Electric core transfer box and using method thereof

A turnover box and cell technology, applied to rigid containers, containers, packaging, etc., can solve the problems of low production efficiency, waste of labor, inconvenience, etc., and achieve the effects of convenient inventory, improved transfer efficiency, and space saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

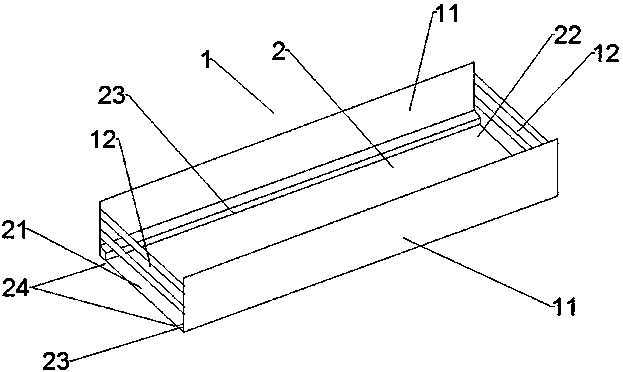

Embodiment 1

[0042] The battery turnover box of this embodiment, such as figure 1 As shown, it includes a turnaround box main frame 1 and a pumping plate 2. The turnaround box main frame 1 includes two relatively parallel side plates 11 and fixed brackets 12 that fix the side plates 11 at both ends of the two side plates 11, The distance between the two side plates 11 matches the distance between the two ends of the positive and negative tabs of the cell, and the pumping plate 2 is slidably connected to the two side plates 11; the pumping plate 2 includes an extraction end 21 and an insertion end 22 , the two ends of the connection between the pumping plate 2 and the side plate 11 are respectively provided with limit bars 23, the distance between the two limit bars 23 matches the length of the battery cell, and a limit bar is formed between the two limit bars. Groove 24, the turnover box main frame 1 and the pumping plate 2 form a space for placing batteries, and the depth of the space for...

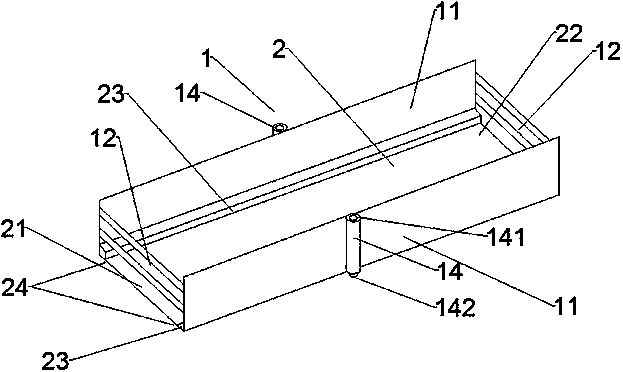

Embodiment 2

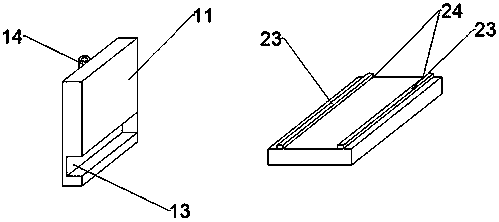

[0049] The battery turnover box of this embodiment, such as figure 2 and image 3 As shown, it includes the turnover box main frame 1 and the pumping plate 2. The turnover box main frame 1 includes two relatively parallel side plates 11 and fixed brackets 12 that fix the side plates 11 at both ends of the two side plates 11, The distance between the two side plates 11 matches the distance between the positive and negative tabs of the cell. The bottom of the side plates 11 is provided with a slide rail 13 that matches the pumping plate 2. The pumping plate 2 passes through the The slide rail 13 is slidably connected with the two side plates 11 and can be easily separated. The pumping plate 2 includes an extracting end 21 and an inserting end 22. The two ends of the pumping plate 2 connected to the side plate 11 are respectively provided with limiting strips 23, and the limiting strips 23 are made of elastic materials. It is more convenient to put it in, and it will not damag...

Embodiment 3

[0057] The battery turnover box of this embodiment, such as Figure 4 and Figure 5 As shown, it includes a turnaround box main frame 1 and a pumping plate 2. The turnaround box main frame 1 includes two relatively parallel side plates 11 and fixed brackets 12 that fix the side plates 11 at both ends of the two side plates 11, The distance between the two side plates 11 matches the distance between the positive and negative tabs of the battery cell. The pumping plate 2 is provided with a slide rail 25 that matches the side plate 11. The pumping plate 2 passes through the sliding rail 25. The rail 25 is slidably connected with the two side plates 11 and can be easily separated. The pumping plate 2 includes an extracting end 21 and an inserting end 22, and the two ends of the pumping plate 2 connected to the side plate 11 are respectively provided with limiting strips 23, the limiting strips 23 are made of elastic materials, and the battery cells It is more convenient to put i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com