A preparing process of antibacterial composite fibers

A composite fiber, preparation process technology, applied in fiber treatment, light/infrared/X-ray fiber treatment, detergent composition, etc., can solve the problems of simple processing technology, no antibacterial and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

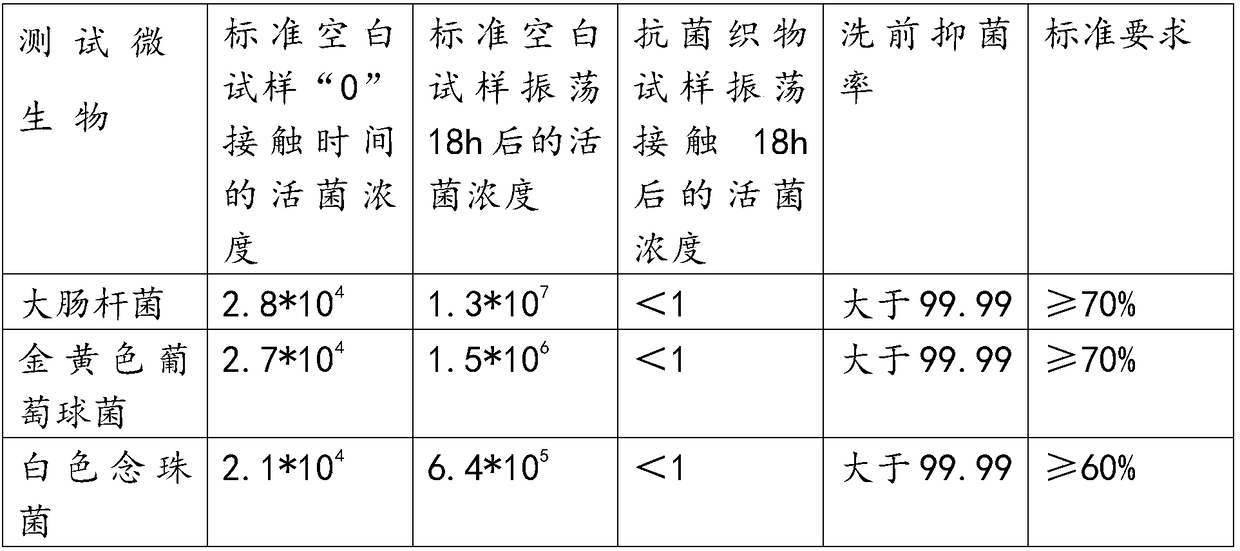

Examples

Embodiment Construction

[0022] The present invention will be described in further detail below.

[0023] A preparation process of antibacterial composite fiber, comprising the following steps:

[0024] Include the following steps:

[0025] S1. For initial washing, immerse the composite fiber in clean water for stirring and cleaning, and add deodorant and detergent at the same time. The water temperature is controlled at 75-95°C, and the cleaning time is 60-120 minutes;

[0026] S2, high-temperature sterilization, dehydrating the composite fibers that have been washed in step S1, and then performing high-temperature sterilization at a temperature of 200-300°C;

[0027] S3. Ultraviolet treatment, irradiating the composite fiber dried in step S2 under an ultraviolet lamp, and the irradiation time is 4-6h;

[0028] S4, cleaning again, rinsing the composite fiber processed in step S3, the number of times of rinsing is 40-60 times;

[0029] S5, drying at high temperature, drying the composite fiber rins...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com