Tri-axial exciting apparatus capable of off-chip excitation of MEMS microstructure

A vibration excitation device and microstructure technology, applied in the testing of machine/structural components, measurement devices, vibration testing, etc., can solve the problem of inaccurate preload or piezoelectric ceramic output force, inflexibility, and increased error in measurement results and other problems, to avoid the interference of the pressure sensor, smooth the adjustment process, and reduce the shear force.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

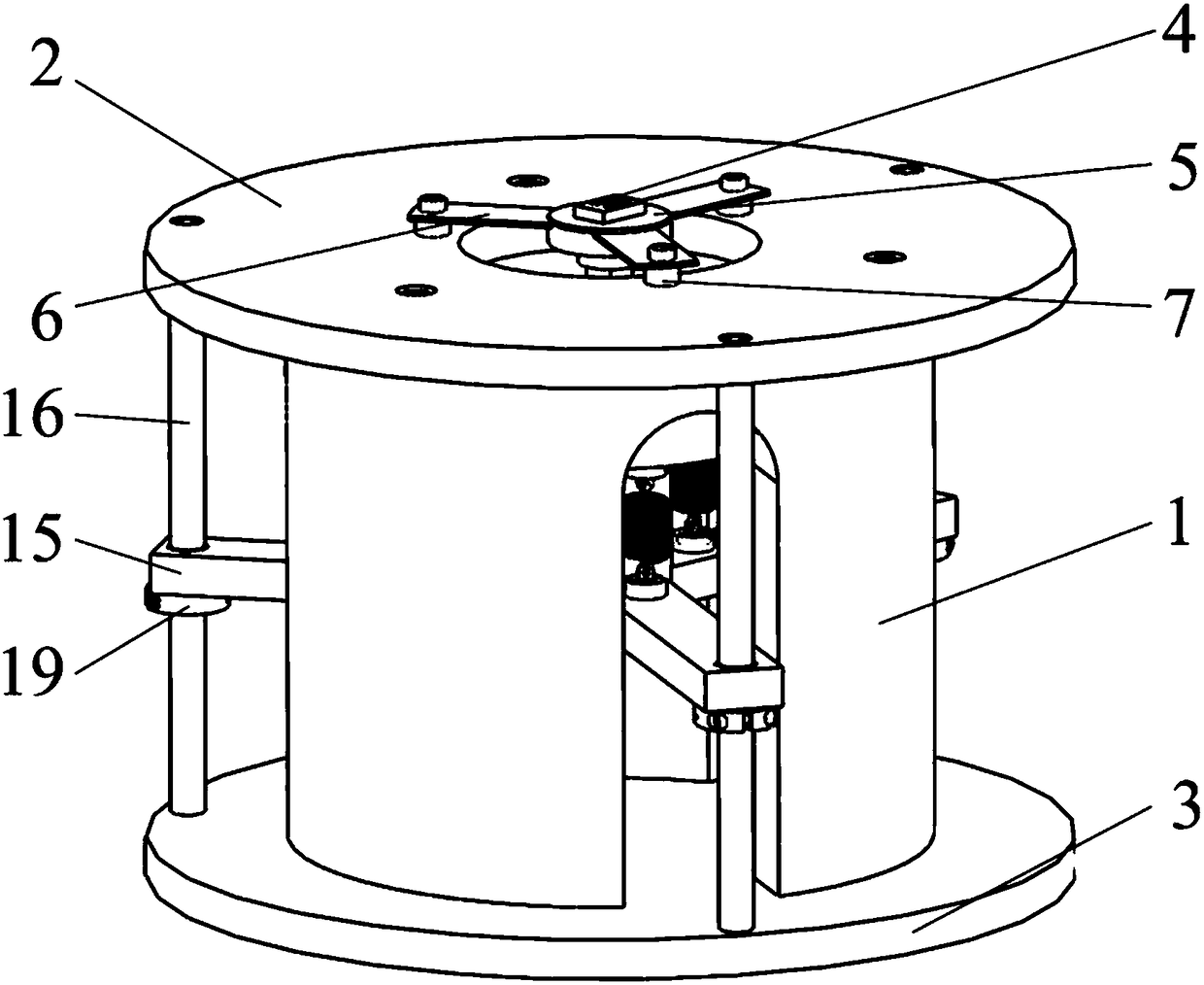

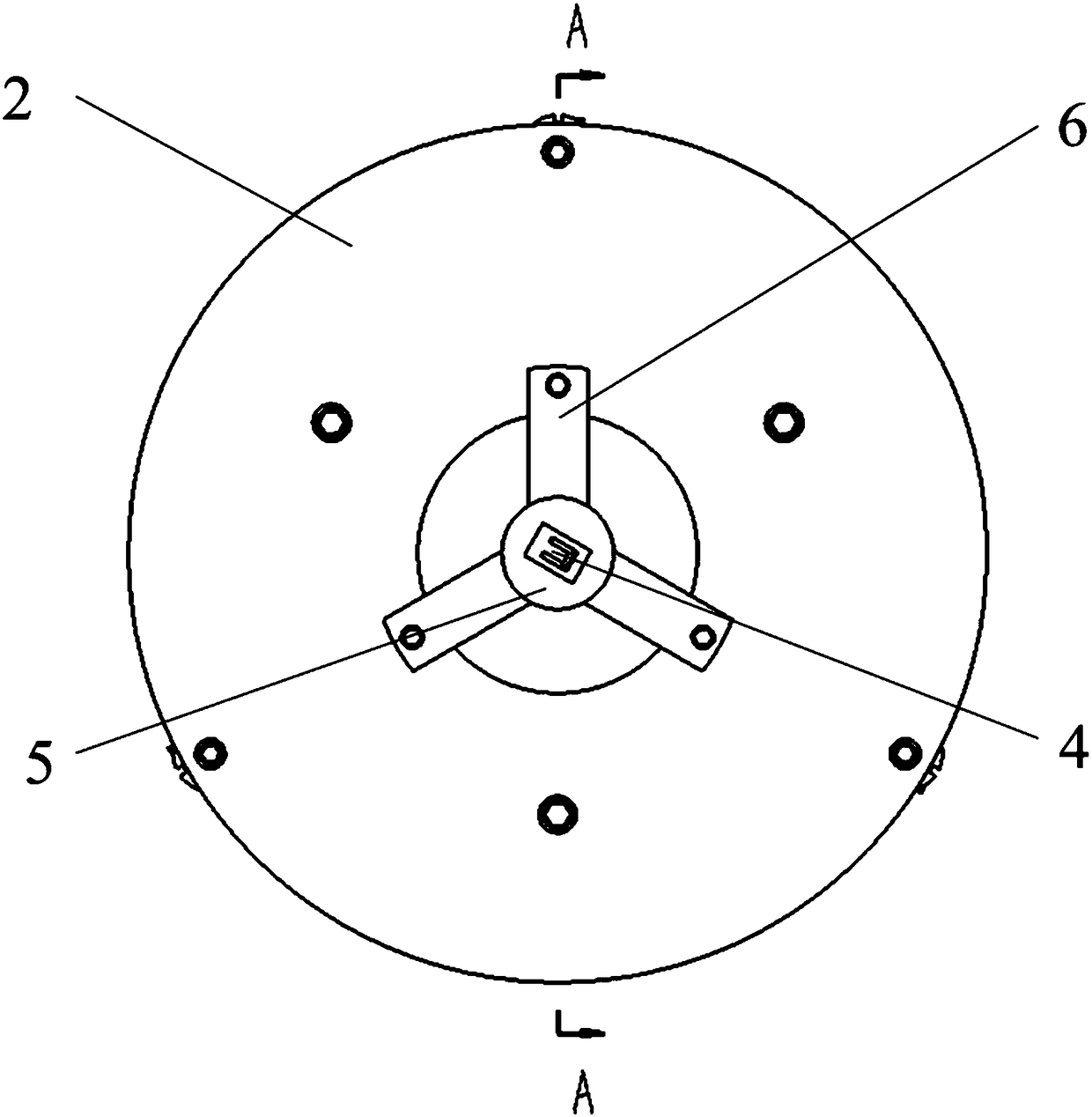

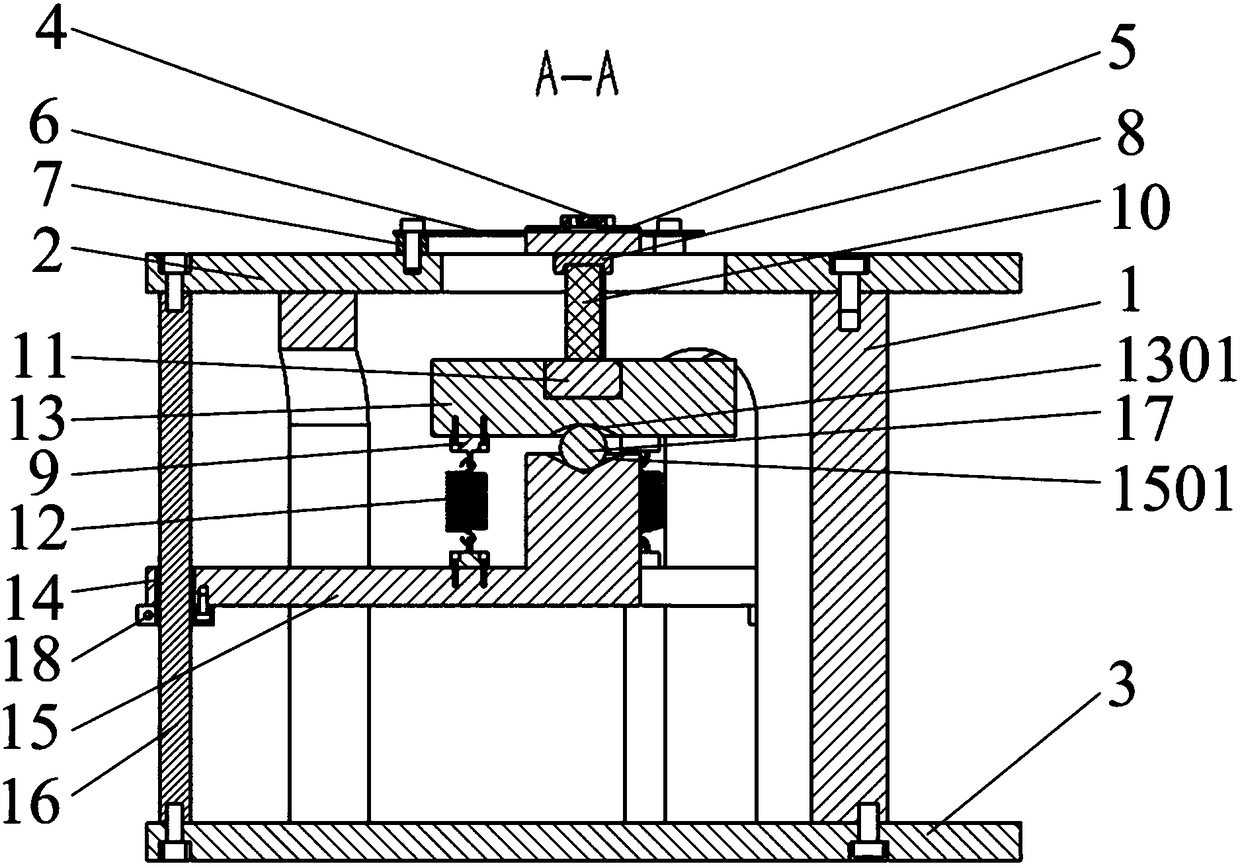

[0038] Such as Figure 1 to Figure 6 As shown, the present invention relates to a three-axis vibration excitation device that can excite MEMS microstructures off-chip, including a hollow sleeve 1, and stacked piezoelectric ceramics 10 and pressure sensors 11 are arranged in the sleeve 1. As well as a movable base composed of an upper coupling block 13, a steel ball 17 and a lower coupling block 15, an elastic support 6 and a MEMS microstructure 4 are arranged on the sleeve 1.

[0039] An annular top plate 2 and a bottom plate 3 with equal outer diameters and larger than the outer diameter of the sleeve are respectively fixed by screws on the top and bottom of the sleeve 1 , and the MEMS microstructure 4 is mounted on the annular top plate 2 through elastic supports 6 . The elastic supporting member 6 is composed of a cylindrical pressing piece 601 and three radially arranged supporting pieces 602 uniformly distributed on the outer edge of the pressing piece 601. The thickness ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com