Textile machine yarn storage device

A machine storage and textile technology, which is applied to spinning machines, textiles and papermaking, and continuous winding spinning machines, can solve the problems of large space occupation, avoid excessive space occupation, high yarn storage efficiency, Avoid the effect of excessive yarn winding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Further detailed explanation through specific implementation mode below:

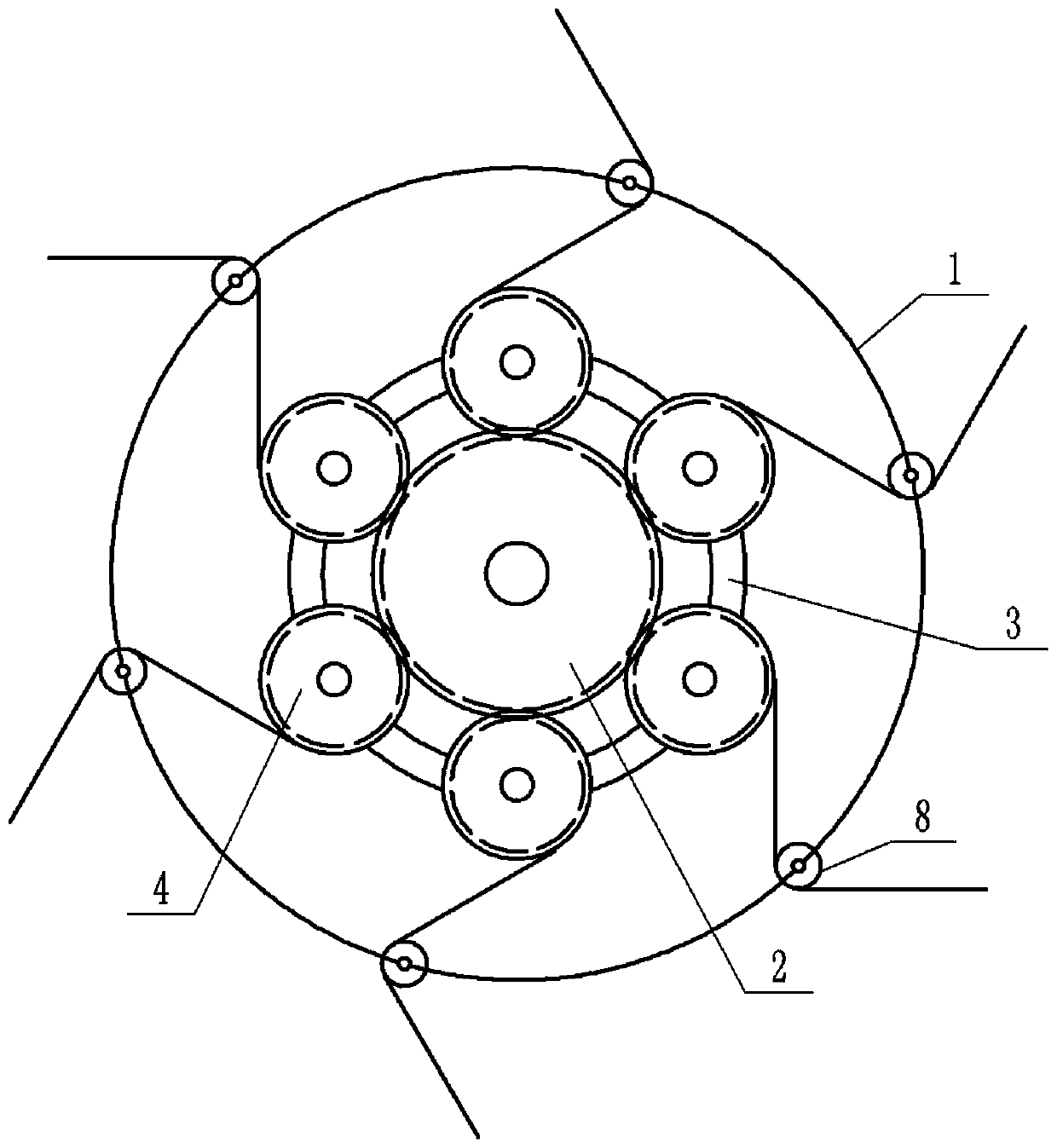

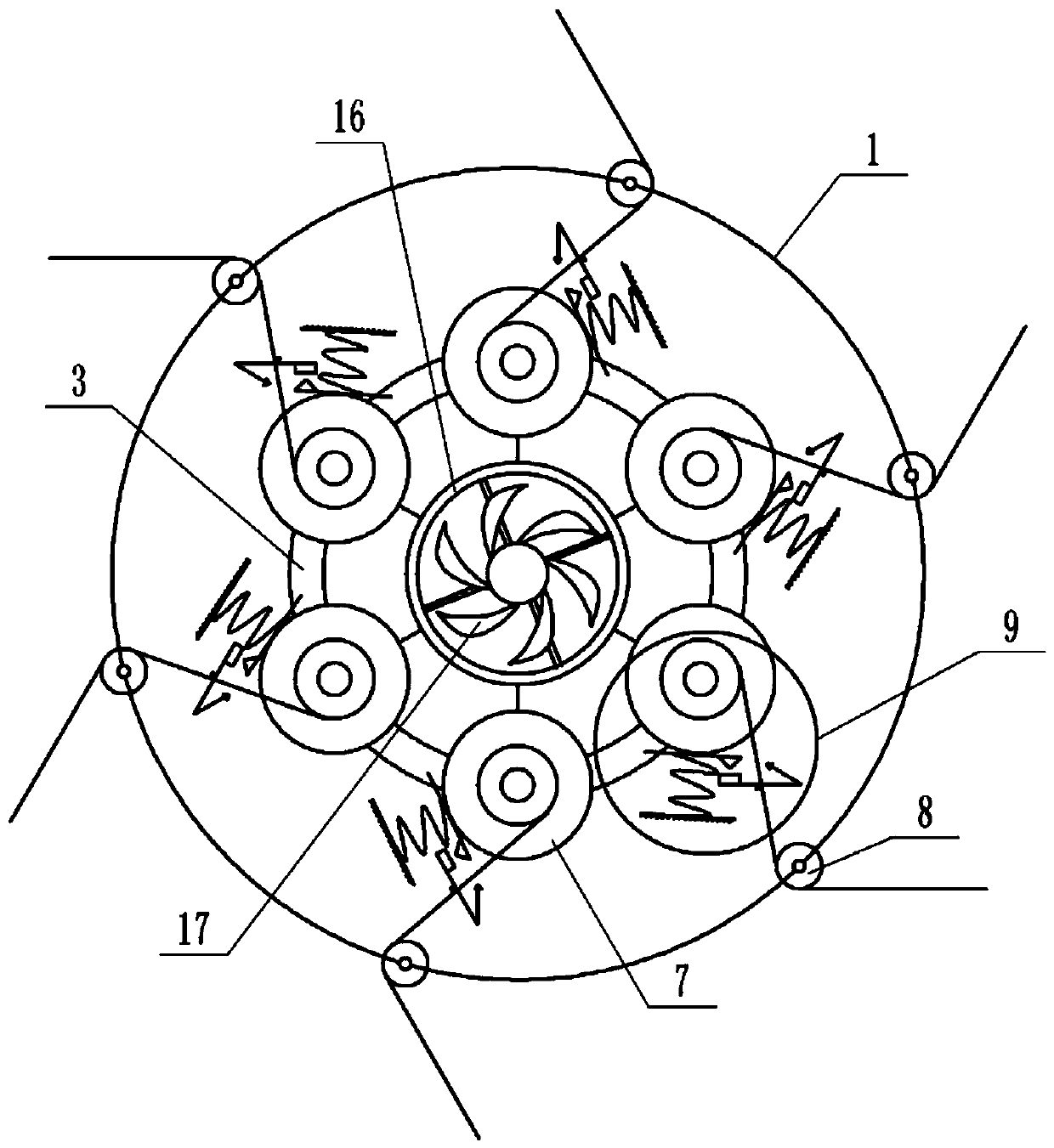

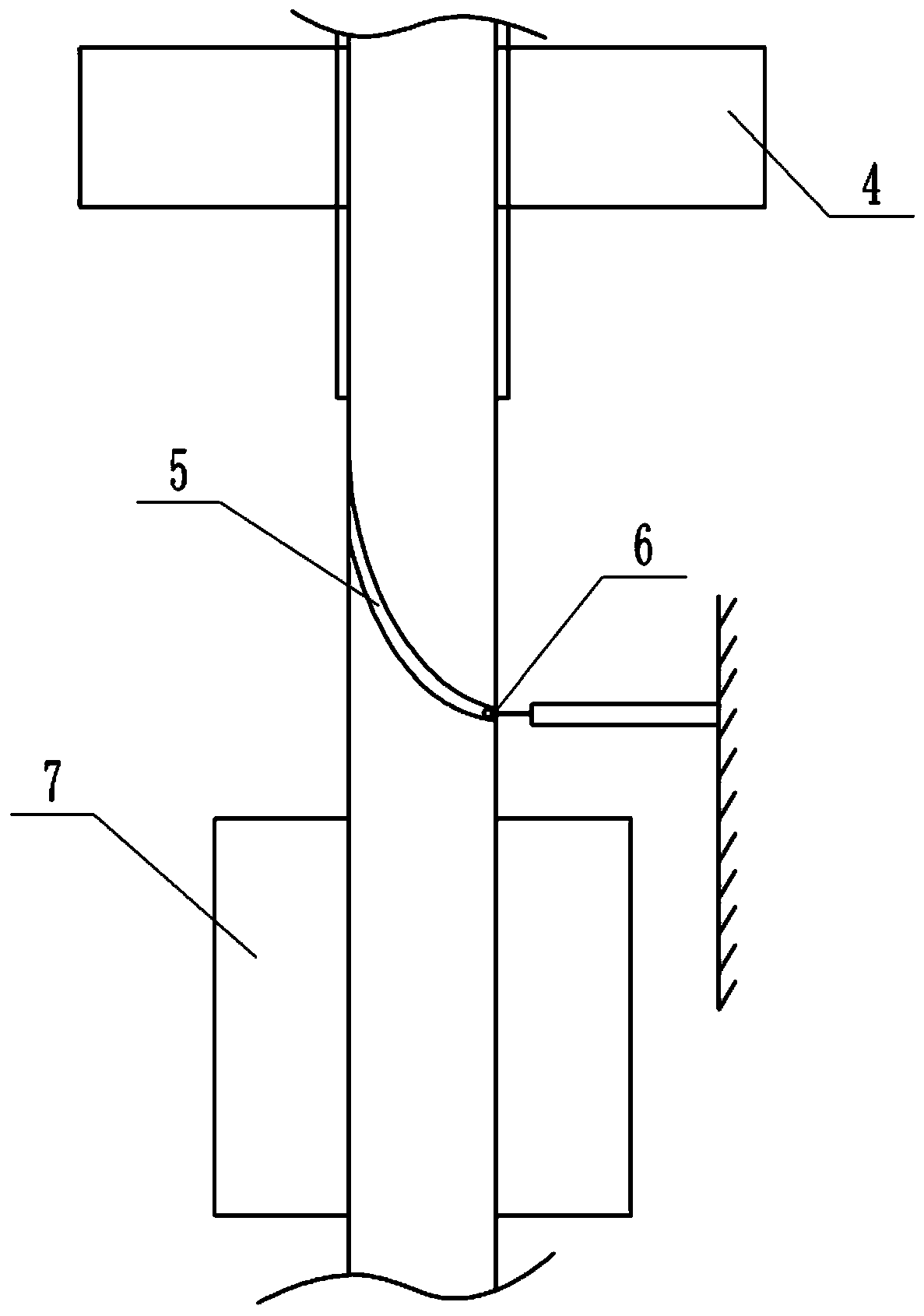

[0020] The reference signs in the drawings of the description include: auxiliary roller fixing frame 1, sun gear 2, planetary carrier 3, planetary gear 4, chute 5, slider 6, yarn storage roller 7, tension roller 8, yarn breaking mechanism 9 , pressing plate 10, stage clip 11, cut off lever 12, briquetting block 13, bearing block 14, cutting plate 15, air duct 16, ash-absorbing blade 17.

[0021] The embodiment of textile machine yarn storage device is basically as attached figure 1 Shown: the planetary gear train including the motor, the frame, the rotation connecting frame and the auxiliary roller fixing frame 1 arranged on the outer peripheral frame of the planetary gear train, the planetary gear train including the sun gear 2 driven by the motor, the fixed connecting frame The planetary carrier 3 and several planetary gears 4 meshed on the outer periphery of the sun gear 2 and rotatably conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com