Assembly type shaft durkduct joint support

A prefabricated, air duct technology, applied in the direction of pipe supports, pipes/pipe joints/pipes, mechanical equipment, etc., can solve the problems that the vertical shaft air duct supports cannot be assembled on site, and there are many sporadic operations, so as to achieve no fire hazard and molding effect. Good, cost-reducing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in various ways defined and covered by the claims.

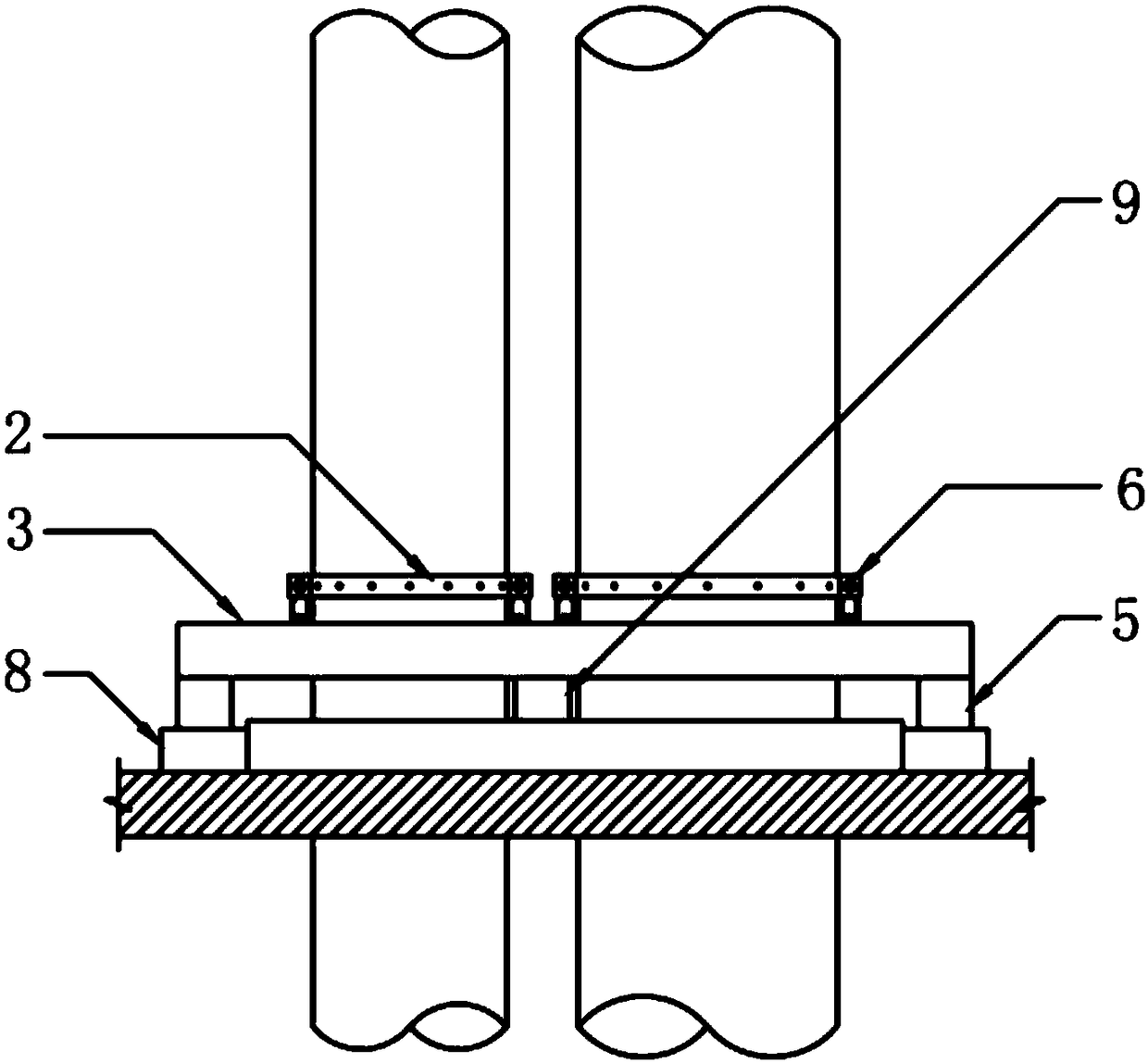

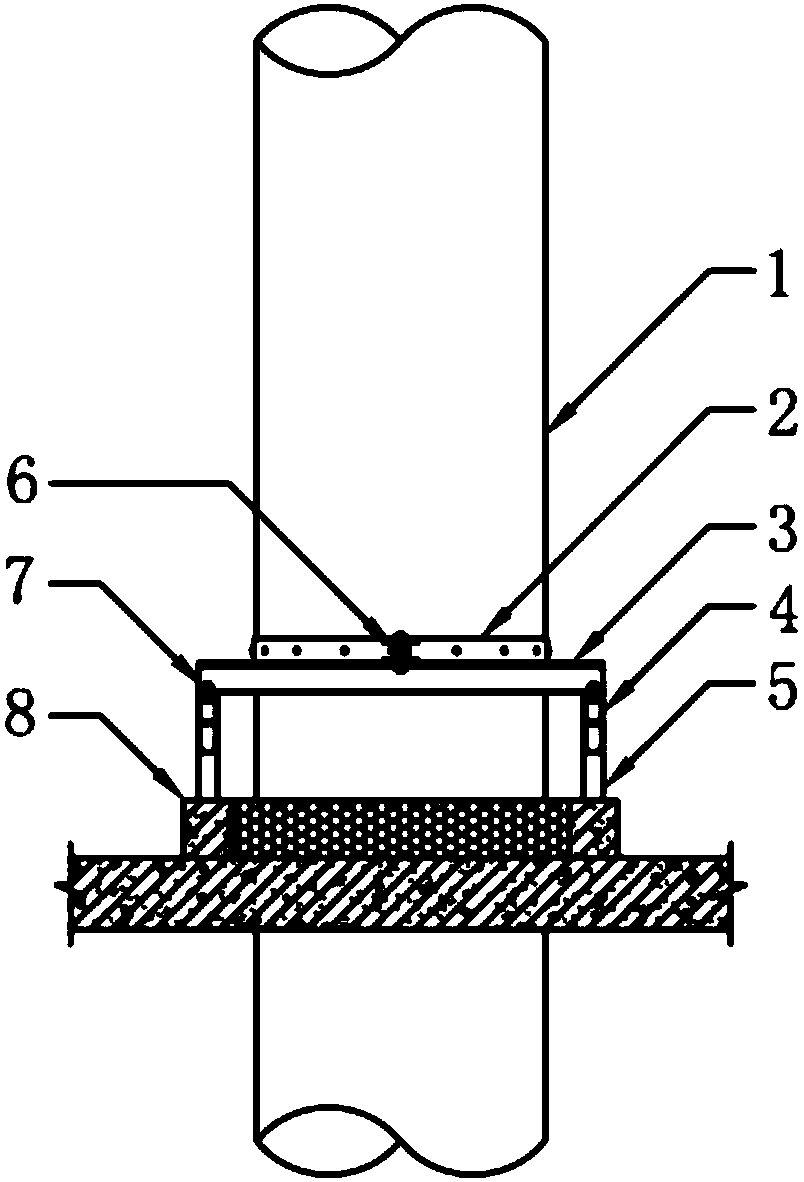

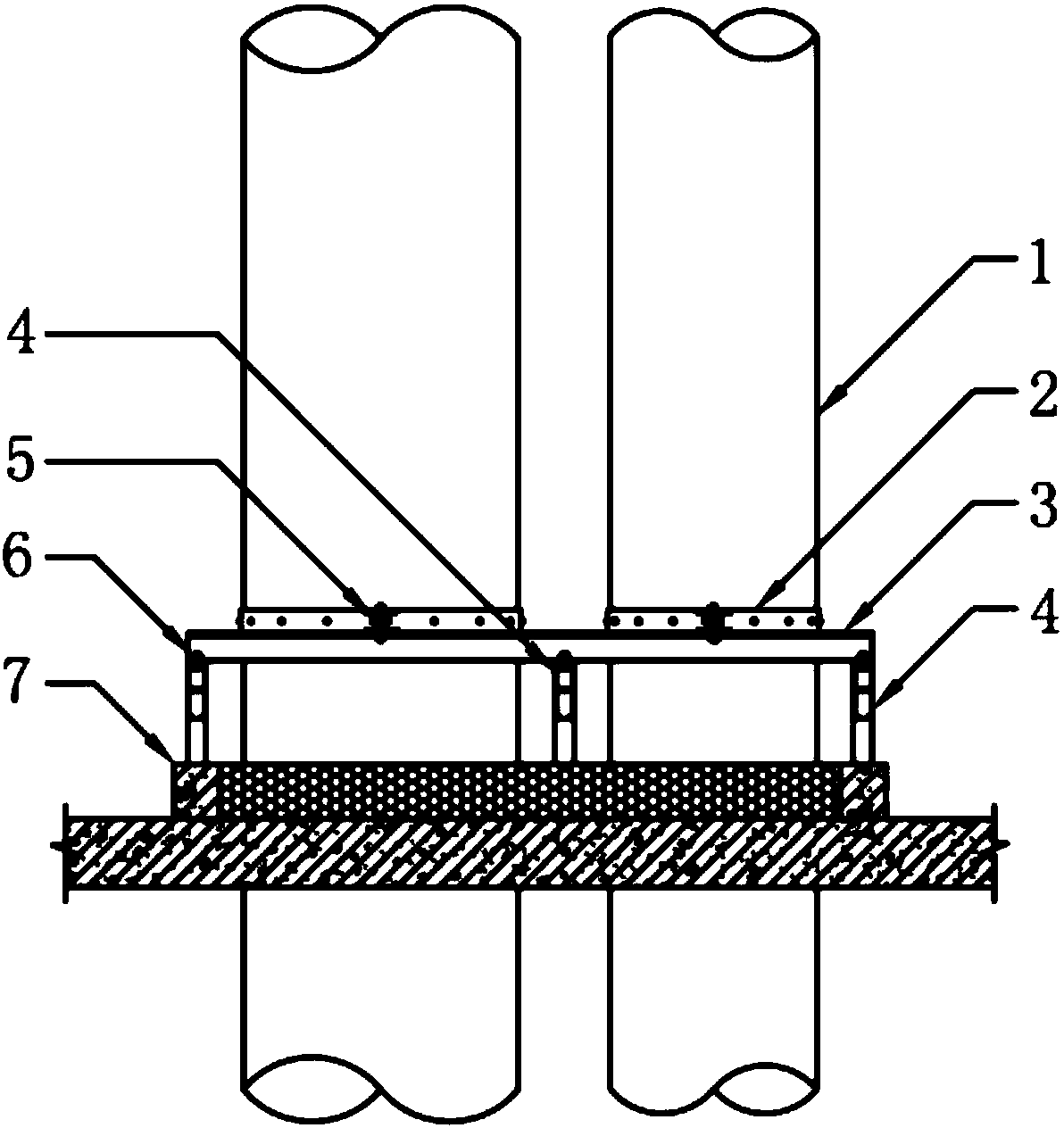

[0027] An assembled vertical shaft air duct joint bracket, such as Figure 1-5 As shown, it includes a flat steel hoop 2, a secondary crosspiece 3, a main crosspiece 4, a support column 5 and a hoop lock 6. Each vertical air duct 1 needs at least two secondary crosspieces 3 and two main crosspieces 4, and the two secondary crosspieces 3 and two main crosspieces 4 form a four-sided bar that can flexibly change the size of the middle square frame, thereby It is suitable for not too many sporadic operations when installing the vertical air duct 1. At the same time, the fixing bolt 7 is arranged between the main rail 4 and the secondary rail 3. Bolt holes are provided at both ends of the secondary rail 3, and the bottom of the fixing bolt 7 The bolt caps are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com