Method, device and equipment for defecting and classifying steel sheet defects, and computer readable medium

A defect detection and classification method technology, applied in computer parts, calculation, program control design, etc., to achieve the effect of standardization and improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

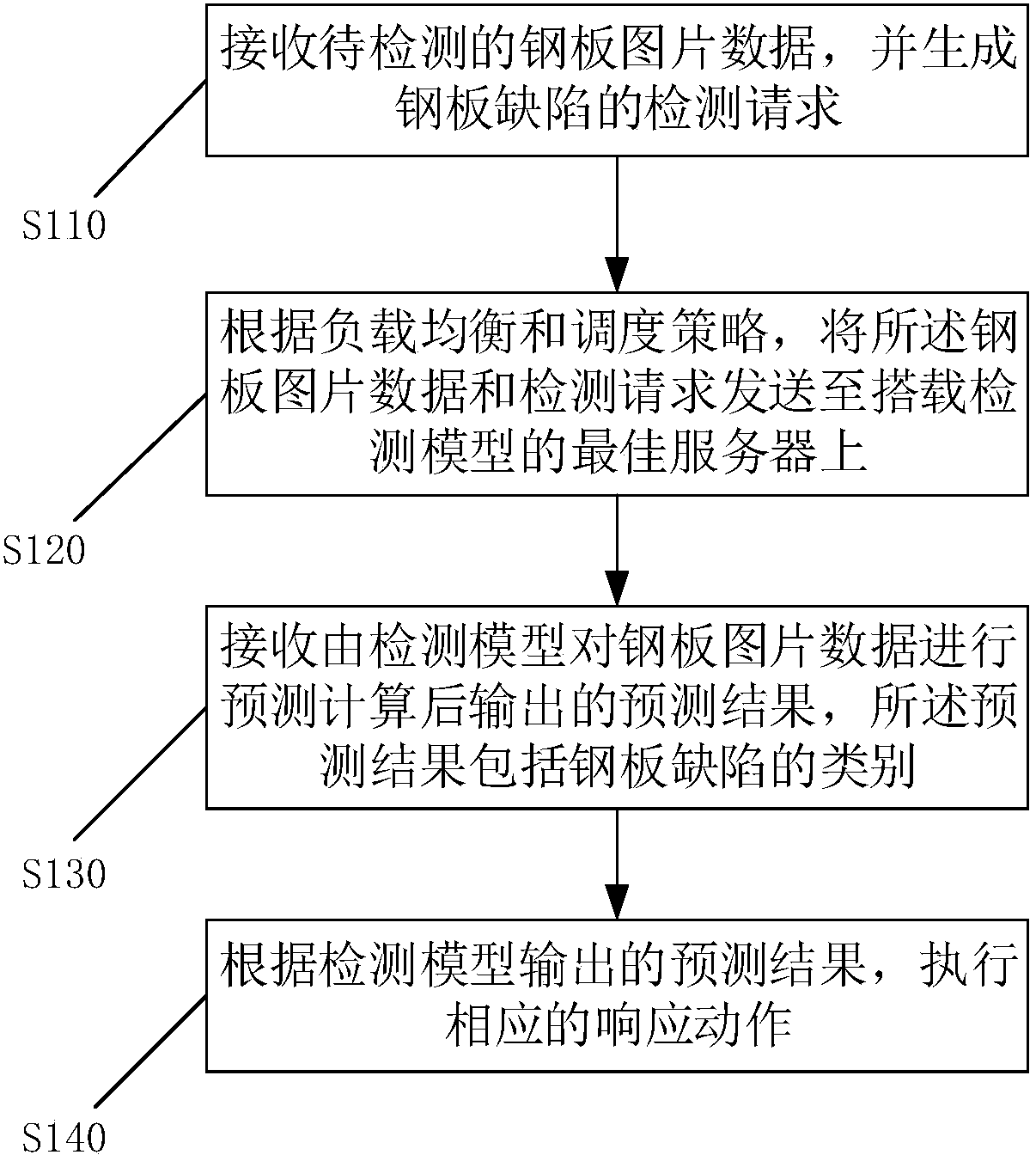

[0067] see figure 1 , which is a flow chart of the steps of the steel plate defect detection and classification method according to Embodiment 1 of the present invention. The first embodiment provides a steel plate defect detection and classification method, including the following steps:

[0068] S110: Receive steel plate image data to be detected, and generate a detection request for steel plate defects.

[0069] When it is necessary to detect the surface defect of the steel plate, the image of the steel plate surface can be collected first, for example, it can be collected by equipment such as a camera. Then, after the image information of the corresponding steel plate is collected, a detection request is generated to detect surface defects of the steel plate.

[0070] S120: Send the steel plate picture data and the detection request to the optimal server equipped with the detection model according to the load balancing and scheduling strategy.

[0071] Before sending th...

Embodiment 2

[0081] The difference from Embodiment 1 is that this Embodiment 2 also updates the detection model on the basis of Embodiment 1. The specific scheme is as follows:

[0082] see Figure 4 , which is a flow chart of the steps of the method for detecting and classifying steel plate defects in the second embodiment. Embodiment 2 provides a steel plate defect detection and classification method, including the following steps:

[0083] S210: Receive steel plate image data to be detected, and generate a detection request for steel plate defects.

[0084] S220: Send the steel plate picture data and the detection request to the best server equipped with the detection model according to the load balancing and scheduling strategy.

[0085] S230: Receive a prediction result output after the detection model predicts and calculates the steel plate image data, and the prediction result includes the type of the steel plate defect.

[0086] S240: Execute a corresponding response action acco...

Embodiment 3

[0091] see Figure 5 , which is a flow chart of the steps of the method for detecting and classifying steel plate defects in the third embodiment. Embodiment 3 provides a steel plate defect detection and classification method, including the following steps:

[0092] S310: Receive steel plate picture data and a steel plate defect detection request.

[0093] S320: Carry out prediction calculation of steel plate defect on the image data of the steel plate through the detection model and output the prediction result, the prediction result includes the category of the steel plate defect.

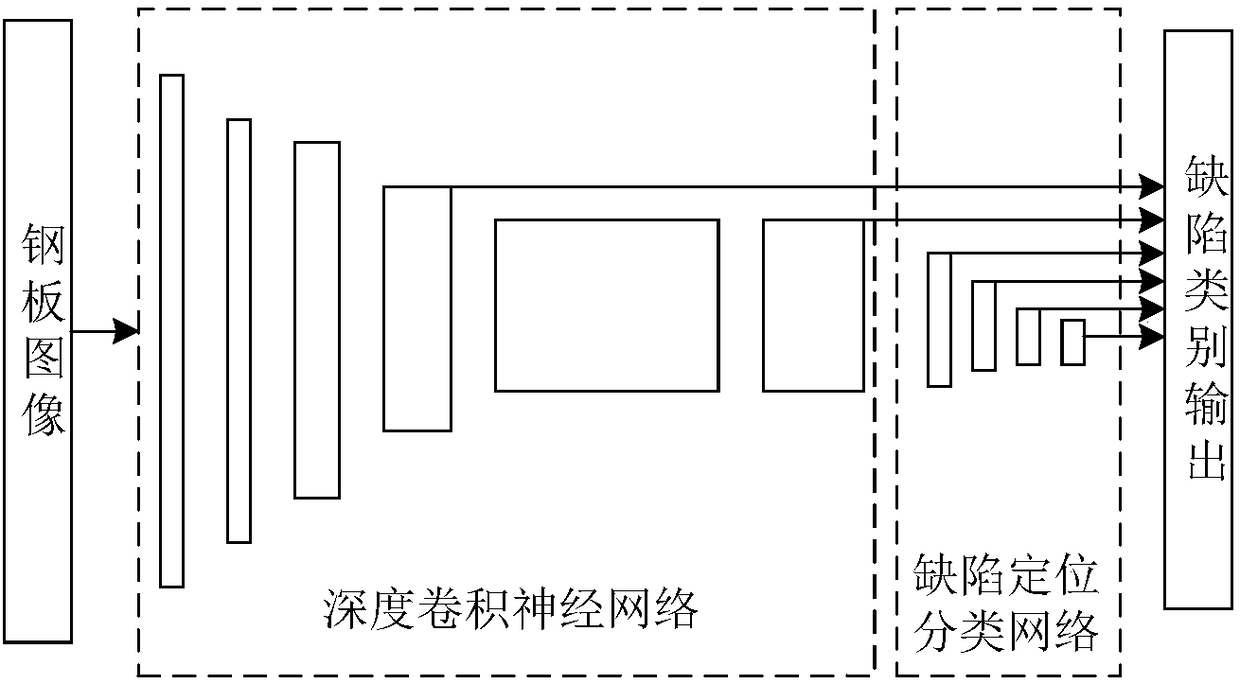

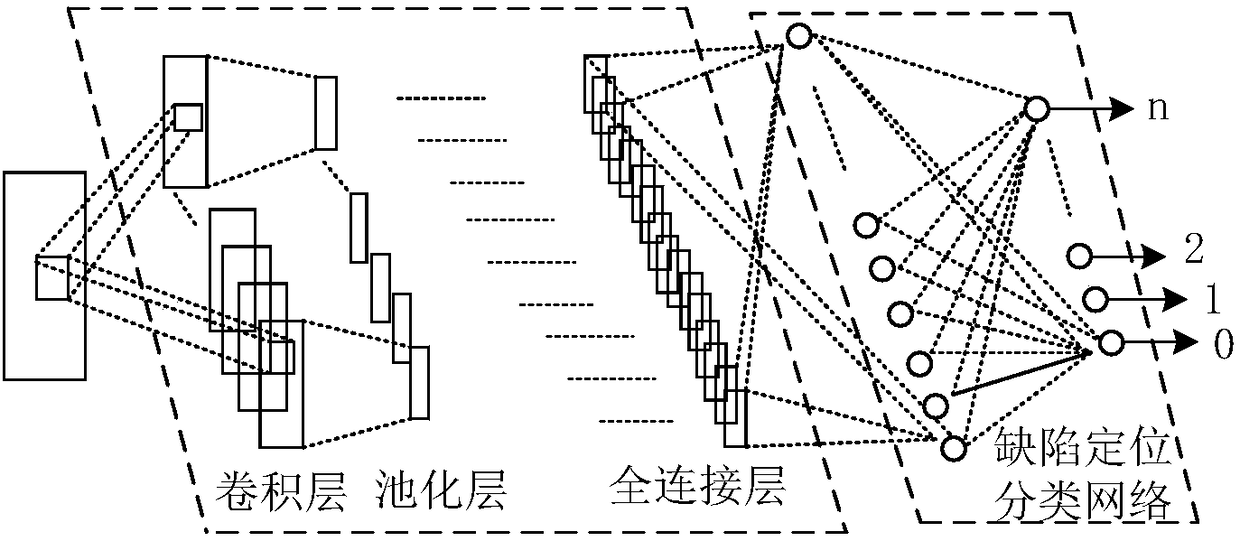

[0094] Wherein, the detection model includes: a deep convolutional neural network and a defect location and classification network.

[0095] The deep convolutional neural network is used to extract the features of the steel plate picture, and the features are input into the defect location and classification network.

[0096] The defect location and classification network is used to judge whet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com