A sensor cable with high temperature resistance of 500°C

A sensor and high-temperature-resistant technology, which is applied in the field of cables, can solve the problems of poor high-temperature resistance and errors, and achieve the effects of long life, satisfactory service life, and prevention of monitoring and control failure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] In order to have a further understanding and understanding of the structural features of the present invention and the achieved effects, the preferred embodiments and accompanying drawings are used for a detailed description, as follows:

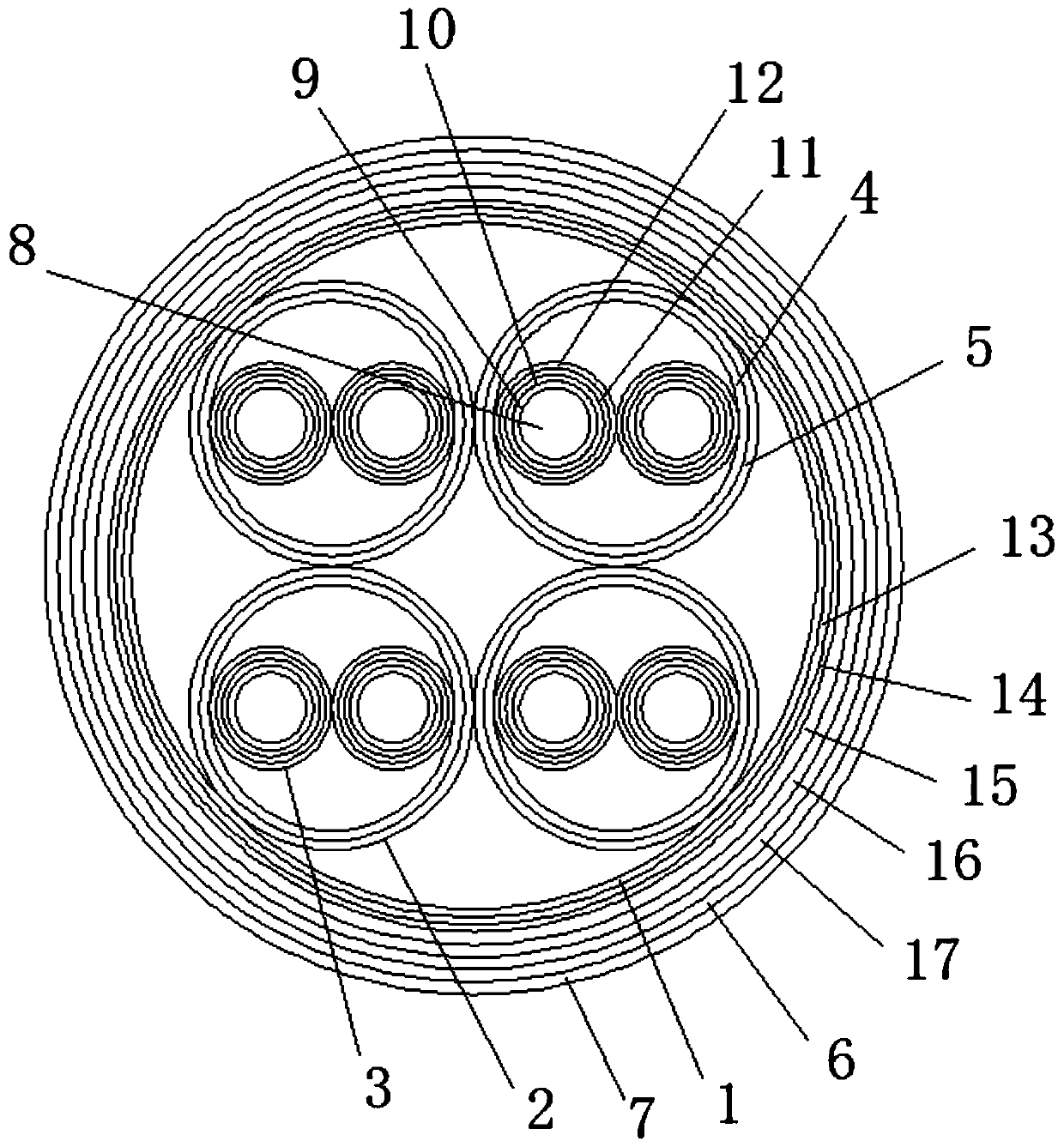

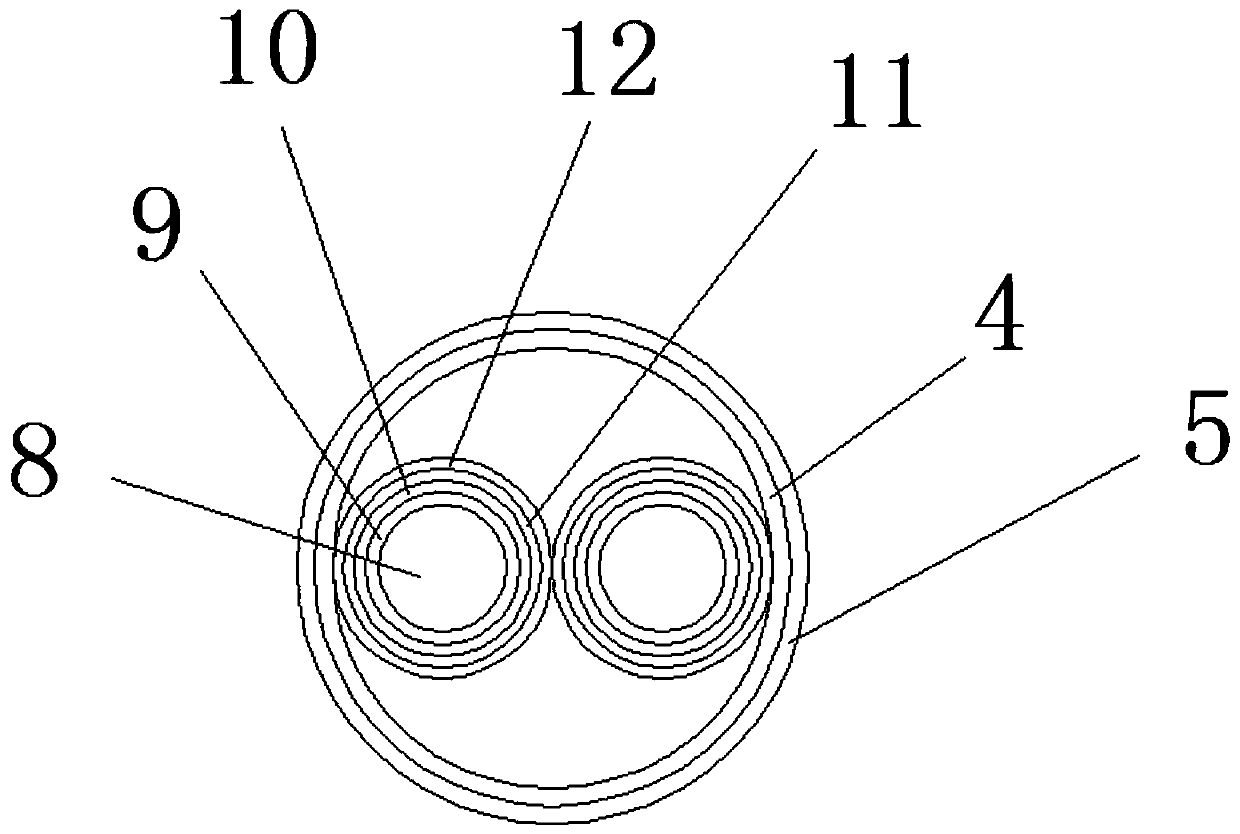

[0015] Such as figure 1 As shown, the present invention discloses a sensor cable with a high temperature resistance of 500°C, which includes an outer inorganic glass tape layer 1 and a plurality of cables 2 arranged in the outer inorganic glass tape layer 1, and the cables 2 include multiple A twisted wire core 3, a nickel-plated alloy wire braided shielding layer 4, an inorganic glass cloth tape around the cladding 5, the outer surface of the twisted wire core 3 is coated with a nickel-plated alloy wire braided shielding layer 4, the described The nickel-plated alloy wire braided shielding layer 4 is covered with an inorganic glass cloth tape around the cladding layer 5 .

[0016] By setting the nickel-plated alloy wire braided shie...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com