Dry-type transformer with heat radiation and noise reduction functions

A dry-type transformer and iron core technology, applied in transformer/inductor cooling, transformer/inductor magnetic core, transformer/inductor components, etc., can solve the problems of high mechanical friction strength and inability to fully guarantee the shockproof effect, etc. To avoid excessive friction, good heat dissipation, and reduce noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

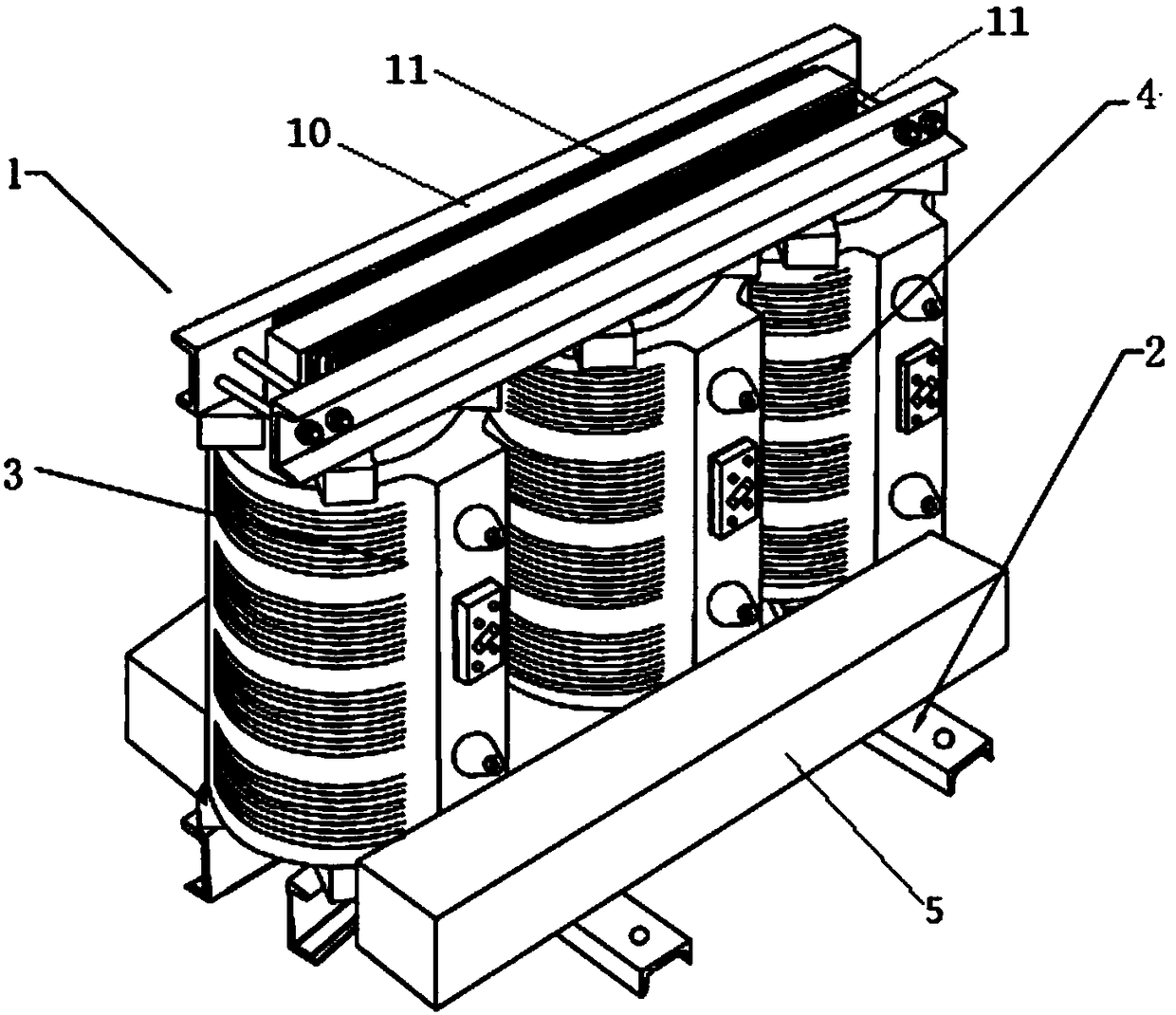

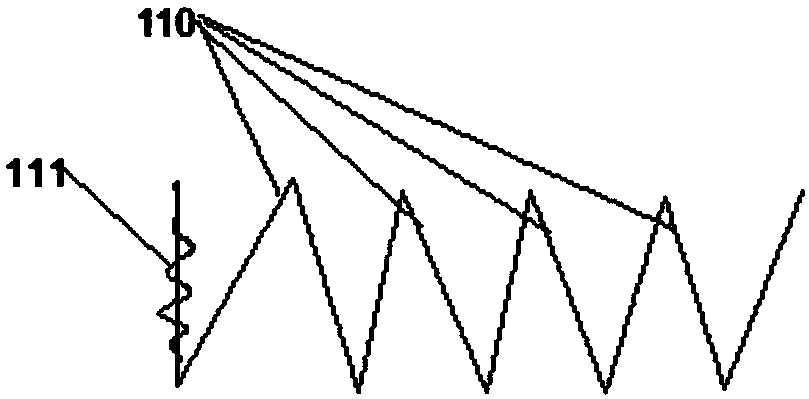

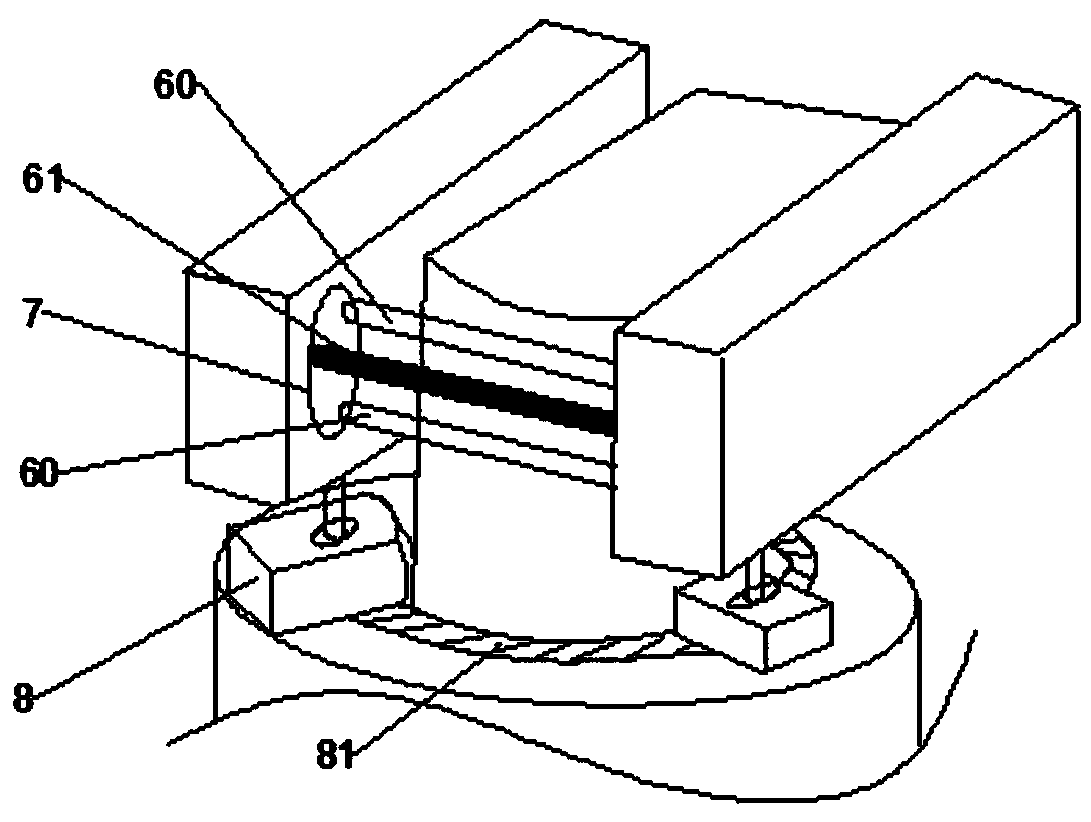

[0029] The invention discloses a heat dissipation and noise reduction dry-type transformer, comprising a clip 1 (such as figure 1 As shown, clips 1) and base 2 are set up and down, and iron cores 3 are respectively fixed on the clips 1, and the iron cores 3 are fixed and limited by the clips 1; Winding coil 4, the iron core 3 is placed on the base 2, and the base 2 is also provided with a number of fans 5 on both sides of the iron core 3, and the fans 5 are detachably installed, such as figure 1 The clips 1 shown in the drawings all include a group of strip-shaped steel plates 10 and fixing screws. Fixing holes are arranged at both ends of the strip-shaped steel plates 10. The fixing screws p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com