Coil framework and binding post connecting structure and mounting method thereof

A coil skeleton and connection structure technology, applied in the direction of electromagnetic terminals/connectors, electrical components, electromagnets, etc., can solve the problems of easy bending of the terminal, short circuit between the circuit board and the coil, and easy loosening of the terminal, so as to prevent short circuit , the effect of increasing the installation distance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

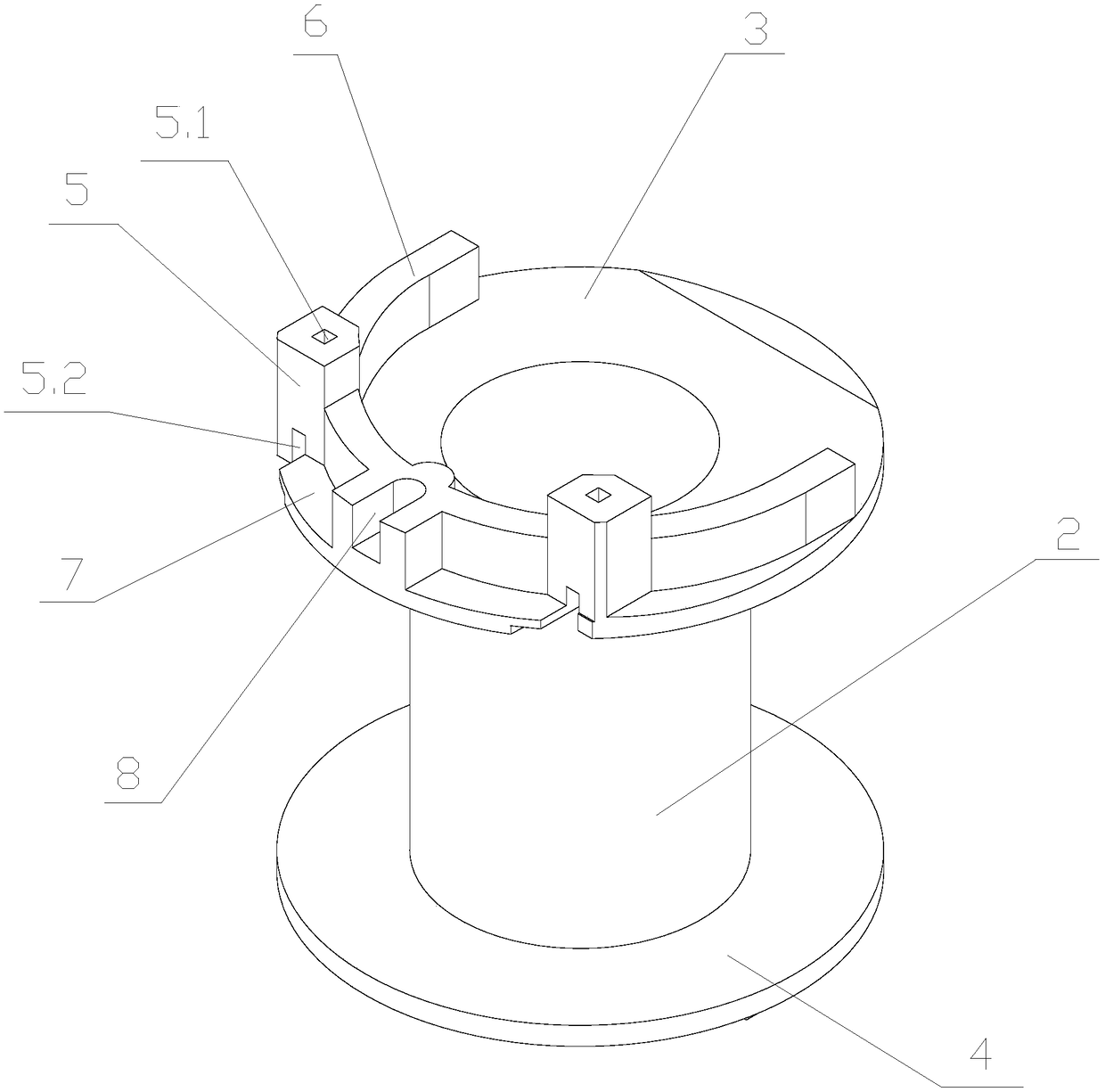

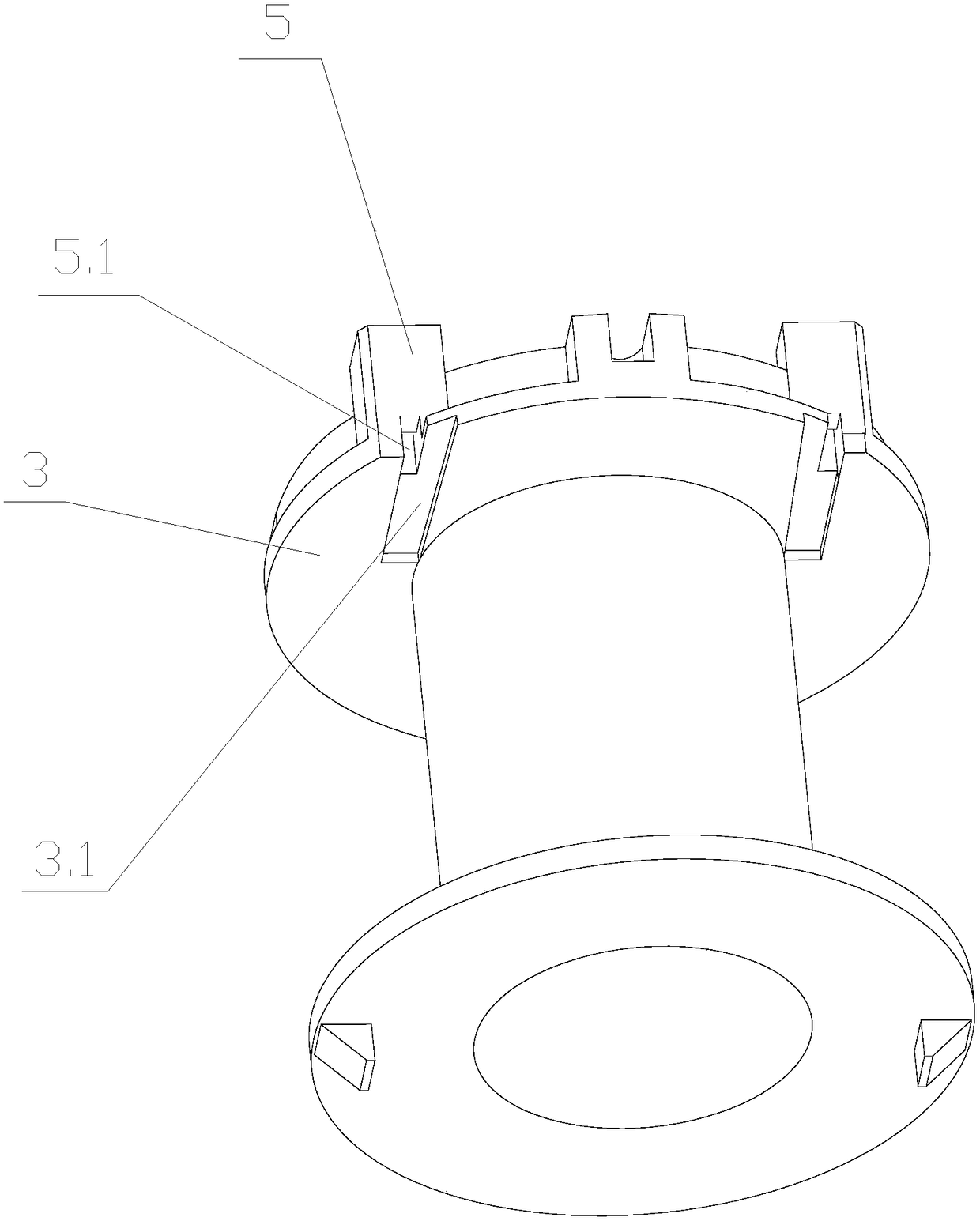

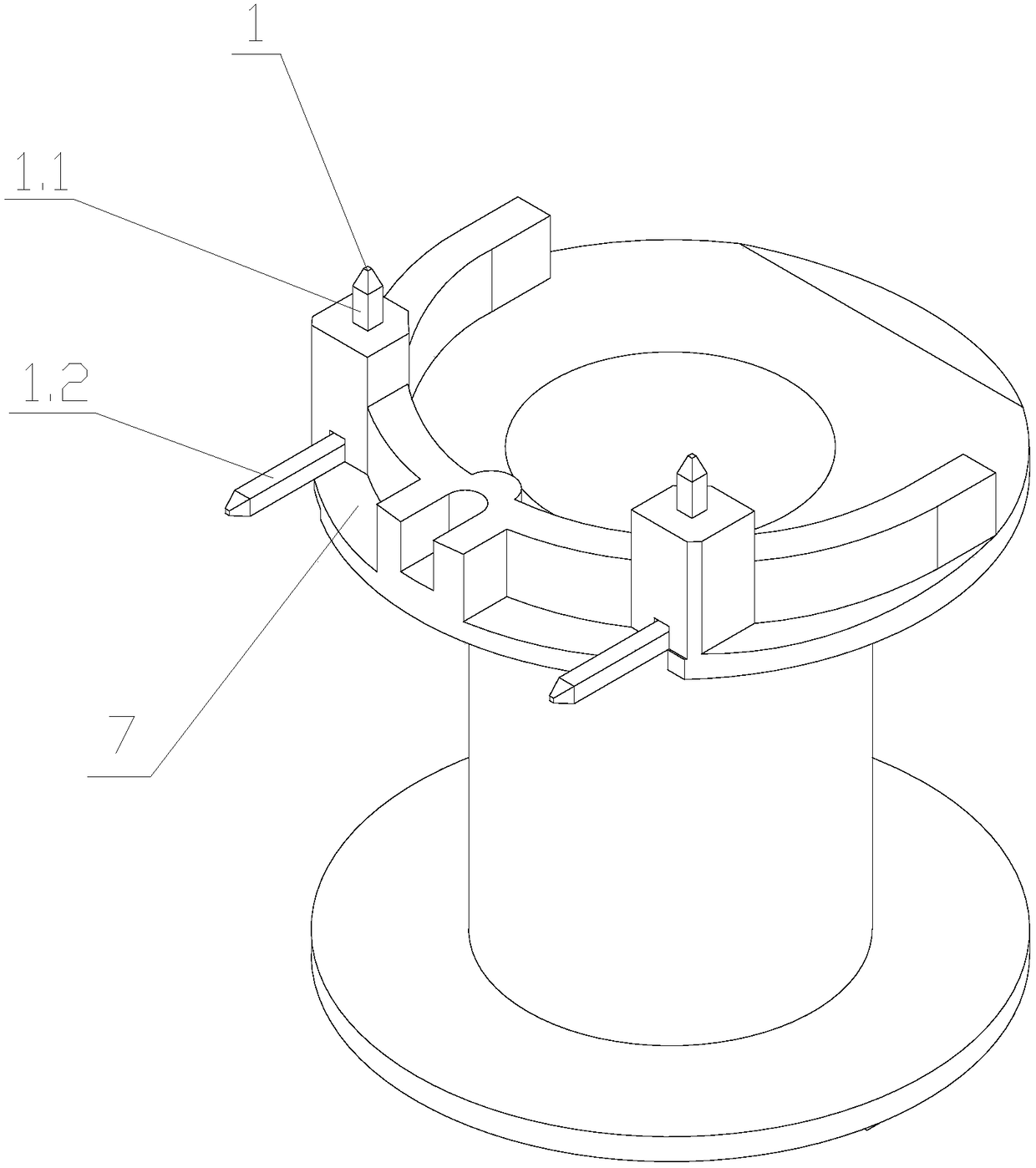

[0021] Such as Figure 1-4 As shown, a connection structure between a coil bobbin and a terminal, including a coil bobbin and a terminal 1, the coil bobbin includes a cylindrical winding part 2 for winding a wire, and the upper end of the winding part 2 is provided with a first platform part 3. The lower end of the winding part 2 is provided with a second platform part 4, the terminal post 1 is connected to the first platform part 3, and the first platform part 3 is protruded with a pluggable terminal part 1 vertically The mounting part 5 of section 1.1, the first platform part 3 is also protruded with a rib 6, the distance from the outer side of the rib 6 to the edge of the first platform part 3 is greater than zero, and the outer side of the rib 6 and the first platform part 3 A receiving groove 7 that can support the horizontal section 1.2 of the terminal post 1 is formed. The arrangement of the installation part 5 and the accommodating groove 7 forms a positioning and supp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com