Centrifugal pump system

A technology of centrifugal pump and body, applied in the direction of pump, pump control, pump components, etc., can solve the problem of wasting labor and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

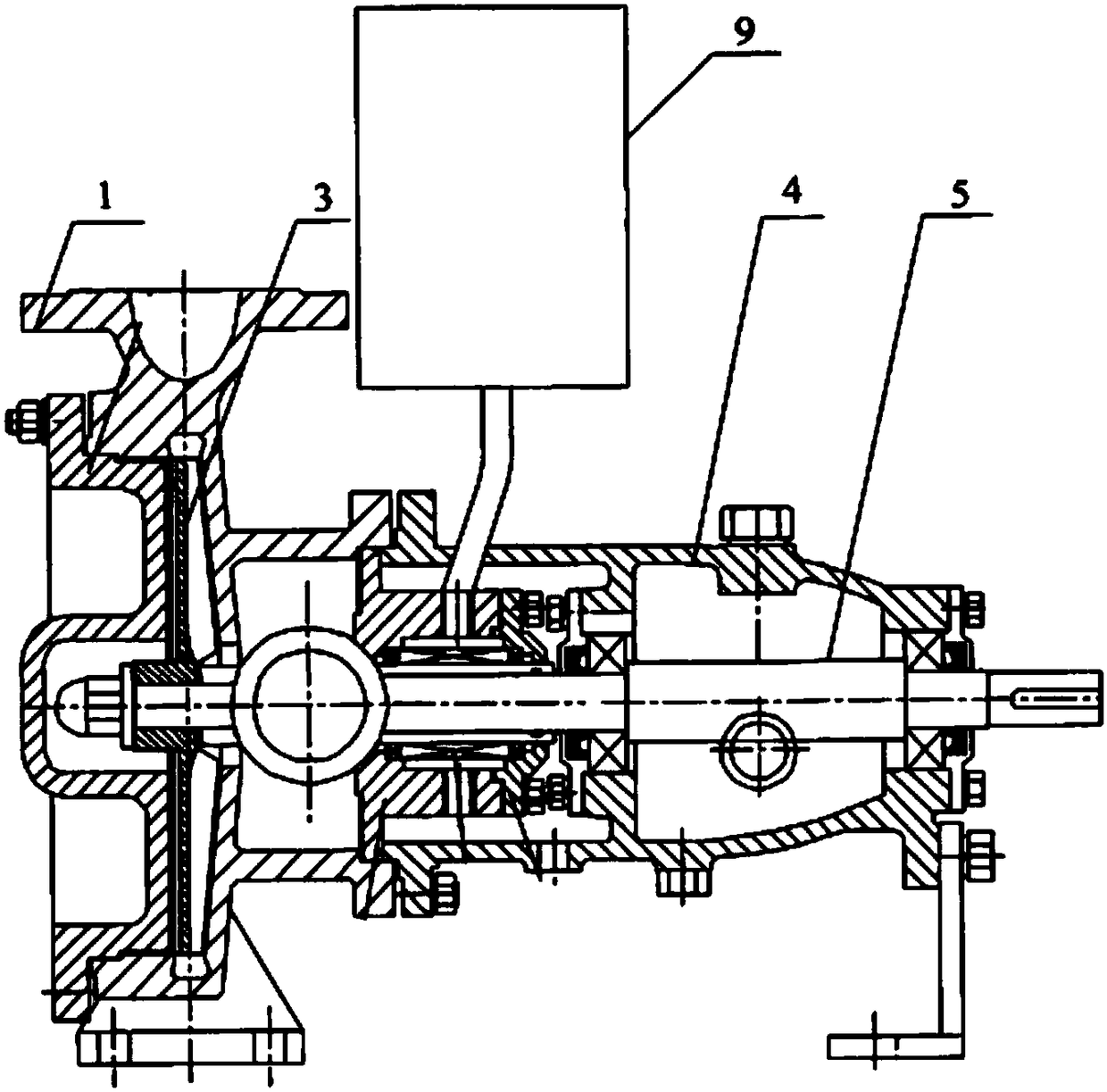

[0006] Please refer to Figure 1-Figure 2 , In an embodiment of the present application, the centrifugal pump system includes: a centrifugal pump, and the centrifugal pump further includes: a body 1; a transmission rod 5, one end of which is arranged inside the body; a bearing 4, arranged on one side of the body The rotating blade 3 is arranged on the transmission rod; the sealing member is arranged at the water inlet of the body; the water storage container 9 is connected to the sealing member.

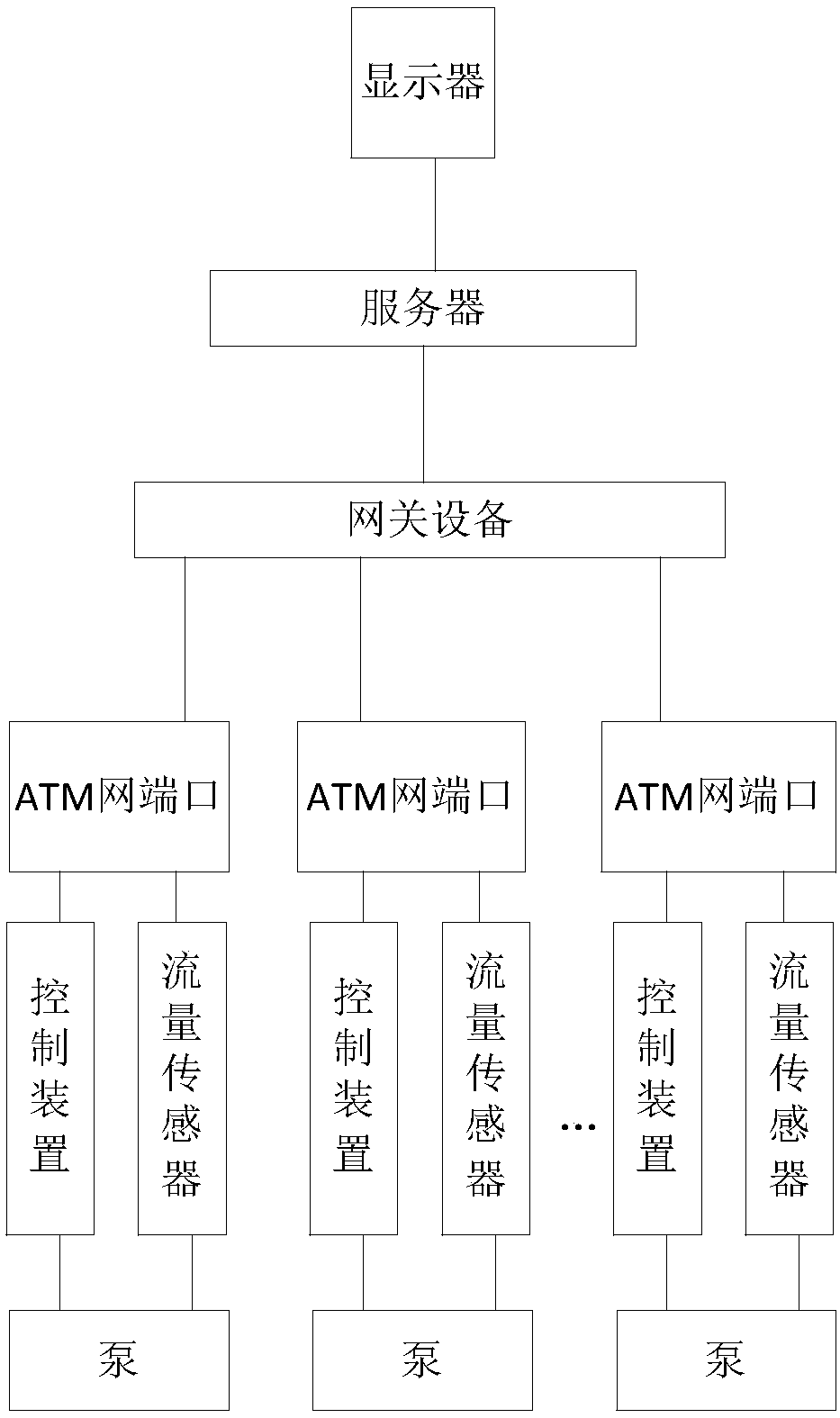

[0007] In an embodiment of the present application, the centrifugal pump system further includes: a flow sensor connected to the centrifugal pump for detecting the flow of the pump; an ATM network port; a gateway device connected to the ATM network port; a server connected to the The gateway device; the display, connected to the server; the control device, connected to the centrifugal pump; the flow sensor transmits the flow signal of the centrifugal pump to the server through the AT...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com