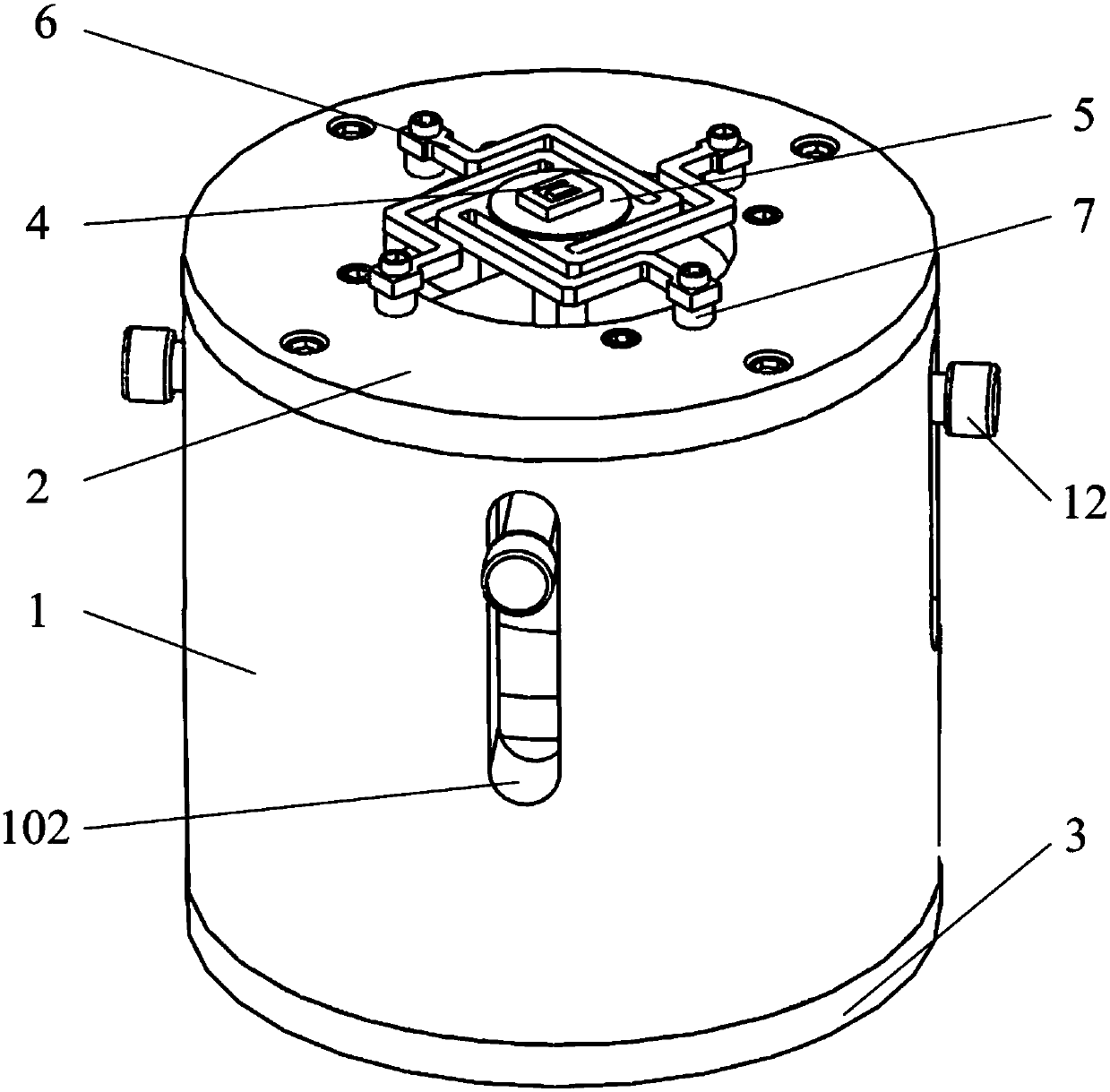

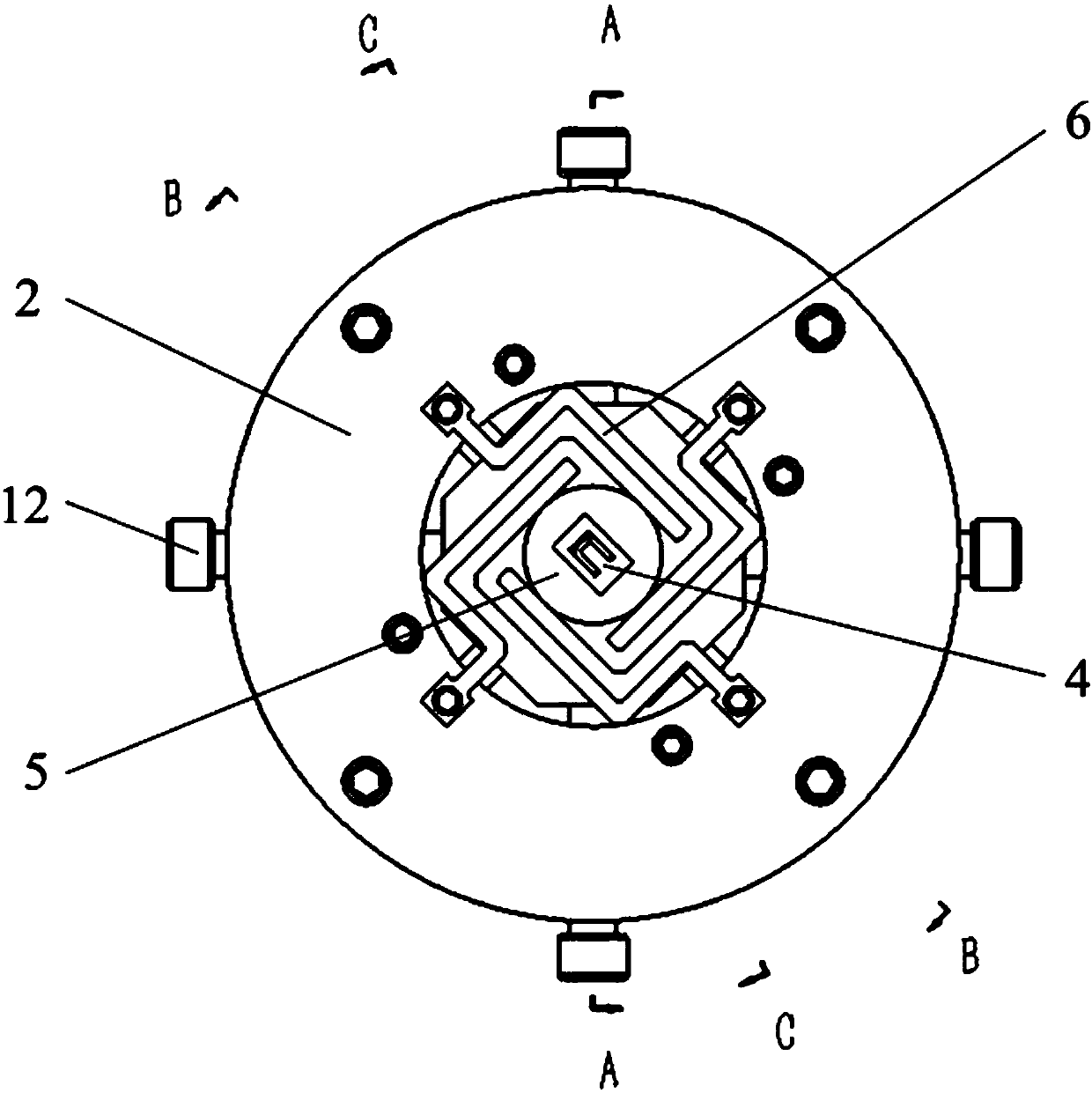

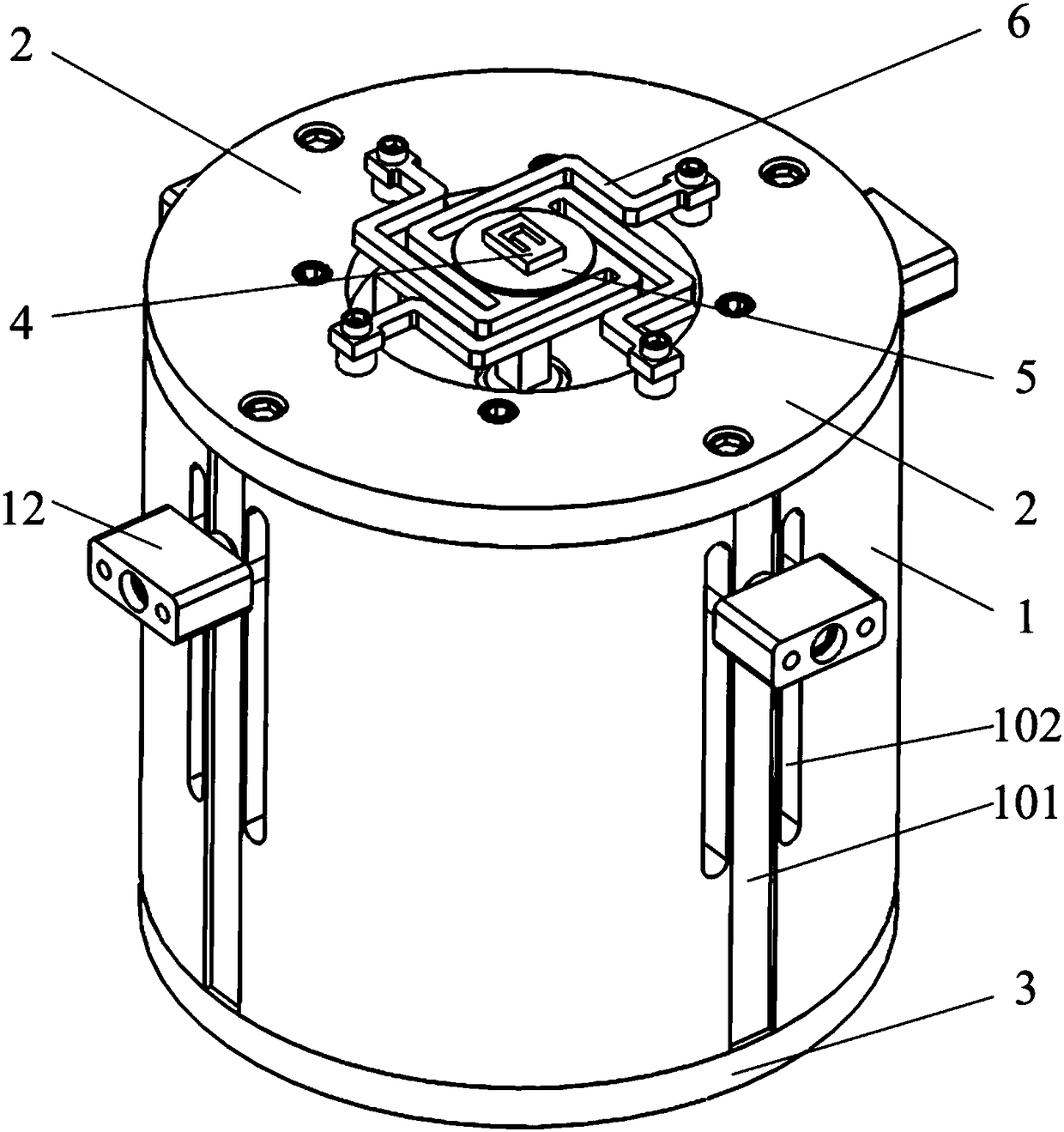

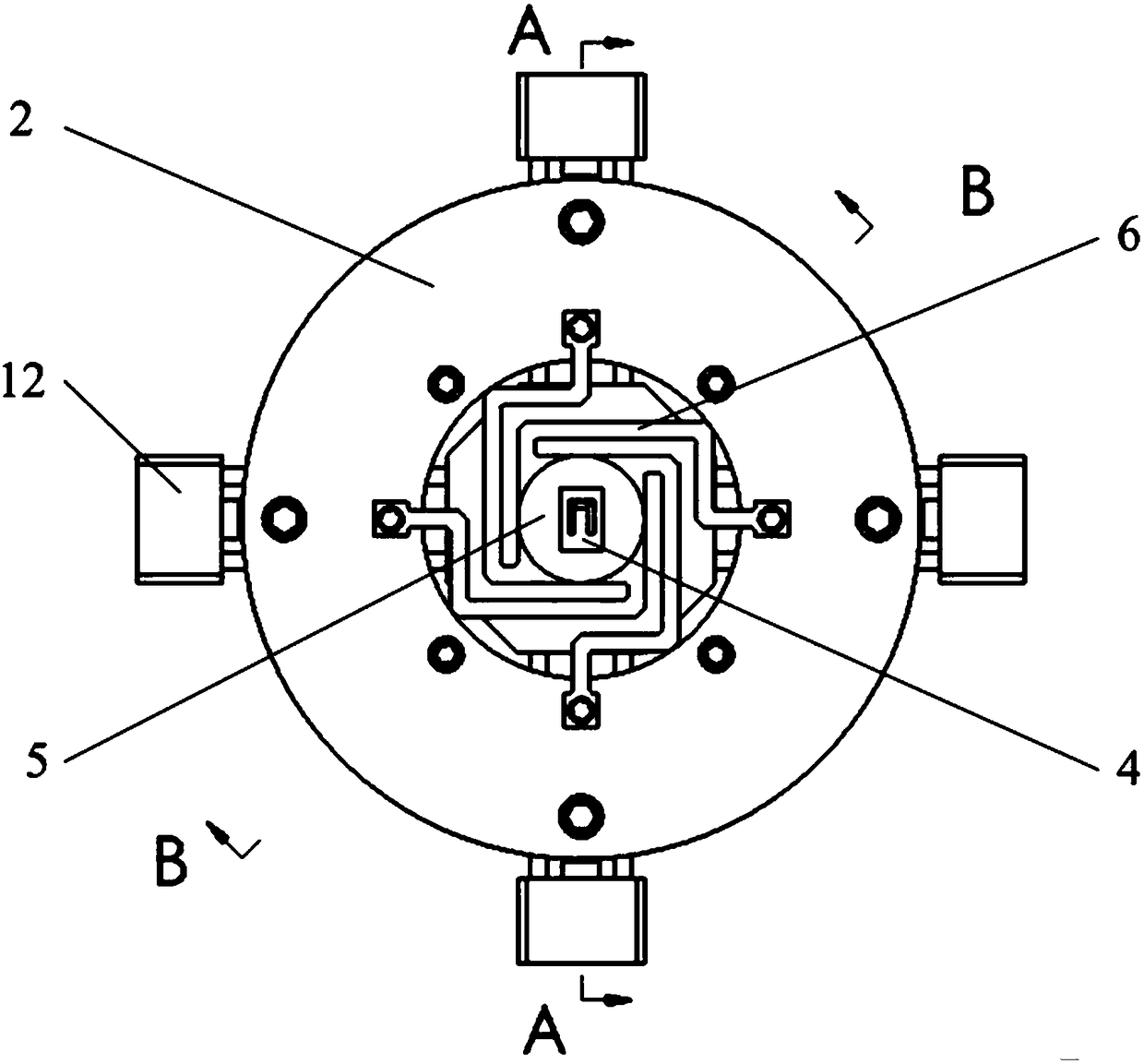

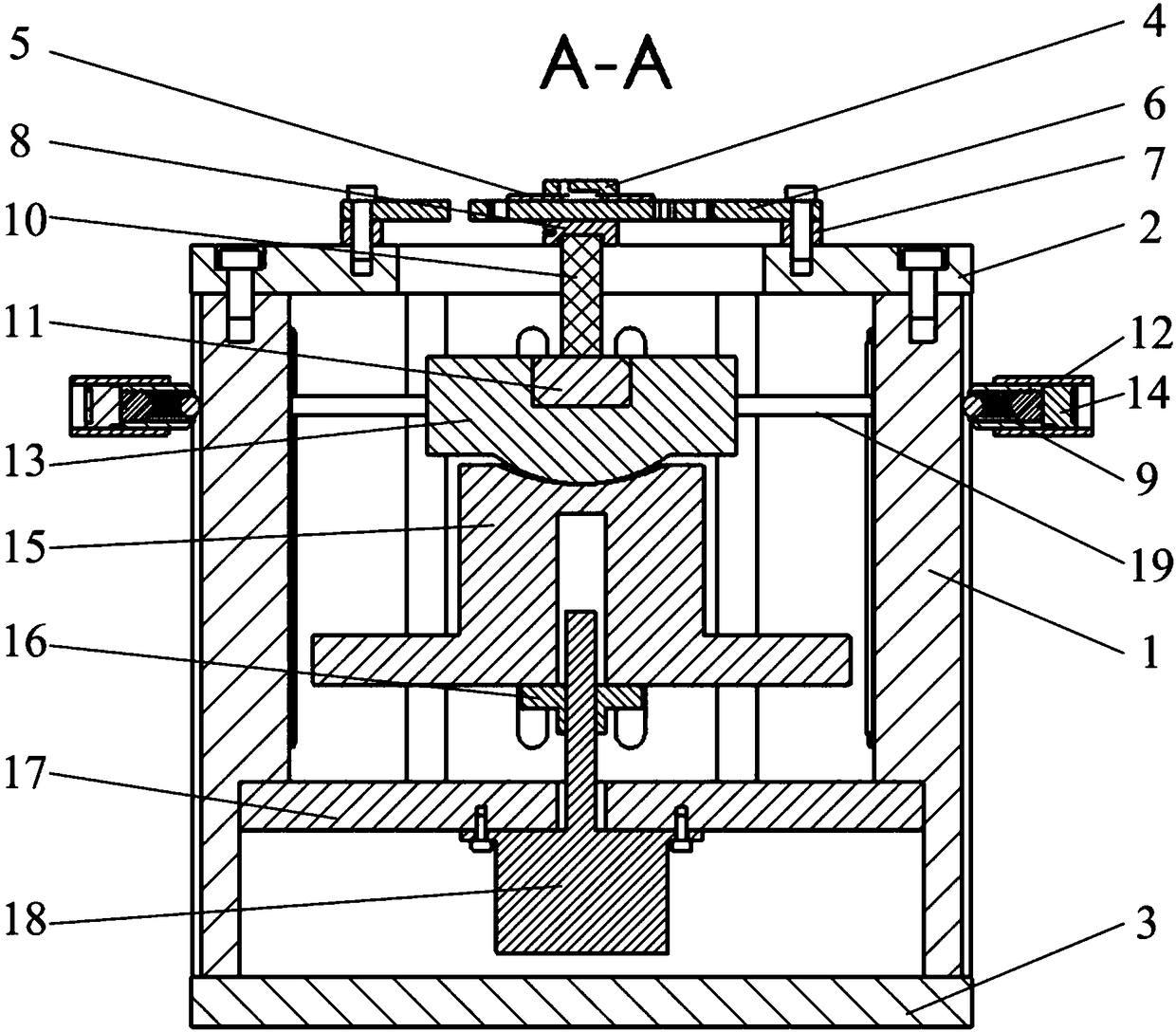

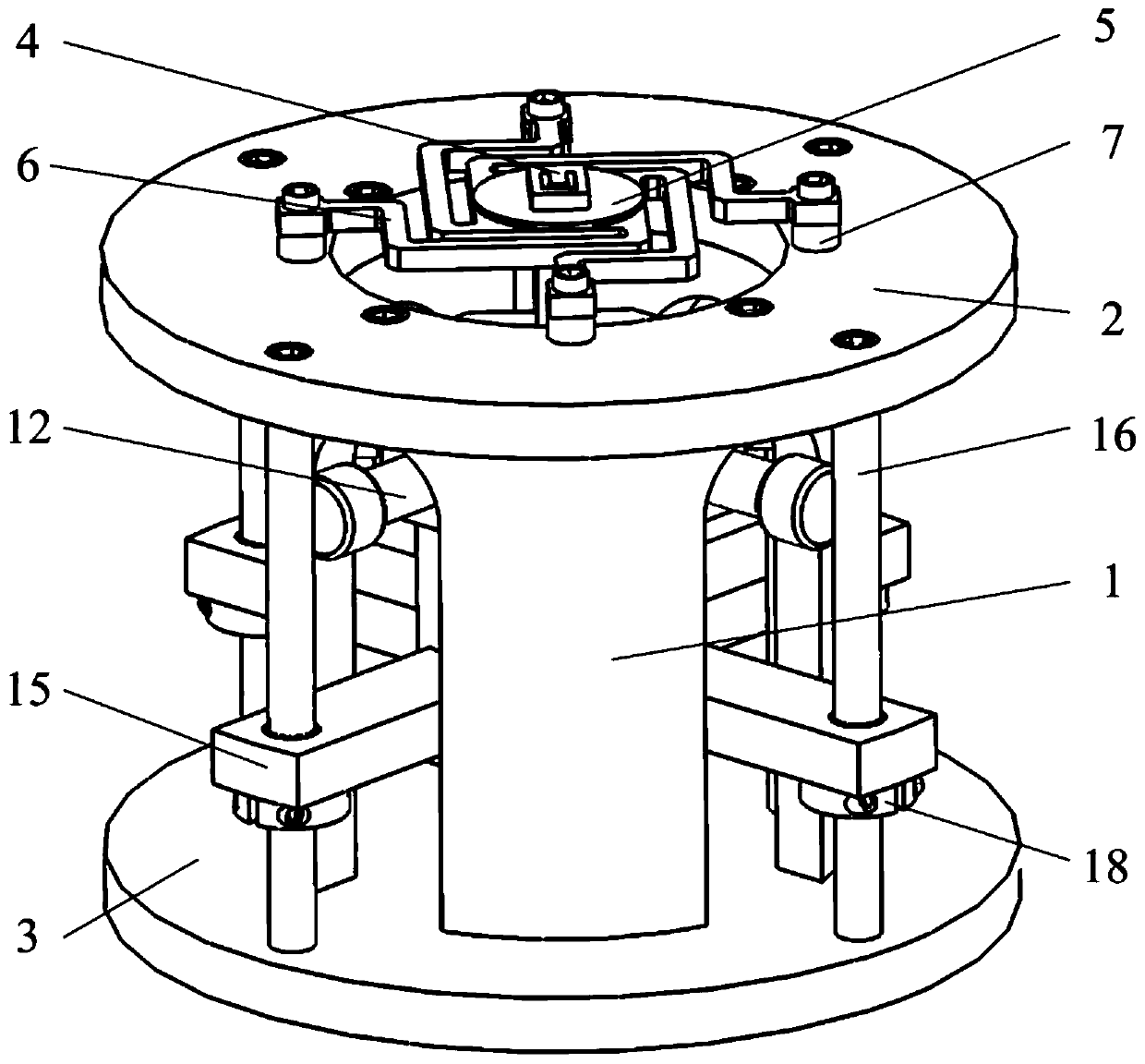

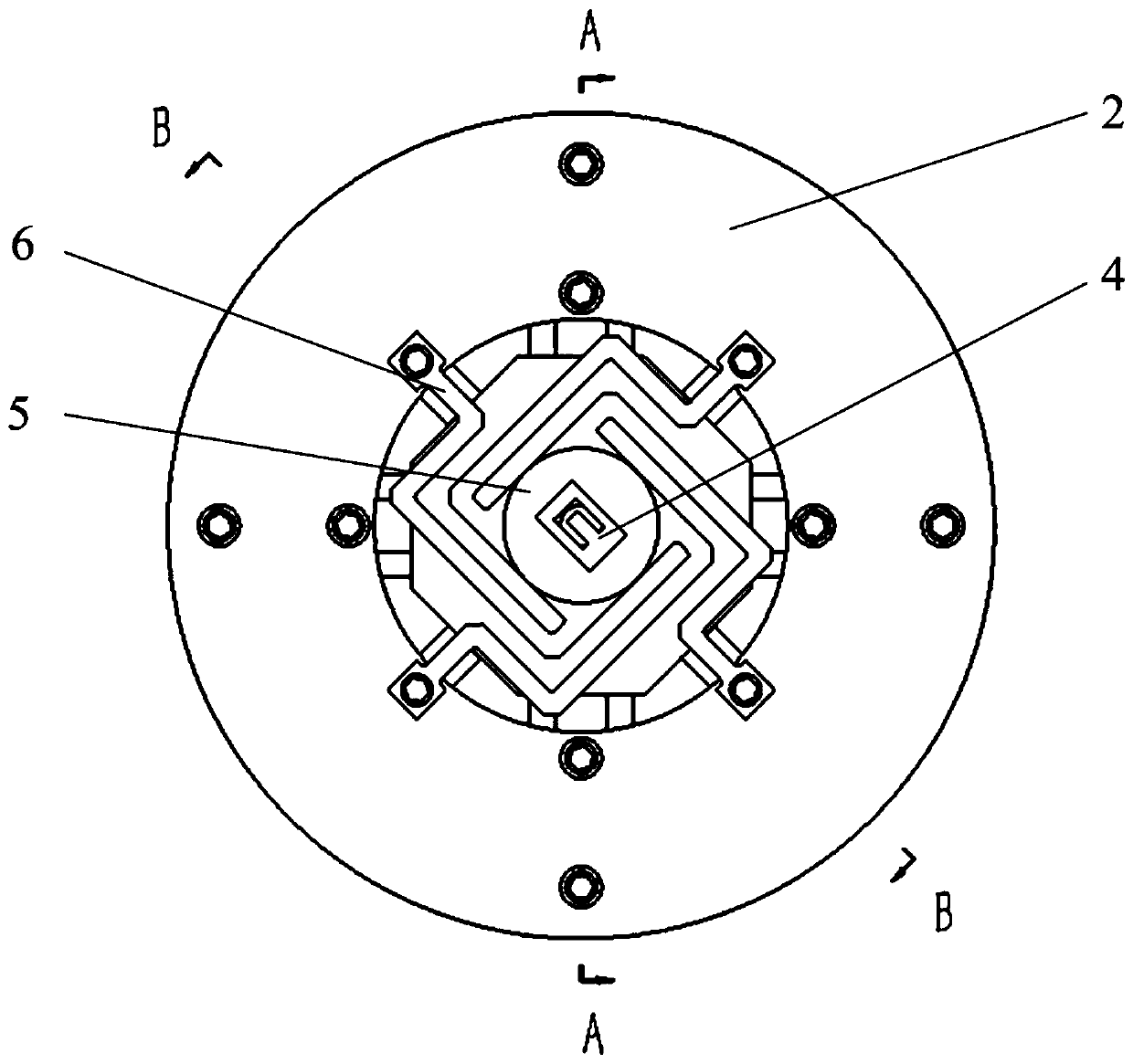

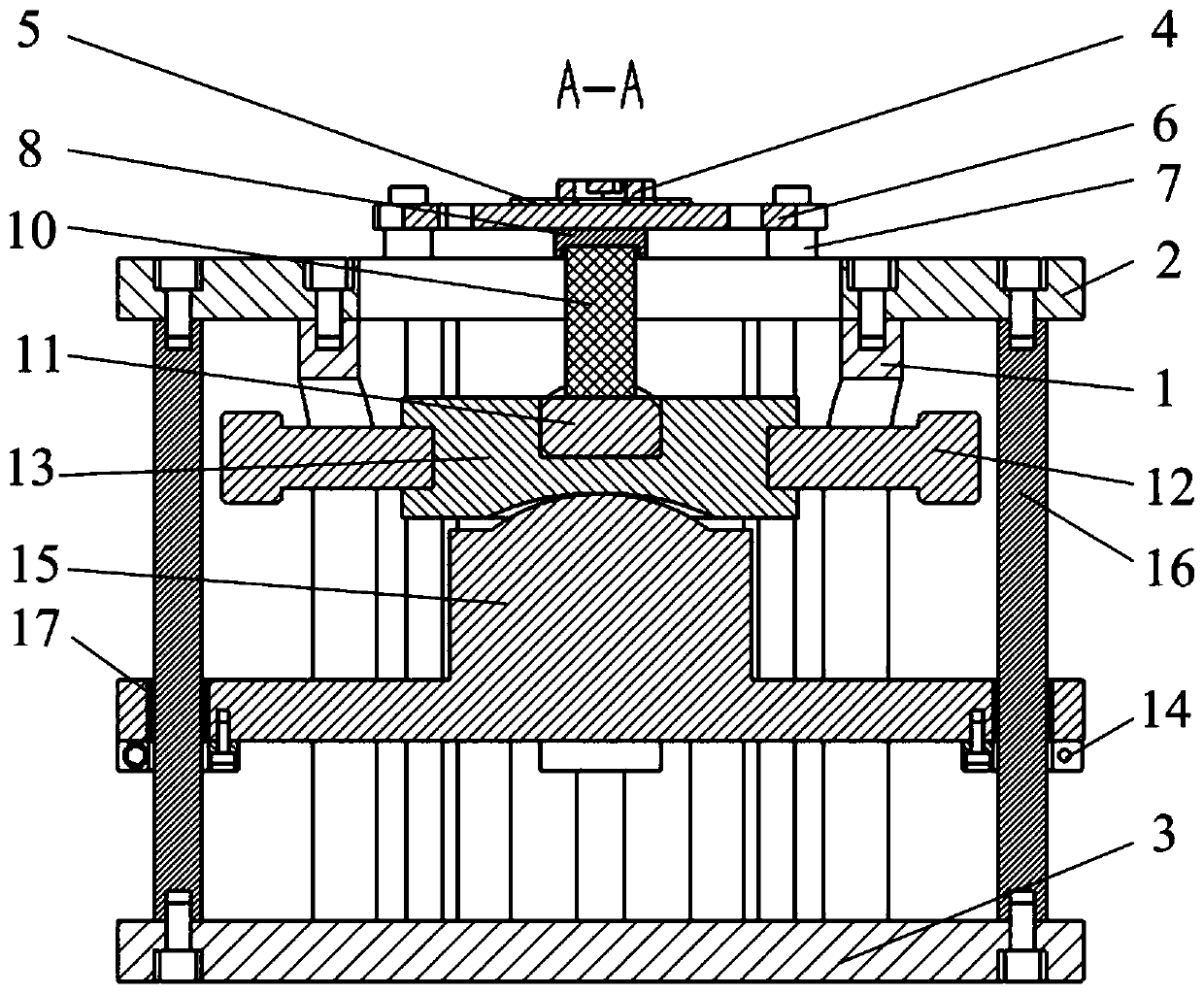

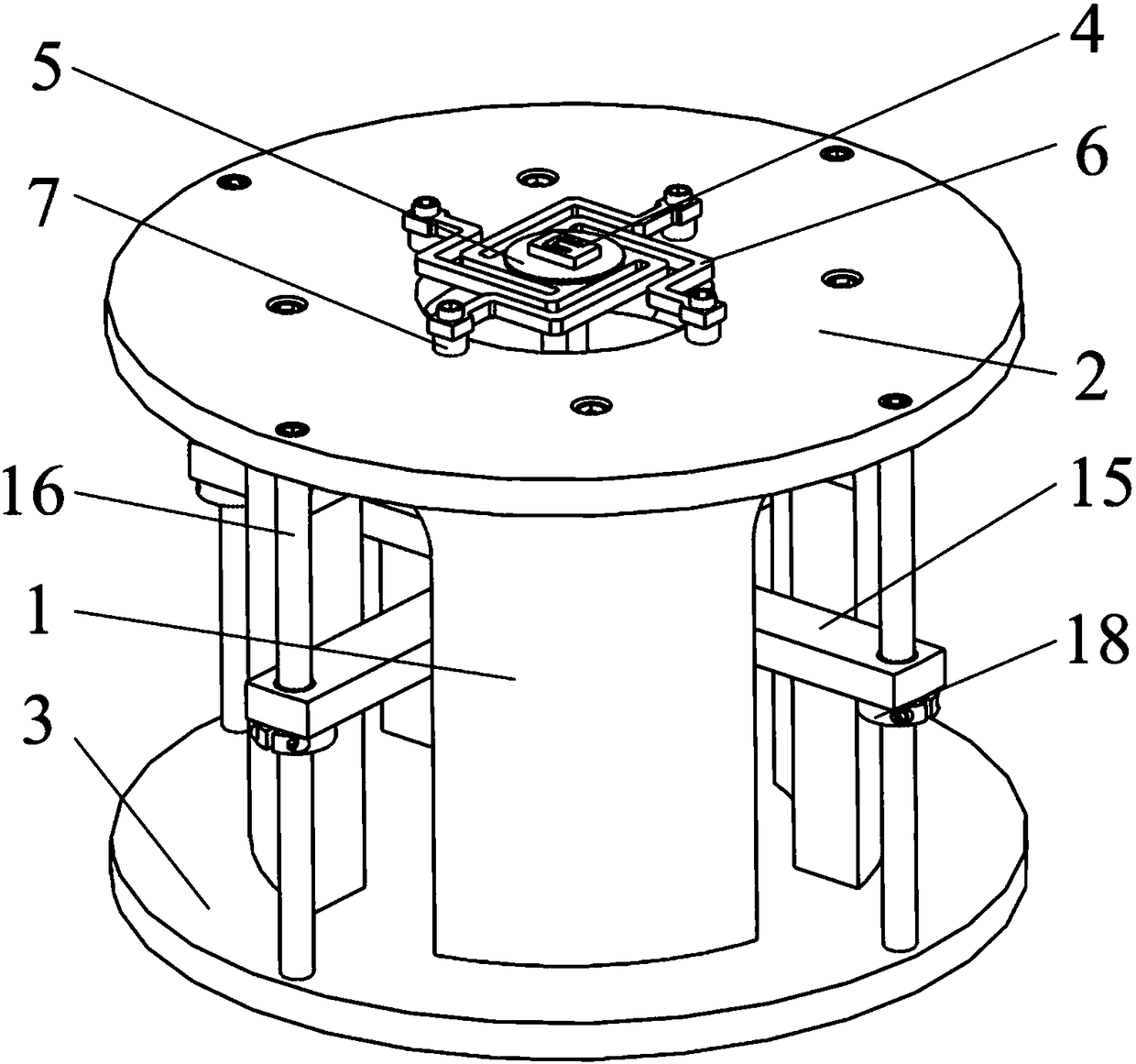

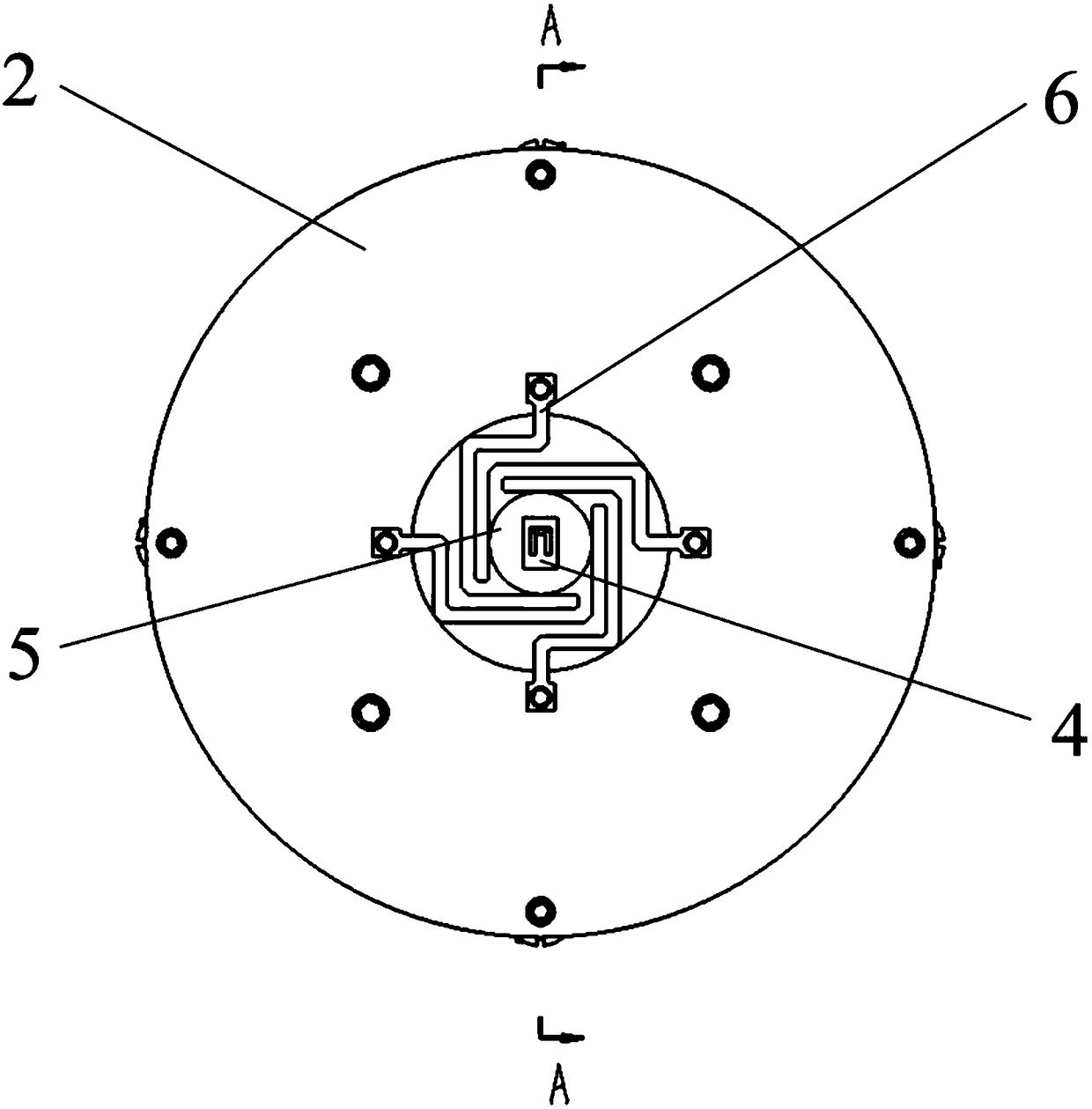

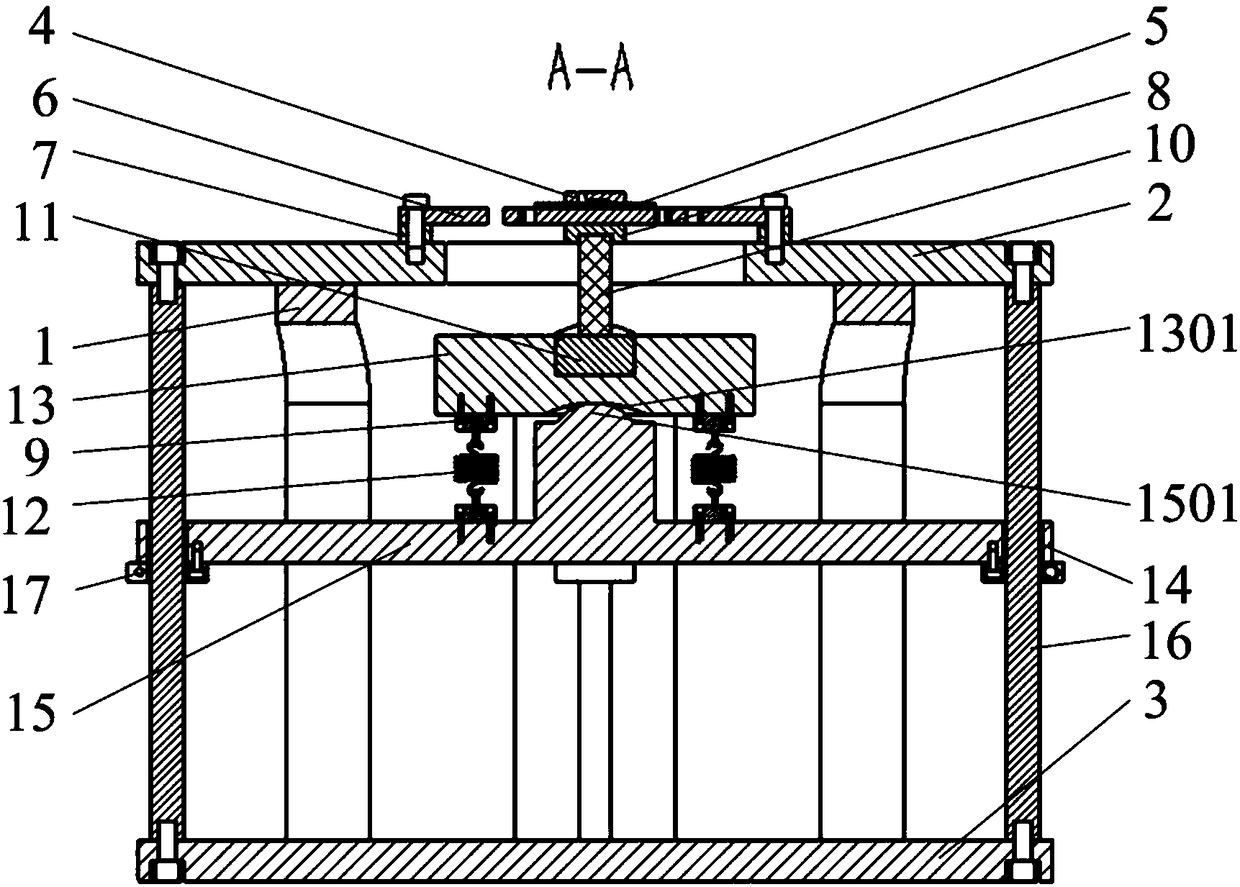

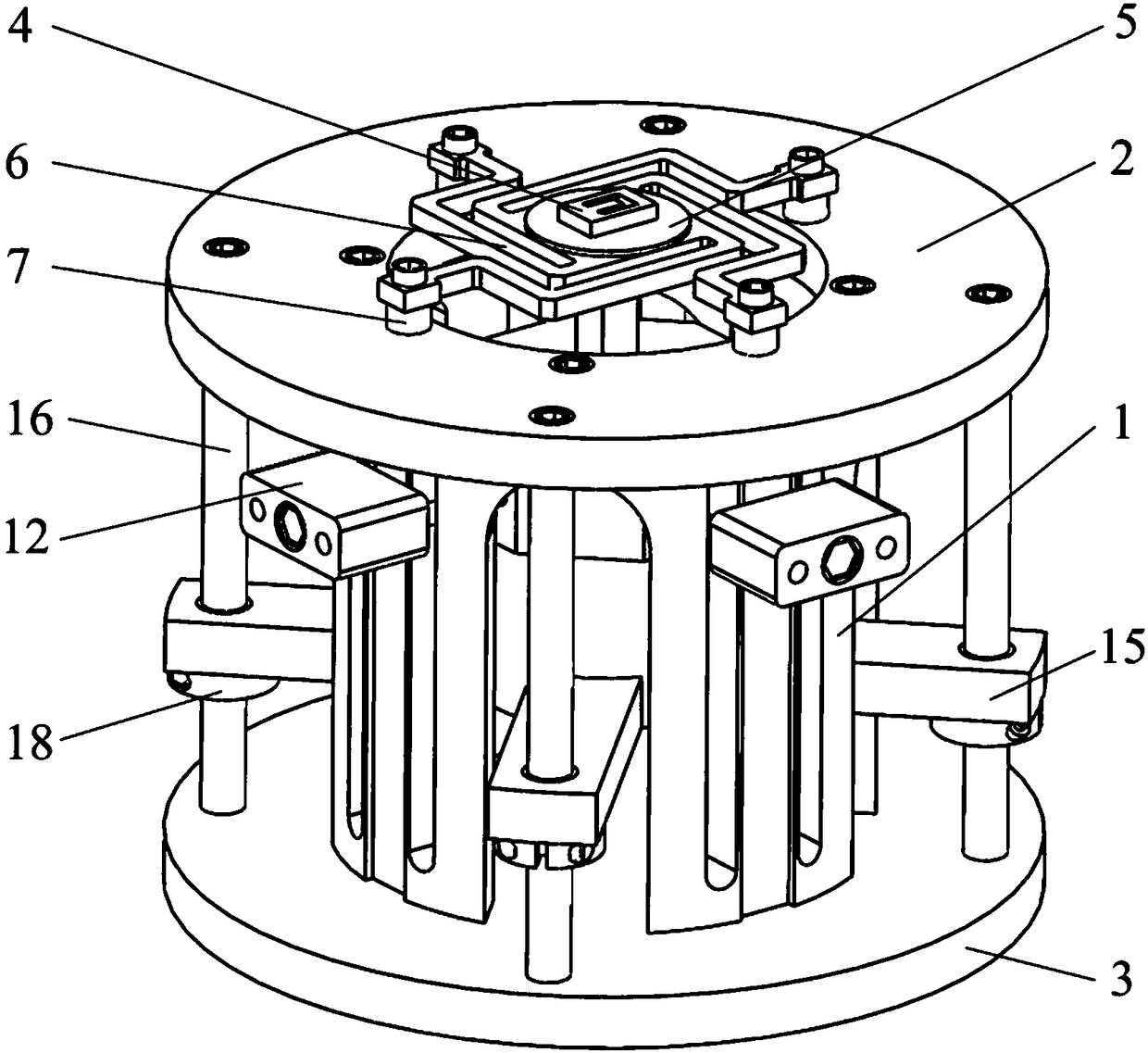

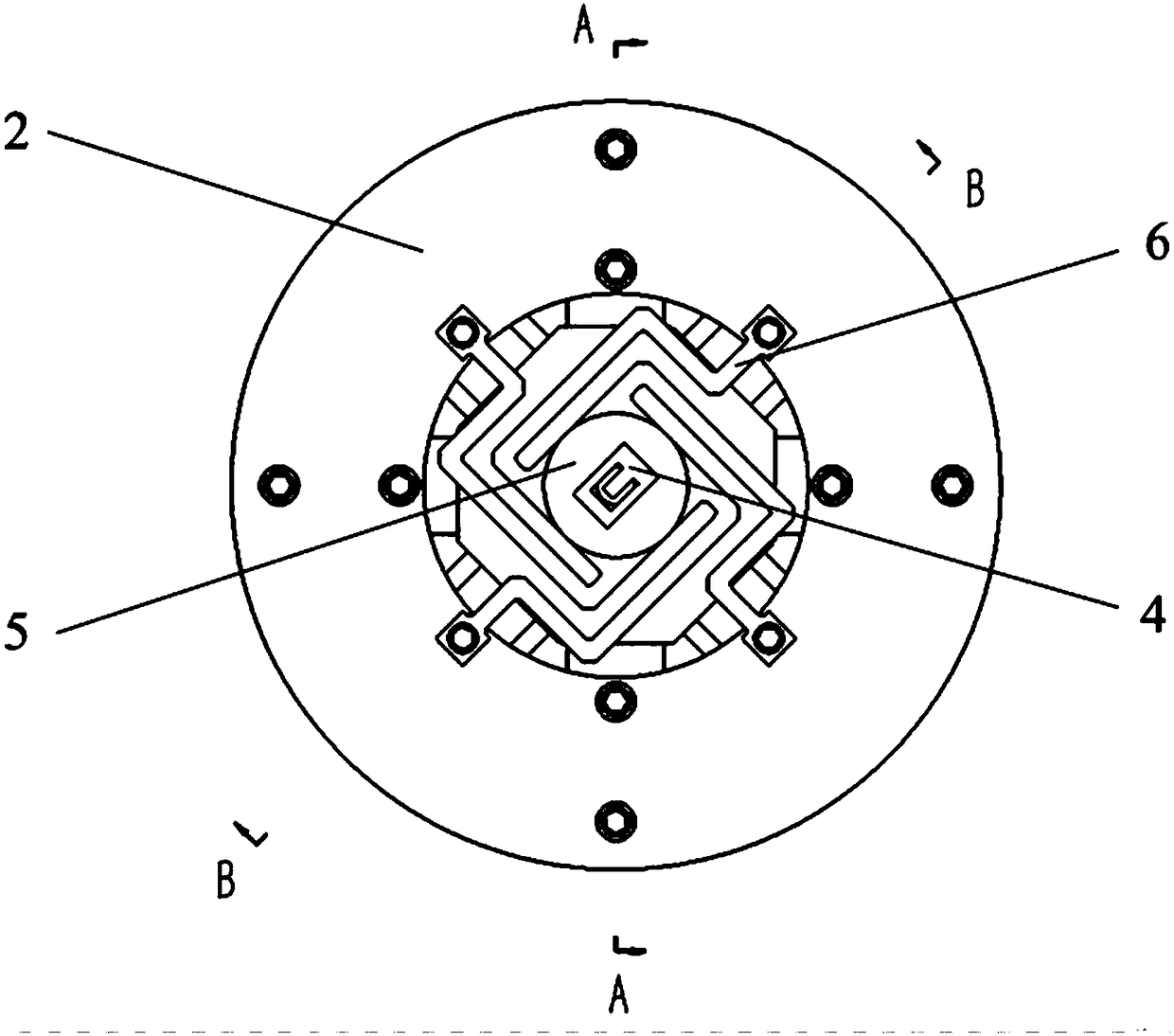

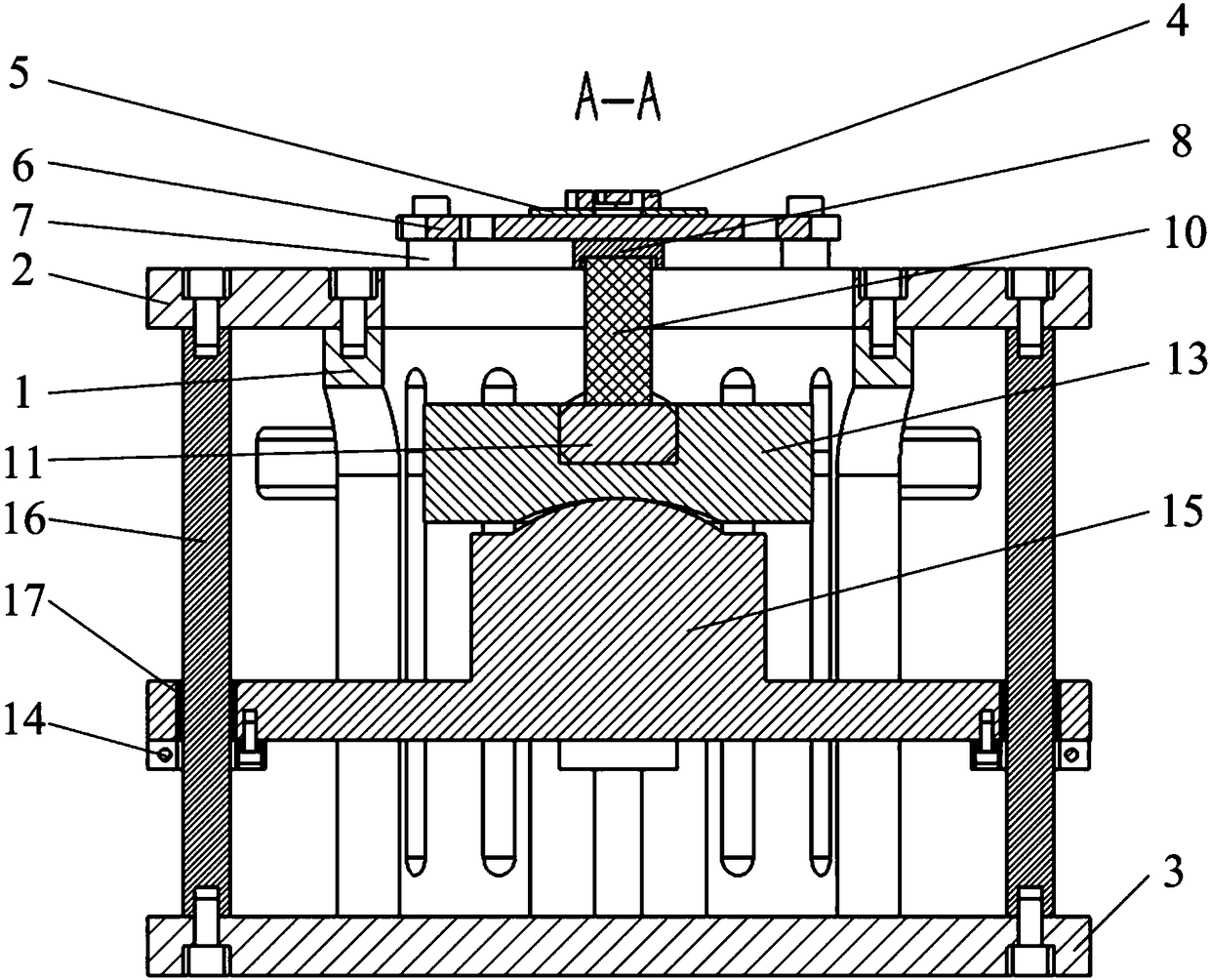

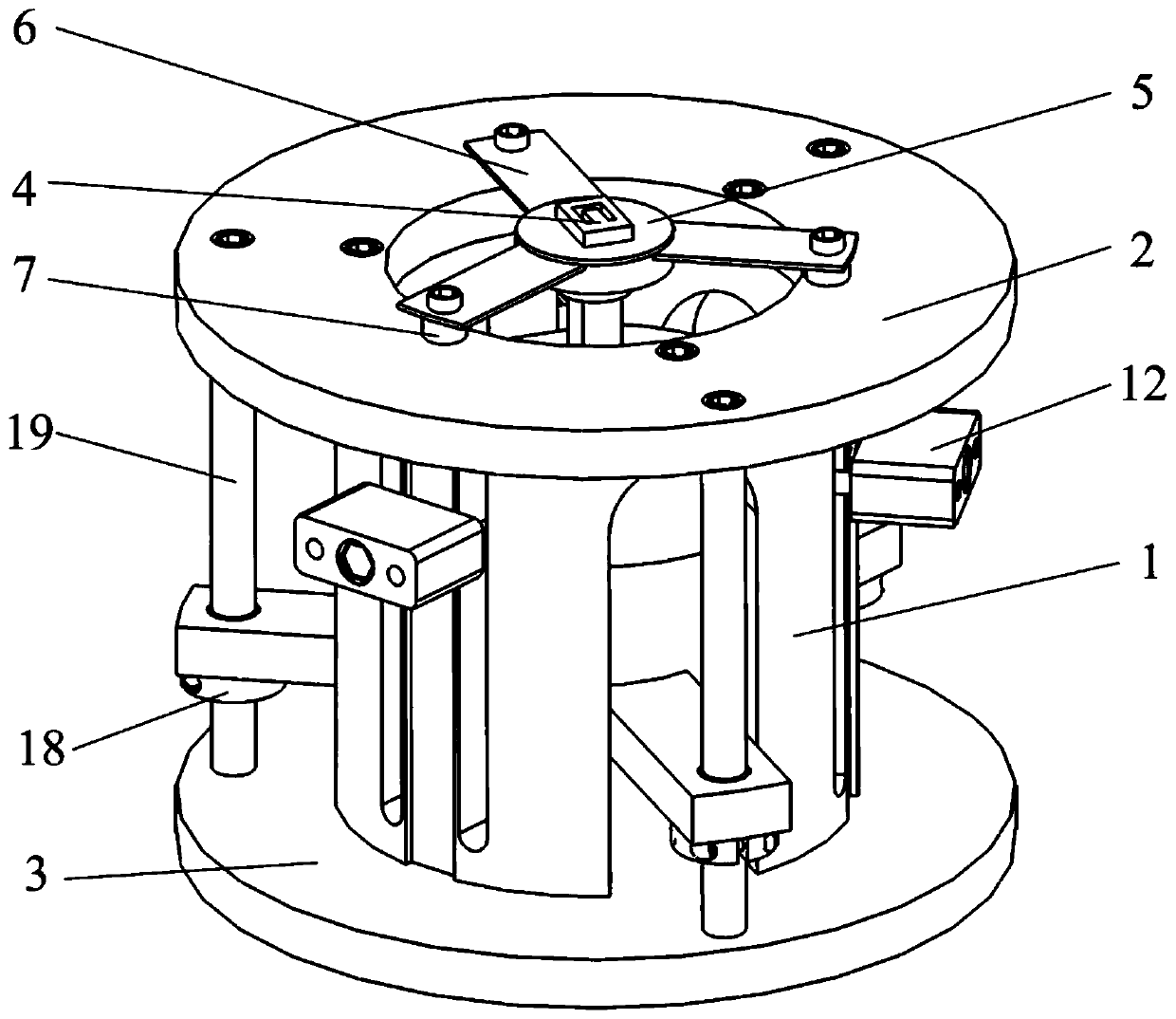

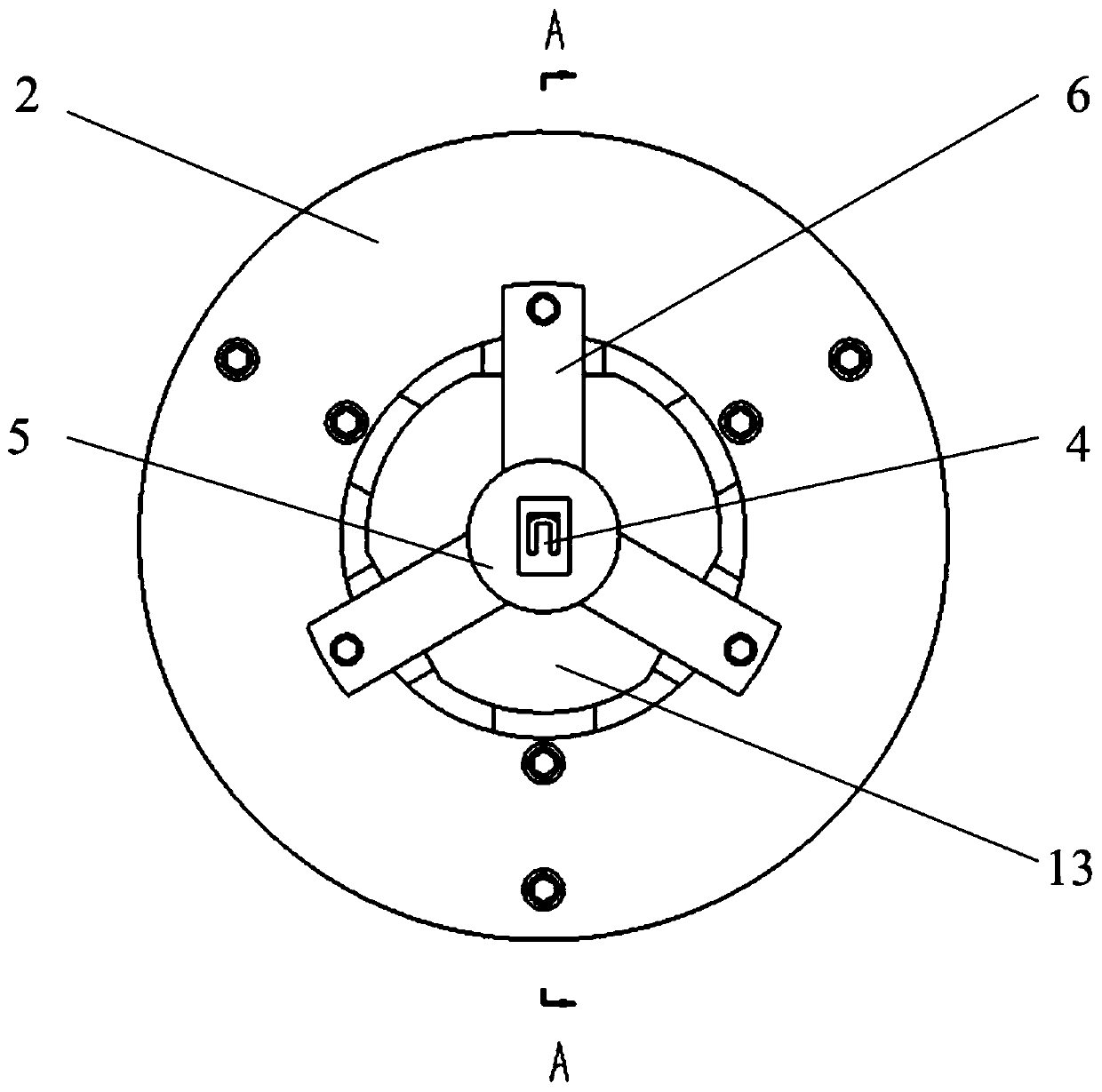

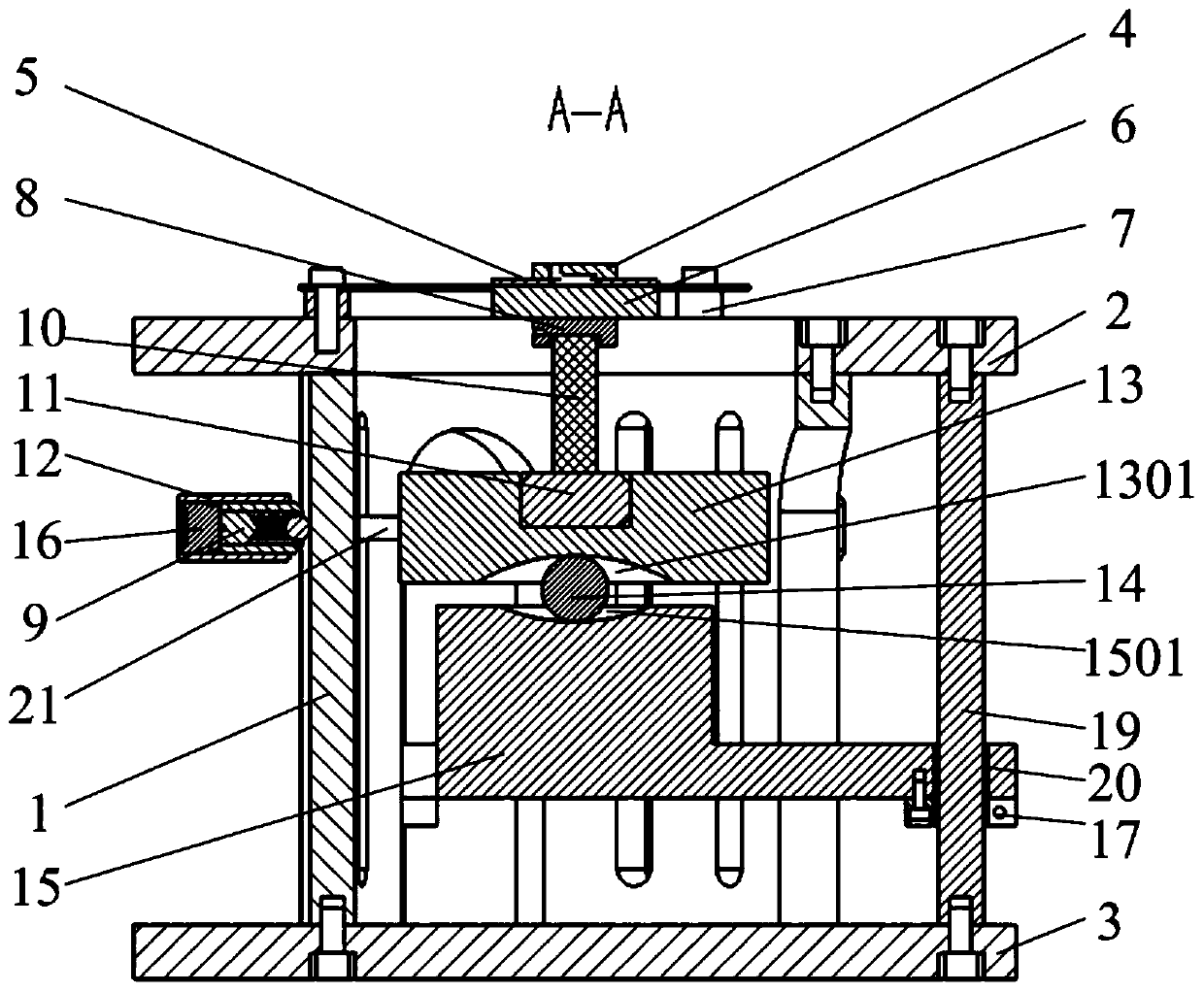

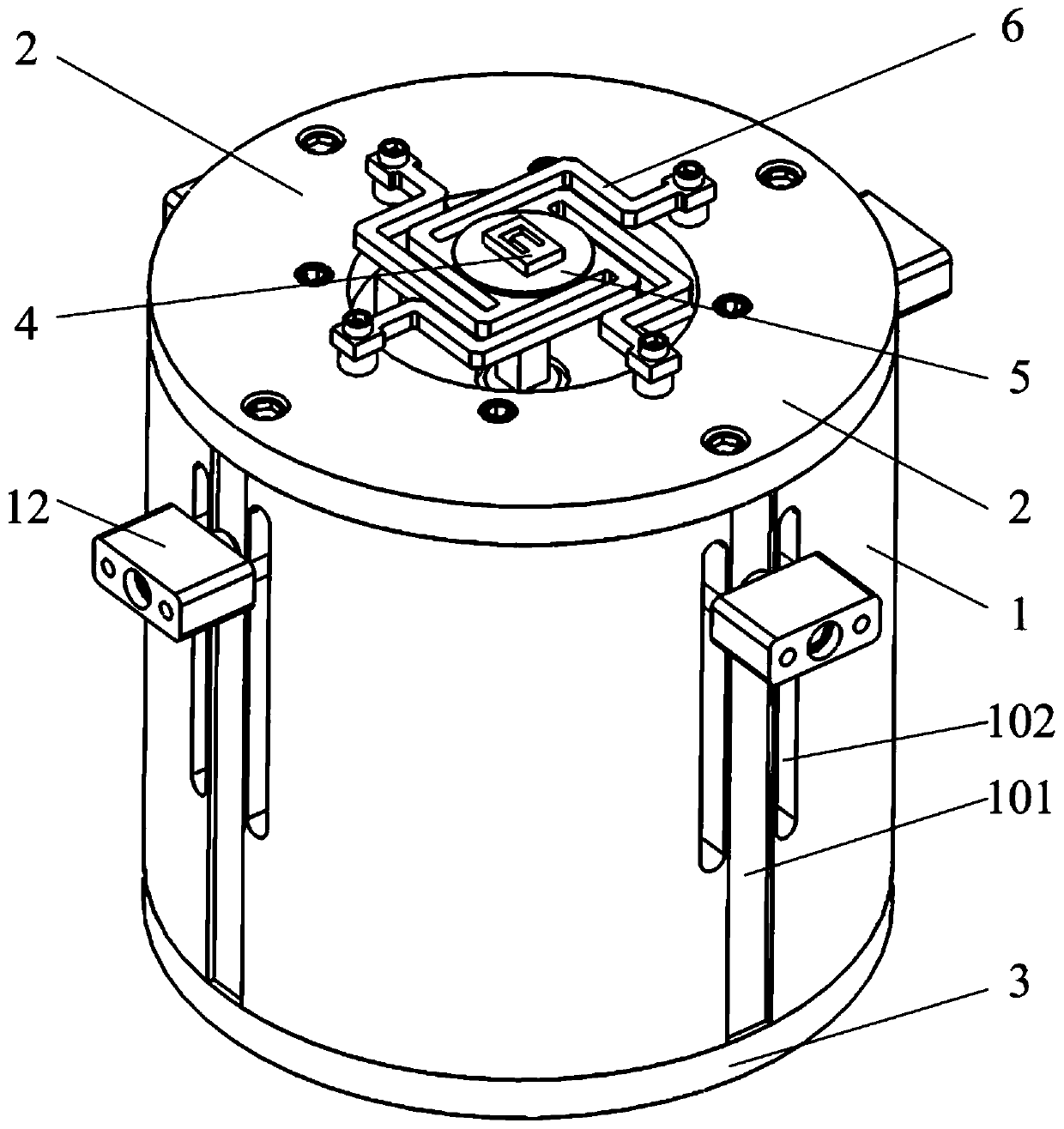

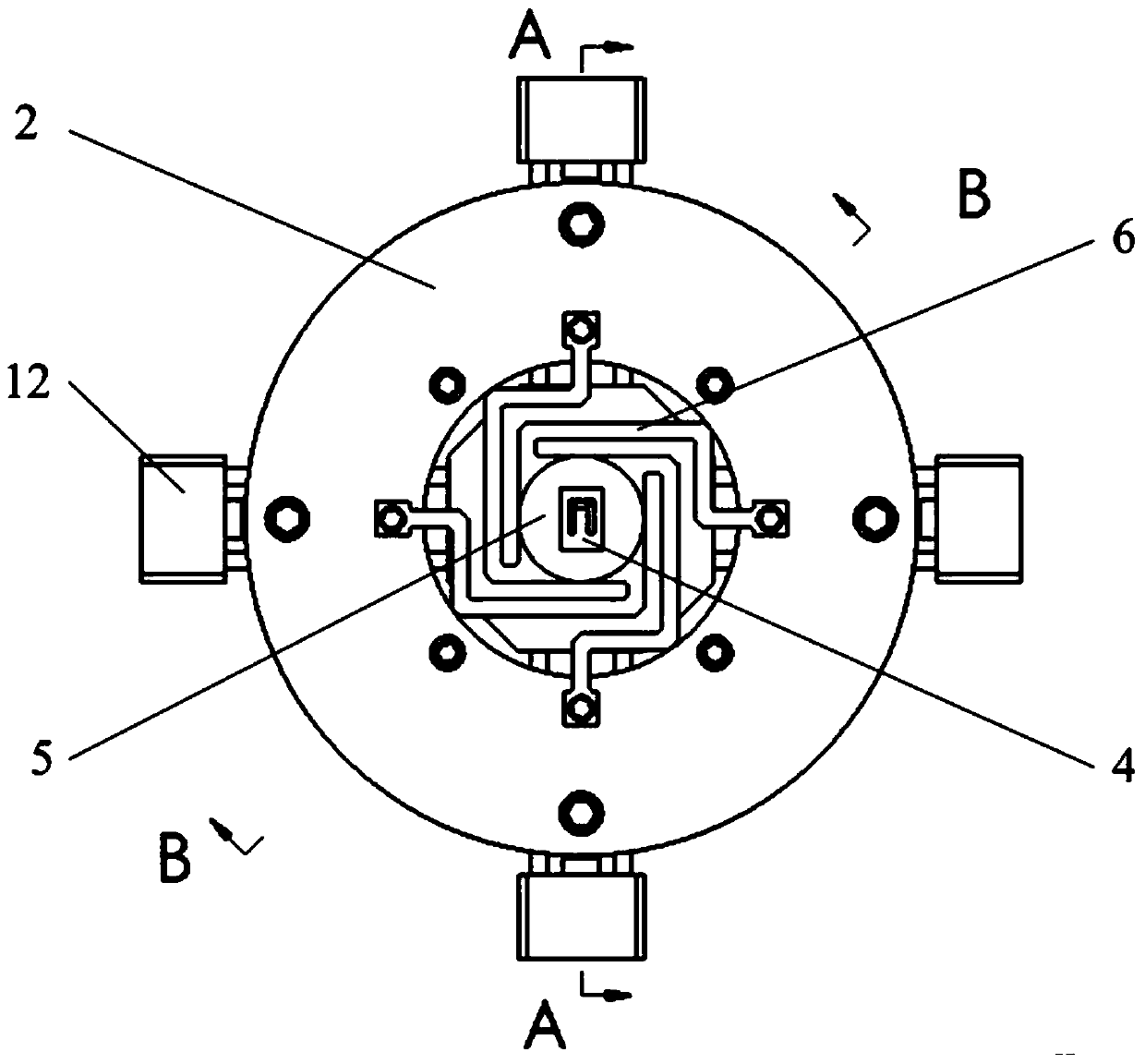

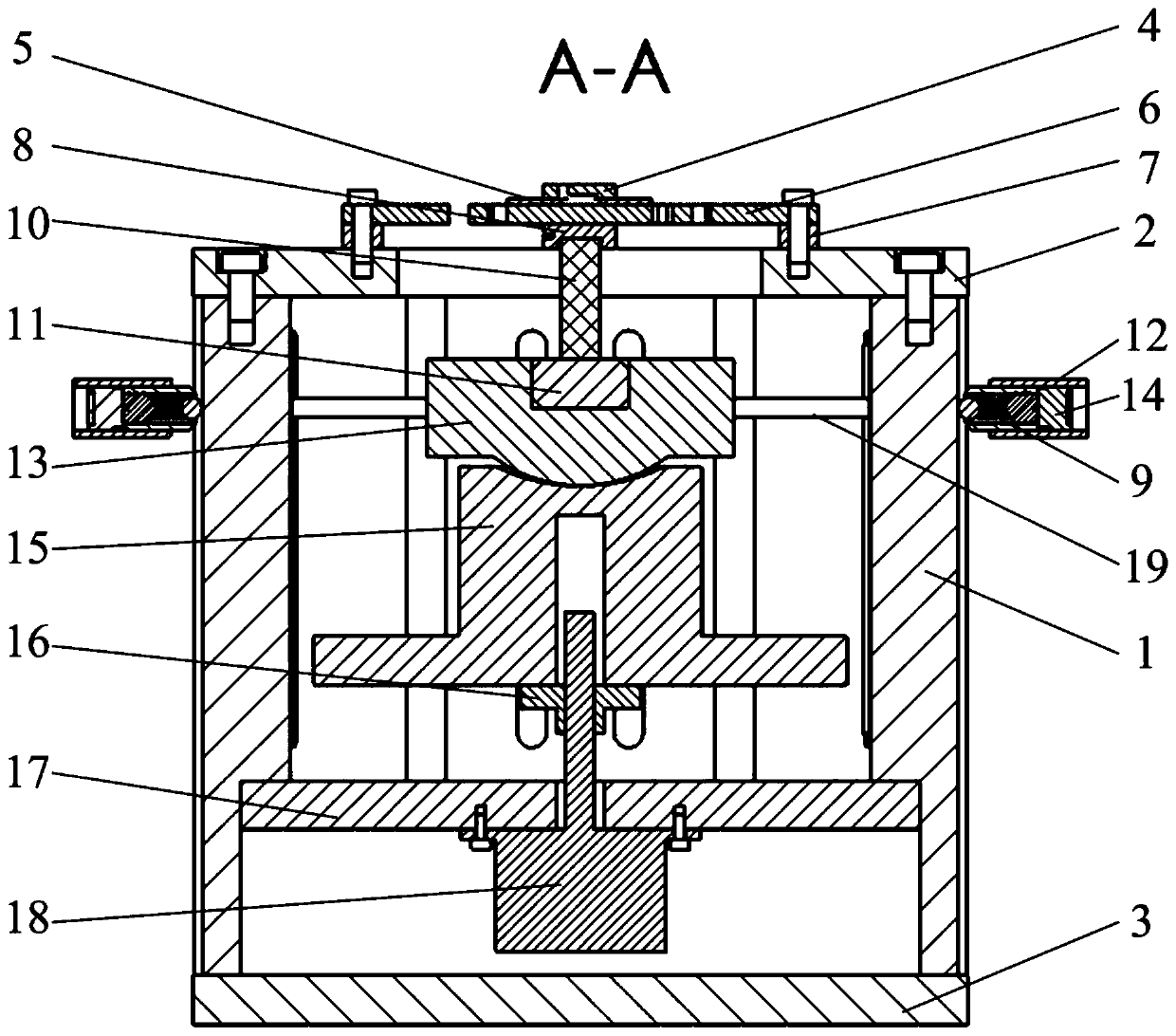

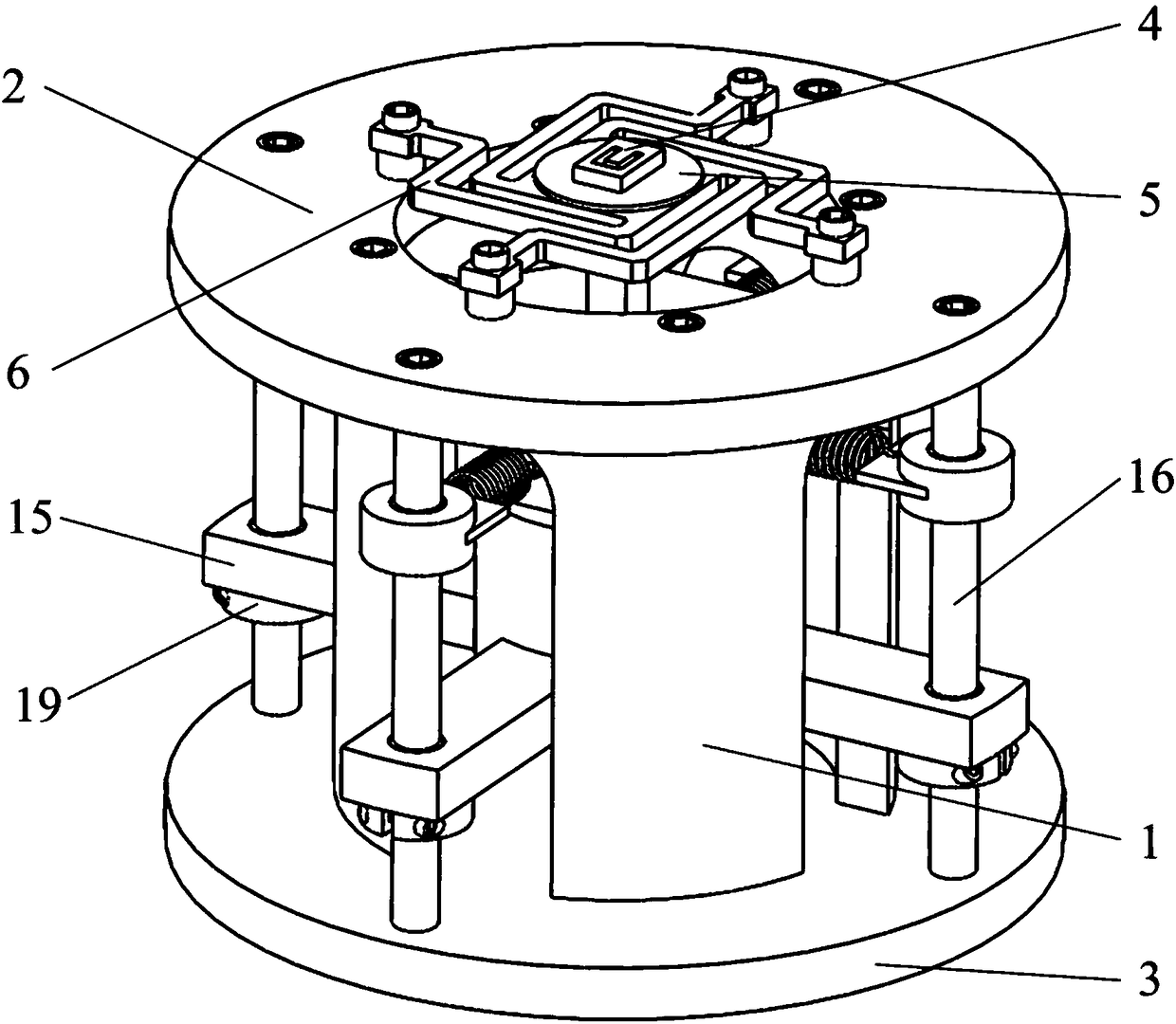

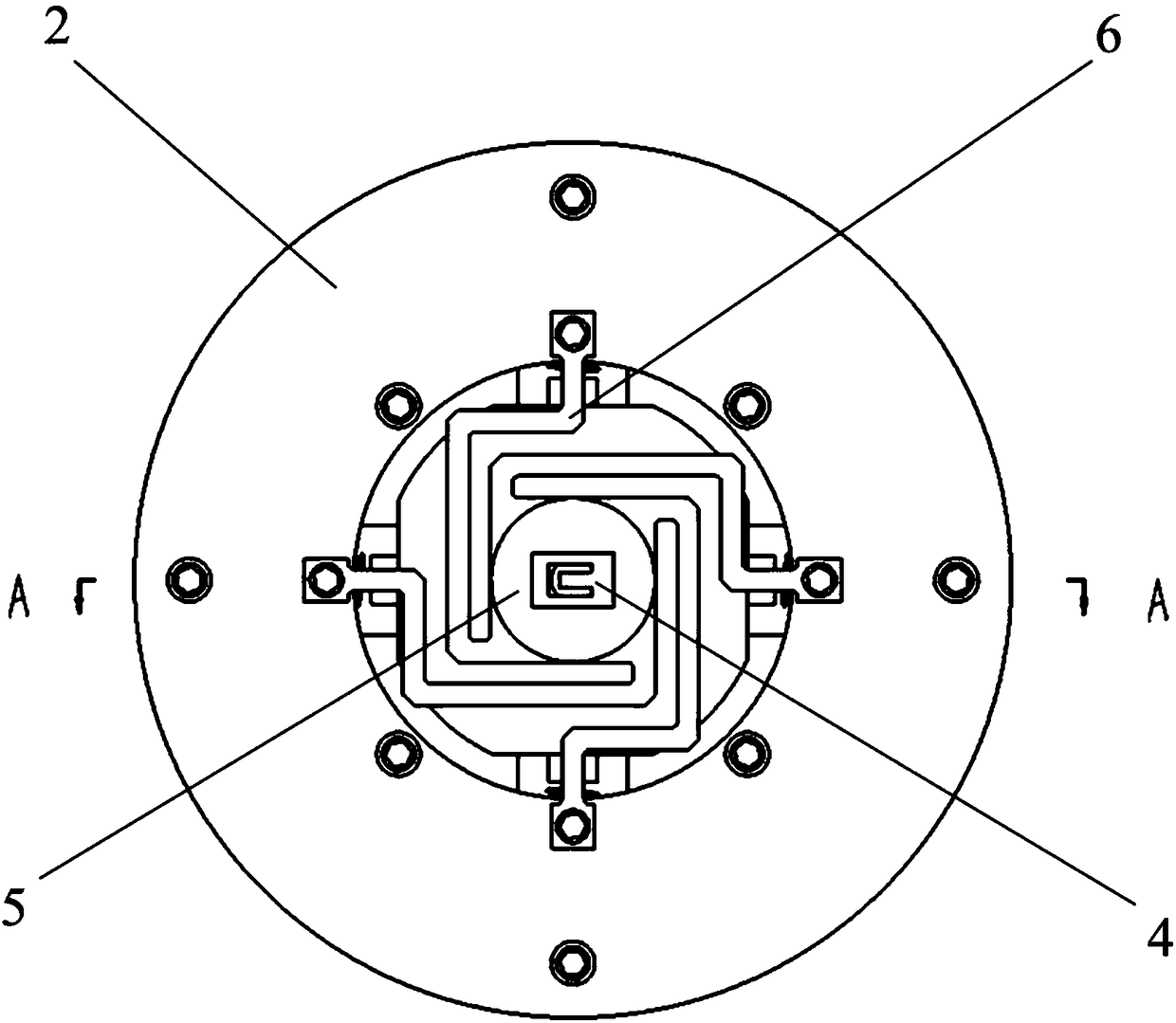

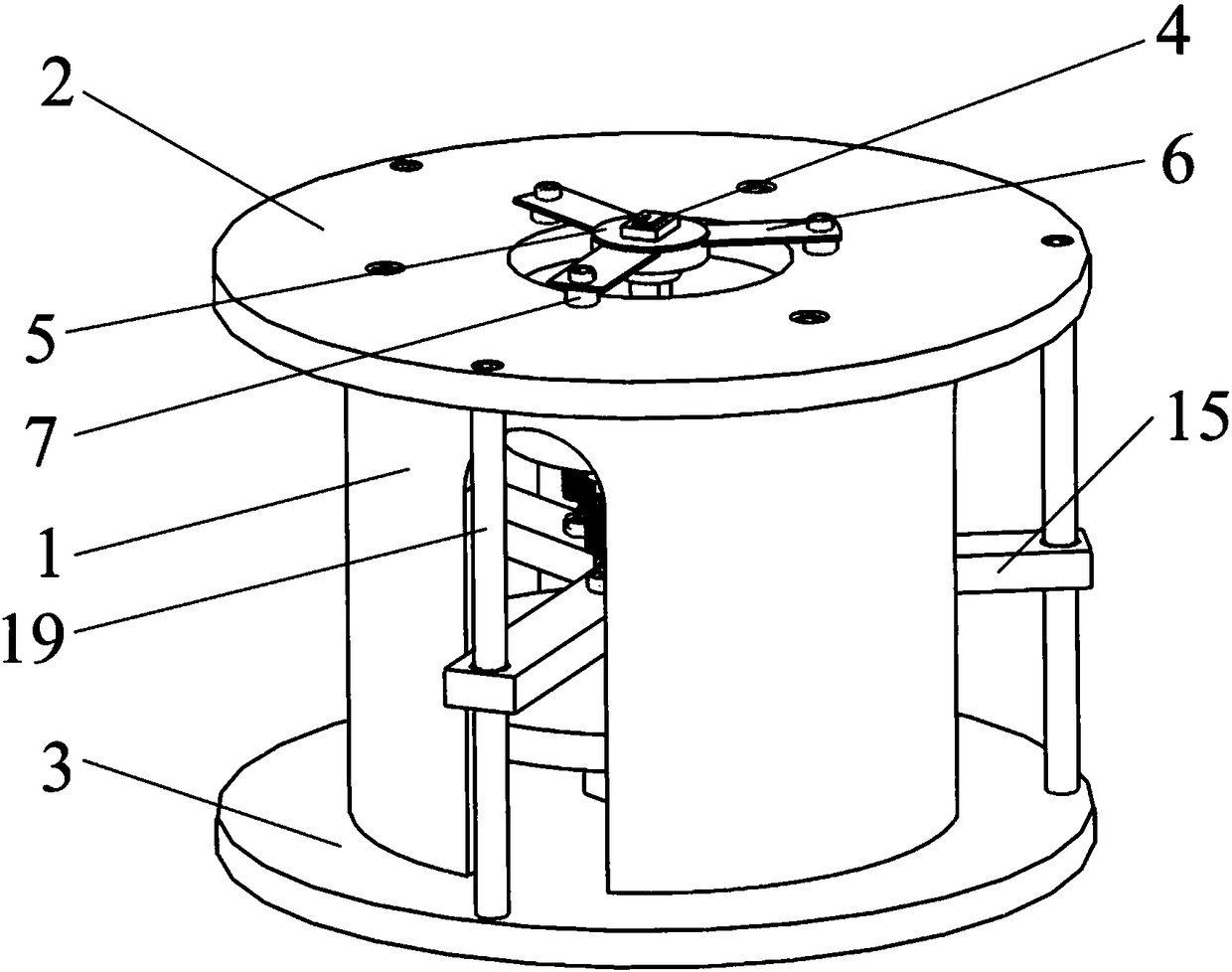

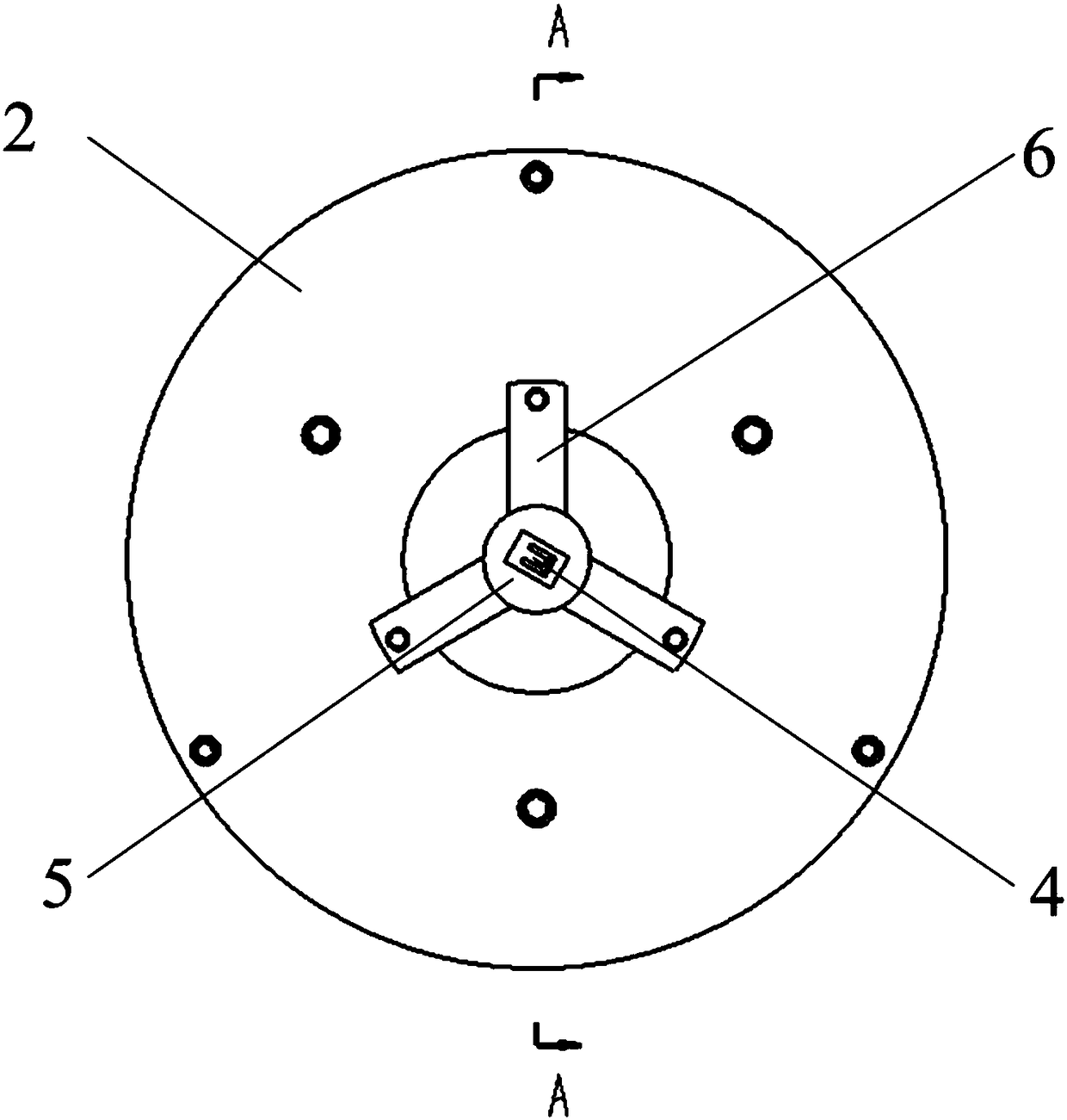

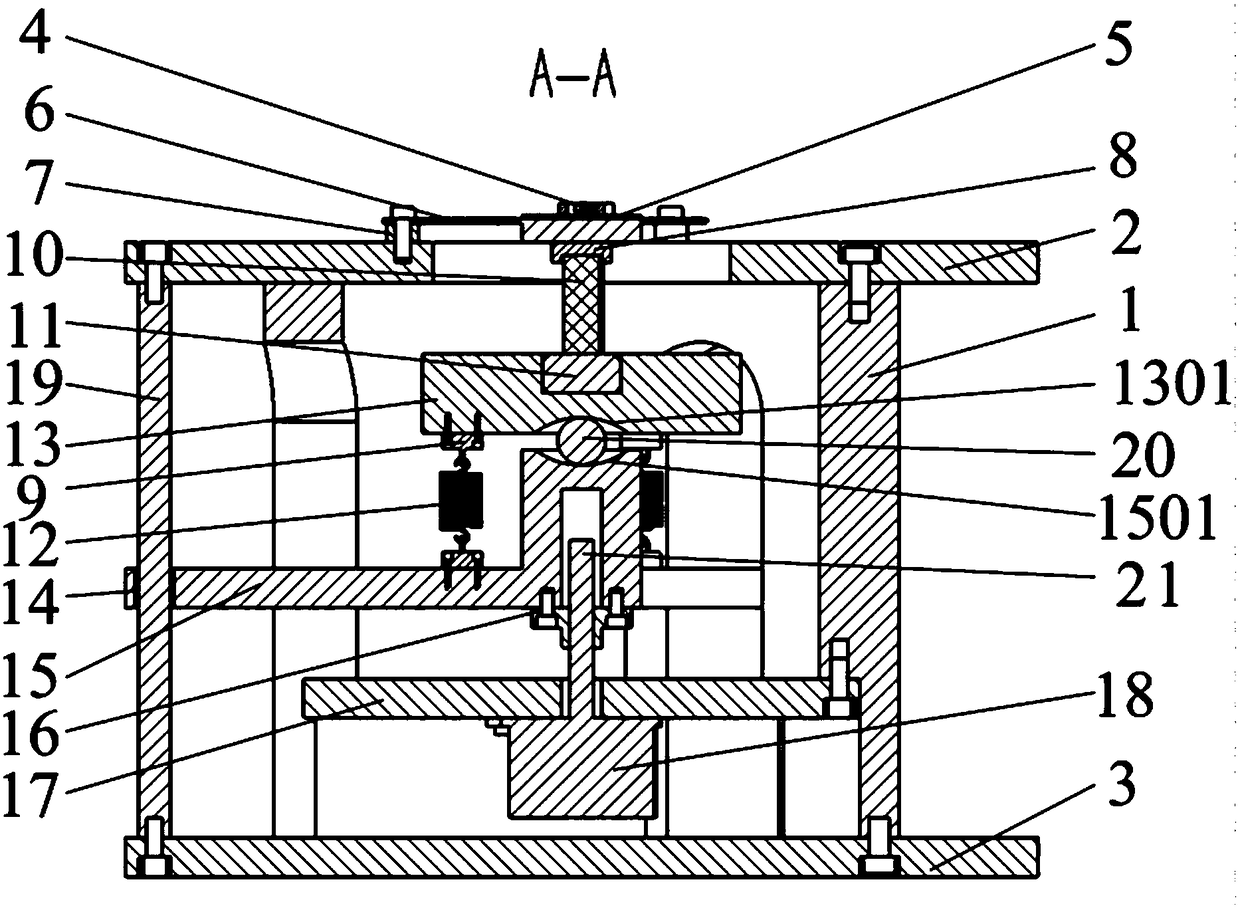

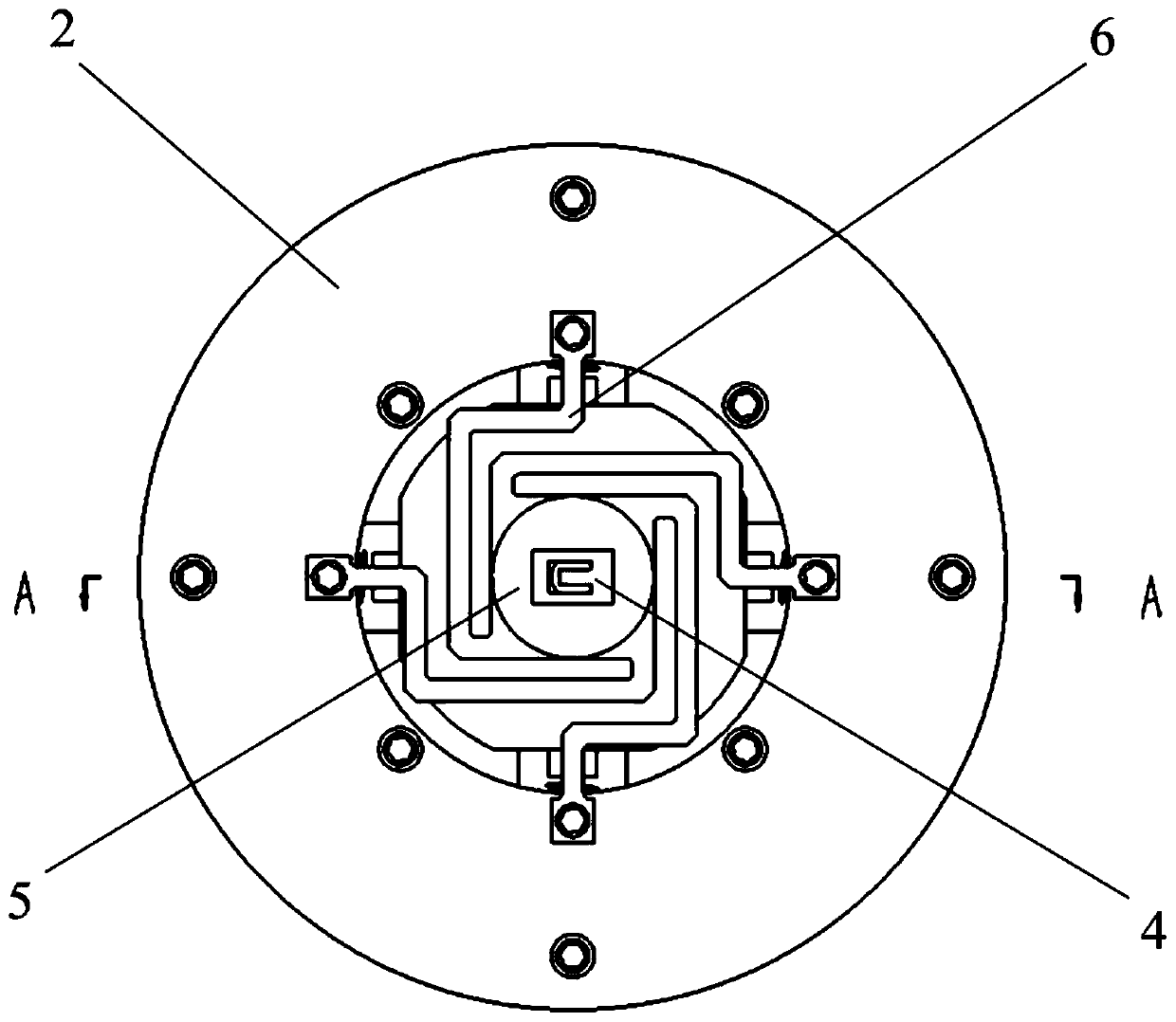

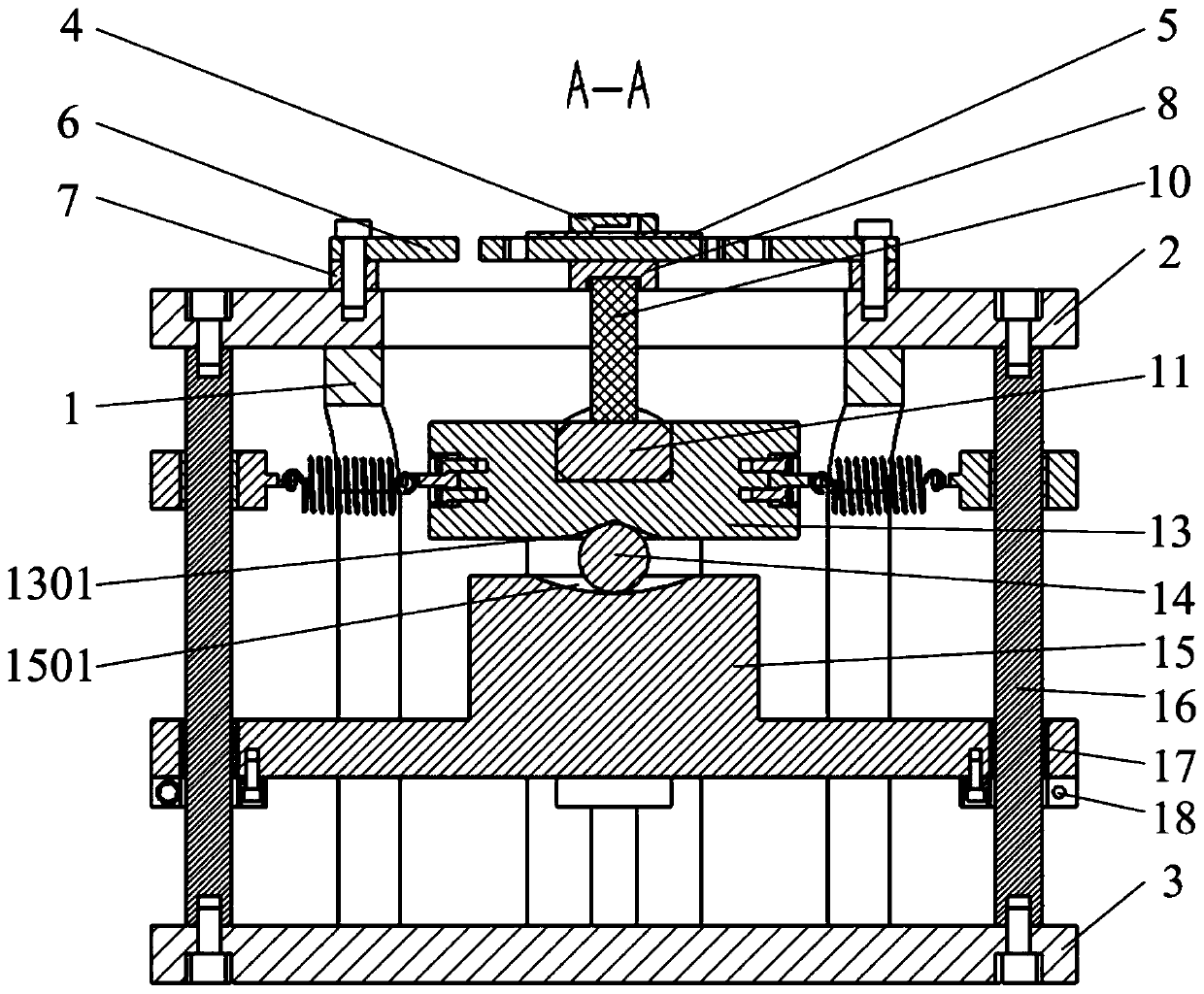

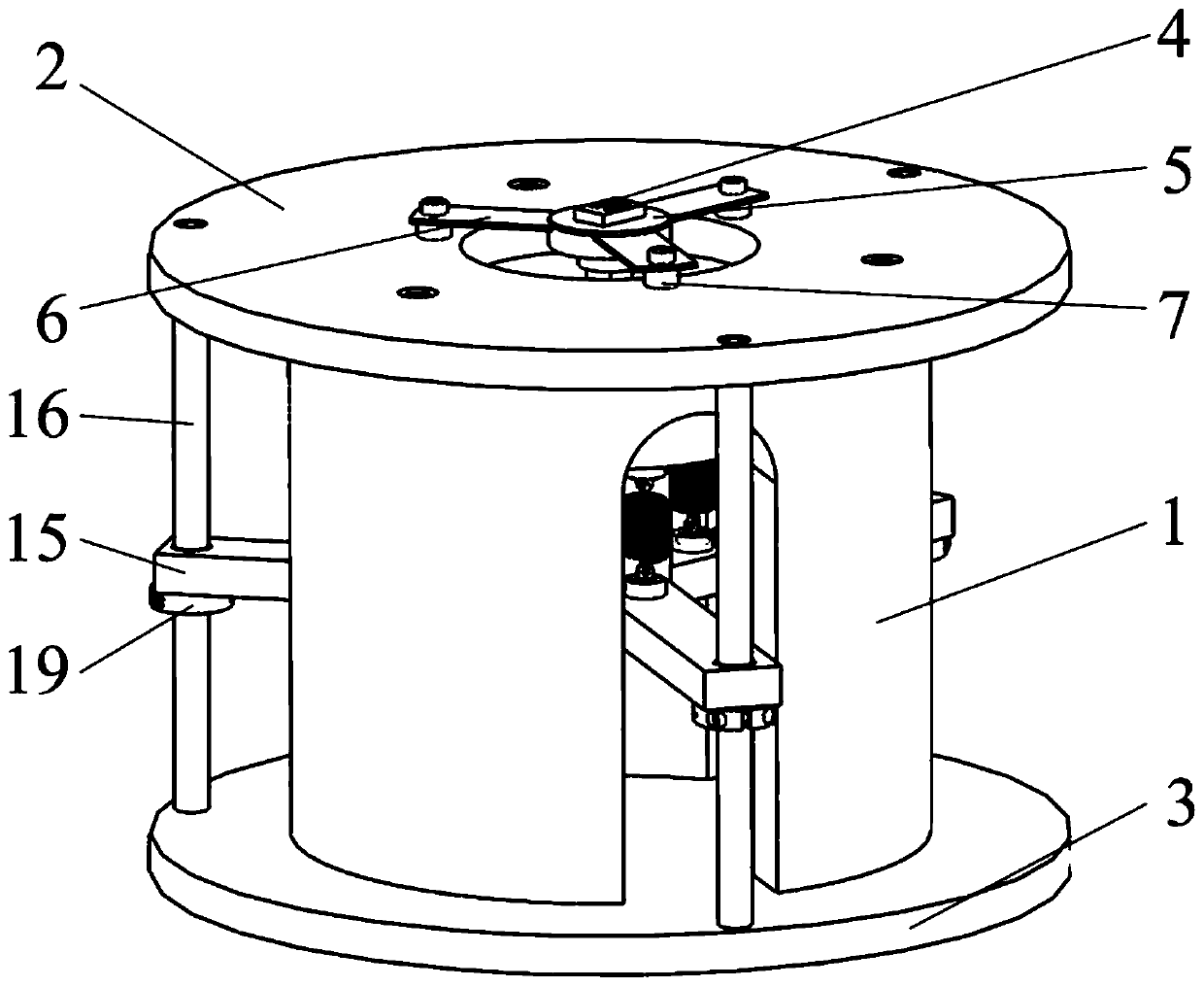

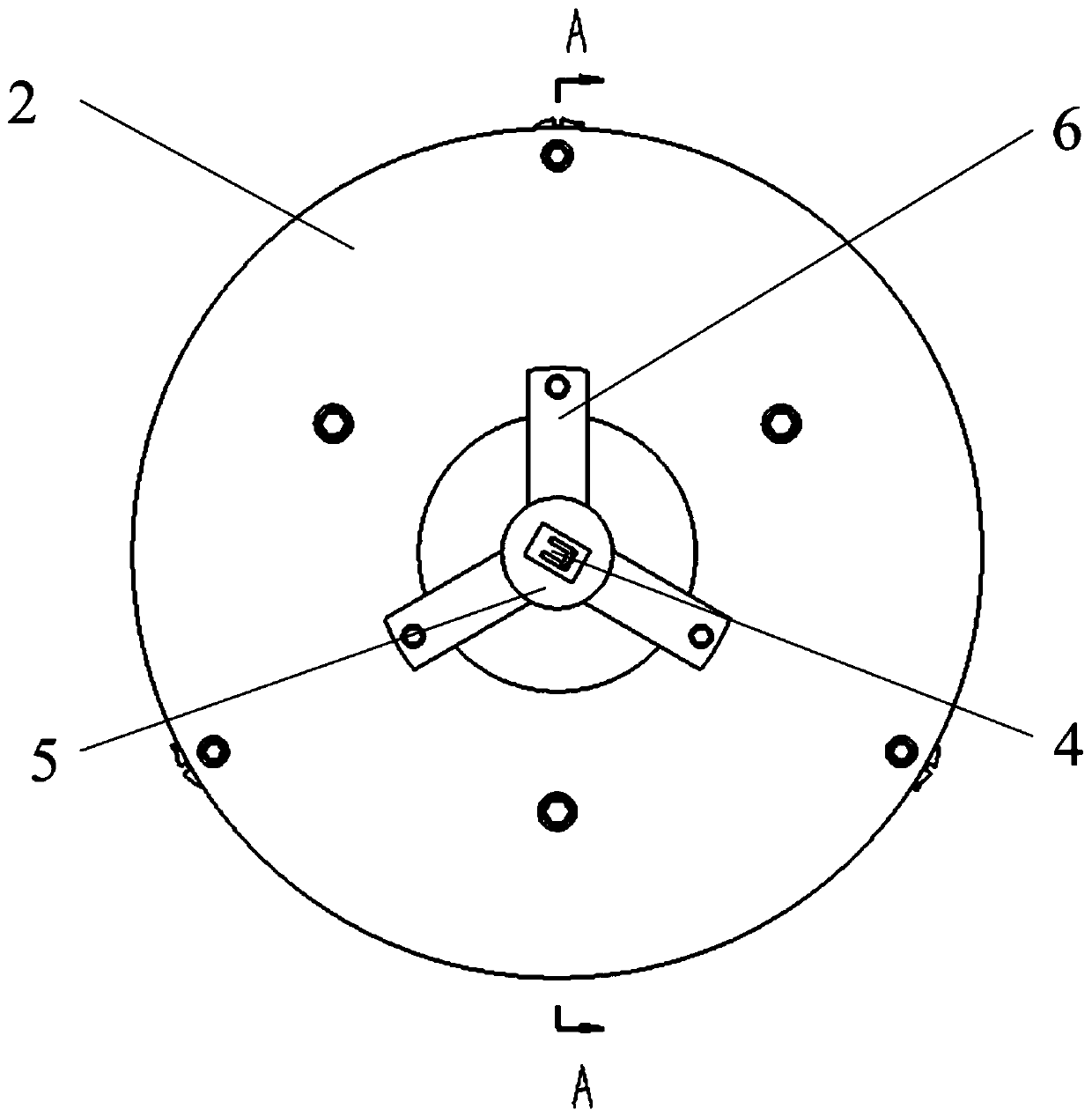

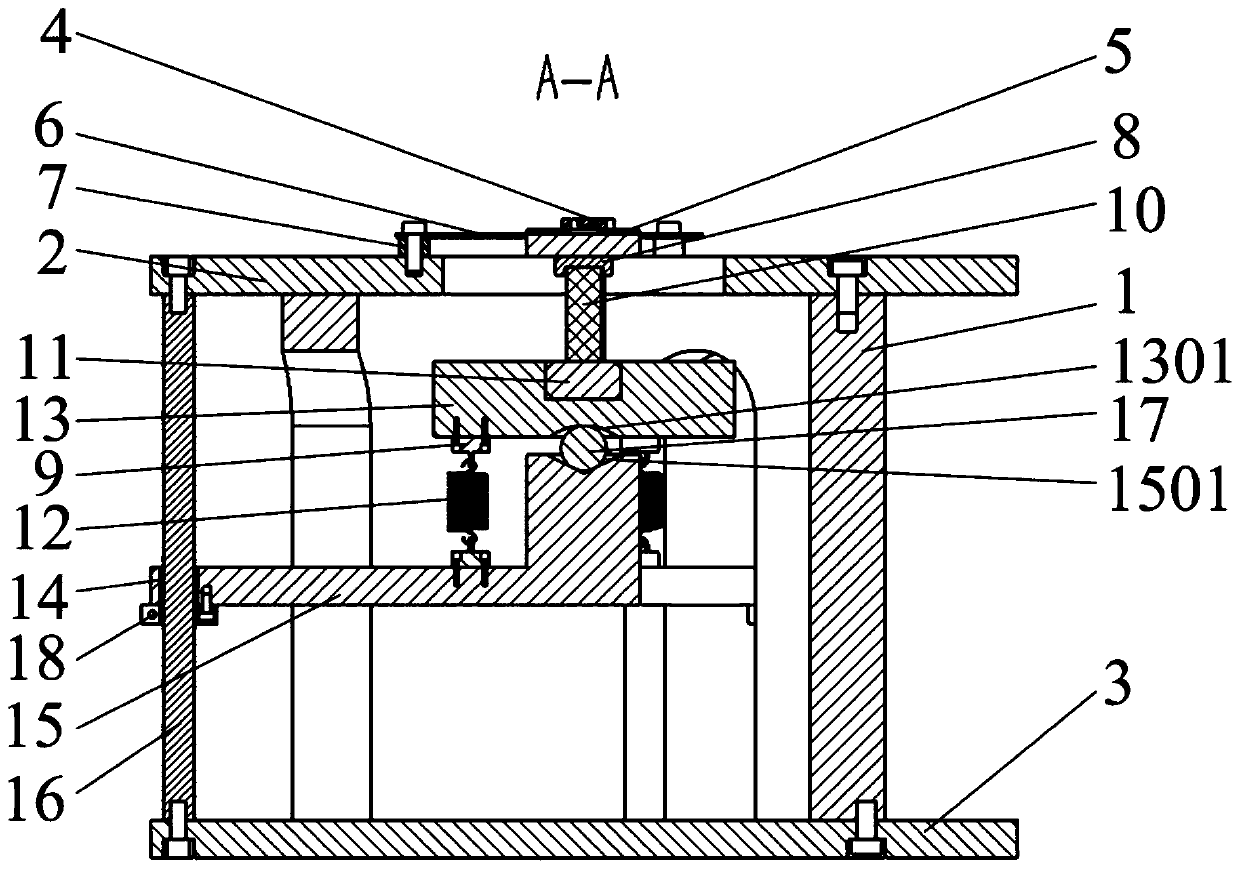

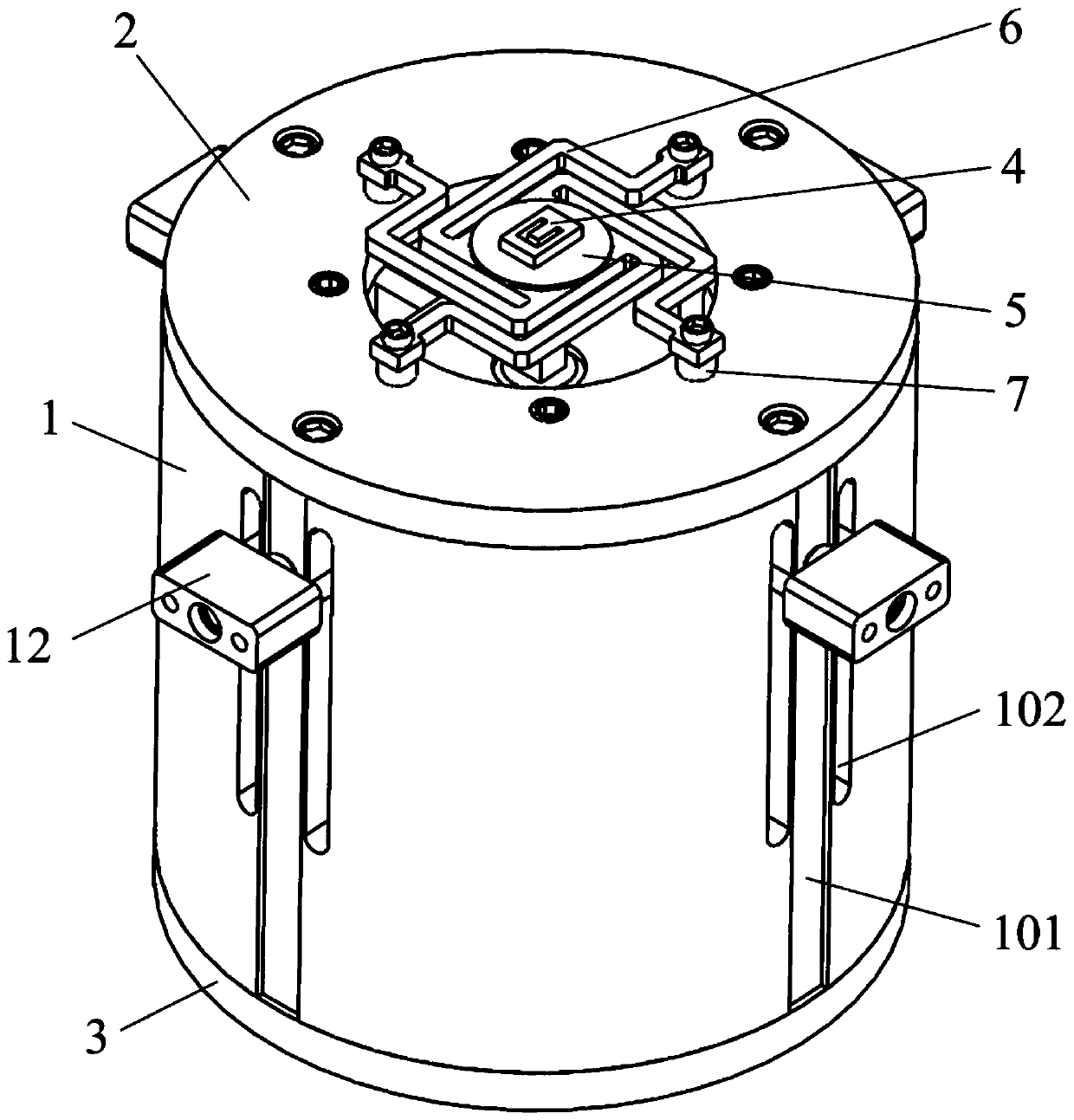

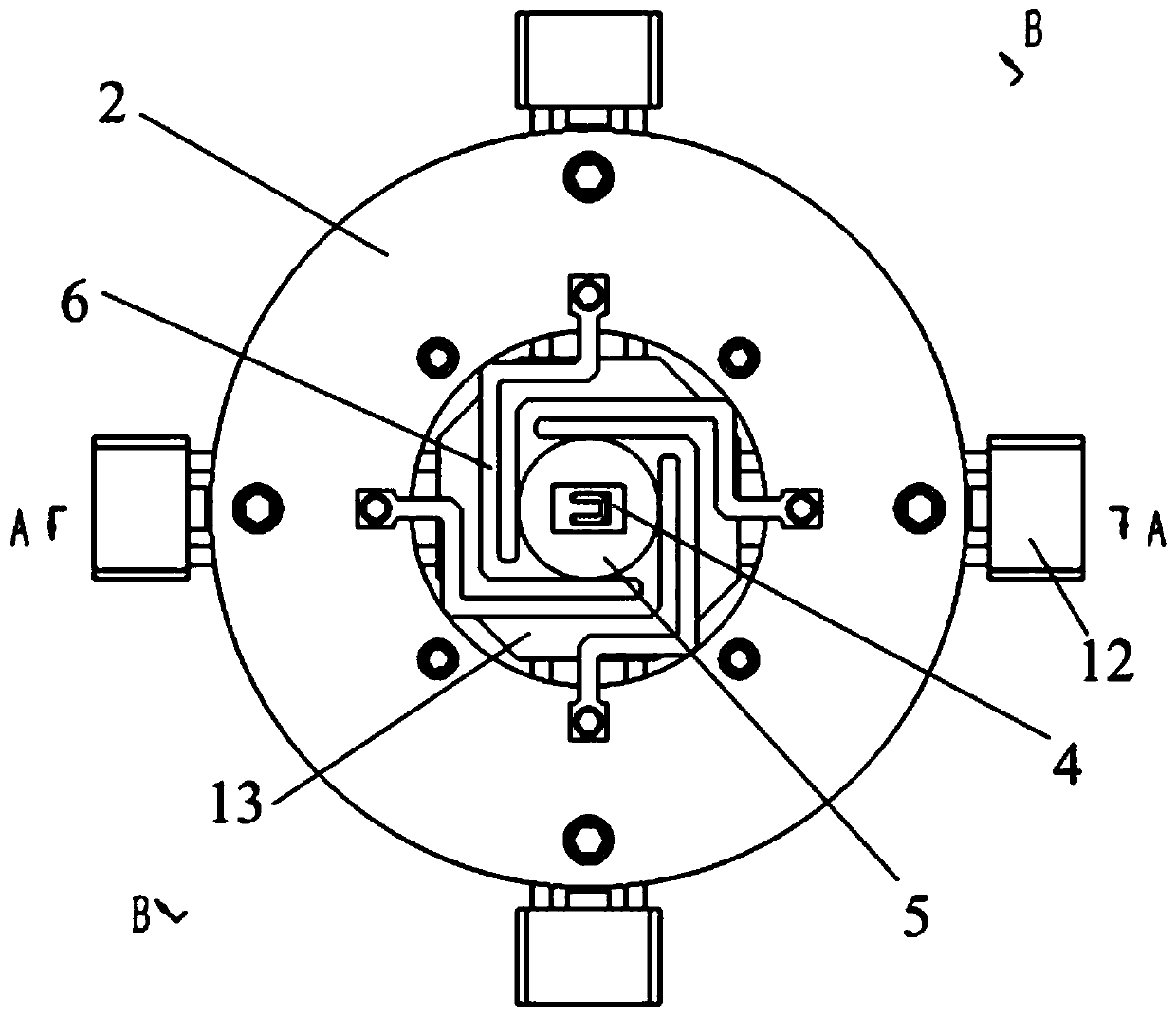

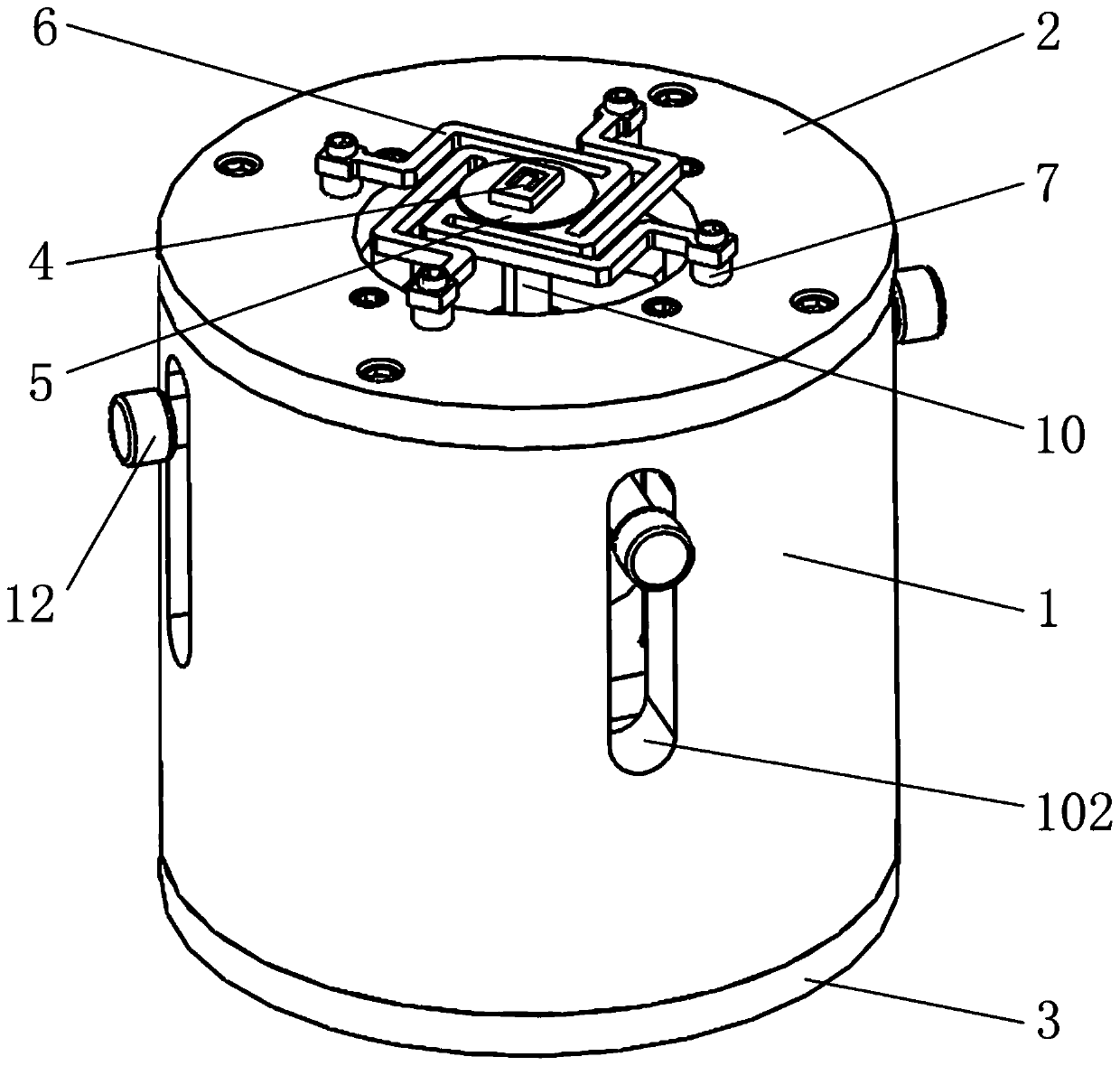

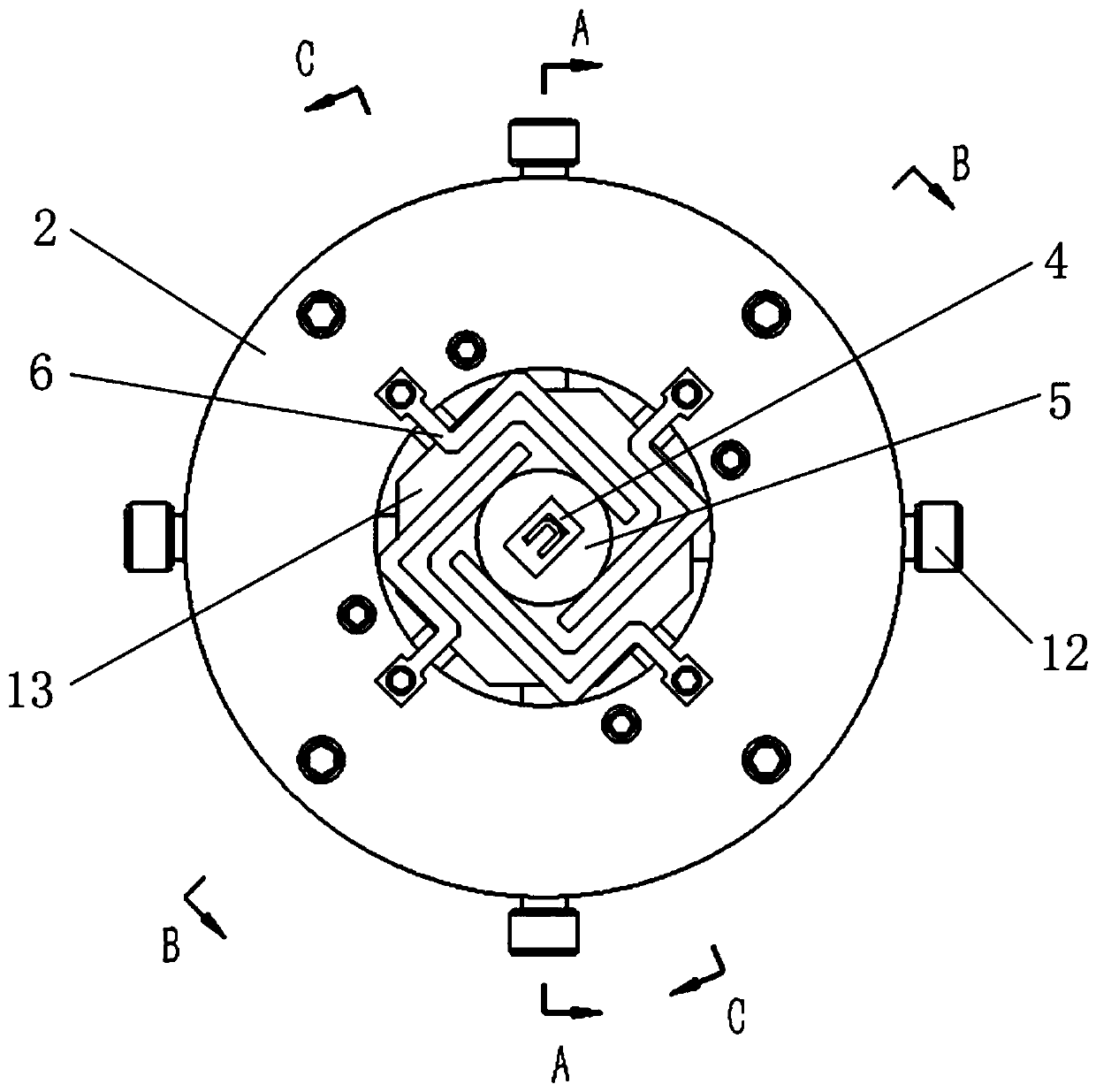

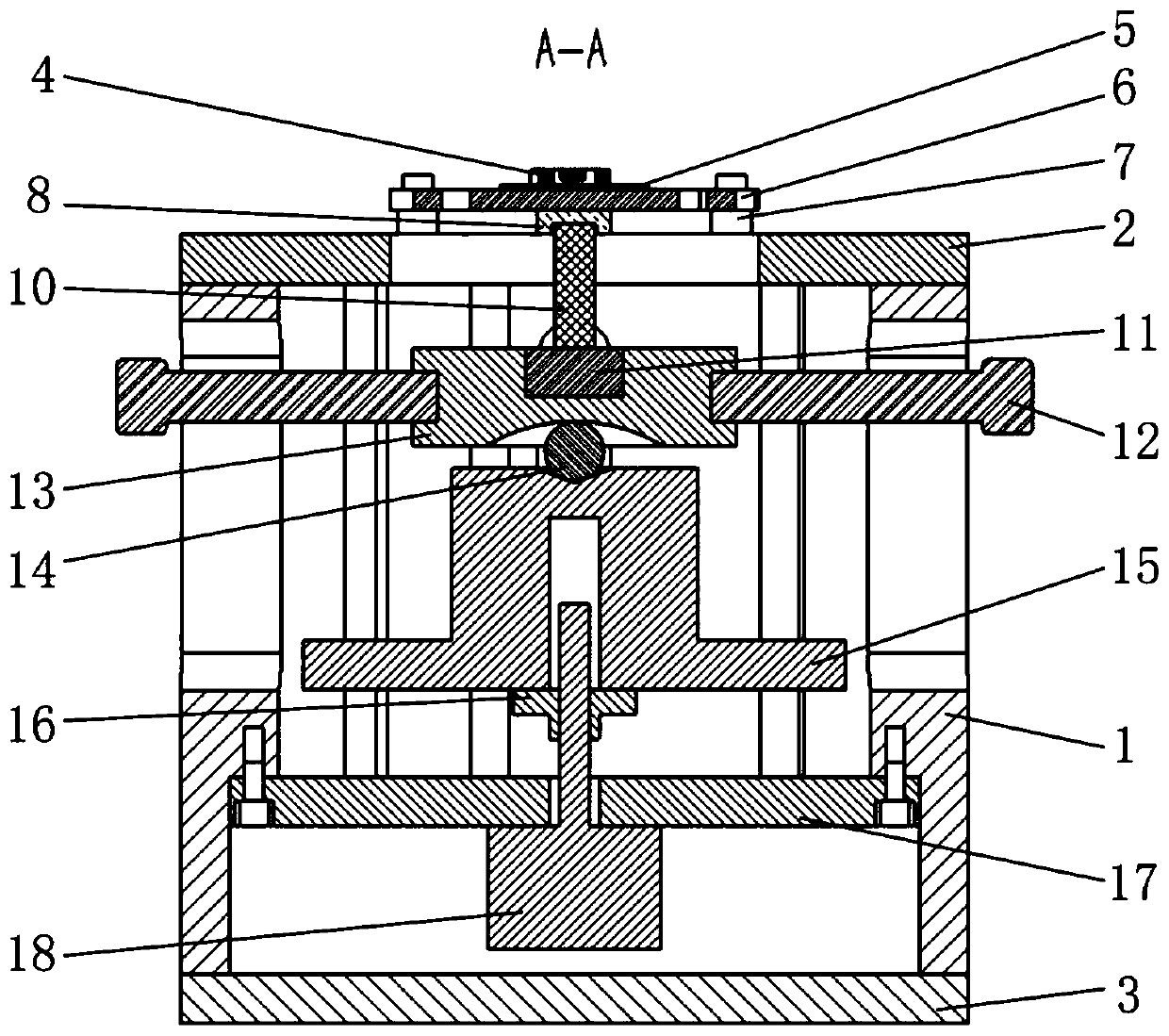

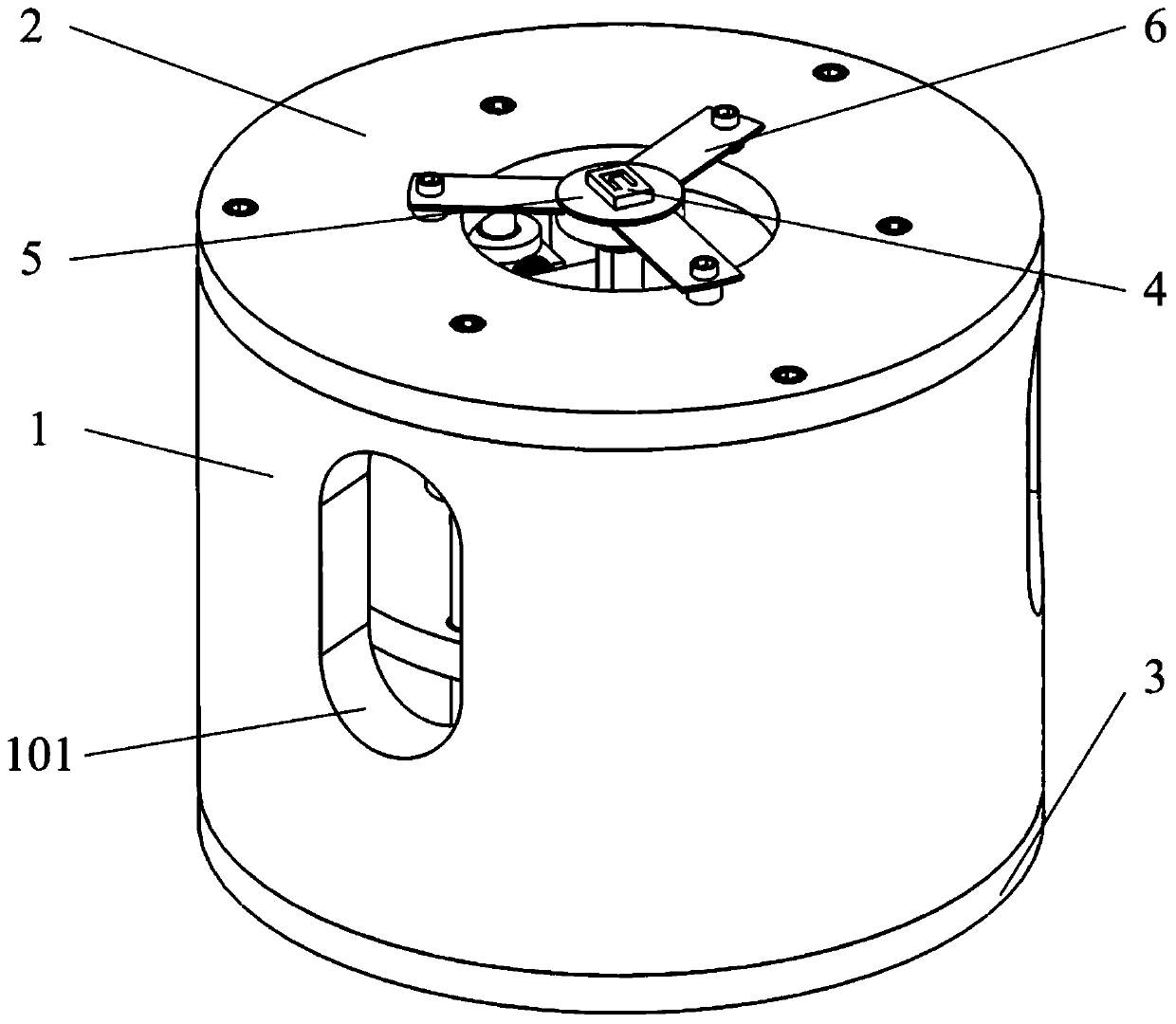

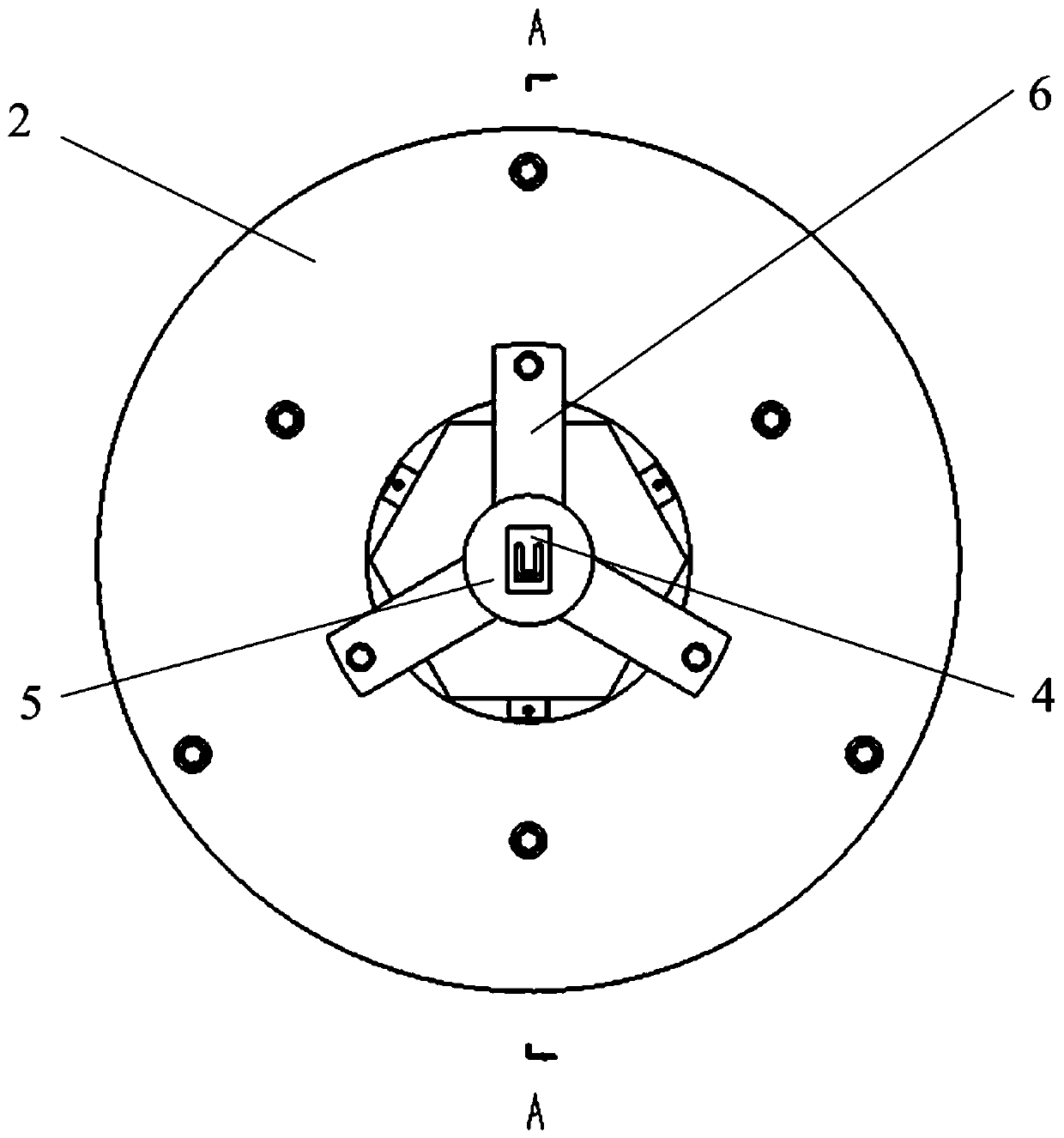

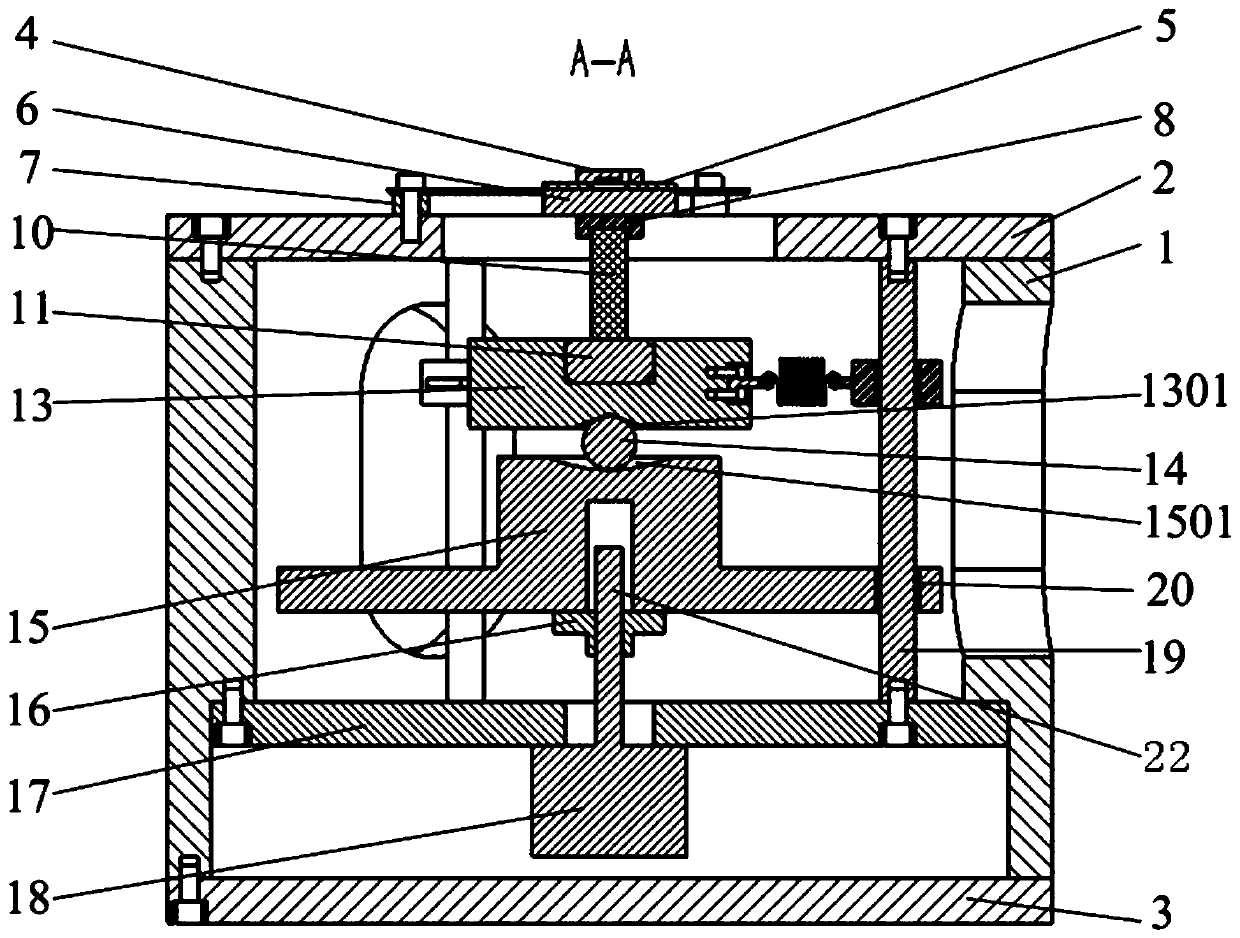

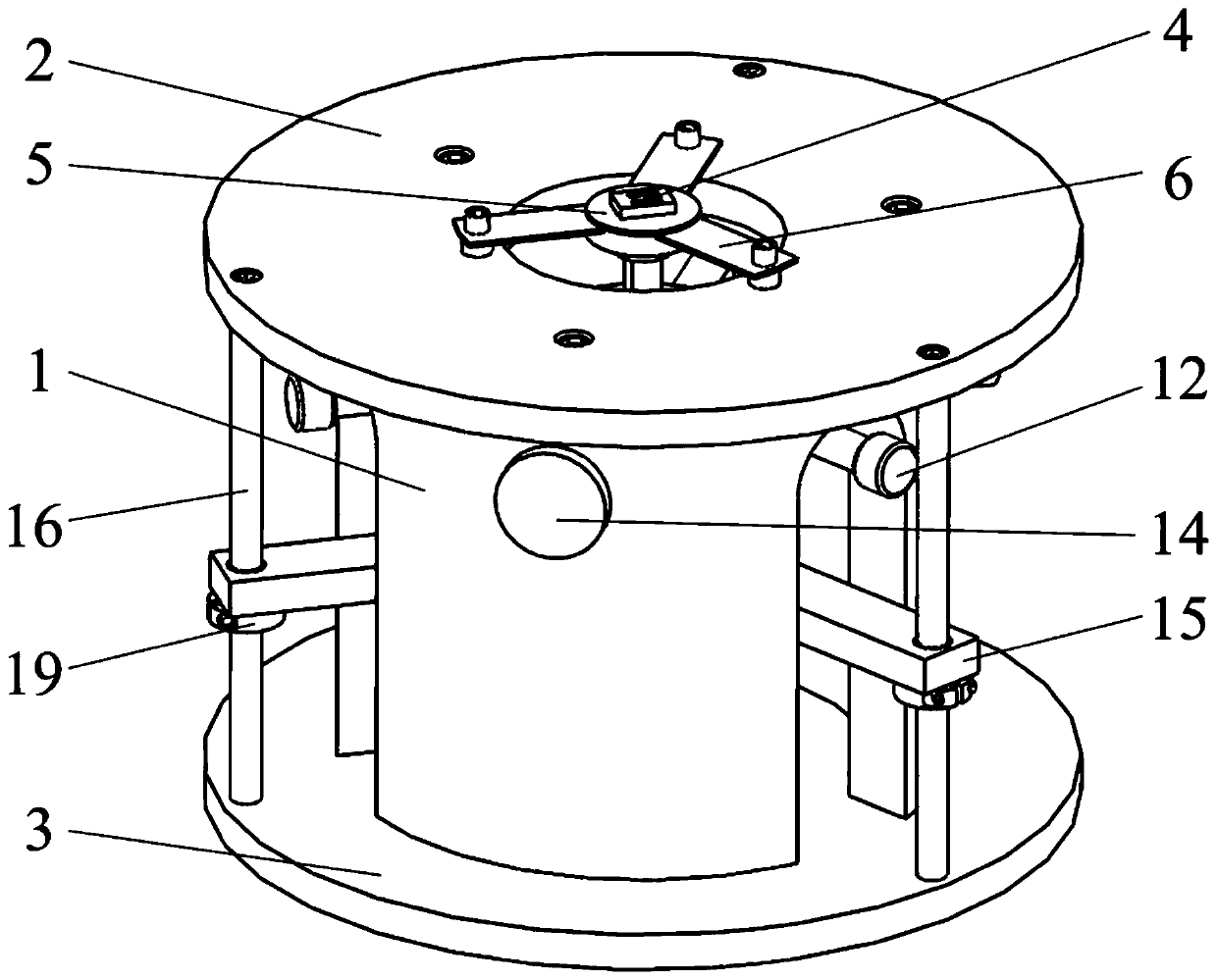

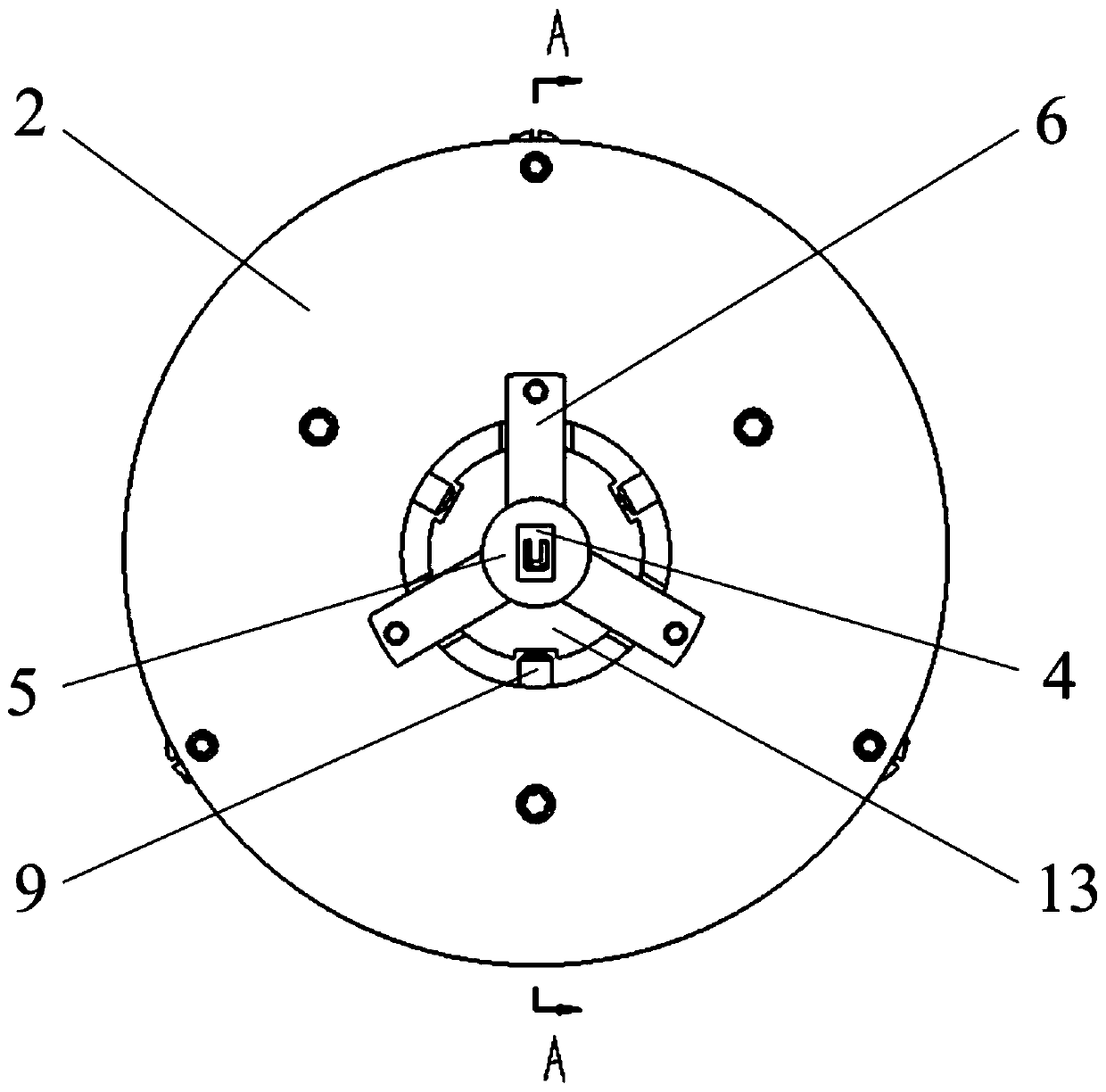

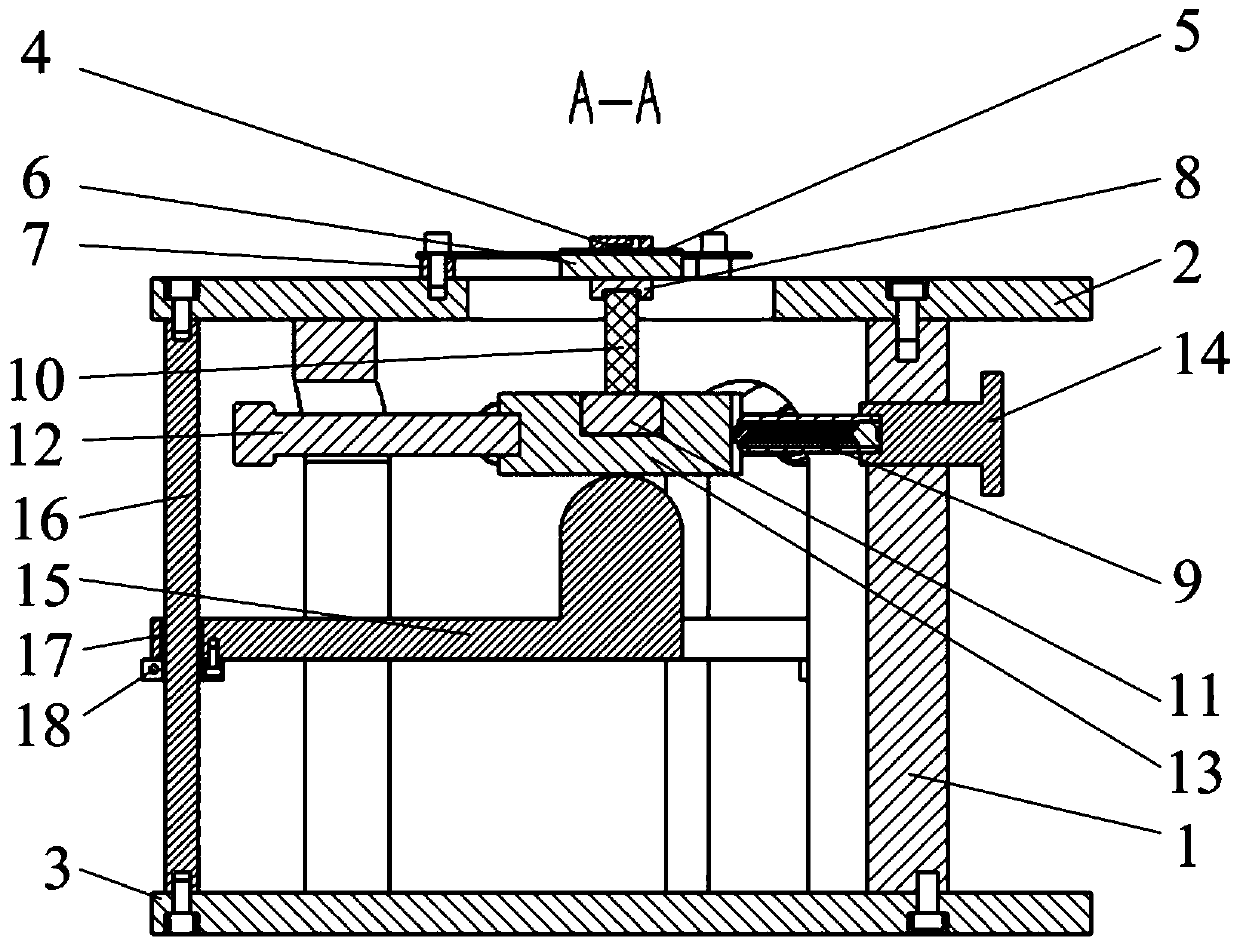

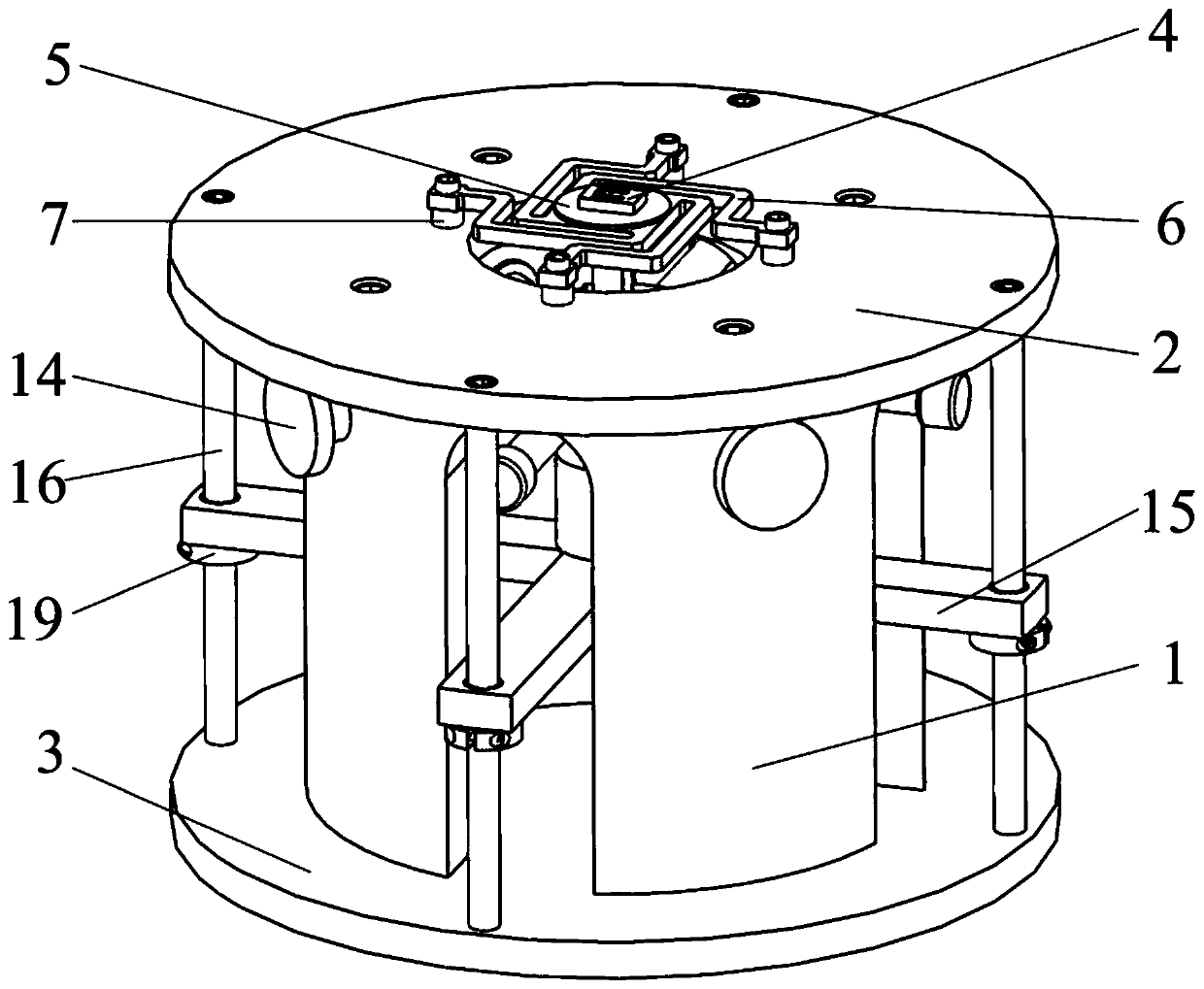

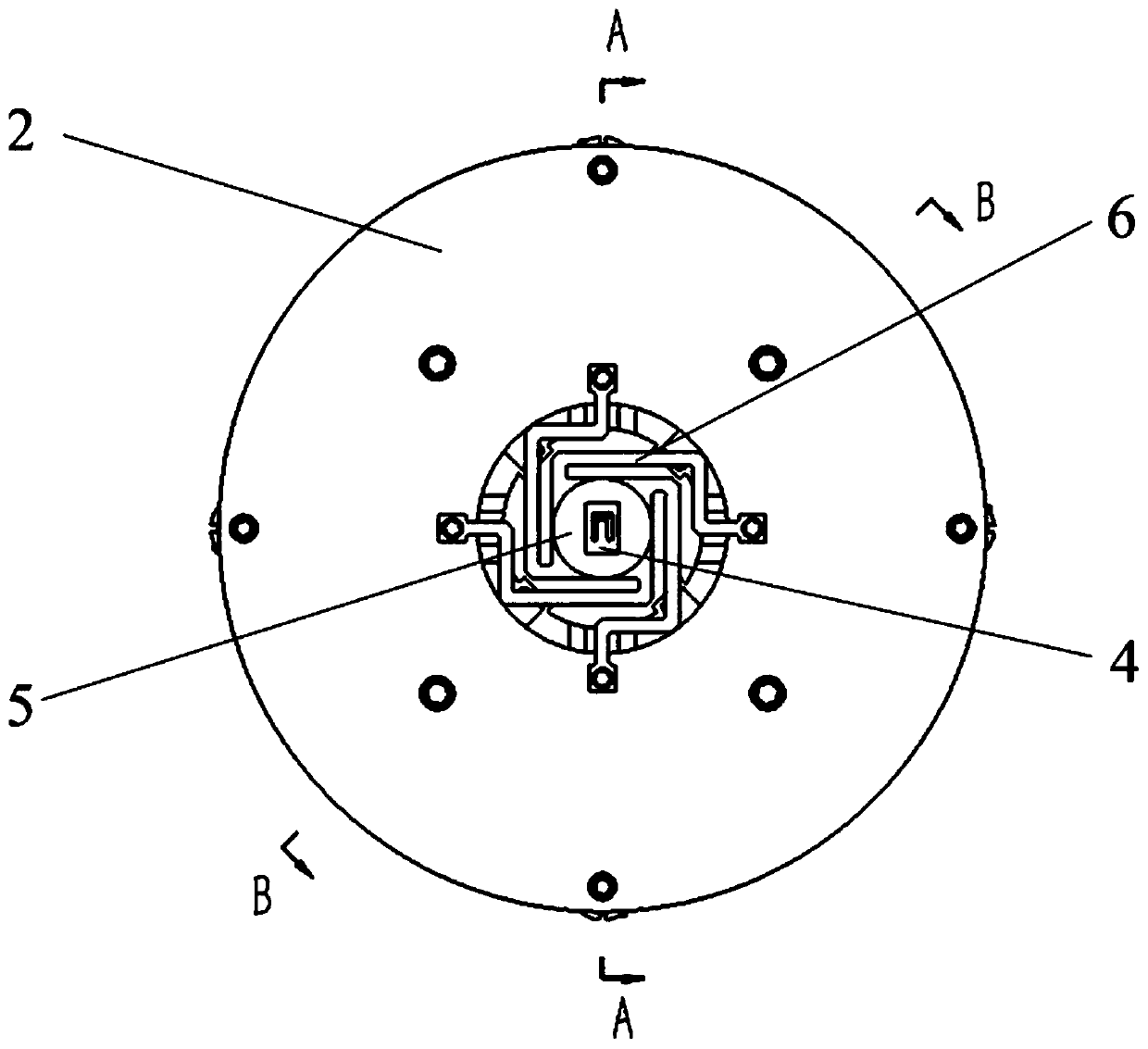

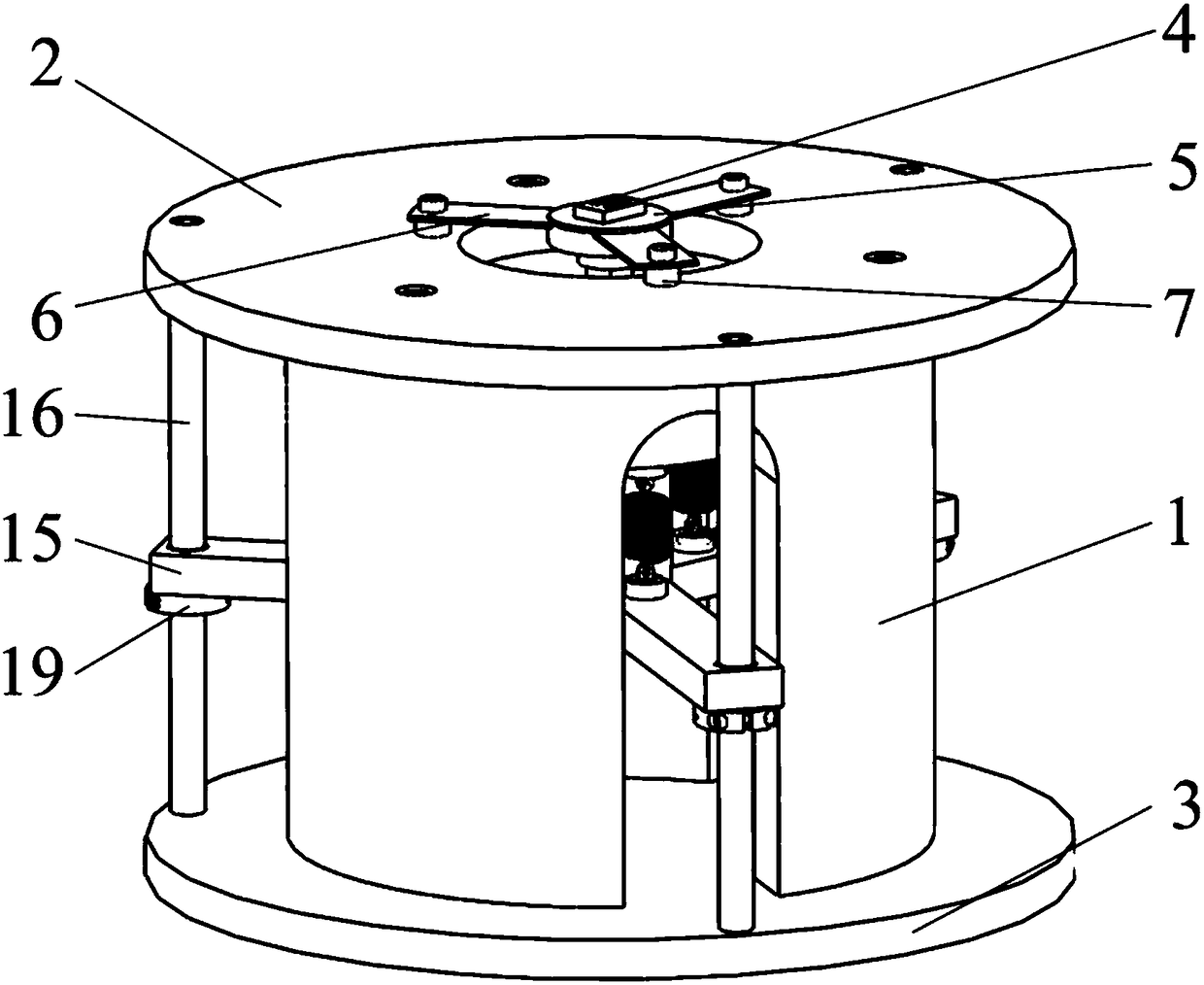

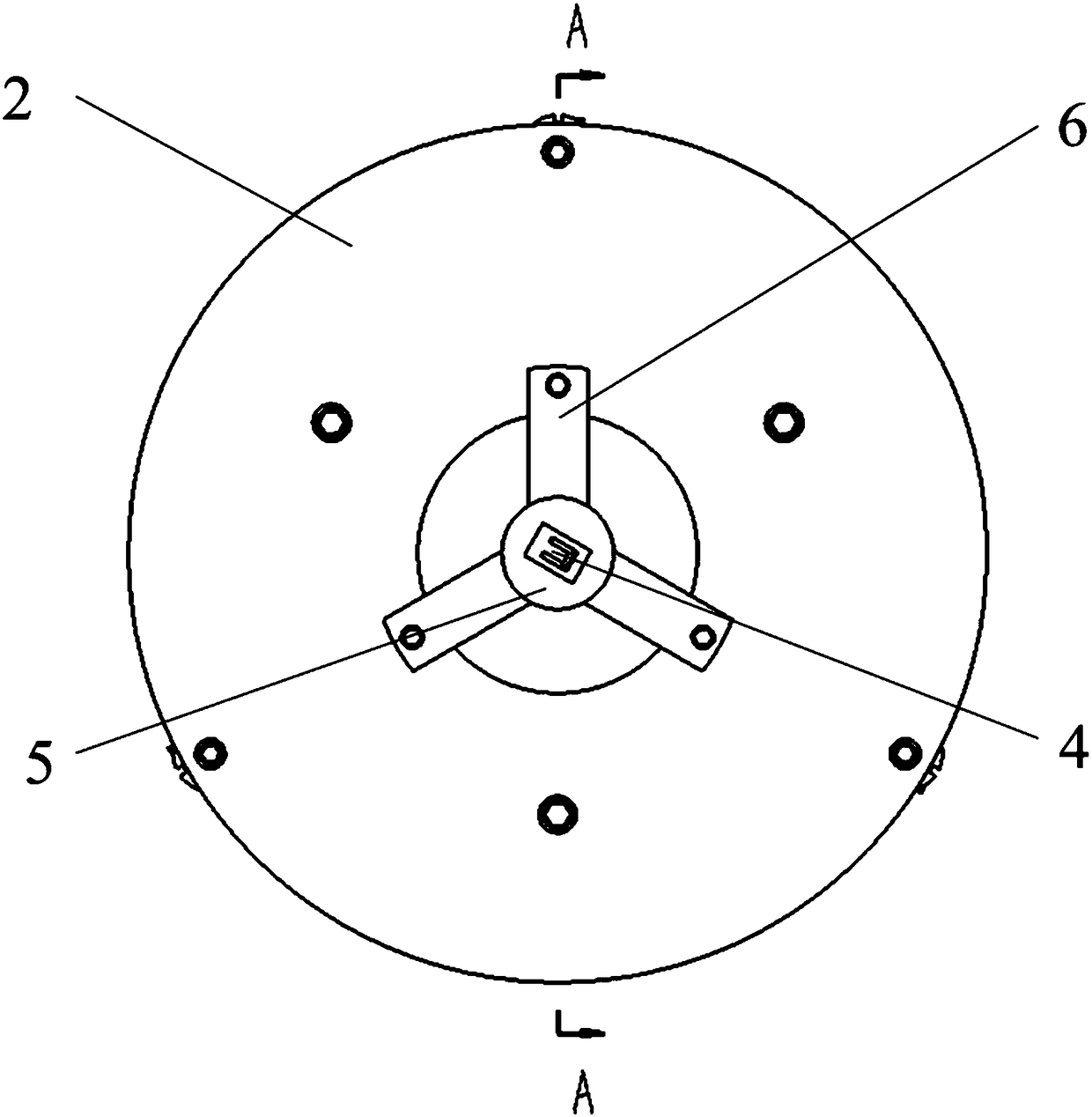

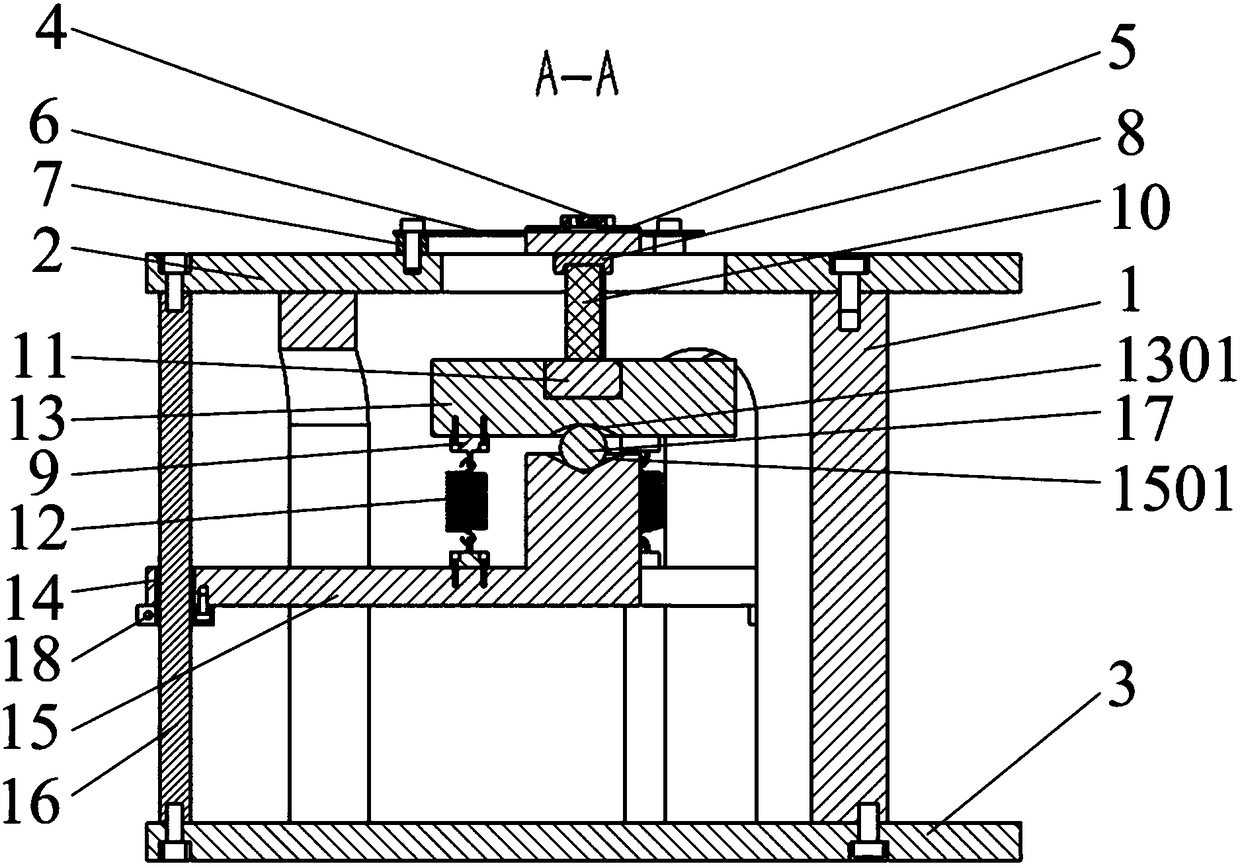

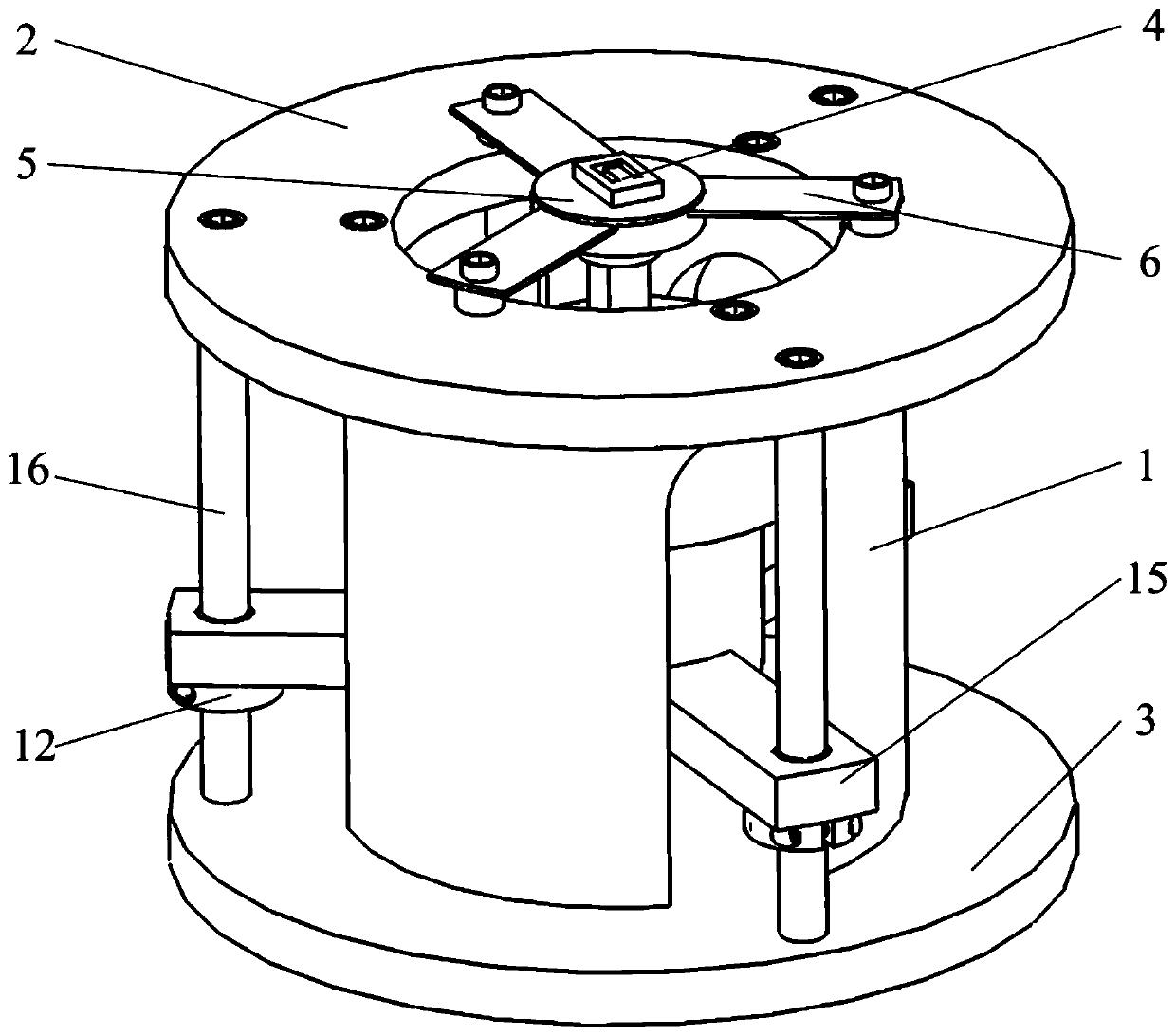

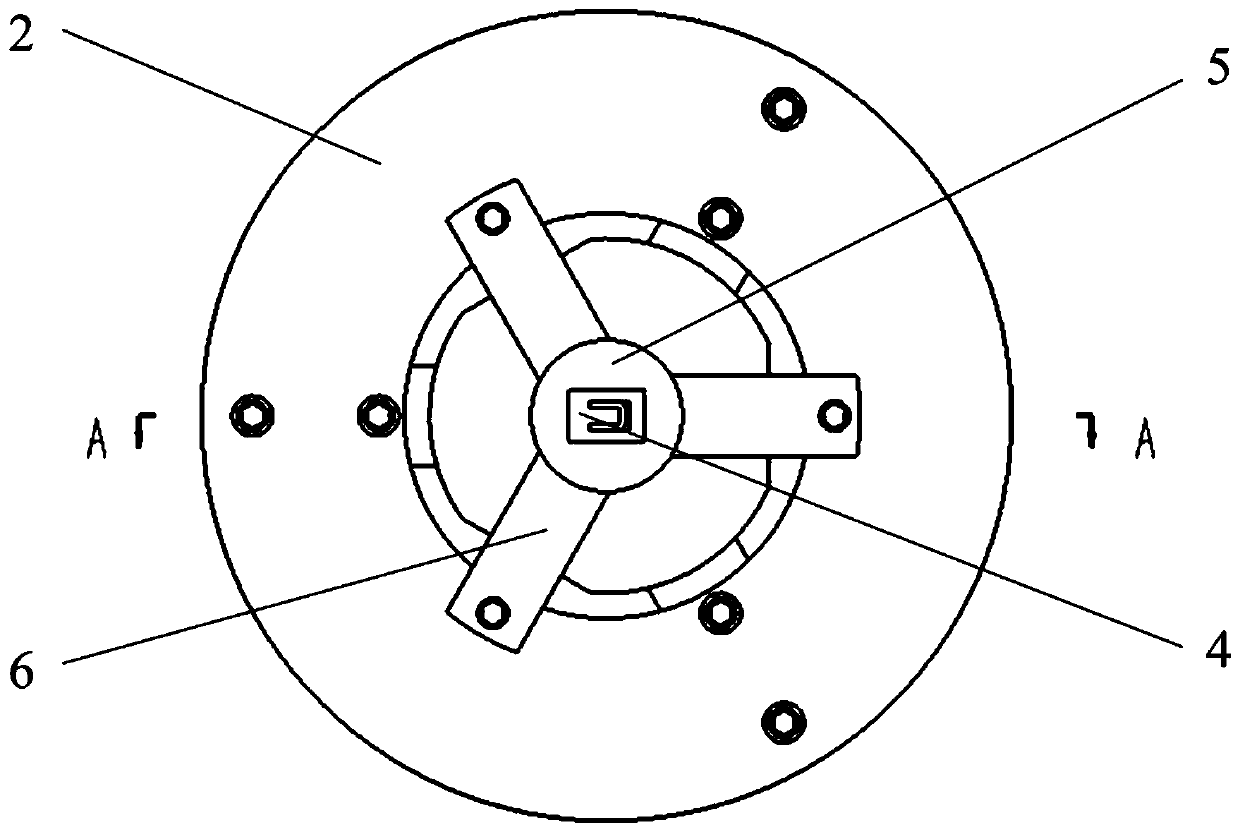

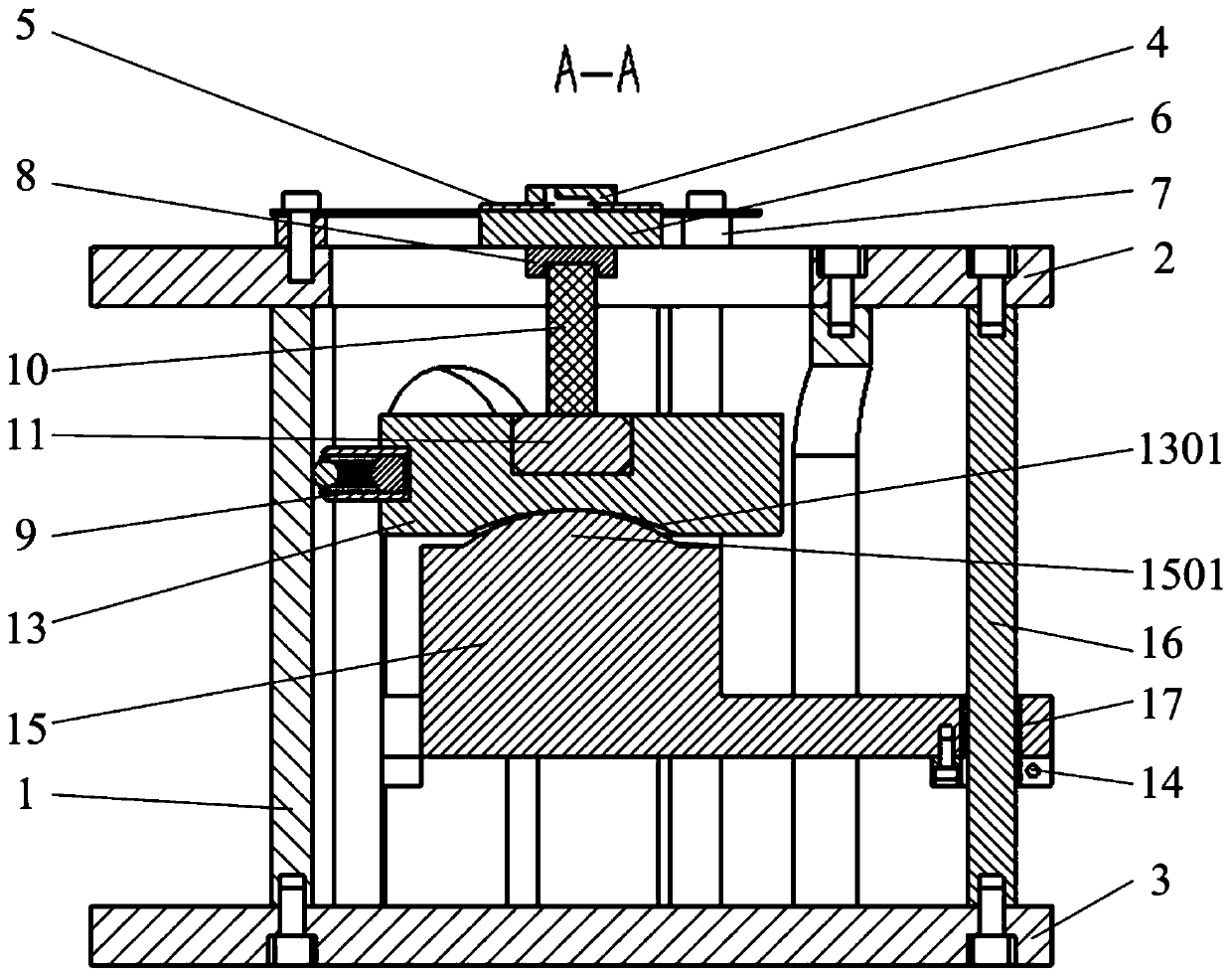

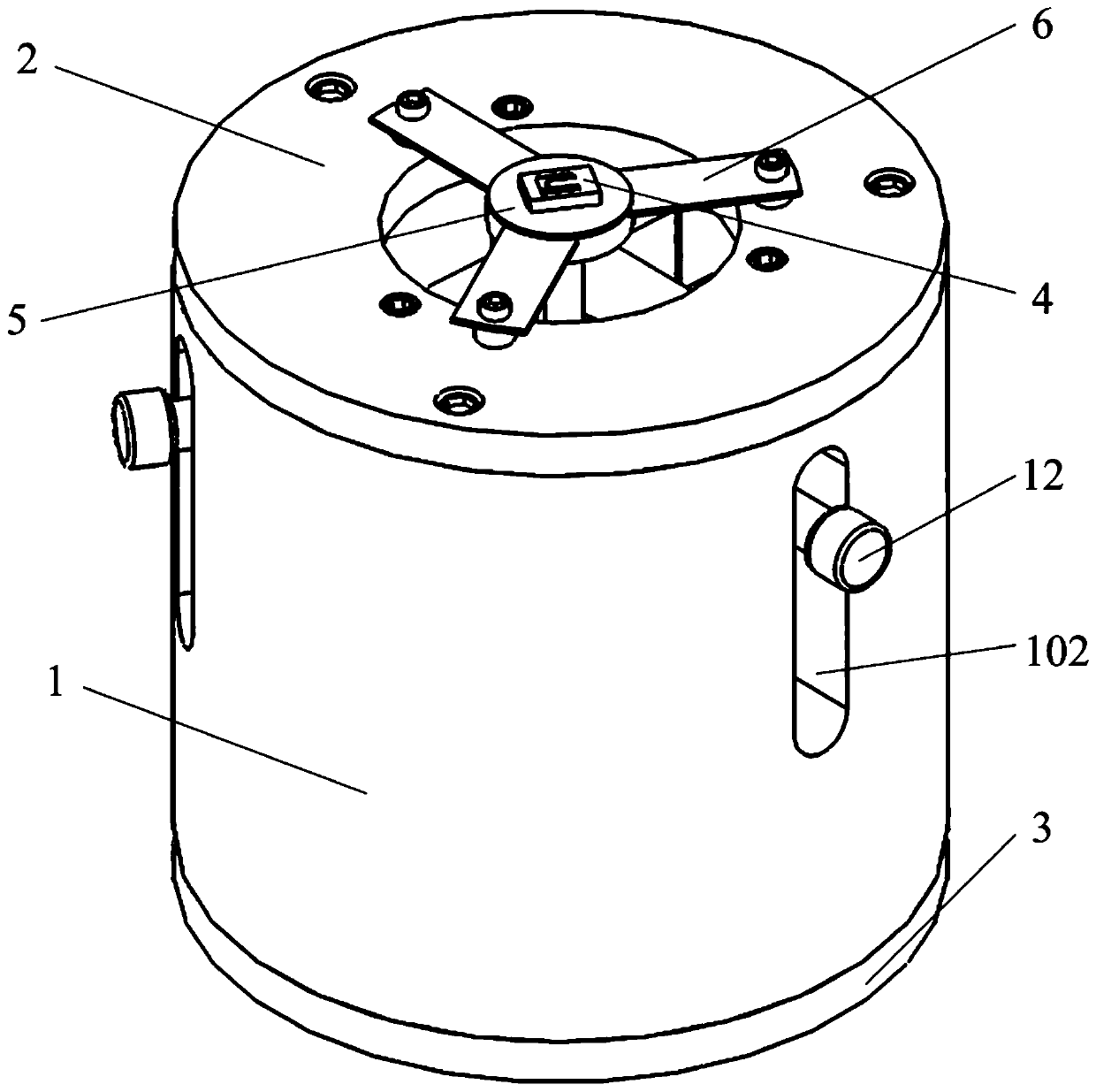

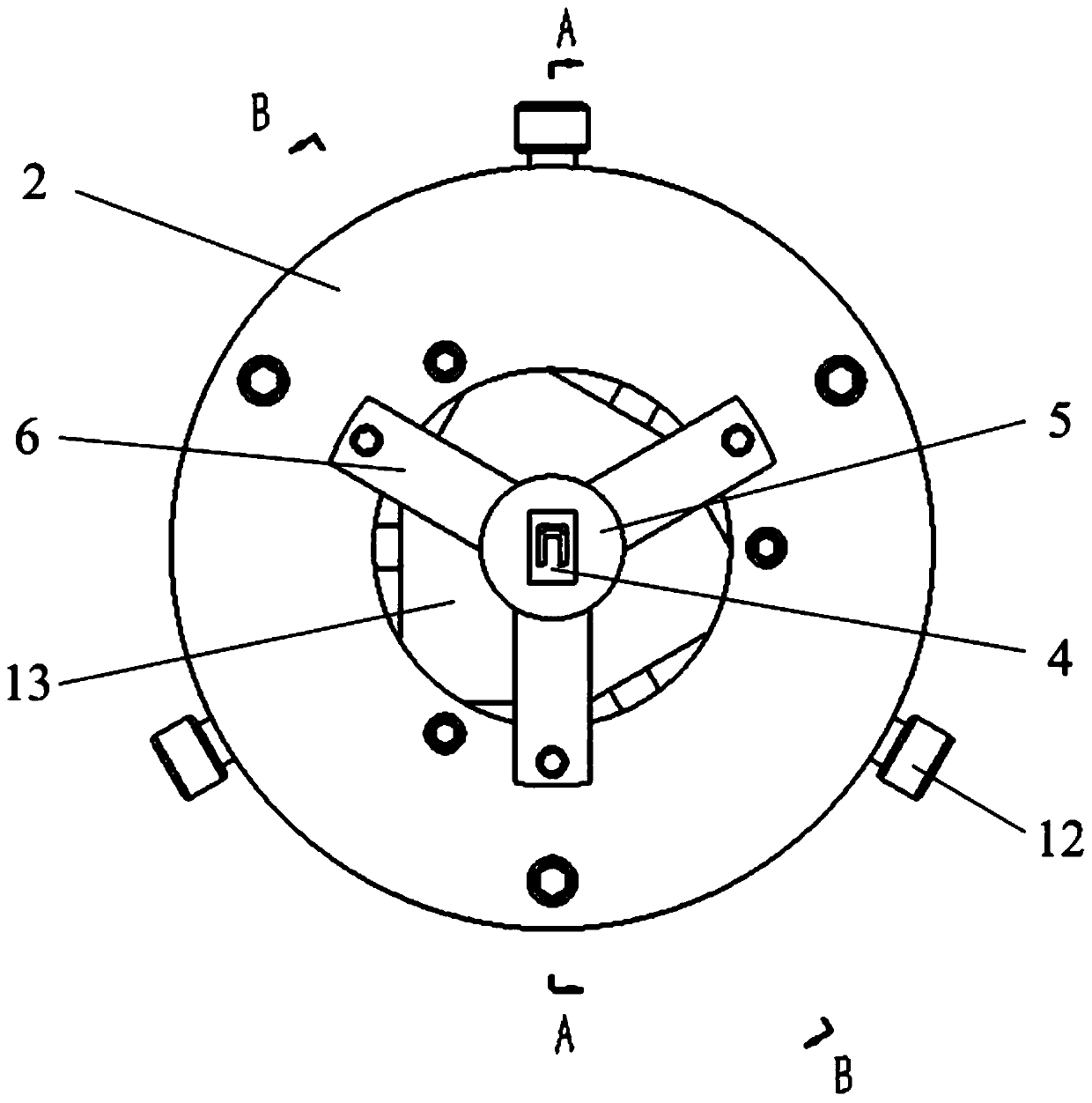

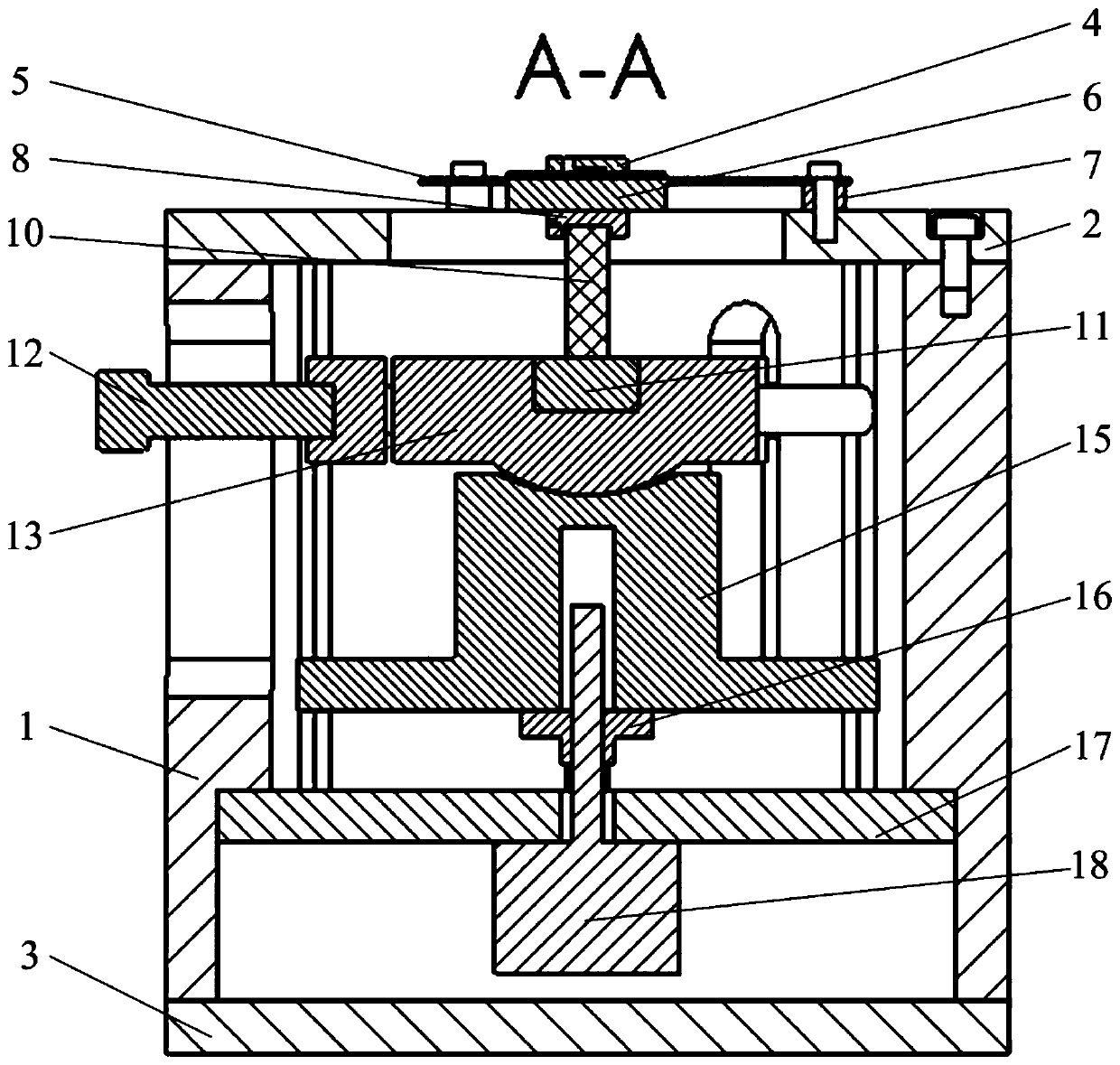

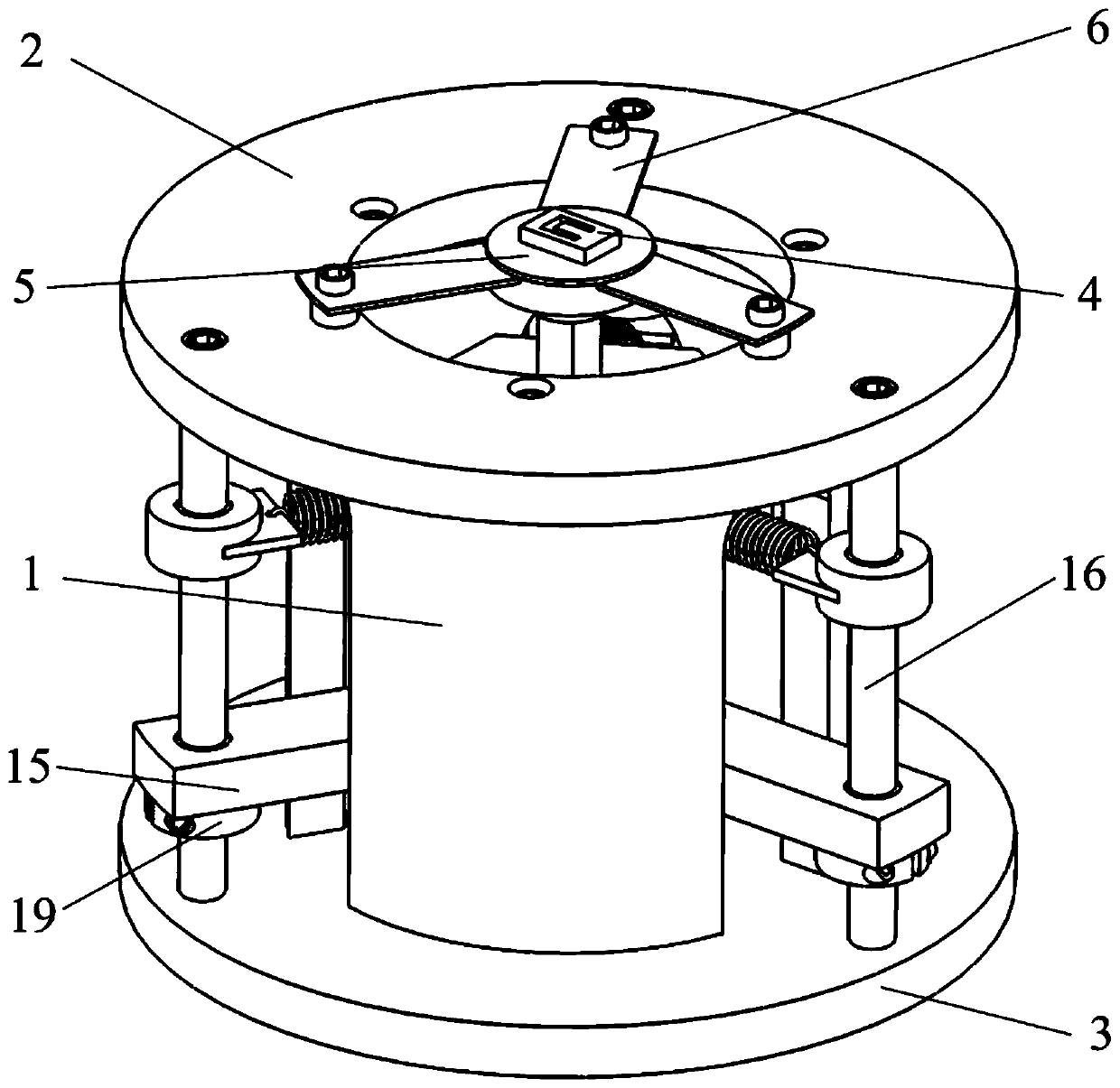

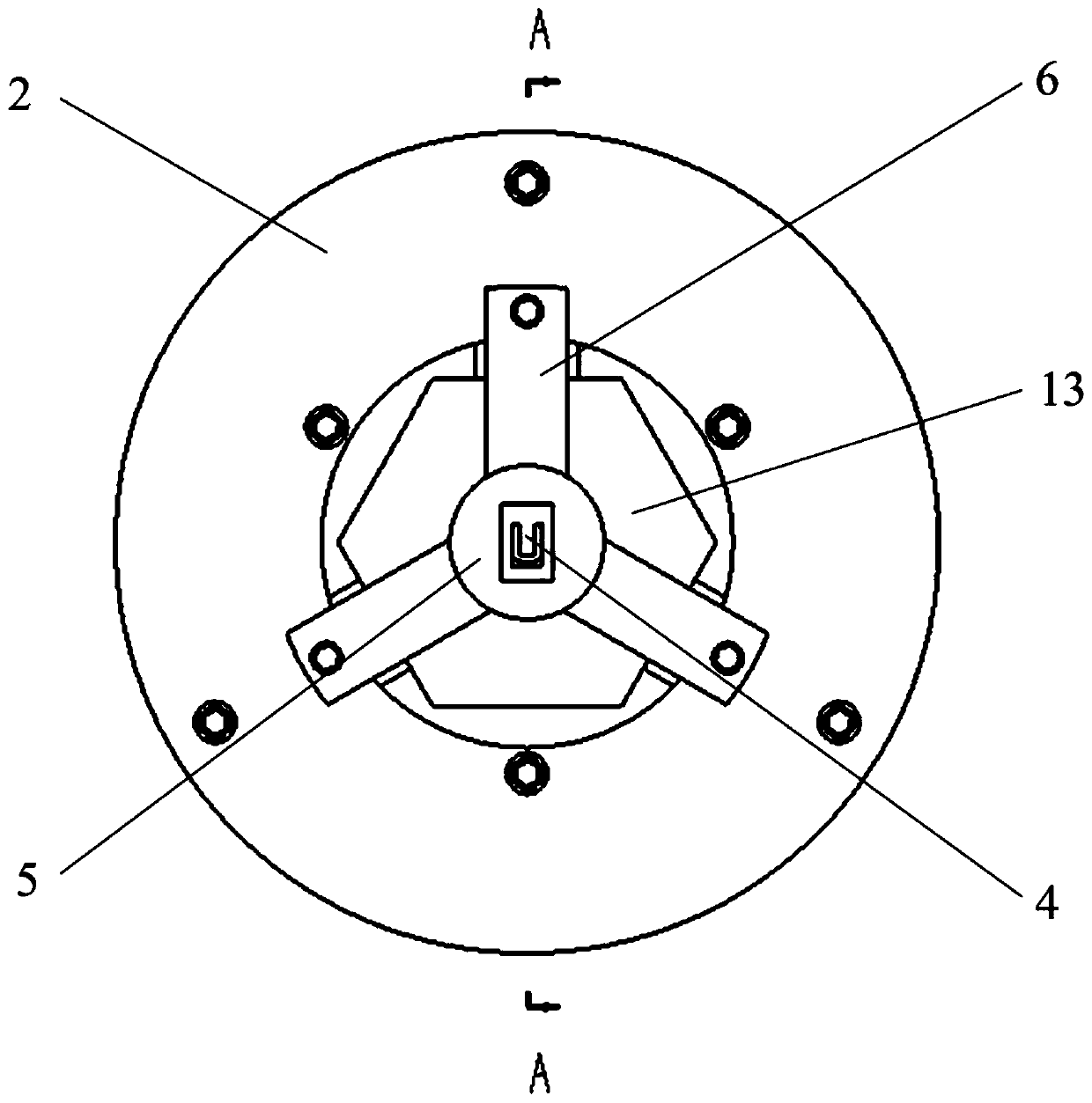

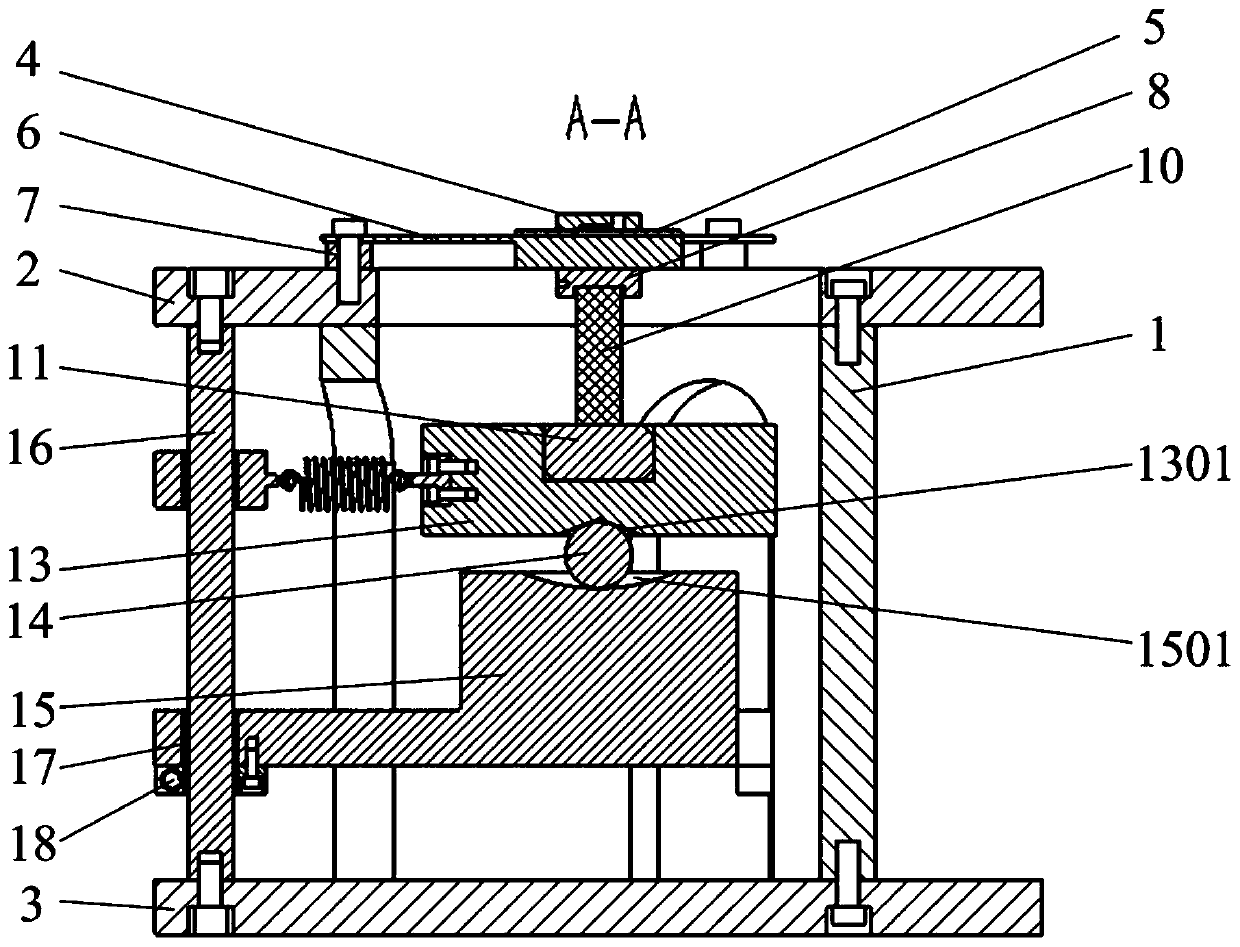

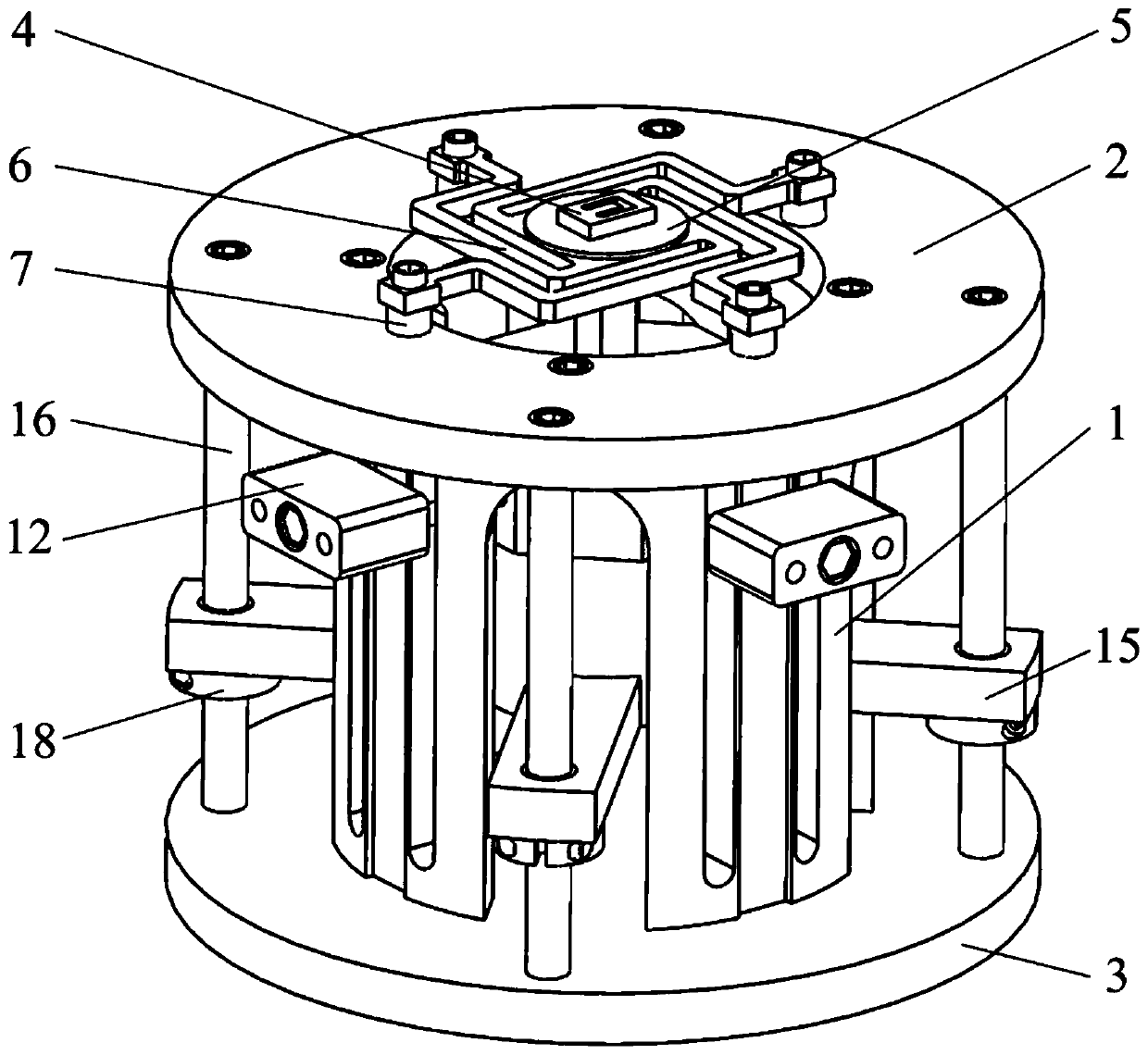

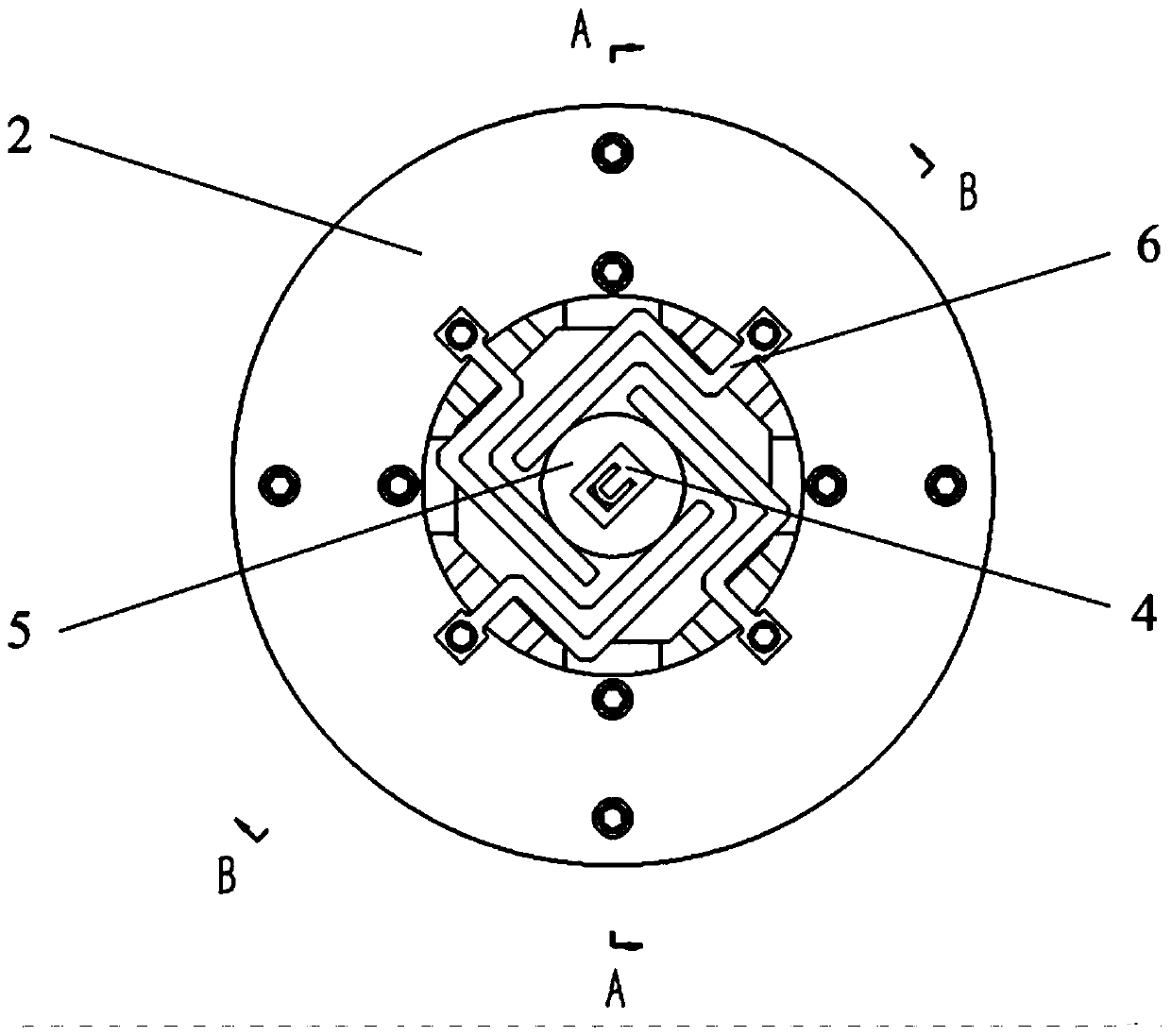

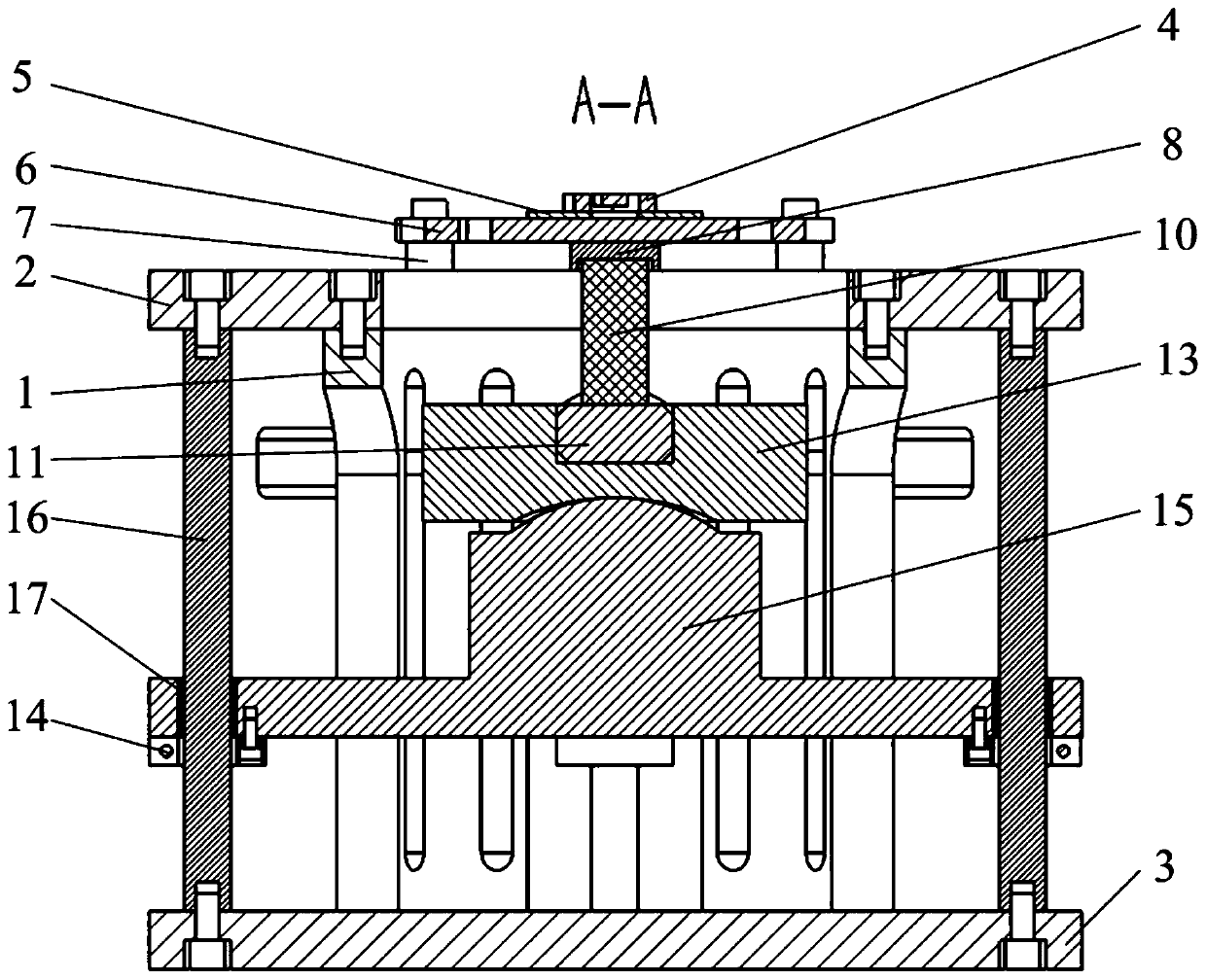

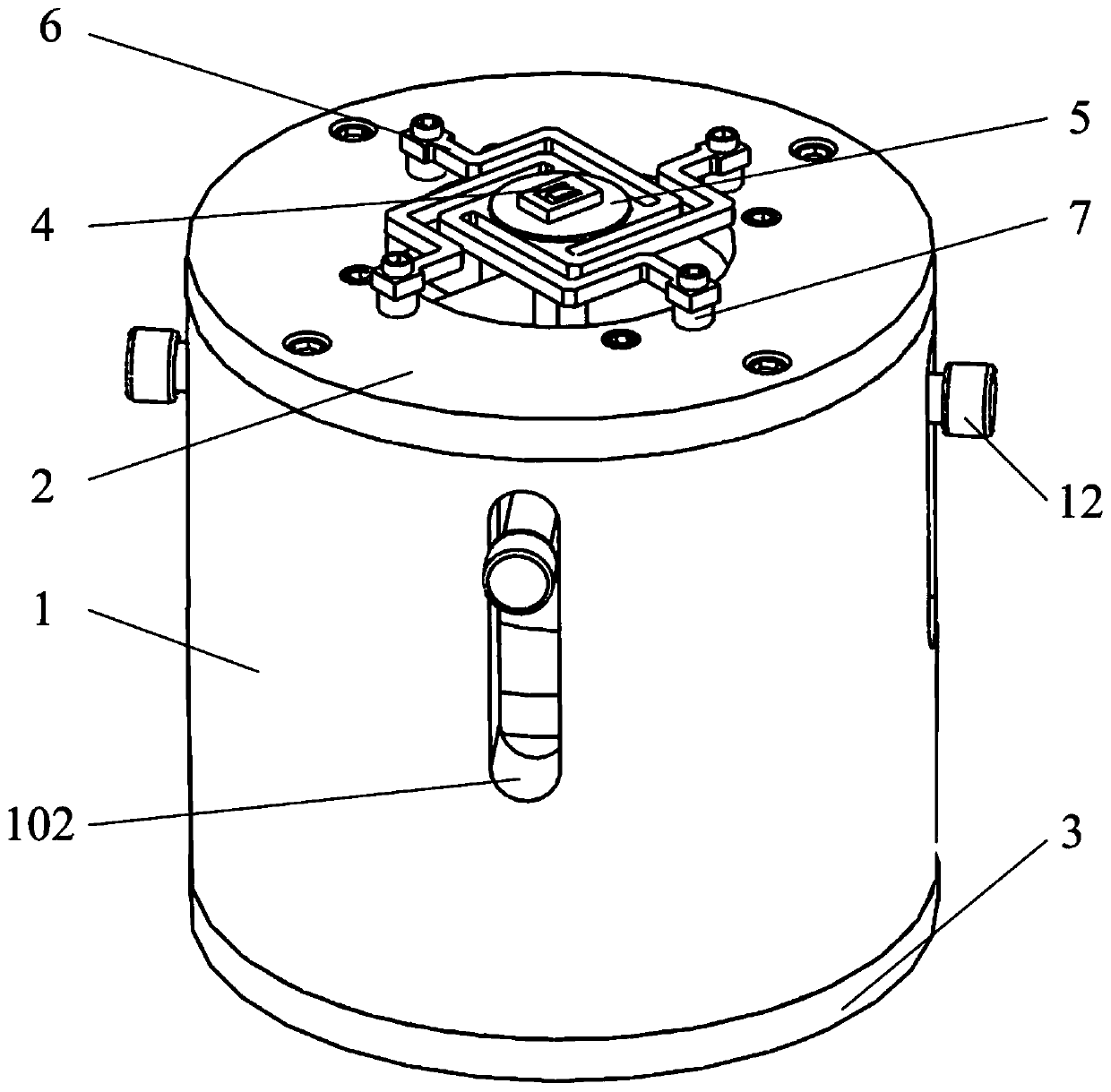

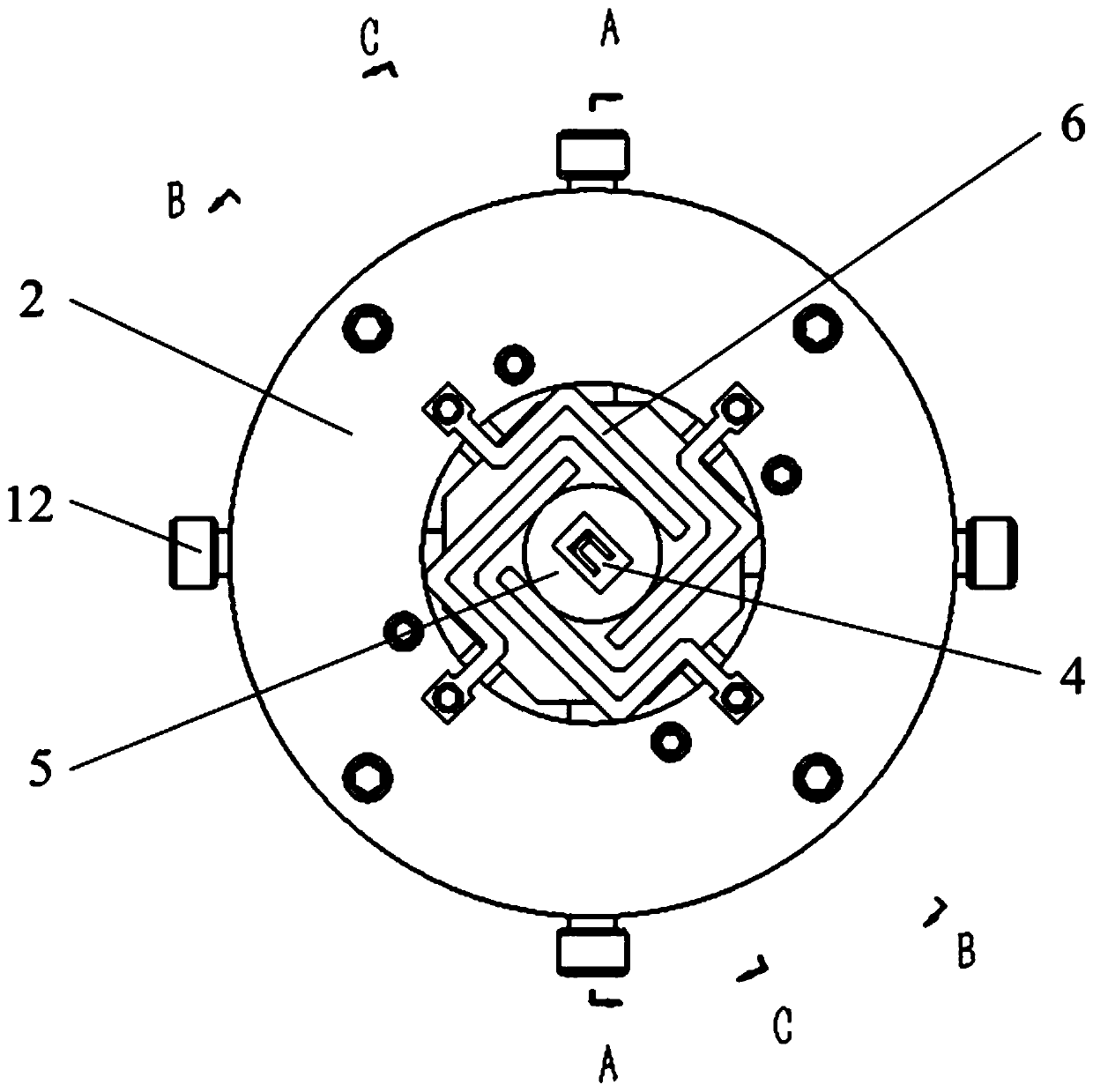

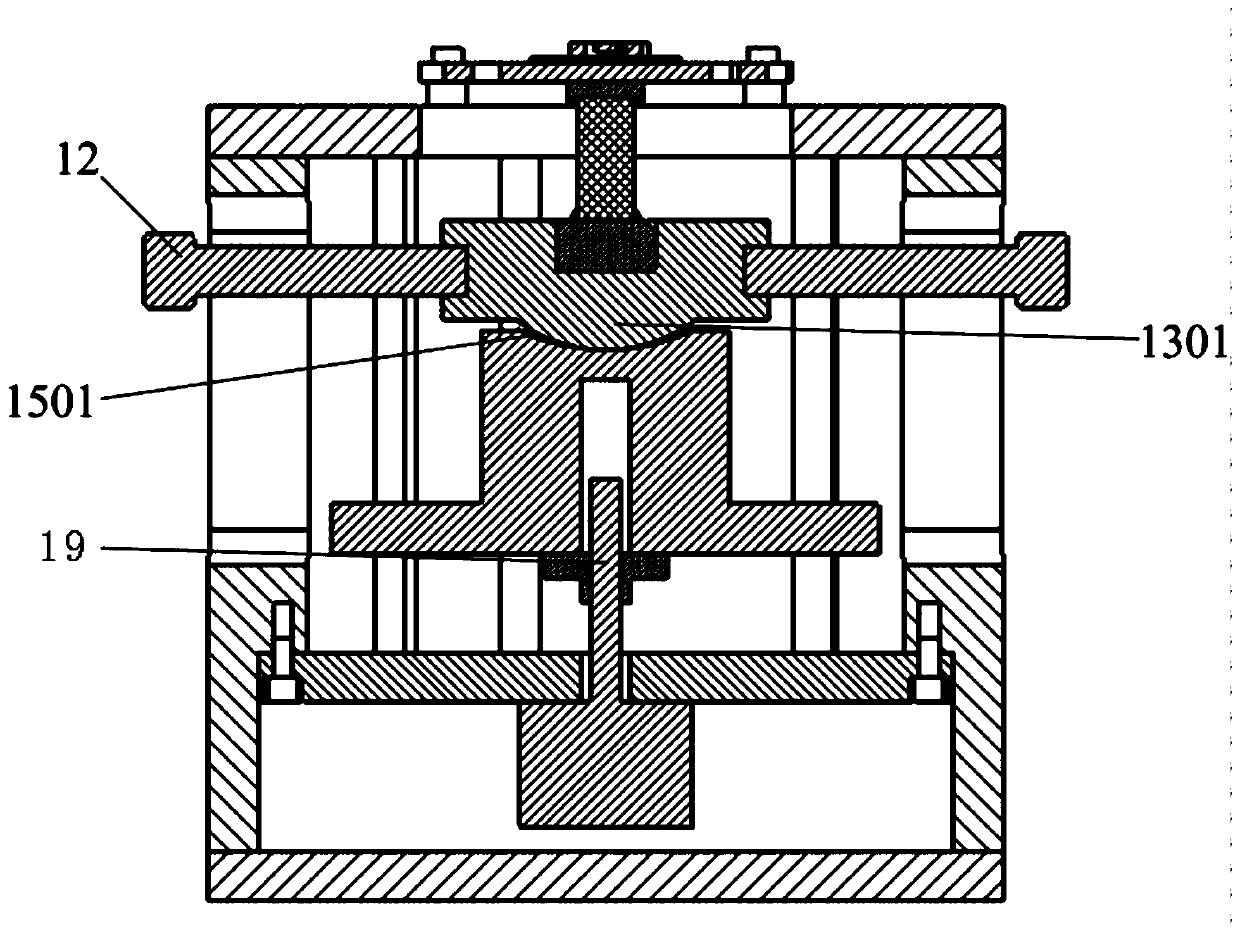

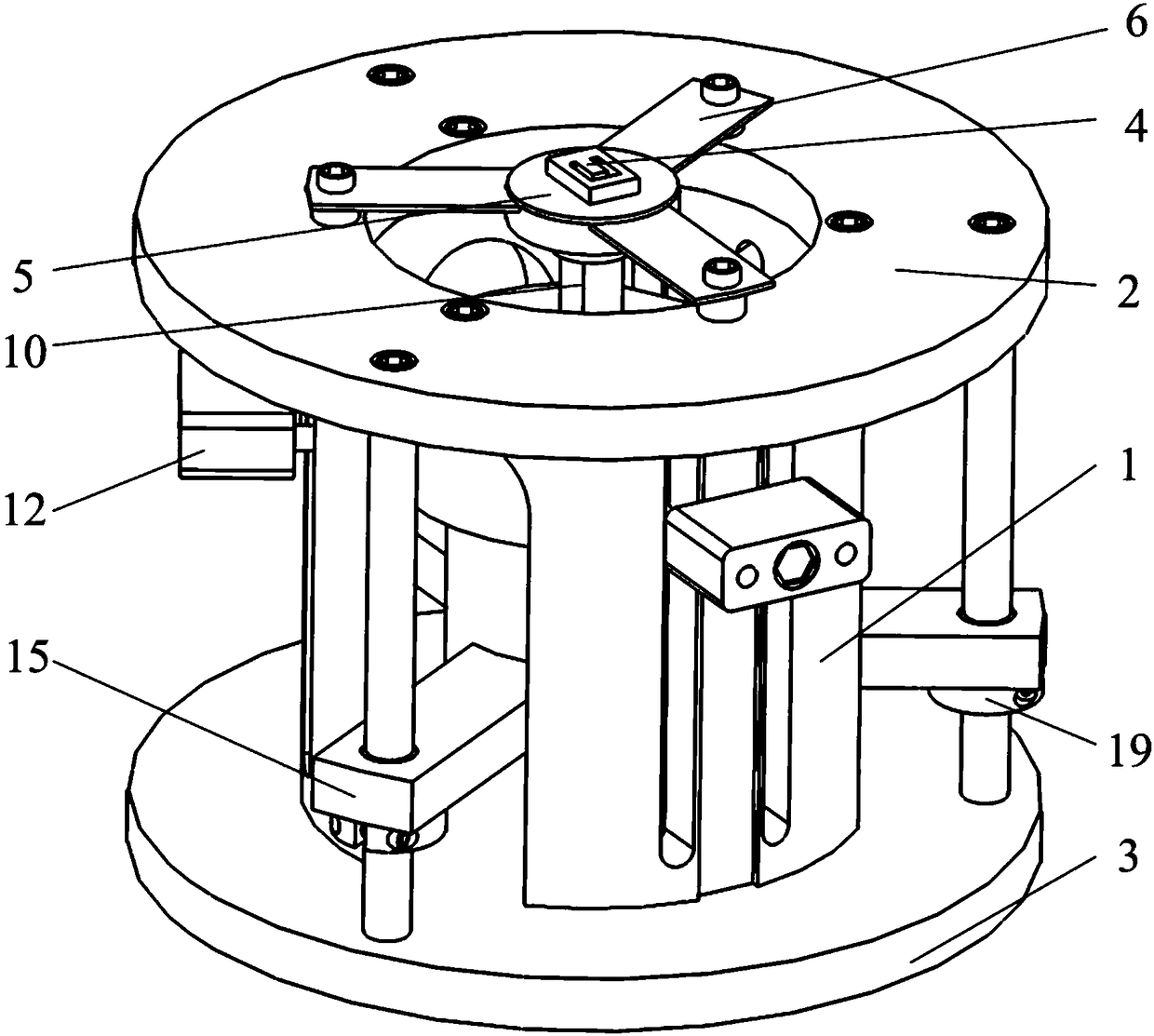

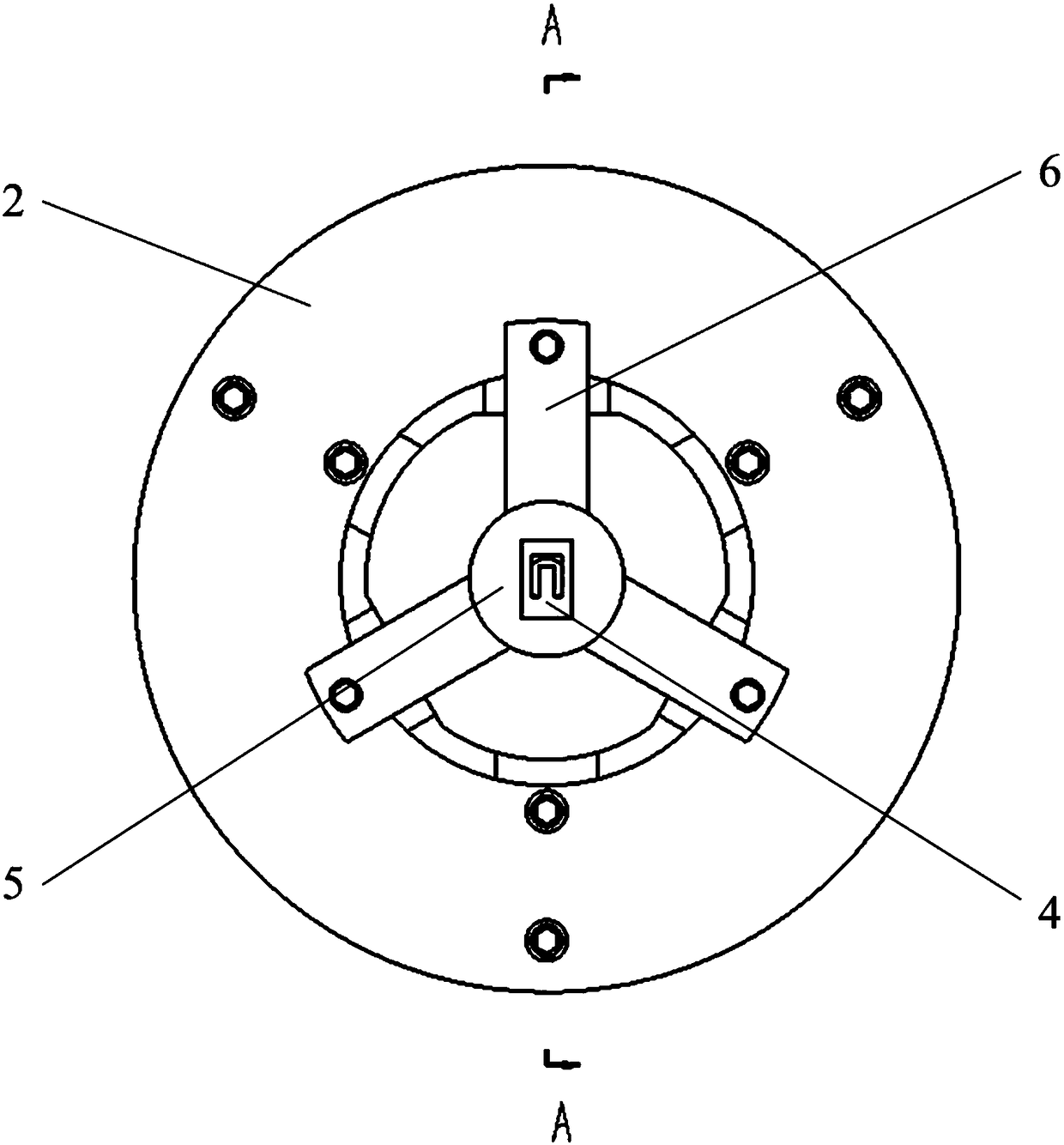

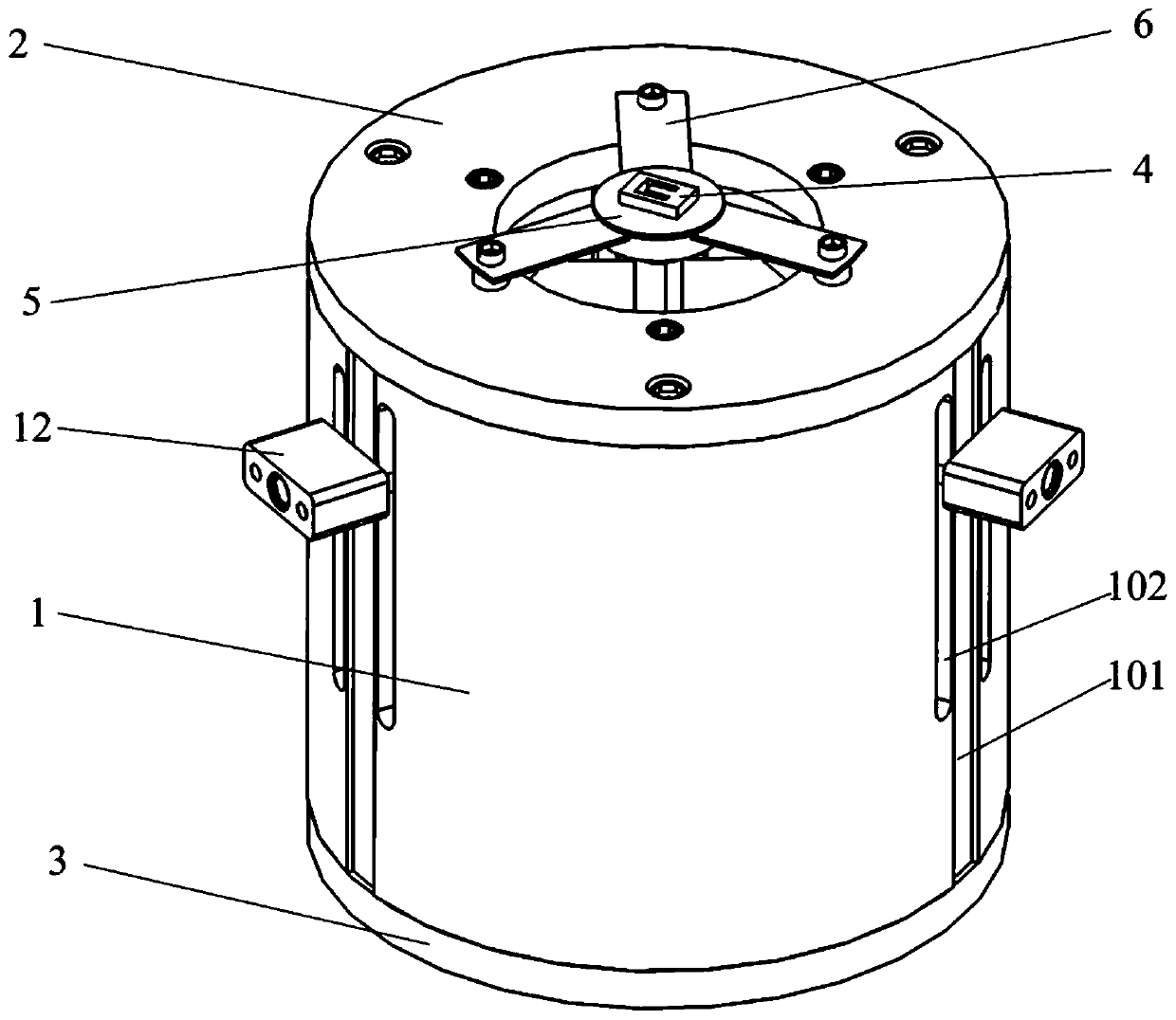

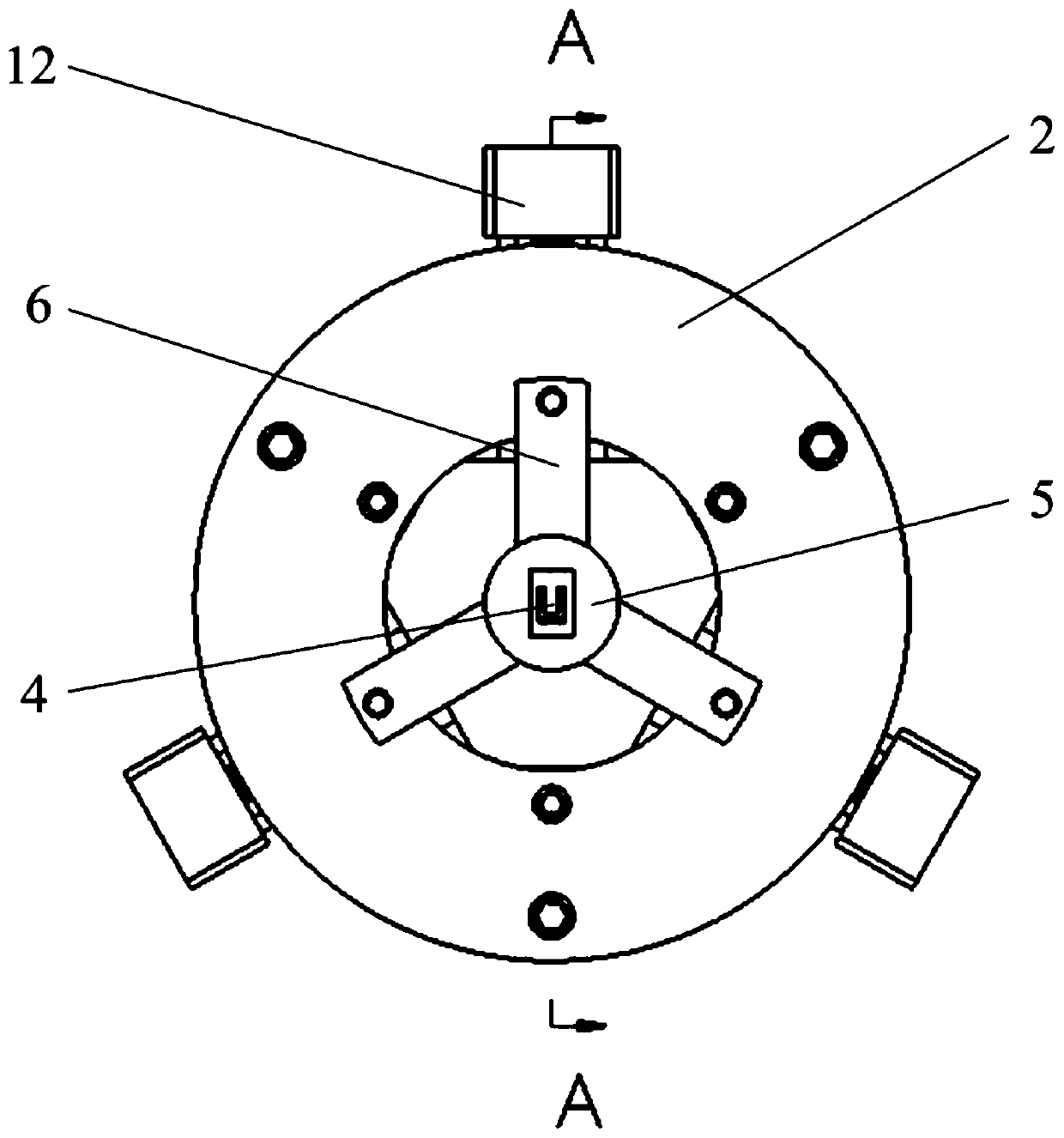

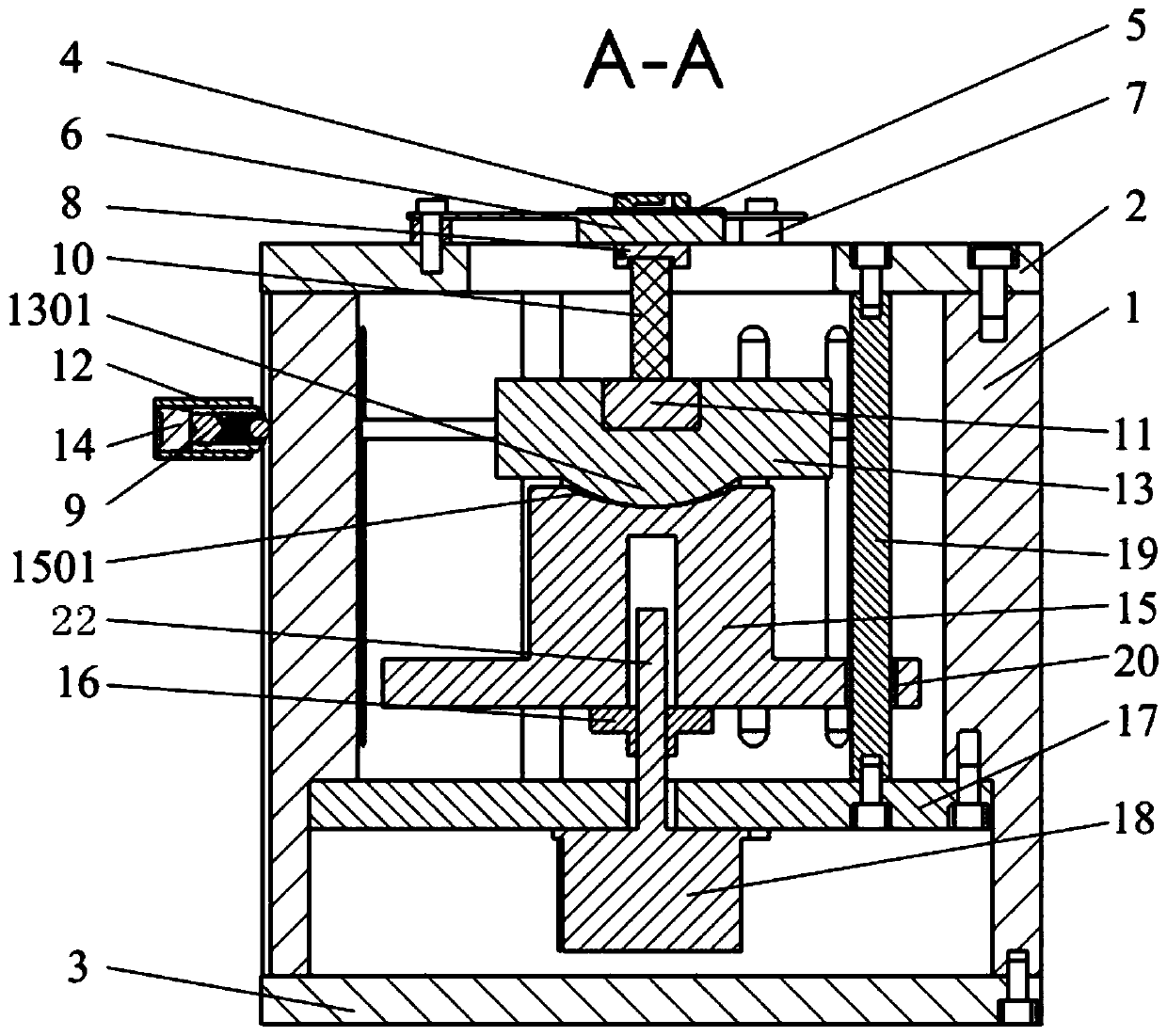

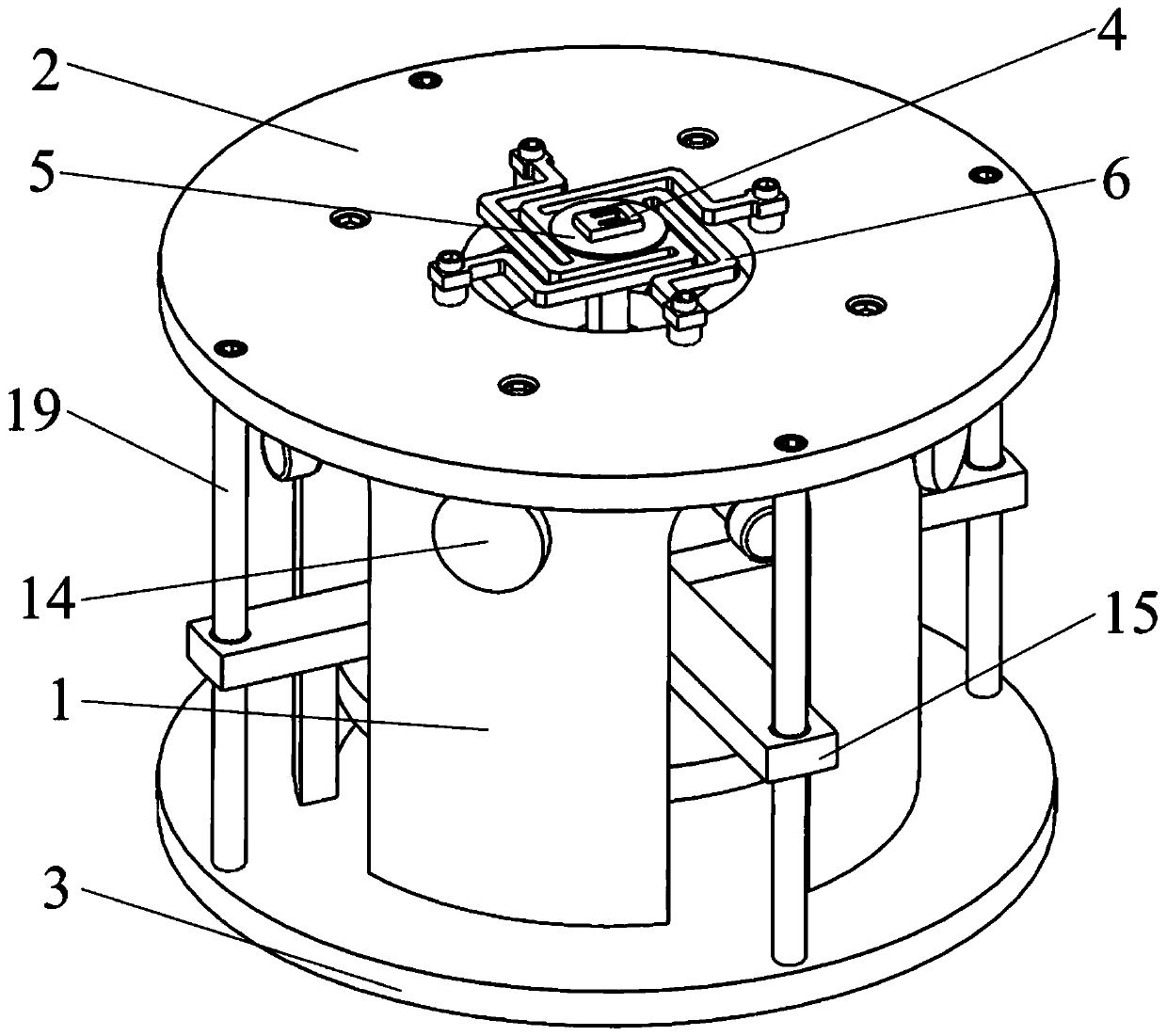

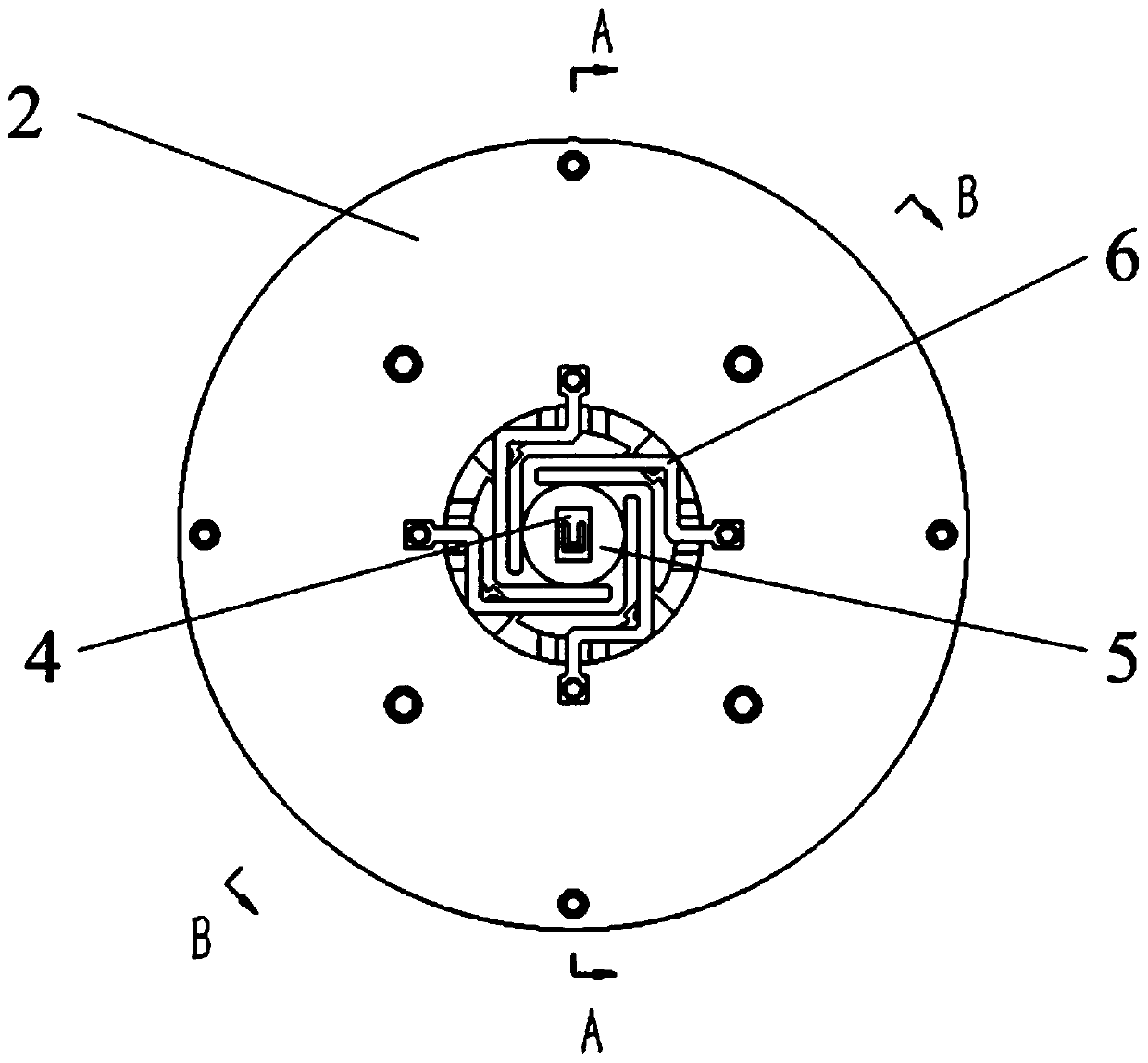

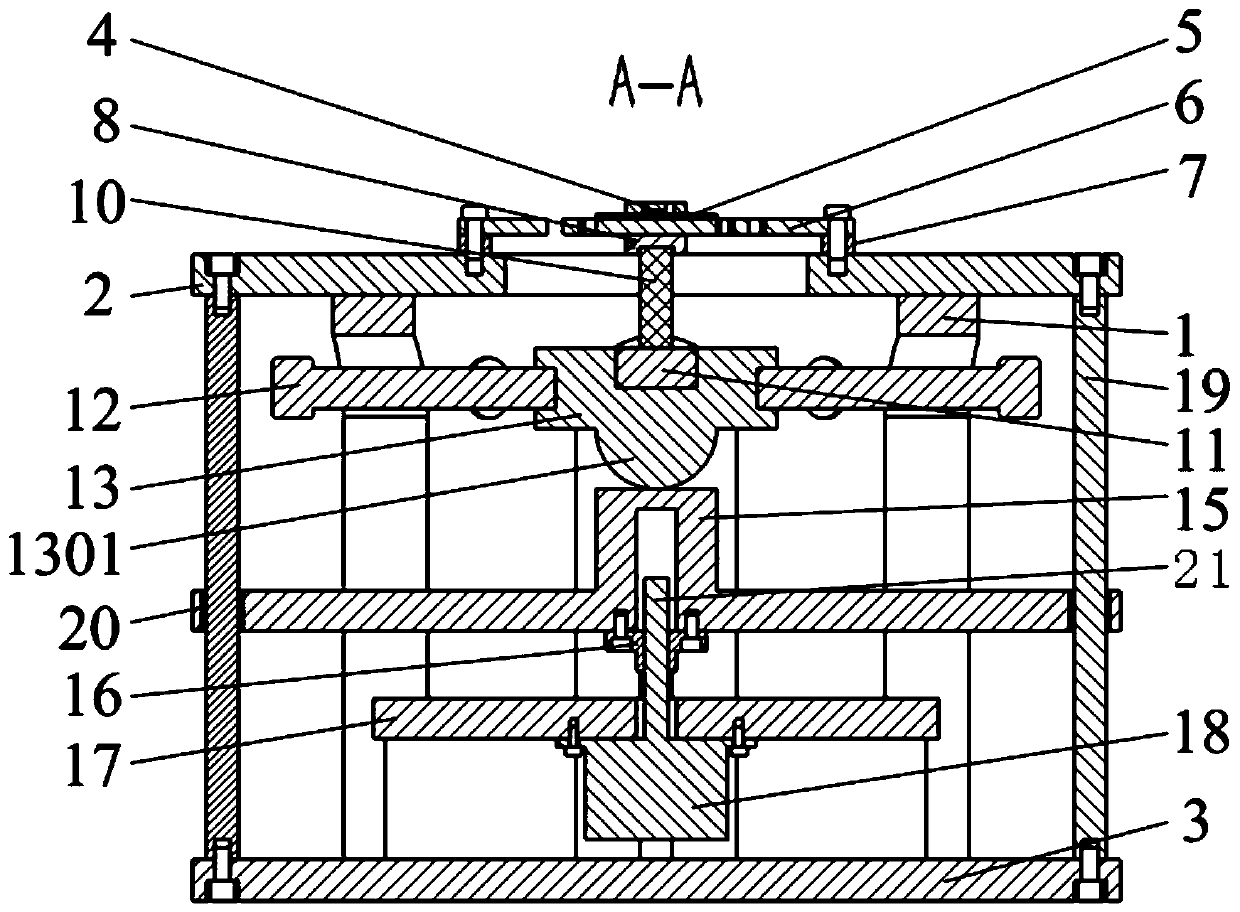

The invention discloses a four-axis piezoelectric ceramic excitation device for testing the dynamic characteristics of an MEMS microstructure. The device comprises a sleeve, a bottom plate, a piezoelectric ceramic, a pressure sensor, an upper connecting block, a lower connecting block, a steel ball, an elastic supporting part and an MEMS microstructure. An annular top plate is arranged at the upper end of the sleeve. The microstructure is arranged on the annular top plate through the elastic supporting piece. Guide shafts are uniformly distributed between the annular top plate and the bottom plate. The lower connecting block is provided with guide supporting arms. The guide supporting arms penetrate through the wall of the sleeve to be sleeved on the guide shafts. Locking devices are arranged on the guide supporting arms respectively. Spherical grooves are formed in the upper connecting block and the lower connecting block respectively. The piezoelectric ceramic is clamped between thepressure sensor and the elastic supporting part. The outer edge of the upper connecting block is jacked into the inner wall of the sleeve through a ball head plunger. According to the device, pre-tightening forces of different sizes can be applied to the piezoelectric ceramic, and the obtained measurement values of pre-tightening forces are more accurate. As a result, the adjustment process for compensating the parallelism error between two working surfaces of the piezoelectric ceramic becomes more smooth and smoother. As a result, dynamic characteristic parameters can be conveniently tested.

Owner:BOHAI UNIV

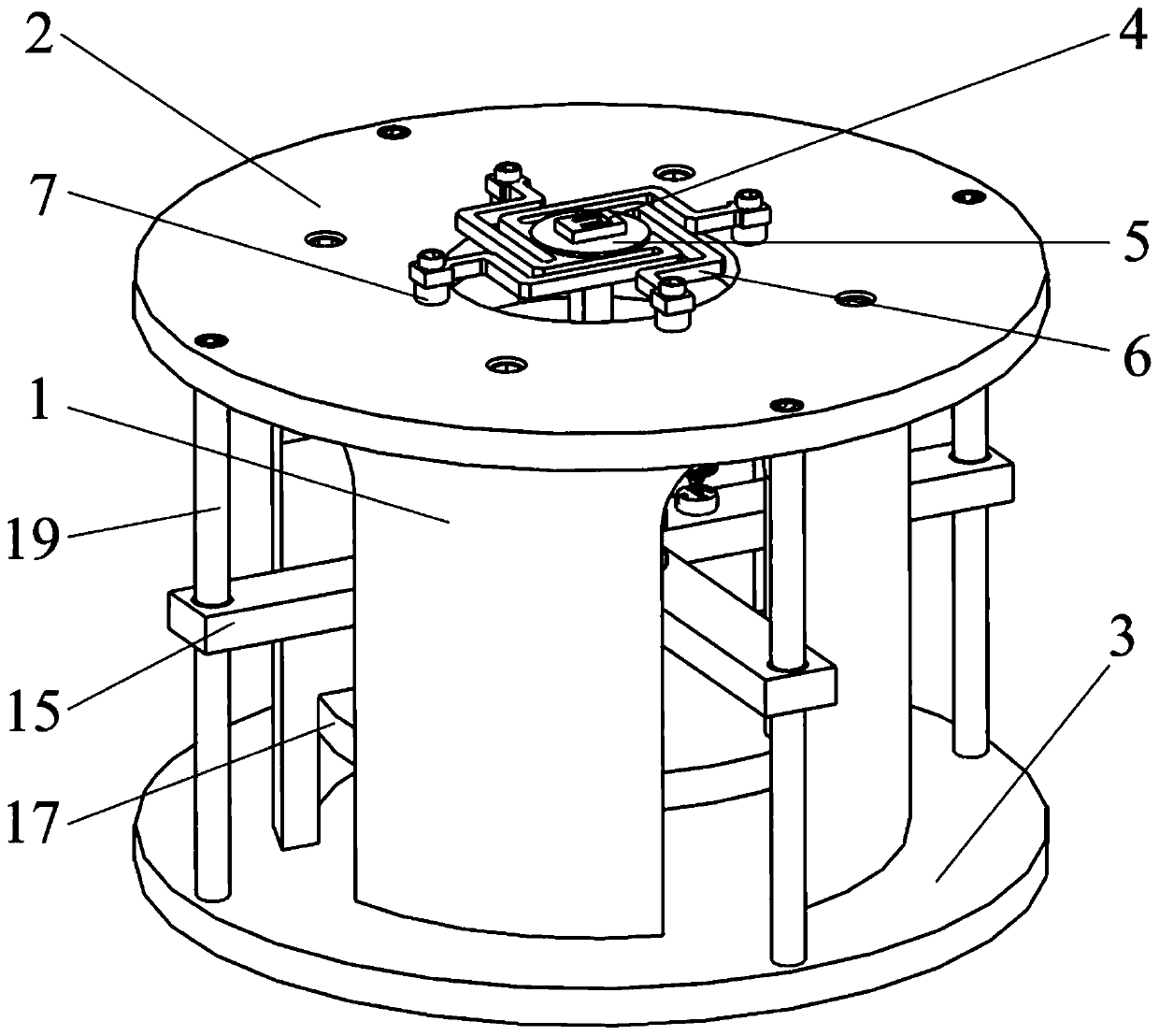

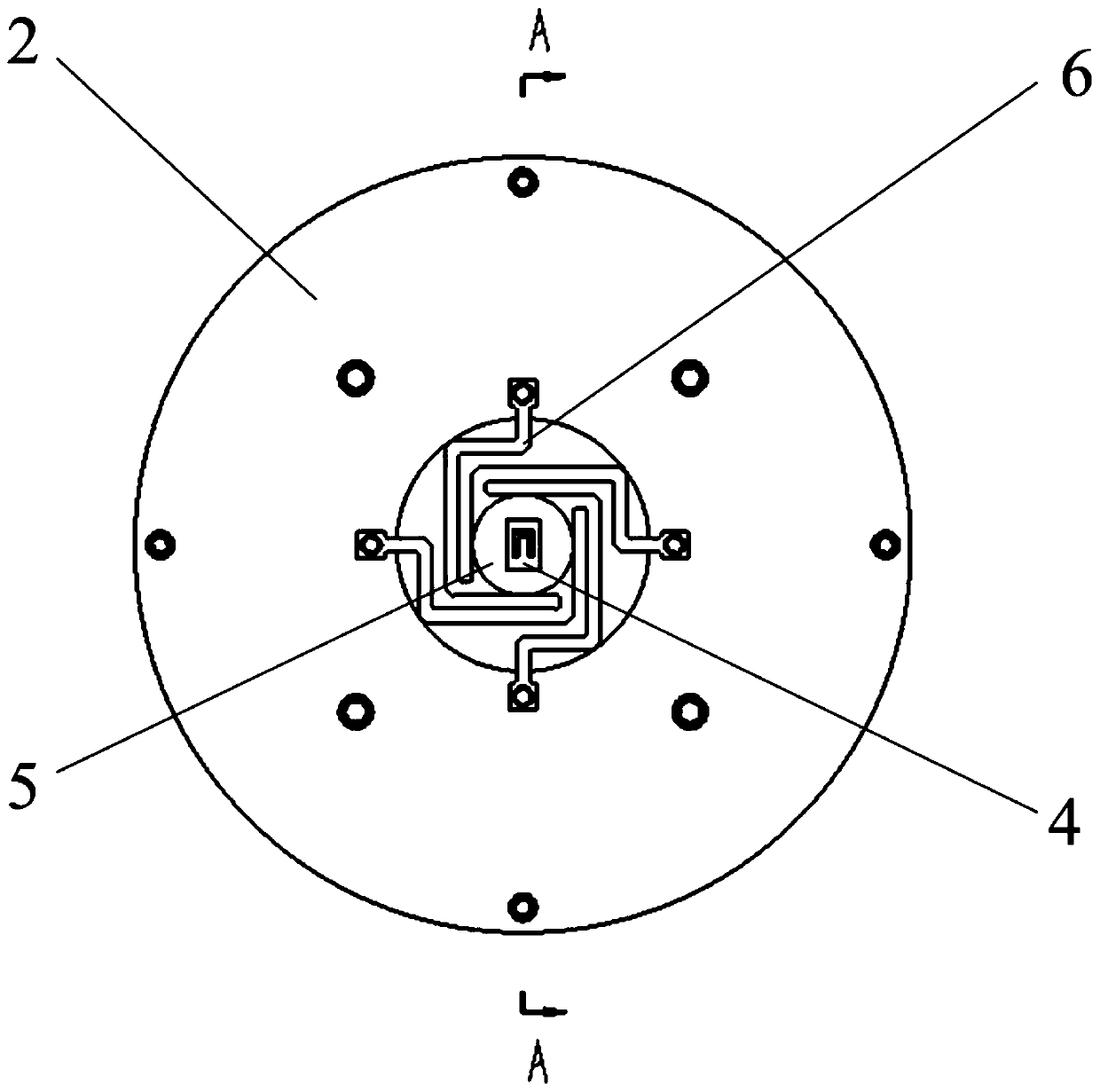

Four-axis excitation device for performing out-of-chip excitation on MEMS microstructure

InactiveCN108168814AReduce shear forceRegulation stabilitySubsonic/sonic/ultrasonic wave measurementUsing wave/particle radiation meansElectricitySteel ball

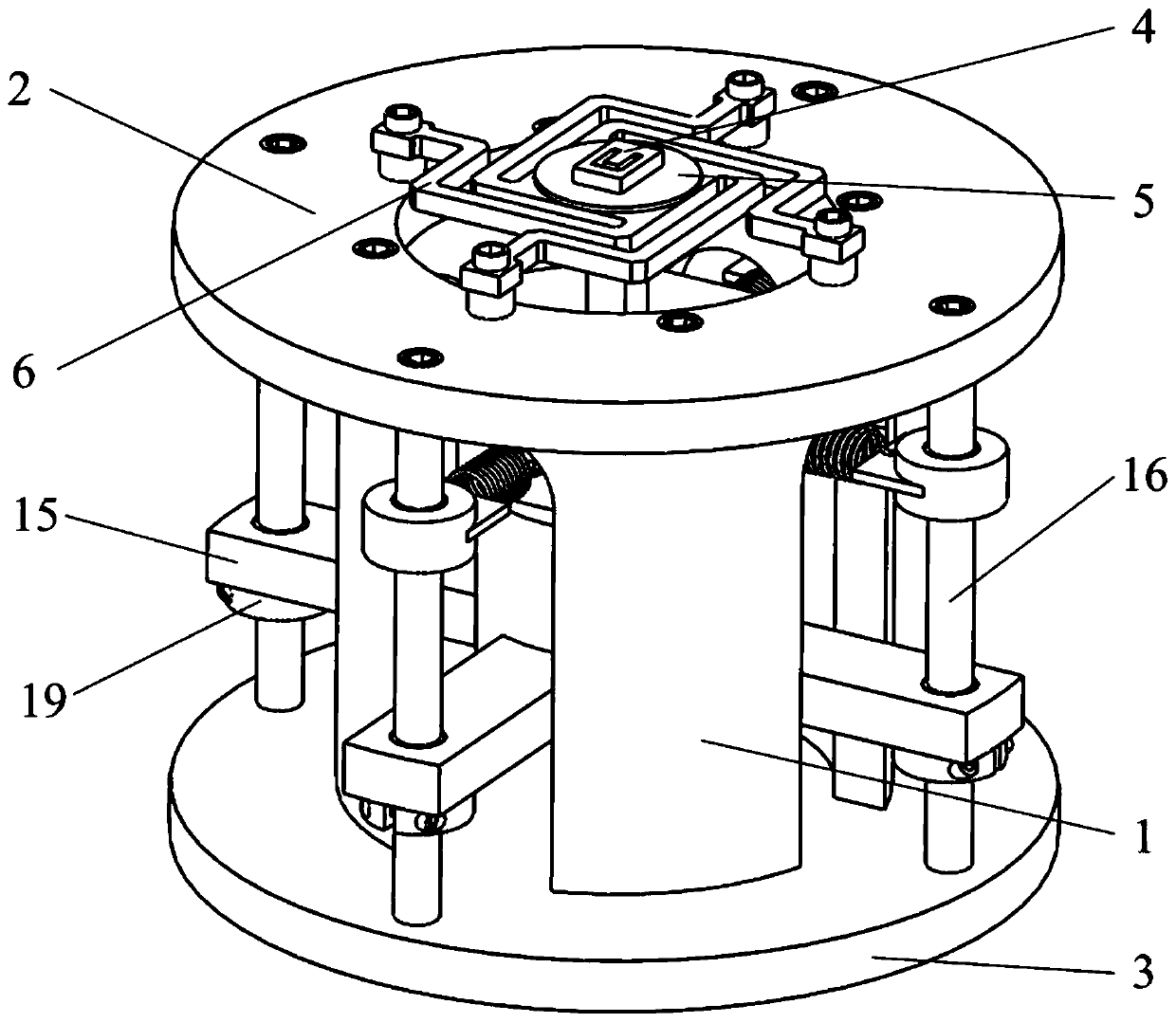

The invention discloses a four-axis excitation device capable of dynamically driving an MEMS microstructure. The excitation device comprises a sleeve, a bottom plate, a piezoelectric ceramic, a pressure sensor, an upper connecting block, a lower connecting block, a steel ball, an elastic supporting part and the MEMS microstructure; an annular top plate is arranged at the upper end of the sleeve, the microstructure is arranged on the annular top plate through the elastic supporting part; guide shafts are uniformly distributed between the top plate and the bottom plate, the lower connecting block is uniformly provided with guide support arms which penetrate through the sleeve wall and sleeve the guide shafts; the upper connecting block and the lower connecting block are respectively providedwith a conical groove and a spherical groove which are matched with each other, tension springs are uniformly distributed between the upper connecting block and the lower connecting block to make thesteel ball be clamped between the conical groove and the spherical groove; and the piezoelectric ceramic is clamped between the pressure sensor and the elastic supporting part. According to the device, pre-tightening force of different sizes can be applied to the piezoelectric ceramics, meanwhile, the obtained pre-tightening force measurement value is more accurate, so that the adjustment processof the parallelism error of the two working surfaces of the compensation piezoelectric ceramic can be smoother, and dynamic characteristic parameters can be tested conveniently.

Owner:BOHAI UNIV

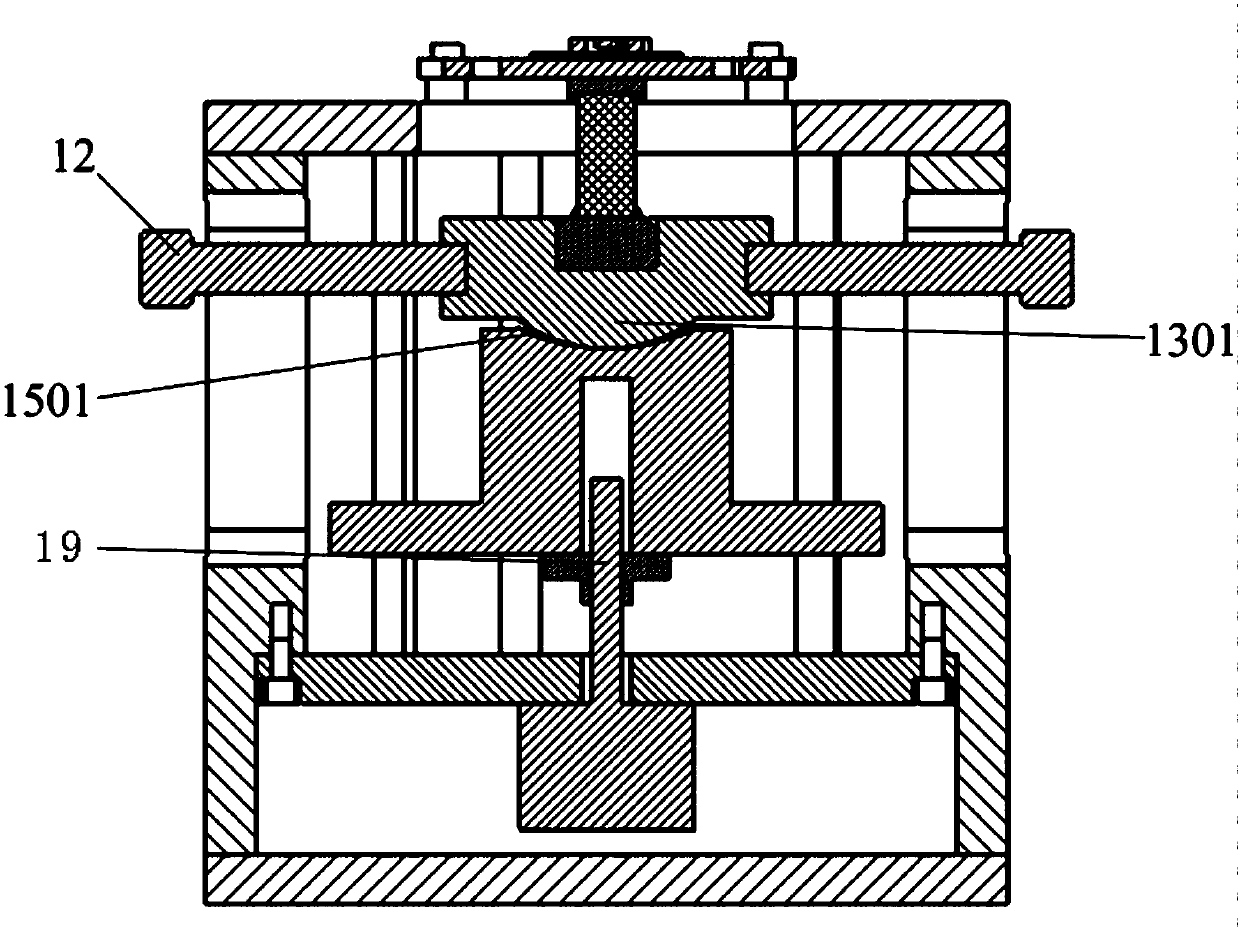

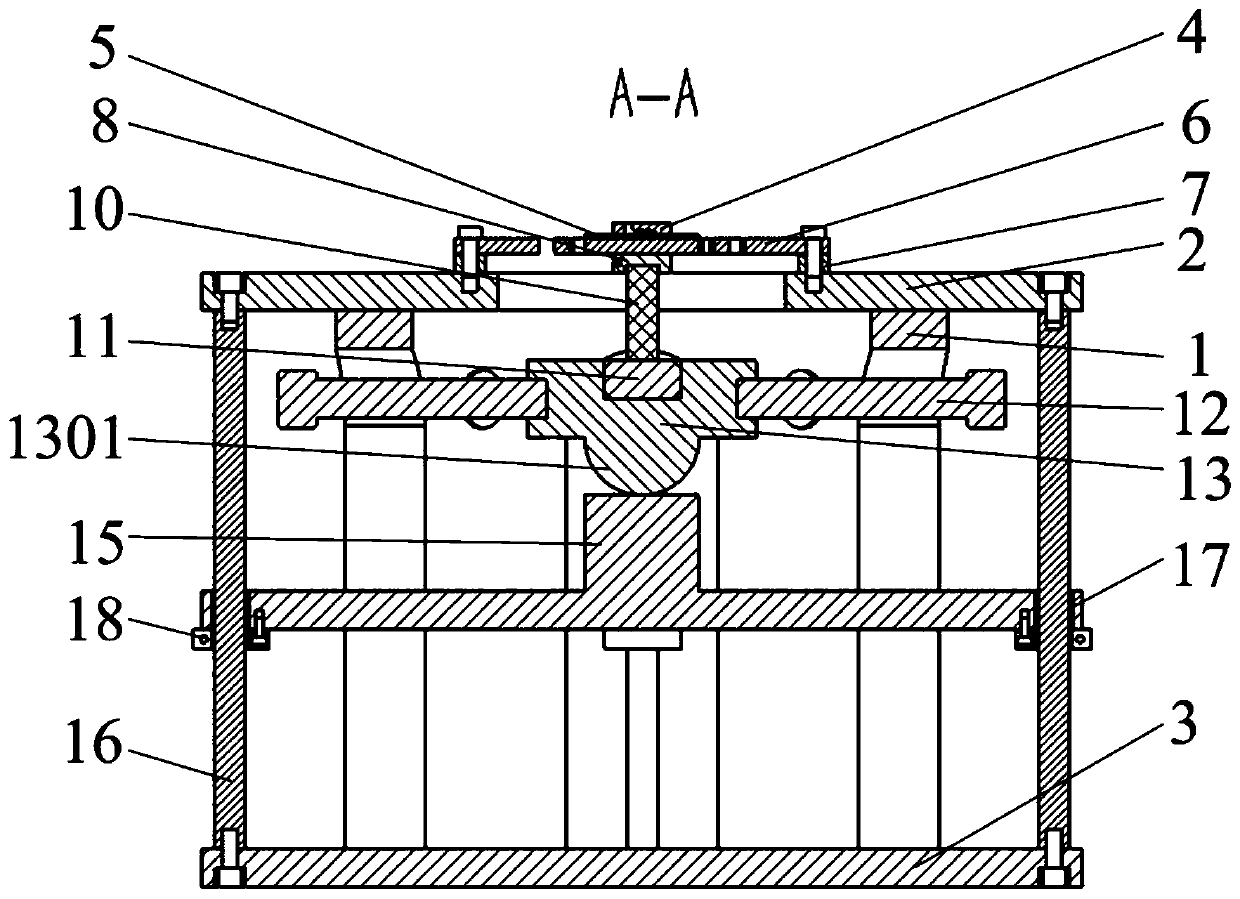

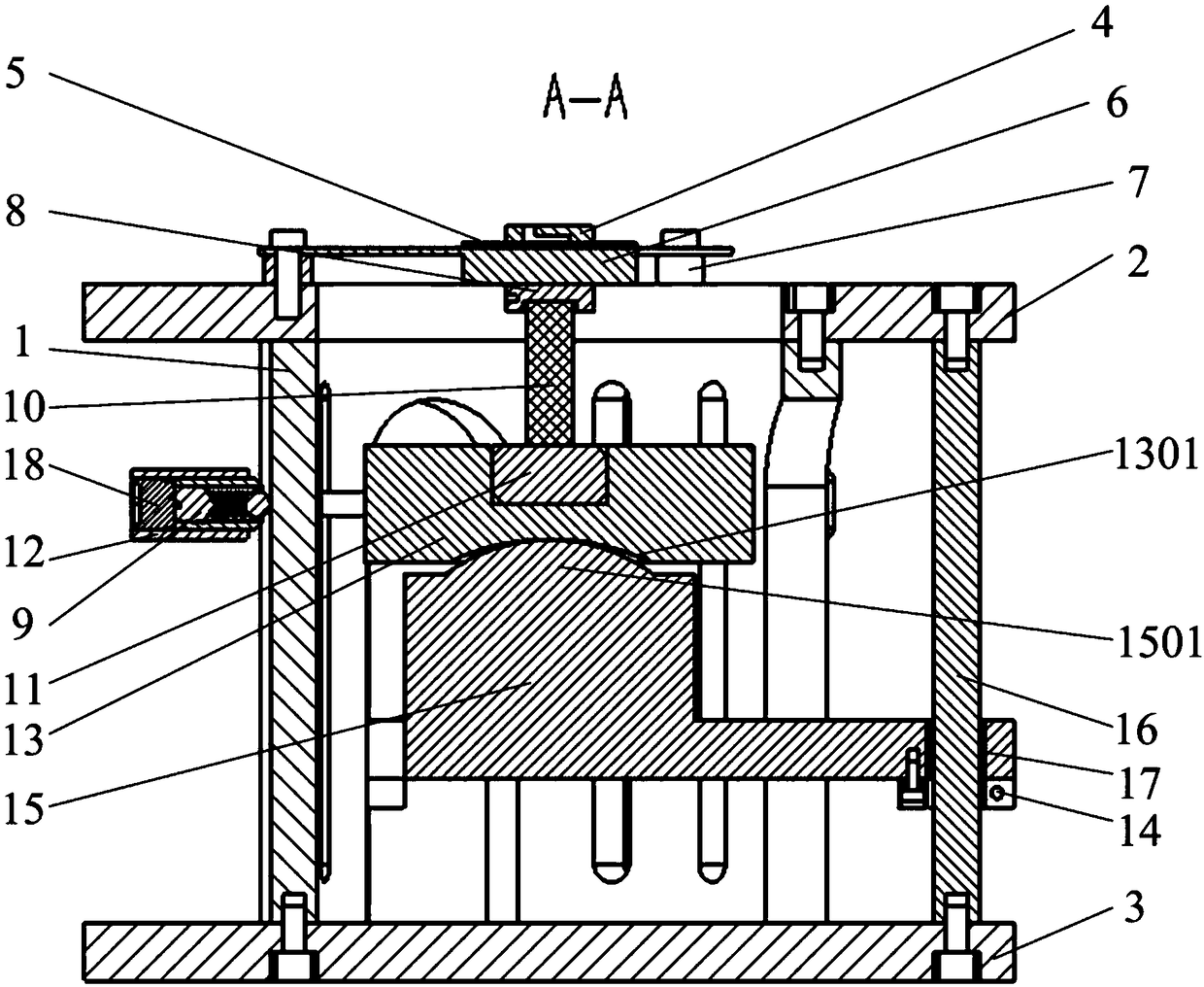

MEMS (Micro-electromechanical System) microstructure tetra-axial base exciting device driven by stack piezoelectric ceramic

The invention discloses an MEMS (Micro-electromechanical System) microstructure tetra-axial base exciting device driven by stack piezoelectric ceramic. The MEMS microstructure tetra-axial base exciting device comprises a sleeve, the stack piezoelectric ceramic, a pressure sensor, an upper connecting block, a lower connecting block and an MEMS microstructure, wherein a hemispherical head is arranged at the lower end of the upper connecting block and presses the lower connecting block; the piezoelectric ceramic is clamped between the pressure sensor and elastic supporting members; ball head plungers are uniformly distributed in the circumference between the upper connecting block and the sleeve; steel balls at the inner ends of the ball head plungers jack into a sliding chute in the outer edge of the upper connecting block; guiding shafts are uniformly distributed in the circumference between an annular top plate and a base plate; and guiding support arms which are uniformly distributedon the edge of the lower connecting block respectively penetrate through the sleeve and sleeve the corresponding guiding shafts. The device has the advantages that pretightening forces with differentstrengths can be applied to the stack piezoelectric ceramic, a pretightening force measurement value is more accurate, the adjusting process of compensating parallelism error between two working facesof the stack piezoelectric ceramic is enabled to smoother, and dynamic characteristic parameters are favorably tested.

Owner:BOHAI UNIV

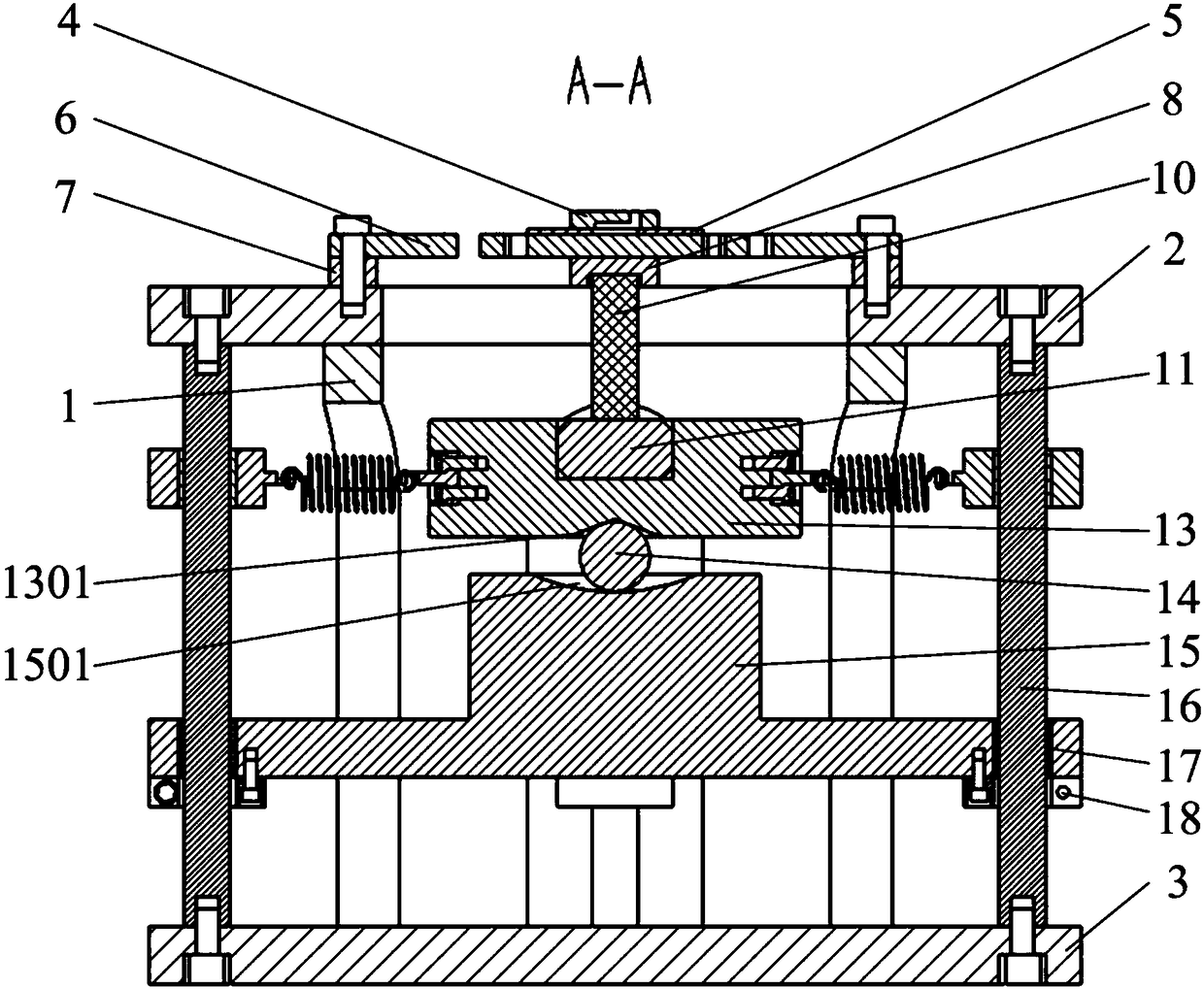

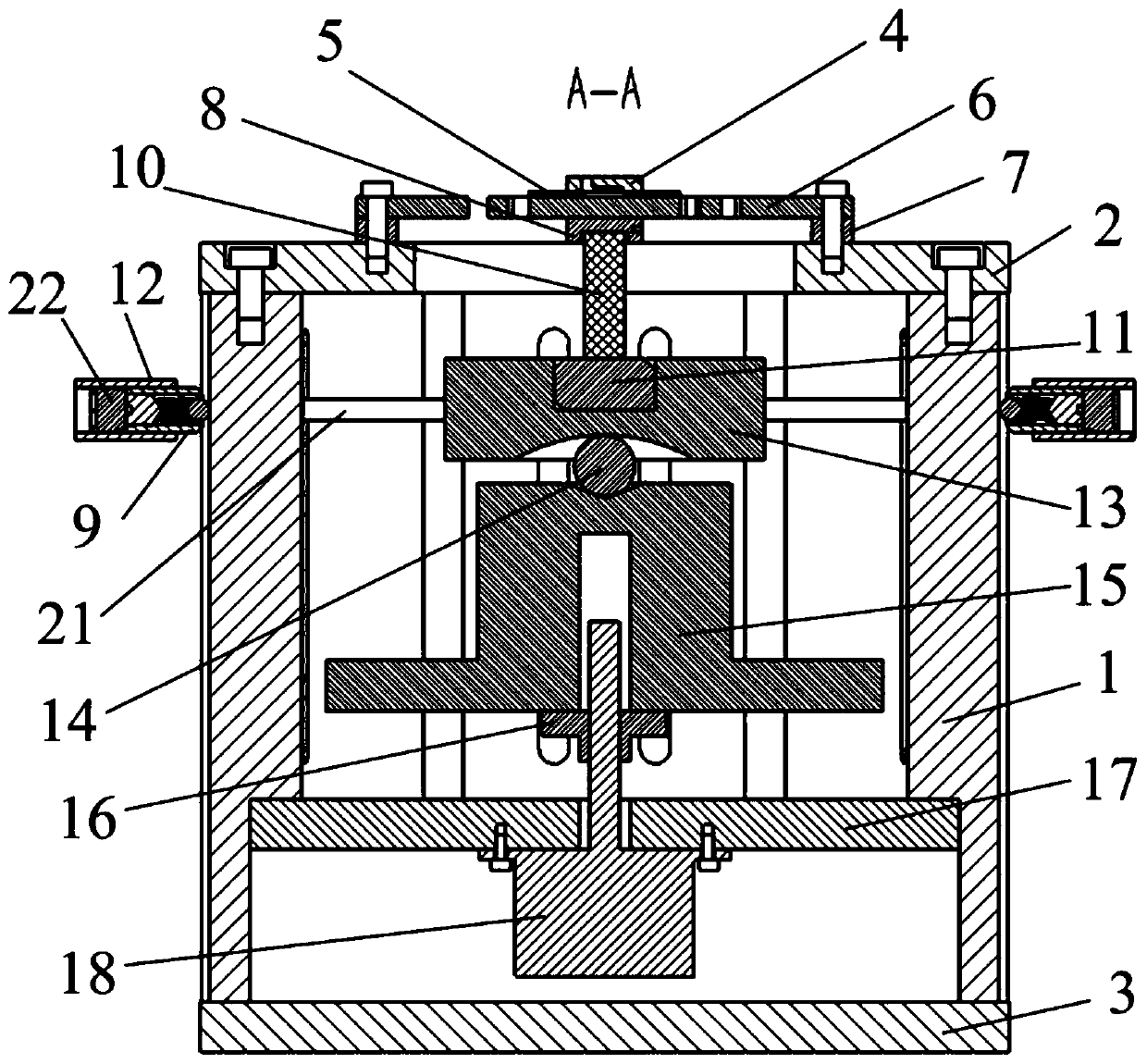

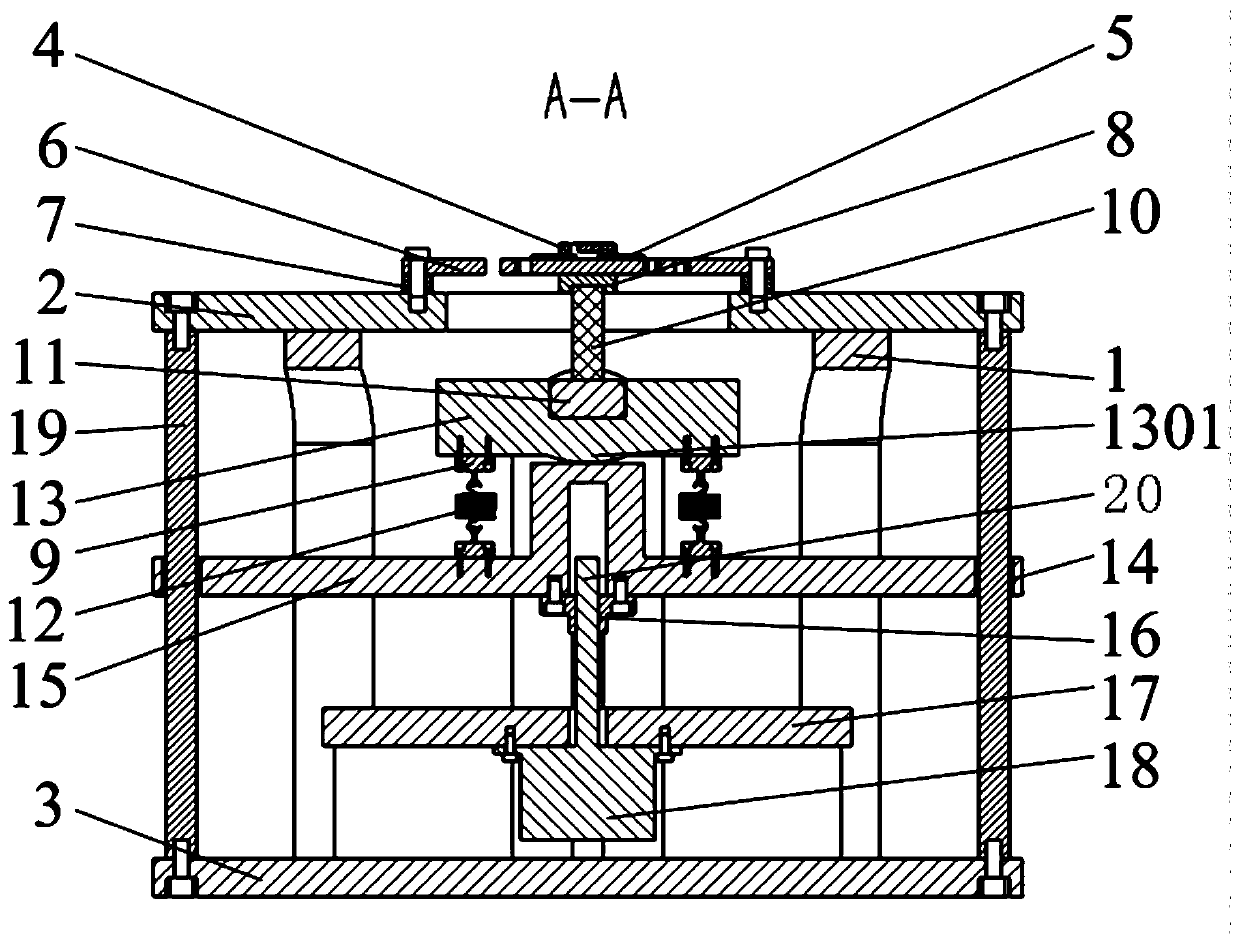

Four-axis excitation device capable of loading impact load on MEMS microstructure

The invention discloses a four-axis excitation device capable of loading impact load on an MEMS microstructure. The four-axis excitation device comprises a sleeve, a stacked piezoelectric ceramic, a pressure sensor, an upper connecting block, a lower connecting block and an MEMS micro structure; wherein a supporting plate and an electric lead screw transmission mechanism connected with the lower connecting block are arranged in the sleeve; the upper connecting block and the lower connecting block are respectively provided with spherical protrusions and spherical grooves which are matched witheach other; the piezoelectric ceramic is clamped between the pressure sensor and the elastic supporting piece; and ball head plungers are uniformly distributed on the upper connecting block, and the outer ends of the ball head plungers are jacked into rectangular grooves in the inner wall of the sleeve. According to the device, pre-tightening force of different magnitudes can be flexibly applied to the stacked piezoelectric ceramics. Meanwhile, the obtained pre-tightening force measurement value is more accurate, so that the adjustment process for compensating the parallelism error of the twoworking surfaces of the stacked piezoelectric ceramic can be smoother, the shearing force between the layers of the stacked piezoelectric ceramics is greatly reduced, falling of micro-devices for testing can be avoided, and dynamic characteristic parameters of the MEMS micro-structures can be tested conveniently.

Owner:BOHAI UNIV

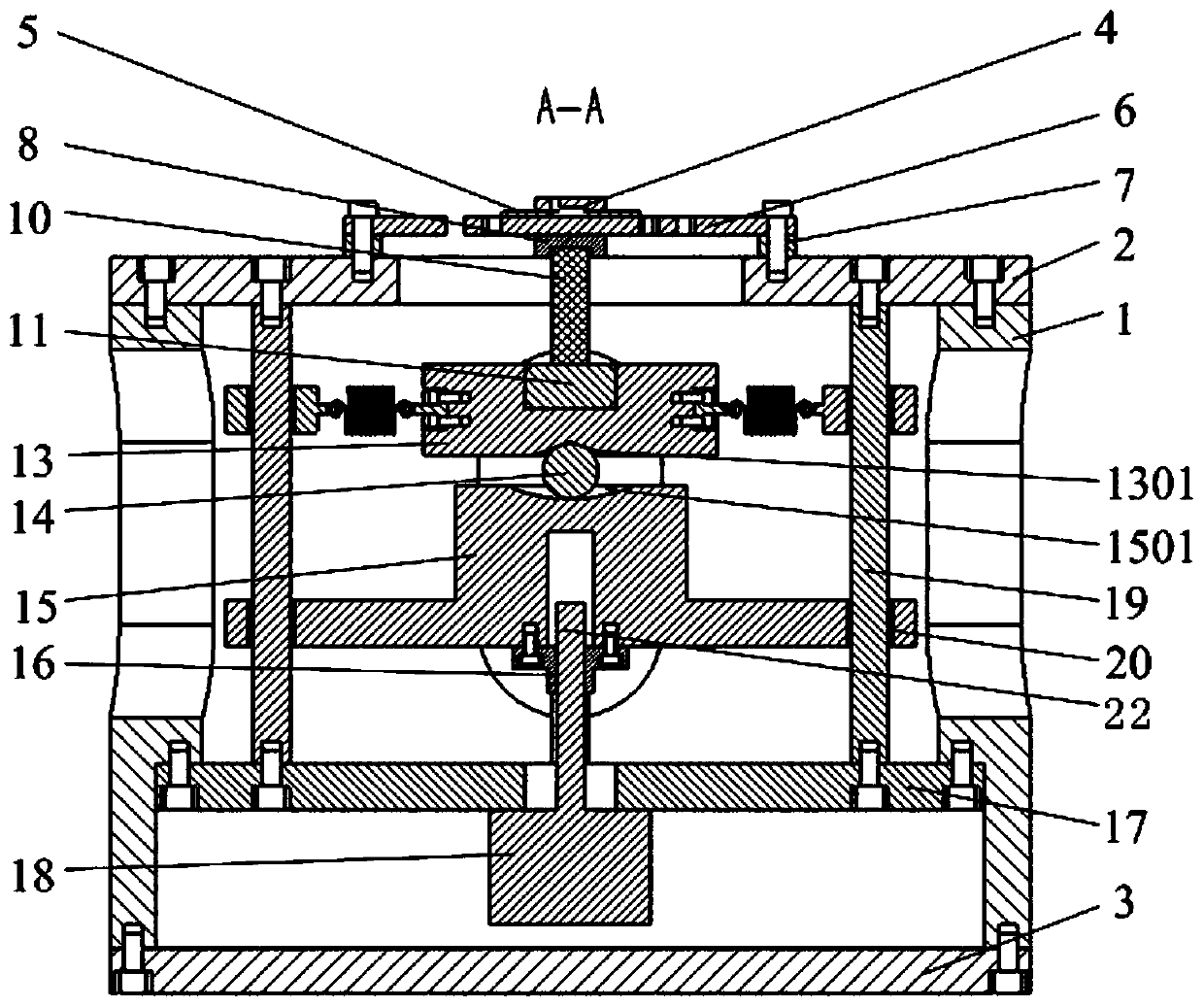

MEMS microstructure four-axis type dynamic loading apparatus based on piezoelectric ceramics

The invention discloses an MEMS microstructure four-axis type dynamic loading apparatus based on piezoelectric ceramics. The apparatus comprises a sleeve, the piezoelectric ceramics, a pressure sensor, upper and lower connection blocks, and an MEMS microstructure, a support plate and an electric leading screw transmission mechanism are arranged in the sleeve, the upper connection block and the lower connection block are respectively provided with a spherical projection and a spherical groove matched with each other, the piezoelectric ceramics are clamped between the pressure sensor and an elastic support member, an outer rim of the upper connection block is connected with installation blocks through connecting rods uniformly distributed in a circumferential manner, the installation blocksare respectively provided with bulb plungers, and steel balls at the outer ends of the bulb plungers are respectively ejected into rectangular grooves of an outer wall of the sleeve. According to theapparatus, different pre-tightening forces can be flexibly applied to the piezoelectric ceramics, obtained measuring values of the pre-tightening forces are more accurate, the adjusting process for compensating parallelism errors of two operating surfaces of the piezoelectric ceramics becomes more smooth, the falling of micro-devices for the test can be avoided, and the test of dynamic characteristic parameters of the MEMS microstructure is facilitated.

Owner:BOHAI UNIV

A four-axis vibration excitation device of mems microstructure based on the base excitation method

InactiveCN108217582BReduce shear forceRegulation stabilityVibration testingMicrostructural devicesElectricityBaseboard

The invention discloses a MEMS microstructure four-axis vibration device based on a base excitation method, which includes a sleeve and a bottom plate, piezoelectric ceramics, a pressure sensor, upper and lower coupling blocks, elastic supports and MEMS microstructures; The upper end is provided with an annular top plate, and the microstructure is set on the annular top plate through an elastic support; guide shafts are uniformly distributed between the annular top plate and the bottom plate, and the lower connecting block is evenly distributed with guide arms that are passed through the sleeve wall and set in the On the guide shaft, a locking device is provided on the guide arm; matching spherical grooves and spherical protrusions are respectively provided on the upper and lower connecting blocks; piezoelectric ceramics are sandwiched between the pressure sensor and the elastic support; the upper The outer edge of the coupling block is pushed into the inner wall of the sleeve through the ball plunger. The device can apply different sizes of pre-tightening force to the piezoelectric ceramics, so that the obtained pre-tightening force measurement value is more accurate, and the adjustment process of compensating the parallelism error of the two working surfaces of the piezoelectric ceramics becomes smoother and smoother, which is convenient Test dynamic characteristic parameters.

Owner:BOHAI UNIV

MEMS micro-structure four-axis excitation device

InactiveCN108168813AReduce shear forceRegulation stabilityVibration testingMicro structureEngineering

The invention discloses a MEMS micro-structure four-axis excitation device. The four-axis excitation device comprises a sleeve, a bottom plate, a piezoelectric ceramic, a pressure sensor, an upper connecting block, a lower connecting block, an elastic supporting part and an MEMS micro-structure; an annular top plate is arranged at the upper end of the sleeve, the micro-structure is arranged on theannular top plate through the elastic supporting part; guide shafts are uniformly distributed between the annular top plate and the bottom plate, and guide support arms are uniformly distributed on the lower connecting block and penetrate through the sleeve wall and sleeve the guide shafts, and a locking device is arranged on each guide support arm; the upper connecting block and the lower connecting block are provided with a spherical groove and a spherical bulge that are matched; the piezoelectric ceramic is clamped between the pressure sensor and the elastic supporting piece; and tension springs are uniformly and circumferentially connected between the bottom surface of the upper connecting block and the guide support arms of the lower connecting block. According to the device, pre-tightening force of different sizes can be applied to the piezoelectric ceramic, and the obtained pre-tightening force measurement value is more accurate, so that the adjustment process of the parallelism error of the two working surfaces of the compensation piezoelectric ceramic becomes smoother, and the dynamic characteristic parameters can be conveniently tested.

Owner:BOHAI UNIV

MEMS microstructural four-axis shock excitation device using piezoelectric ceramics as excitation source

The invention discloses an MEMS microstructural four-axis shock excitation device using piezoelectric ceramics as an excitation source. The device comprises a sleeve, a baseboard, the piezoelectric ceramics, a pressure sensor, upper and lower linking blocks, an elastic support piece and an MEMS microstructure, wherein an annual top board is arranged at the upper end of the sleeve, and the microstructure is arranged on the annular top board via the elastic support piece; guiding shafts are uniformly distributed between the annular top board and the baseboard, guiding support arms are distributed on the lower linking block and pass through the sleeve wall to sleeve the guiding shafts, and a locking device is arranged on the guiding support arms; the upper and lower linking blocks are separately provided with a spherical groove and a spherical bump; the piezoelectric ceramics is clamped between the pressure sensor and the elastic support piece; and the outer edge of the upper linking block is ejected into the inner wall of the sleeve via ball plungers uniformly distributed and connected. The device can apply different sizes of pretightening force to the piezoelectric ceramics, so thatthe acquired measured value of the pretightening force is more accurate, and thus an adjustment process for compensating a parallelism error of two working surfaces of the piezoelectric ceramics canbecome smoother, and the tests of dynamic characteristic parameters are facilitated.

Owner:BOHAI UNIV

A four-axis dynamic loading device for mems microstructure based on piezoelectric ceramics

The invention discloses a MEMS microstructure four-axis dynamic loading device based on piezoelectric ceramics, which includes a sleeve, piezoelectric ceramics, a pressure sensor, upper and lower connecting blocks and MEMS microstructures; a support plate is arranged in the sleeve and the electric screw drive mechanism; the upper and lower connecting blocks are respectively provided with mutually matching spherical protrusions and spherical grooves; piezoelectric ceramics are clamped between the pressure sensor and the elastic support; the outer edge of the upper connecting block passes through The connecting rods evenly distributed on the circumference are connected with installation blocks, on which ball plungers are installed respectively, and the steel balls at the outer ends of the ball plungers are pushed into the rectangular grooves on the outer wall of the sleeve respectively. The device can flexibly apply different sizes of pre-tightening force to the piezoelectric ceramics, and at the same time make the measured value of the pre-tightening force more accurate, and can make the adjustment process of compensating the parallelism error of the two working surfaces of the piezoelectric ceramics smoother and smoother , can avoid the falling off of the micro-device used for testing, and is convenient for testing the dynamic characteristic parameters of the MEMS microstructure.

Owner:BOHAI UNIV

MEMS microstructure four-axis base excitation device driven by stacked piezoelectric ceramics

The invention discloses an MEMS microstructure four-axis base excitation device driven by stacked piezoelectric ceramics, comprising a sleeve, piezoelectric ceramic, a pressure sensor, upper and lowerconnecting blocks, a steel ball, an elastic supporting member and an MEMS microstructure, wherein an annular top plate and a bottom plate are arranged at both ends of the sleeve, and the microstructure is arranged on the annular top plate through the elastic supporting member; guiding shafts are uniformly arranged between the annular top plate and the bottom plate, guide supporting arms are uniformly distributed on the lower edge of the lower connecting block, are penetrated by the sleeve wall and are sheathed on the guiding shafts, and locking devices are respectively arranged on the guide supporting arms; conical grooves and spherical grooves are respectively formed in the upper and lower connecting blocks; and the piezoelectric ceramic is sandwiched between the pressure sensor and theelastic supporting member. The device can apply different pre-tightening forces to the piezoelectric ceramic, and meanwhile, the obtained pre-tightening force measurement value is more accurate, the adjustment process for compensating the parallelism error of two working surfaces of the piezoelectric ceramic can be smoother, and dynamic characteristic parameters can be conveniently tested.

Owner:BOHAI UNIV

A mems microstructure four-axis base excitation device based on piezoelectric ceramics

The invention discloses a MEMS microstructure four-axis base excitation device based on piezoelectric ceramics, which includes a sleeve, piezoelectric ceramics, a pressure sensor, an upper connection block, a steel ball, a lower connection block, an elastic support and a MEMS microstructure ;In the lower part of the sleeve, an electric screw drive mechanism is installed to drive the lower connecting block to move; on the opposite surfaces of the upper connecting block and the lower connecting block, there are respectively conical grooves and spherical grooves, piezoelectric ceramic clips The sleeve is held between the pressure sensor and the elastic support; guide shafts are evenly distributed along the circumference of the sleeve; sliding seats are respectively arranged on the guide shafts, and the upper coupling block and each sliding seat are respectively connected by tension springs. The device can apply different sizes of pre-tightening force to the stacked piezoelectric ceramics, and at the same time make the measured value of the pre-tightening force more accurate, and can make the adjustment process of compensating the parallelism error of the two working surfaces of the stacked piezoelectric ceramics more efficient. Smooth and smooth, it can avoid the falling off of the micro-device used in the test, and it is convenient to test the dynamic characteristic parameters.

Owner:BOHAI UNIV

MEMS microstructure three-axis excitation device with movable base structure

The invention discloses an MEMS microstructure three-axis excitation device with a movable base structure. The MEMS microstructure three-axis excitation device comprises a sleeve, a bottom plate, piezoelectric ceramic, a pressure sensor, upper and lower connecting blocks, a steel ball, an elastic supporting member and an MEMS microstructure; an annular top plate is arranged at the upper end of thesleeve, and the microstructure is arranged on the annular top plate through the elastic supporting member; guiding shafts are uniformly arranged between the top plate and the bottom plate, and guidesupporting arms penetrating through the sleeve wall and sleeving the guiding shafts are uniformly distributed on the lower connecting block; spherical grooves are respectively formed in the upper andlower connecting blocks, and tension springs are uniformly arranged on a circumference between the upper and lower connecting blocks; the piezoelectric ceramic is sandwiched between the pressure sensor and the elastic supporting member; and an electric screw transmission mechanism connected with a lower connecting block via screw is arranged at the lower part in the sleeve. The device can apply different pre-tightening forces to the piezoelectric ceramic, and meanwhile, the obtained pre-tightening force measurement value is more accurate, the adjustment process for compensating the parallelismerror of two working surfaces of the piezoelectric ceramic can be smoother, and dynamic characteristic parameters can be conveniently tested.

Owner:BOHAI UNIV

A mems microstructure four-axis base excitation device driven by stacked piezoelectric ceramics

The invention discloses a MEMS microstructure four-axis base excitation device driven by stacked piezoelectric ceramics, including sleeves, piezoelectric ceramics, pressure sensors, upper and lower connecting blocks, steel balls, elastic supports and MEMS microstructures. The structure; the two ends of the sleeve are respectively provided with an annular top plate and a bottom plate, and the microstructure is set on the annular top plate through an elastic support; there are guide shafts evenly distributed between the annular top plate and the bottom plate, and guide supports are evenly distributed on the outer edge of the lower connection block The arms are respectively passed through the sleeve wall and set on the guide shaft, and locking devices are respectively provided on the guide arms; conical grooves and spherical grooves are respectively provided on the upper coupling block and the lower coupling block; The piezoelectric ceramic is sandwiched between the pressure sensor and the elastic support. The device can apply different sizes of pre-tightening force to the stacked piezoelectric ceramics, and at the same time make the measured value of the pre-tightening force more accurate, and can make the adjustment process of compensating the parallelism error of the two working surfaces of the stacked piezoelectric ceramics more efficient. Smooth and smooth, easy to test dynamic characteristic parameters.

Owner:BOHAI UNIV

A three-axis vibration excitation device that can excite mems microstructure off-chip

InactiveCN108181068BNo stuck issuesReduce shear forceSubsonic/sonic/ultrasonic wave measurementUsing wave/particle radiation meansElectricitySteel ball

The invention discloses a three-axis vibration excitation device that can excite MEMS microstructures off-chip, including sleeves and bottom plates, piezoelectric ceramics, pressure sensors, upper and lower connecting blocks, steel balls, elastic supports and MEMS microstructures. Structure; there is an annular top plate on the upper end of the sleeve, and the microstructure is set on the annular top plate through elastic supports; there are guide shafts evenly distributed between the top and bottom plates, and the lower connecting blocks are uniformly distributed through the sleeve wall and set in the Guide arm on the guide shaft; spherical grooves and tapered grooves for holding steel balls are respectively arranged on the upper and lower connecting blocks, and tension springs are evenly distributed on the circumference between the upper and lower connecting blocks; piezoelectric ceramics It is sandwiched between the pressure sensor and the elastic support; locking devices are respectively provided on the guide arms. The device can apply different sizes of pre-tightening force to the piezoelectric ceramics, so that the obtained pre-tightening force measurement value is more accurate, and the adjustment process of compensating the parallelism error of the two working surfaces of the piezoelectric ceramics becomes smoother and smoother, which is convenient Test dynamic characteristic parameters.

Owner:BOHAI UNIV

Four-axis vibration excitation device for testing the dynamic characteristics of mems microstructures

InactiveCN108217586BNo stuck issuesReduce shear forceVibration testingMicrostructural devicesElectricitySteel ball

The invention discloses a four-axis excitation device for testing the dynamic characteristics of MEMS microstructures, which includes a sleeve, piezoelectric ceramics, pressure sensors, upper and lower coupling blocks, steel balls and MEMS microstructures; inside the sleeve There is a support plate and an electric screw drive mechanism; a spherical groove and a tapered groove for holding steel balls are respectively arranged on the upper and lower connecting blocks; piezoelectric ceramics are clamped between the pressure sensor and the elastic support; An installation block is connected to the outer edge of the upper connection block through connecting rods uniformly distributed on the circumference, ball plungers are respectively installed on the installation blocks, and steel balls at the outer ends of the ball plunger are pushed into rectangular grooves on the outer wall of the sleeve respectively. The device can flexibly apply different sizes of pre-tightening force to the piezoelectric ceramics, and at the same time make the measured value of the pre-tightening force more accurate, and can make the adjustment process of compensating the parallelism error of the two working surfaces of the piezoelectric ceramics smoother and smoother , can avoid the falling off of the micro-device used for testing, and is convenient for testing the dynamic characteristic parameters of the MEMS microstructure.

Owner:BOHAI UNIV

Four-axis base excitation device for testing the dynamic characteristics of mems microstructures

InactiveCN108217587BNo stuck issuesReduce shear forceVibration testingMicrostructural devicesMicro devicesEngineering

The invention discloses a four-axis base excitation device for testing the dynamic characteristics of MEMS microstructures, which includes sleeves, stacked piezoelectric ceramics, pressure sensors, upper and lower connecting blocks, steel balls and MEMS microstructures; There is a support plate and an electric screw drive mechanism inside the cylinder; spherical grooves and conical grooves for holding steel balls are respectively arranged on the upper and lower connecting blocks; the stacked piezoelectric ceramics are clamped between the pressure sensor and the elastic support between the pieces; ball plungers are evenly distributed on the upper connection block, and the outer end of the ball plunger pushes into the rectangular groove on the inner wall of the sleeve. The device can flexibly apply different sizes of pre-tightening force to the stacked piezoelectric ceramics, and at the same time make the measured value of the pre-tightening force more accurate, and can make the adjustment process of compensating the parallelism error of the two working surfaces of the stacked piezoelectric ceramics easy. It is smoother and smoother, greatly reduces the shear force between the layers of the stacked piezoelectric ceramics, can avoid the falling off of the micro-device used for testing, and is convenient for testing the dynamic characteristic parameters of the MEMS microstructure.

Owner:BOHAI UNIV

A mems microstructure three-axis base excitation device based on piezoelectric ceramics

InactiveCN108168818BNo stuck issuesReduce shear forceTelevision system detailsPiezoelectric/electrostriction/magnetostriction machinesElectricitySteel ball

The invention discloses a MEMS microstructure three-axis base excitation device based on piezoelectric ceramics, which includes a sleeve, piezoelectric ceramics, a pressure sensor, an upper connection block, a steel ball, a lower connection block, an elastic support and a MEMS microstructure ;In the lower part of the sleeve, an electric screw drive mechanism is installed to drive the lower connecting block to move; on the opposite surfaces of the upper connecting block and the lower connecting block, there are respectively conical grooves and spherical grooves, piezoelectric ceramic clips The sleeve is held between the pressure sensor and the elastic support; guide shafts are evenly distributed along the circumference of the sleeve; sliding seats are respectively arranged on the guide shafts, and the upper coupling block and each sliding seat are respectively connected by tension springs. The device can apply different sizes of pre-tightening force to the stacked piezoelectric ceramics, and at the same time make the measured value of the pre-tightening force more accurate, and can make the adjustment process of compensating the parallelism error of the two working surfaces of the stacked piezoelectric ceramics more efficient. Smooth and smooth, it can avoid the falling off of the micro-device used in the test, and it is convenient to test the dynamic characteristic parameters.

Owner:BOHAI UNIV

A mems microstructure three-axis excitation device driven by piezoelectric ceramics

ActiveCN108168815BReduce shear forceRegulation stabilitySubsonic/sonic/ultrasonic wave measurementUsing wave/particle radiation meansEngineeringCeramic

The invention discloses an MEMS micro-structure three-axis type excitation device driven by piezoelectric ceramics. The MEMS micro-structure three-axis excitation device comprises a sleeve, a stackedpiezoelectric ceramic, a pressure sensor, an upper connecting block, a lower connecting block and an MEMS micro structure; an annular top plate is arranged at the upper end of the sleeve, the MEMS micro-structure is installed on the annular top plate through the elastic supporting part.; the upper end of the lower connecting block is a hemispheric round head and abuts against the bottom surface ofthe upper connecting block; the piezoelectric ceramic is clamped between the pressure sensor and the elastic supporting piece; ball head plungers are uniformly distributed between the upper connecting block and the sleeve, and the inner ends of the ball head plungers are jacked into a sliding groove in the outer edge of the upper connecting block, and guide shafts are uniformly distributed between the annular top plate and the bottom plate. According to the device, pre-tightening force of different sizes can be applied to the stacked piezoelectric ceramics, the obtained pre-tightening force measurement value is more accurate, so that the adjustment process of the parallelism error of the two working surfaces of the stacked piezoelectric ceramic can be smoother, the shearing force of the layers of the stacked piezoelectric ceramics is reduced, and the dynamic characteristic parameters of the MEMS micro-structure can be tested conveniently.

Owner:广林特装车(锦州)有限公司

A mems microstructure four-axis excitation device driven by piezoelectric ceramics

The invention discloses a MEMS microstructure four-axis excitation device driven by piezoelectric ceramics, comprising a sleeve, stacked piezoelectric ceramics, a pressure sensor, upper and lower connecting blocks and MEMS microstructures; the lower end of the upper connecting block is provided with The hemispherical round head is pressed on the lower connecting block; the piezoelectric ceramic is clamped between the pressure sensor and the elastic support; the ball plunger is evenly distributed on the circumference between the upper connecting block and the sleeve, and the inner end of the ball plunger The steel ball is pushed into the chute on the outer edge of the upper coupling block, and the guide shaft is evenly distributed on the circumference between the annular top plate and the bottom plate, and the guide arms evenly distributed on the outer edge of the lower coupling block are respectively passed through by the sleeve and set on the guide shaft. superior. The device can flexibly apply different sizes of pre-tightening force to the stacked piezoelectric ceramics, so that the measured value of the pre-tightening force is more accurate, and the adjustment process of compensating the parallelism error of the two working surfaces of the stacked piezoelectric ceramics becomes smoother and smoother. , reducing the shear force between the layers of the stacked piezoelectric ceramics, which is convenient for testing the dynamic characteristic parameters of the MEMS microstructure.

Owner:BOHAI UNIV

Tri-axial exciting apparatus capable of off-chip excitation of MEMS microstructure

InactiveCN108181068ANo stuck issuesReduce shear forceSubsonic/sonic/ultrasonic wave measurementUsing wave/particle radiation meansElectricityEngineering

The invention discloses a tri-axial exciting apparatus capable of off-chip excitation of an MEMS microstructure. The apparatus comprises a sleeve, a base plate, piezoelectric ceramics, a pressure sensor, an upper connection block, a lower connection block, a steel ball, elastic support members and the MEMS microstructure, the upper end of the sleeve is provided with an annular top board, the microstructure is arranged above the annular top board through the elastic support members, guide shafts are uniformly distributed between the top board and the base plate, the lower connection block is uniformly distributed with guide support arms penetrated by a sleeve wall and sleeving the guide shafts, the upper connection block and the lower connection block are respectively provided with a spherical groove and a tapered groove for clamping the steel ball, extension springs are uniformly distributed between the upper connection block and the lower connection block in a circumferential manner,the piezoelectric ceramics are clamped between the pressure sensor and the elastic support members, and the guide support arms are respectively provided with locking devices. According to the apparatus, different pre-tightening forces can be applied to the piezoelectric ceramics, obtained measuring values of the pre-tightening forces are more accurate, the adjusting process for compensating parallelism errors of two operating surfaces of the piezoelectric ceramics becomes more smooth, and the test of dynamic characteristic parameters is facilitated.

Owner:BOHAI UNIV

A mems microstructure three-axis vibration excitation device based on base excitation method

InactiveCN108168817BReduce shear forceNo stuck issuesTelevision system detailsImpedence networksElectricityEngineering

The invention discloses a MEMS microstructure three-axis vibration device based on a base excitation method, which includes a sleeve, piezoelectric ceramics, a pressure sensor, upper and lower connecting blocks, elastic supports and a MEMS microstructure; The end is provided with an annular top plate and a bottom plate, and the microstructure is set on the annular top plate through an elastic support; guide shafts are evenly distributed between the annular top plate and the bottom plate, and the lower connecting block is provided with a guide arm and is passed through and sleeved by the sleeve wall. On the guide shaft, there are locking devices on the guide arm respectively; on the upper and lower coupling blocks, there are respectively provided spherical grooves and protrusions that cooperate with each other; piezoelectric ceramics are sandwiched between the pressure sensor and the elastic support ; The outer edge of the upper connection block is pushed into the inner wall of the sleeve through the ball plunger. The device can apply different sizes of pre-tightening force to the piezoelectric ceramics, so that the obtained pre-tightening force measurement value is more accurate, and the adjustment process of compensating the parallelism error of the two working surfaces of the piezoelectric ceramics becomes smoother and smoother, which is convenient Test dynamic characteristic parameters.

Owner:BOHAI UNIV

A three-axis excitation device that can load impact loads on mems microstructures

The invention discloses a three-axis excitation device capable of loading impact loads on MEMS microstructures, comprising a sleeve, stacked piezoelectric ceramics, pressure sensors, upper and lower coupling blocks and MEMS microstructures; The supporting plate and the screw nut are connected to the electric screw transmission mechanism of the lower connecting block; the upper and lower connecting blocks are respectively provided with mutually matching spherical protrusions and spherical grooves; the stacked piezoelectric ceramics are clamped between the pressure sensor and the elastic Between the supports; on the upper coupling block, ball plungers are evenly distributed, the outer ends of which are pushed into the rectangular grooves on the inner wall of the sleeve, and guide shafts passing through the lower coupling block are evenly distributed in the sleeve. The device can more flexibly apply different sizes of pre-tightening force to the stacked piezoelectric ceramics, so that the obtained pre-tightening force measurement value is more accurate, and can make the adjustment process of compensating the parallelism error of the two working surfaces of the stacked piezoelectric ceramics easier. It is smoother and smoother, reducing the shear force between the layers of the stacked piezoelectric ceramics, which is convenient for testing the dynamic characteristic parameters of the MEMS microstructure.

Owner:BOHAI UNIV

A mems microstructure three-axis pedestal excitation device driven by stacked piezoelectric ceramics

InactiveCN108225701BNo stuck issuesReduce shear forceSubsonic/sonic/ultrasonic wave measurementUsing wave/particle radiation meansElectricityEngineering

Owner:BOHAI UNIV

A mems microstructure four-axis vibration device with piezoelectric ceramics as the excitation source

InactiveCN108217585BReduce shear forceRegulation stabilityVibration testingMicrostructural devicesElectricityBaseboard

Owner:BOHAI UNIV

A four-axis excitation device that can load impact loads on mems microstructures

The invention discloses a four-axis excitation device capable of applying impact loads to MEMS microstructures, comprising a sleeve, stacked piezoelectric ceramics, pressure sensors, upper and lower coupling blocks and MEMS microstructures; The supporting plate and the electric screw drive mechanism connected to the lower connecting block; the upper and lower connecting blocks are respectively provided with mutually matching spherical protrusions and spherical grooves; stacked piezoelectric ceramics are clamped between the pressure sensor and the elastic support The upper connection block is evenly connected with ball plungers, and the outer ends of the ball plungers push into the rectangular grooves on the inner wall of the sleeve. The device can flexibly apply different sizes of pre-tightening force to the stacked piezoelectric ceramics, and at the same time make the measured value of the pre-tightening force more accurate, and can make the adjustment process of compensating the parallelism error of the two working surfaces of the stacked piezoelectric ceramics easy. It is smoother and smoother, greatly reduces the shear force between the layers of the stacked piezoelectric ceramics, can avoid the falling off of the micro-device used for testing, and is convenient for testing the dynamic characteristic parameters of the MEMS microstructure.

Owner:BOHAI UNIV

MEMS (Micro-electromechanical System) microstructure triaxial exciting device with piezoelectric ceramic as exciting source

The invention discloses an MEMS (Micro-electromechanical System) microstructure triaxial exciting device with piezoelectric ceramic as an exciting source. The MEMS microstructure triaxial exciting device comprises a sleeve, the piezoelectric ceramic, a pressure sensor, an upper connecting block, a lower connecting block, elastic supporting members and an MEMS microstructure, wherein an annular topplate and a base plate are respectively arranged at two ends of the sleeve; the microstructure is arranged on the annular top plate by the elastic supporting member; guiding shafts are uniformly distributed between the annular top plate and the base plate; guiding support arms are uniformly distributed on the edge of the lower connecting block, respectively penetrate through the wall of the sleeve and sleeve the corresponding guiding shafts; locking devices are respectively arranged on the guiding support arms; a conical groove and a bump which are matched with each other are respectively formed in the upper connecting block and the lower connecting block; the piezoelectric ceramic is clamped between the pressure sensor and the elastic supporting members; and the outer edge of the upper connecting block is positioned in the sleeve by a ball head plunger. The device has the advantages that pretightening forces with different strengths can be applied to the piezoelectric ceramic, the obtained pretightening force measurement value is more accurate, the adjusting process of compensating parallelism error between two working faces of the piezoelectric ceramic is enabled to smoother, and dynamic characteristic parameters are favorably tested.

Owner:BOHAI UNIV

A four-axis excitation device that can dynamically drive mems microstructures

InactiveCN108163804BReduce shear forceRegulation stabilityVibration testingMicrostructural devicesEngineeringCeramic

The invention discloses a four-axis excitation device capable of dynamically driving a MEMS microstructure, which includes a sleeve and a bottom plate, piezoelectric ceramics, a pressure sensor, upper and lower connecting blocks, elastic supports and a MEMS microstructure; There is a ring-shaped top plate, and the microstructure is set on the ring-shaped top plate through elastic supports; guide shafts are evenly distributed between the ring-shaped top plate and the bottom plate, and the lower connecting block is evenly distributed with guide arms, which are passed through the sleeve wall and sleeved on the guide shaft On the bottom surface of the upper connection block, a spherical protrusion is arranged at the center, and a tension spring is evenly distributed on the circumference between the bottom surface of the upper connection block and the guide arm of the lower connection block, and the spherical protrusion is elastically pressed on the lower connection block by the tension spring; The piezoelectric ceramic is sandwiched between the pressure sensor and the elastic support. The device can apply different sizes of pre-tightening force to the piezoelectric ceramics, so that the obtained pre-tightening force measurement value is more accurate, and the adjustment process of compensating the parallelism error of the two working surfaces of the piezoelectric ceramics becomes smoother and smoother, which is convenient Test dynamic characteristic parameters.

Owner:BOHAI UNIV

A three-axis dynamic loading device for mems microstructure based on piezoelectric ceramics

InactiveCN108217589BReduce shear forceRegulation stabilityVibration testingMicrostructural devicesEngineeringSteel ball

The invention discloses a MEMS microstructure three-axis dynamic loading device based on piezoelectric ceramics, which includes a sleeve, stacked piezoelectric ceramics, a pressure sensor, upper and lower connecting blocks and a MEMS microstructure; Support plate and electric screw drive mechanism; spherical protrusions and spherical grooves are respectively provided between the upper and lower connecting blocks; stacked piezoelectric ceramics are clamped between the pressure sensor and the elastic support; outside the upper connecting block The edge is connected with mounting blocks through connecting rods evenly distributed on the circumference, and ball plungers are respectively installed on the mounting blocks, and the steel balls at the outer ends of the ball plungers are pushed into the rectangular grooves on the outer wall of the sleeve. The device can more flexibly apply different sizes of pre-tightening force to the stacked piezoelectric ceramics, so that the obtained pre-tightening force measurement value is more accurate, and the adjustment process of compensating the parallelism error of the two working surfaces of the stacked piezoelectric ceramics can be changed. It is smoother and smoother, reducing the shear force between the layers of the stacked piezoelectric ceramics, and it is convenient to test the dynamic characteristic parameters of the MEMS microstructure.

Owner:BOHAI UNIV

A mems microstructure four-axis off-chip vibration device based on the inverse piezoelectric effect

The invention discloses a MEMS microstructure four-axis off-chip vibration device based on the inverse piezoelectric effect, which includes a sleeve, stacked piezoelectric ceramics, a pressure sensor, upper and lower connecting blocks and a MEMS microstructure; There is a support plate and an electric screw drive mechanism connected with the lower connecting block; the lower end of the upper connecting block is provided with a hemispherical round head and pressed on the lower connecting block; the piezoelectric ceramic is clamped between the pressure sensor and the elastic support; Between the upper connecting block and the sleeve, ball plungers are evenly distributed on the circumference, and the steel balls at the inner end of the ball plunger are pushed into the chute on the outer edge of the upper connecting block, and there are evenly distributed balls passing through the lower connecting block in the sleeve. guide shaft. The device can flexibly apply different sizes of pre-tightening force to the stacked piezoelectric ceramics, so that the measured value of the pre-tightening force is more accurate, and the adjustment process of compensating the parallelism error of the two working surfaces of the stacked piezoelectric ceramics becomes smoother and smoother. , reducing the shear force between the layers of the stacked piezoelectric ceramics, which is convenient for testing the dynamic characteristic parameters of the MEMS microstructure.

Owner:BOHAI UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com