Electroplating wastewater treatment device

A technology for electroplating wastewater and treatment device, which is used in metallurgical wastewater treatment, water/sewage treatment, neutralization water/sewage treatment, etc. It can solve the problems that the internal sludge cannot be precipitated in a timely and effective manner, the internal reaction is affected, and there are many impurities. To achieve the effect of easy addition or replacement, controllable stirring force, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In order to further explain the technical means and effects adopted by the present invention to achieve the intended purpose of the invention, the specific implementation, features and effects of the electroplating wastewater treatment device proposed according to the present invention are described in detail below.

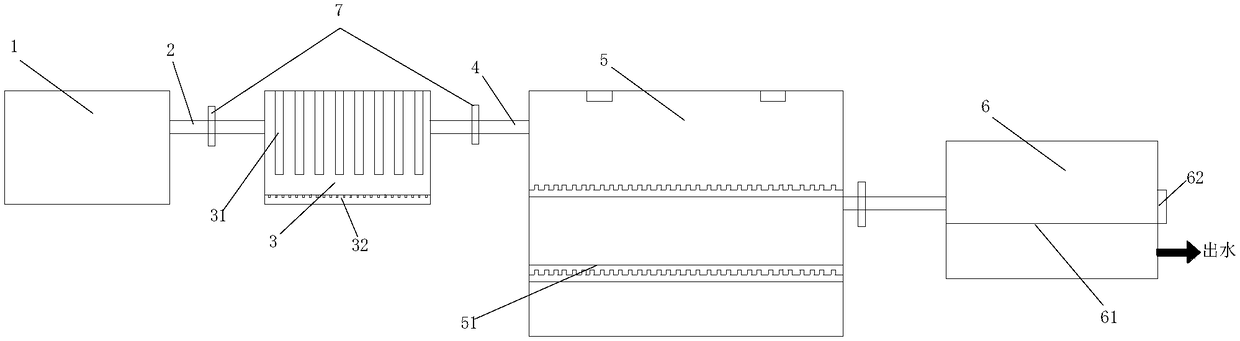

[0032] Such as figure 1 As shown, the present invention discloses a treatment device for electroplating wastewater, comprising:

[0033] Wastewater collection tank 1 is used to collect electroplating wastewater to be treated, including mixed wastewater formed by various electroplating heavy metal wastewater produced by electroplating factories, and adjust the pH value of the wastewater to be less than 5 by acid and alkali;

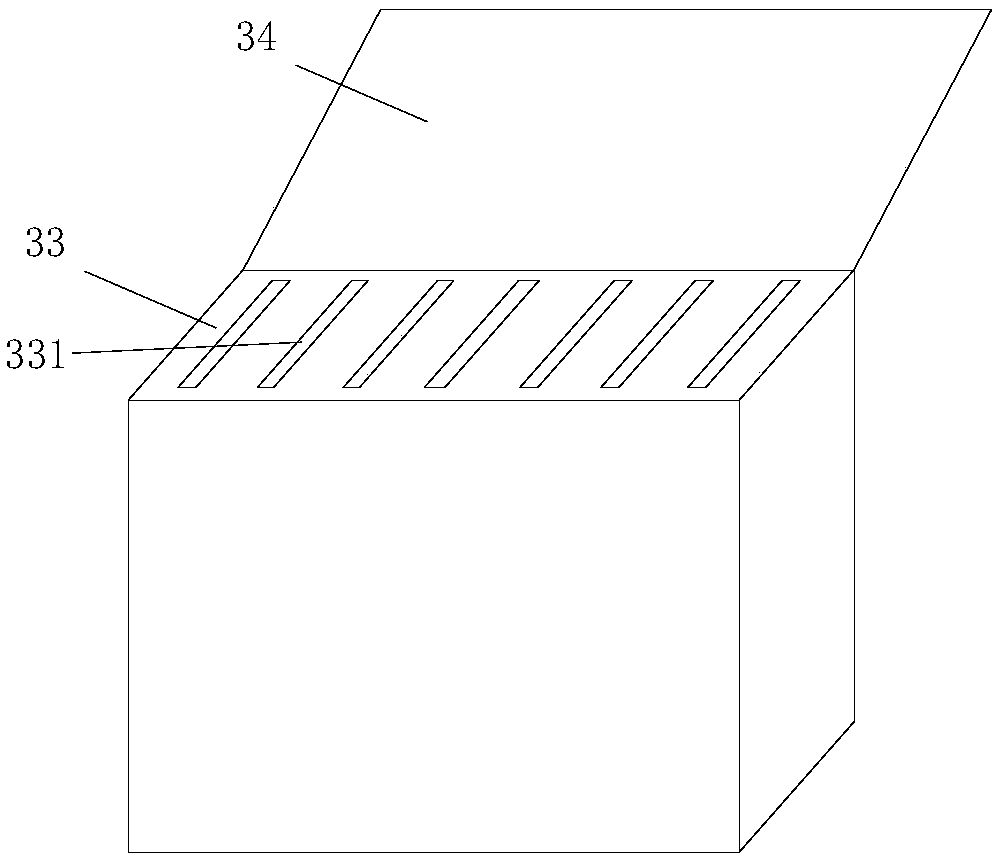

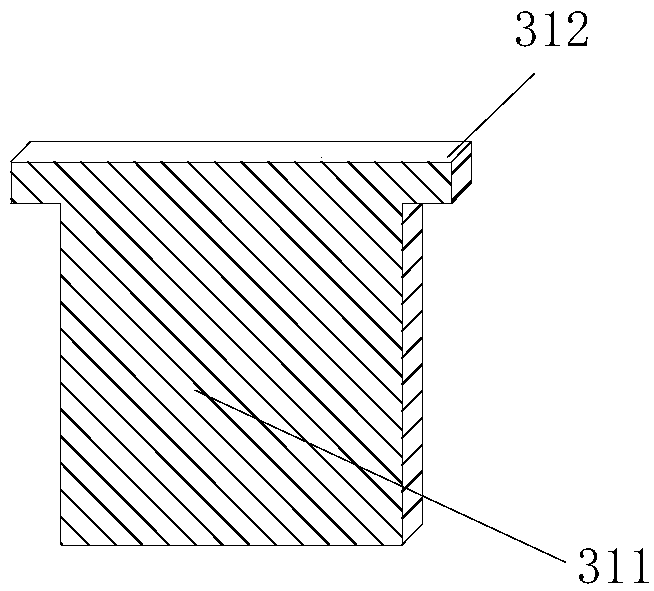

[0034] The pretreatment reaction tank 3 is connected to the waste water collection tank 1 through the first pipeline 2. There are multiple groups of electrolytic material mounting seats 31 arranged in the pretreatment reaction tank 3 f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com