Direct current variable frequency drive control system for air-conditioning coil pipe draught fan

A DC frequency conversion, coil fan technology, applied in the control system, AC motor control, electrical components, etc., can solve the problems that are difficult to meet the technical innovation of fans, high efficiency and energy saving, strong environmental adaptability and diversified applications, and achieve cost optimization. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

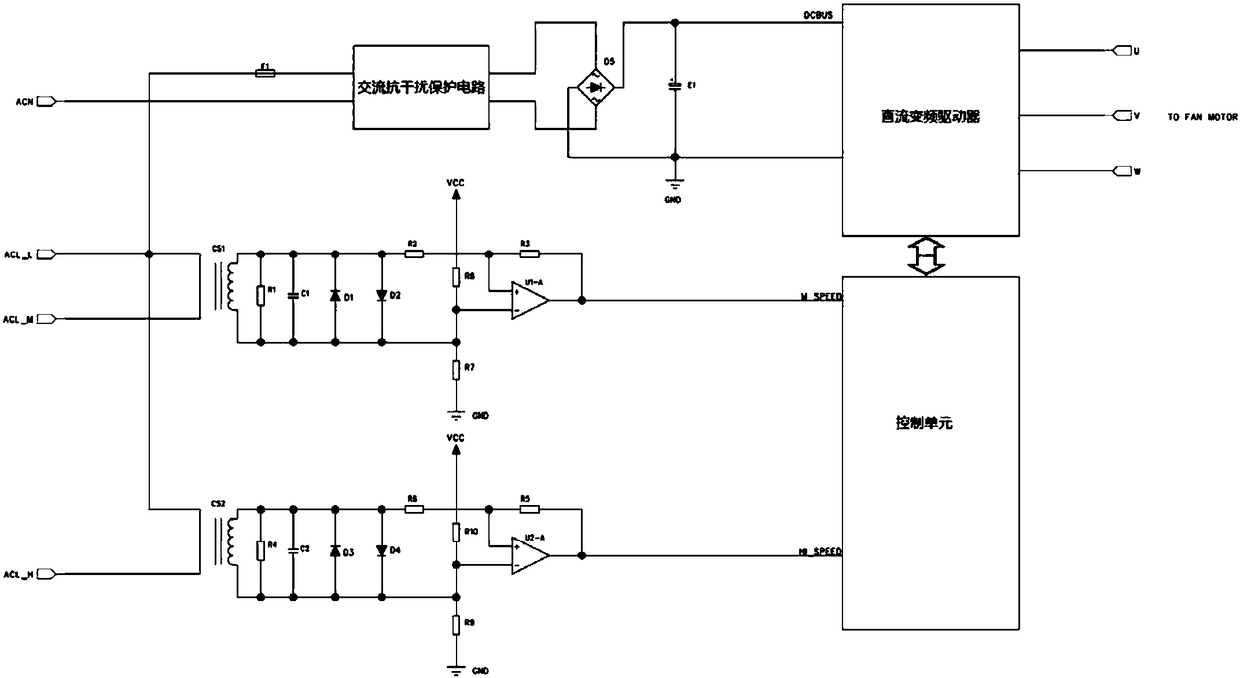

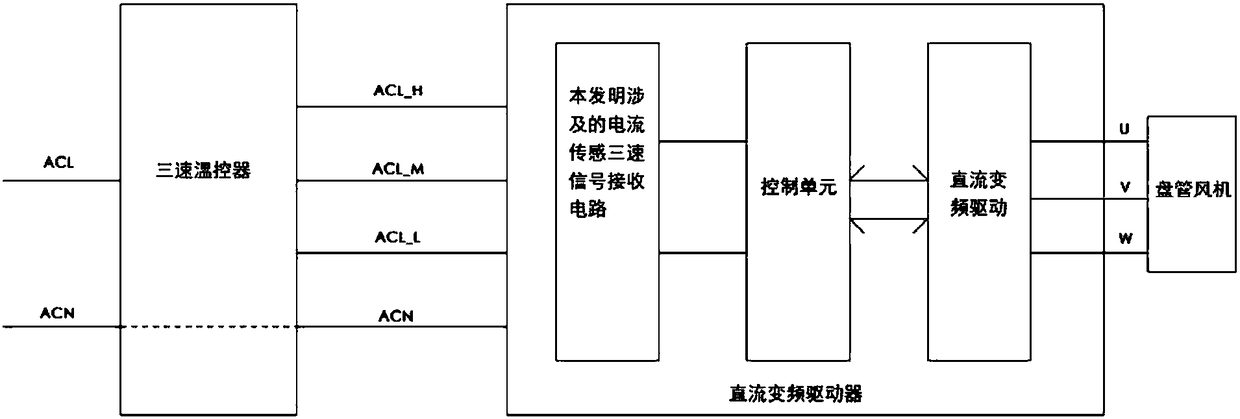

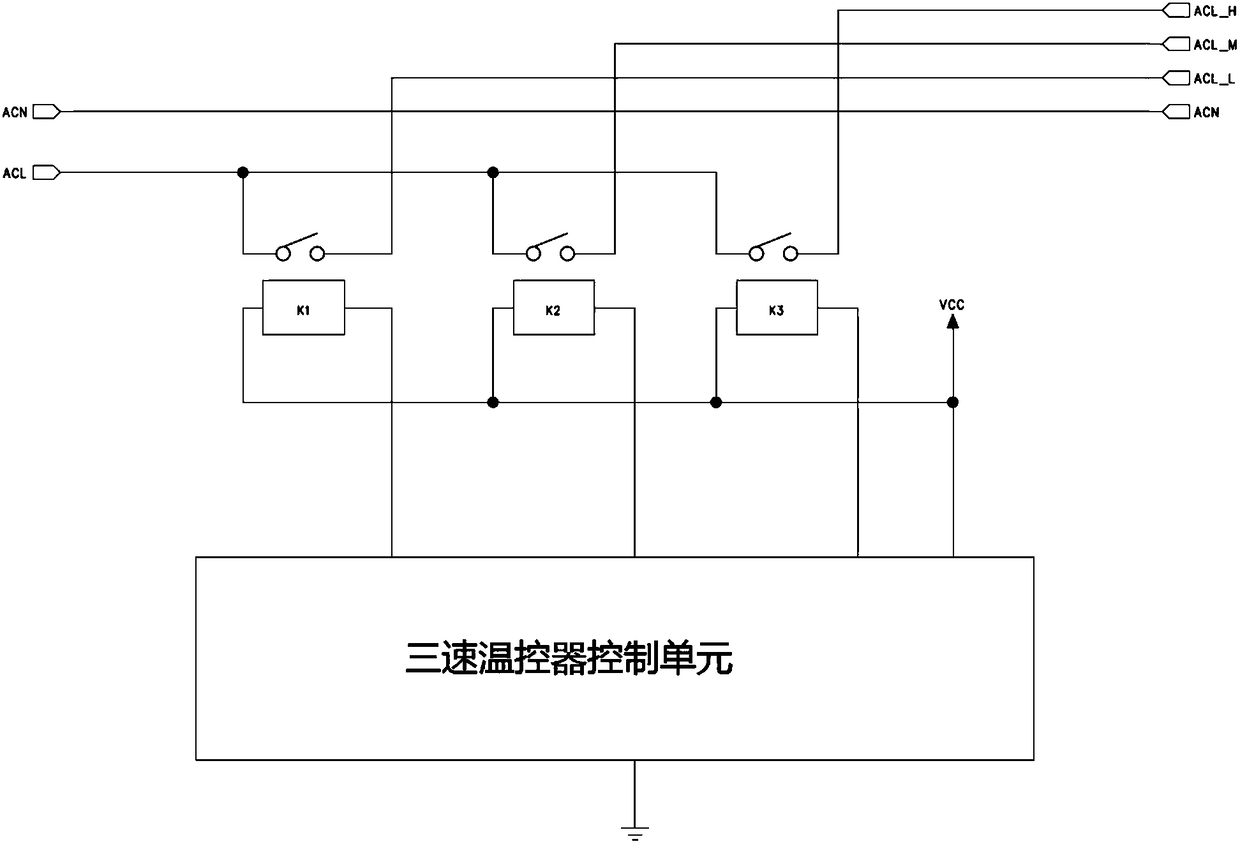

[0061] (1) The three-speed thermostat sends out a low-speed speed regulation signal. The AC high voltage enters the AC input combination circuit through the two terminals ACL_L and ACN. The current sensor Cs1 and the current sensor Cs2 do not pass the AC current. The M_SPEED code obtained in the speed encoding circuit and HI_SPEED codes are both 0, the drive logic code formed by the control unit based on logical judgment is LOW-SPEED signal, the DC variable frequency drive operates according to the instruction corresponding to the LOW-SPEED signal, the coil fan is controlled by the DC variable frequency drive, and the command of the DC variable frequency drive Can be set to low speed or static;

[0062] (2) The three-speed thermostat sends out a medium-speed speed regulation signal. The AC high voltage enters the AC input combination circuit through the two terminals ACL_L and ACN. The current sensor Cs1 has an AC current passing through it, and the current sensor Cs2 has no AC...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com