Vibration energy collecting circuit vibration-prevention hammer for providing energy for wireless sensor

A vibration energy harvesting, wireless sensor technology, applied in mechanical vibration damping devices, piezoelectric effect/electrostrictive or magnetostrictive motors, generators/motors, etc. Line anti-vibration effect, realize conversion and utilization, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

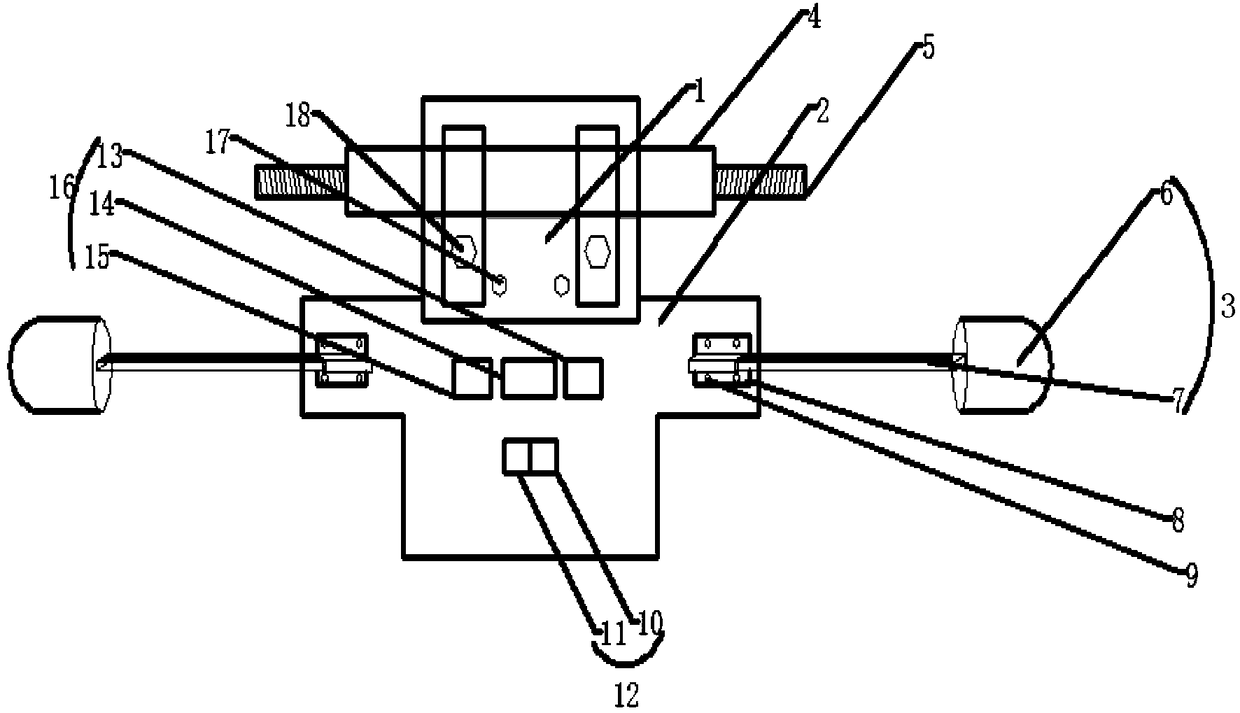

[0026] The present invention will be further described below in conjunction with accompanying drawing:

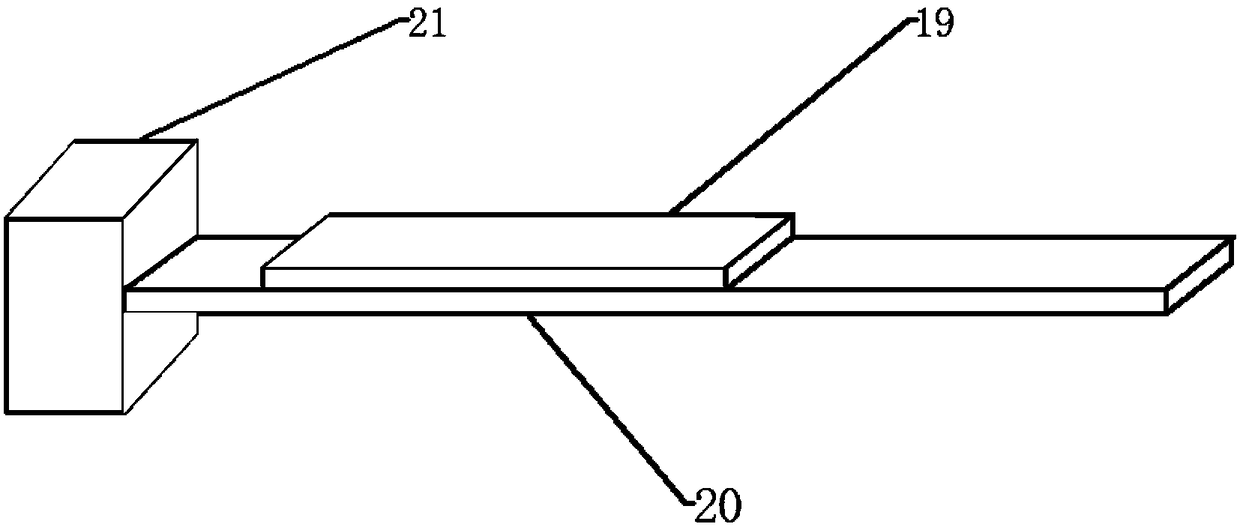

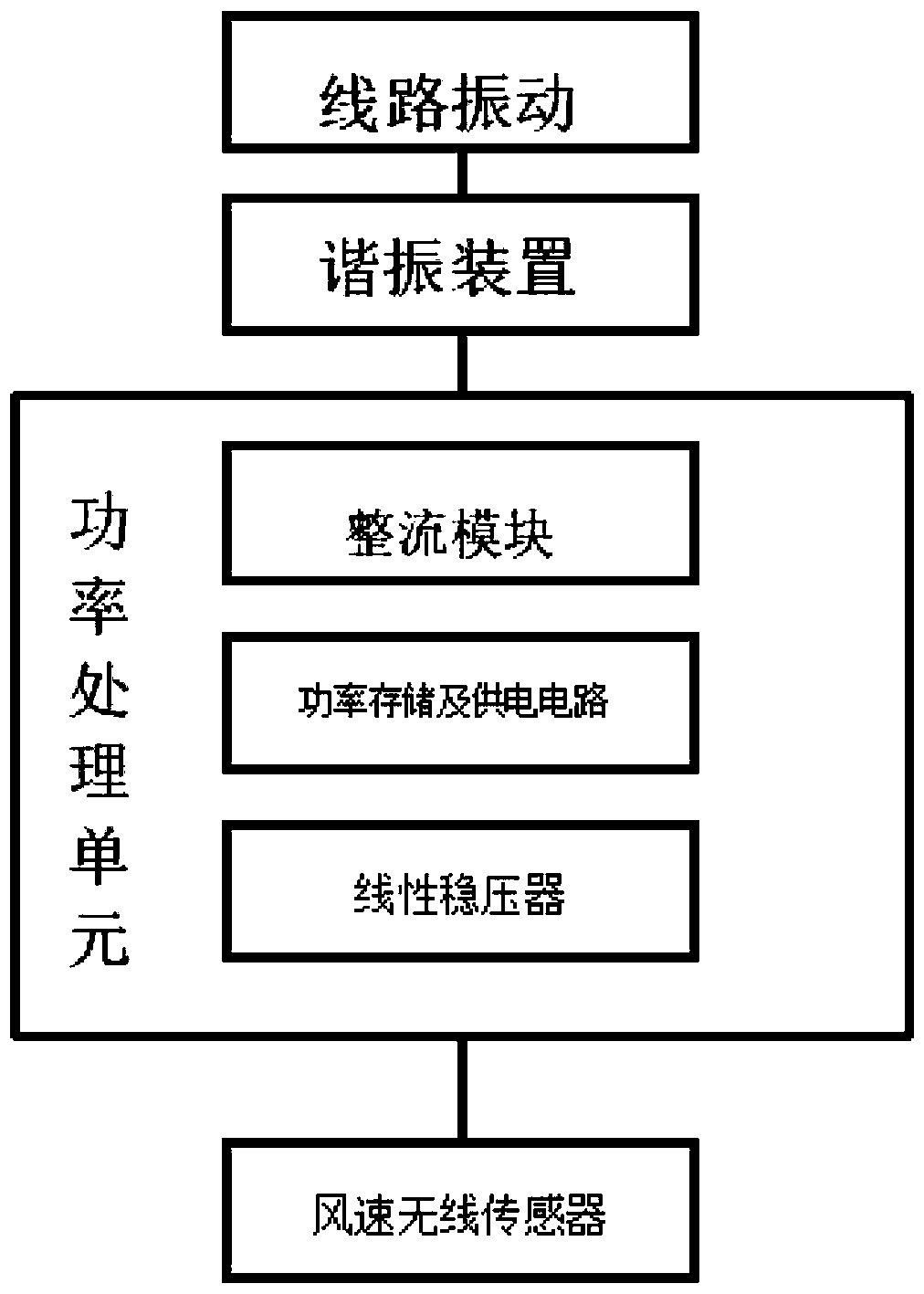

[0027] combine figure 1 Describe this embodiment mode, a kind of anti-vibration hammer of vibration energy collection line that supplies power to wireless sensors in this embodiment mode includes a wire clip assembly 1 and a wire sheath 4 set on a wire 5, and the wire clip assembly 1 is installed on the wire sheath 4, The line anti-vibration hammer also includes a support plate 2, two resonance devices 3, two pressure plates 8, eight pressure plate screws 9, a power processing unit 16, a wind speed wireless sensor 12, two clamp screws 18, and two support plate screws 17, The supporting plate 2 is connected to the lower end of the clamp assembly 1 through the supporting plate screw 17, the resonance device 3 is installed on the supporting plate 2 through the pressing plate 8 and the pressing plate screw 9, and the power processing unit module 16 and the wind speed wireless s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com