Layered cover film easy to strip

An easy-to-open and layered technology, applied to flexible coverings, packaging, wrapping paper, etc., can solve the problems of unsafe hidden dangers, easy to take out and spill the contents, etc., and achieve easy to uncover and uncover force Small, good barrier effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

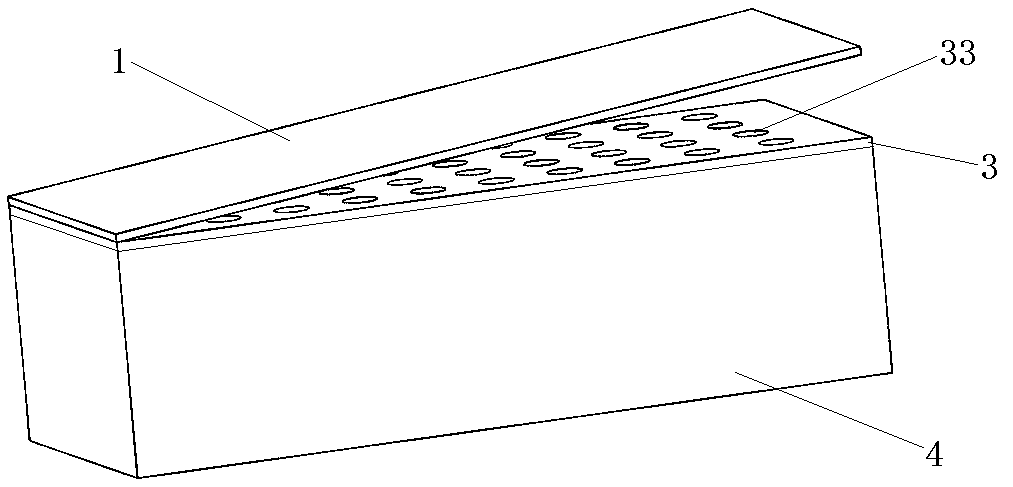

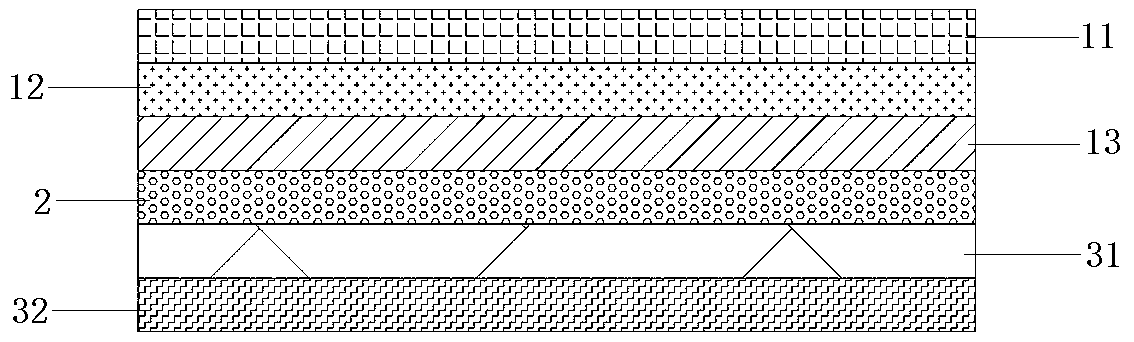

[0026] This embodiment provides a layered easy-to-remove cover film applied on the solid fragrance, the cover film is arranged on the blister tray 4, and the material of the blister tray is PP. The cover film includes an upper film 1 and a lower film 3, the lower film is provided with a vent hole 33, an easy-peelable layer 2 is arranged between the upper film 1 and the lower film 3, and the peeling force between the easy-peelable layer 2 and the upper film 1 is greater than The peeling force between the easy-peelable layer 2 and the lower film 3, tearing the upper film 1, and when the upper film 1 and the lower film 3 are separated, the easy-peelable layer 2 adheres to the upper film 1, exposing the vent holes on the lower film 3 33. The content of the blister tray 4 can volatilize the odor through the vent hole 33.

[0027] The upper film 1 in this embodiment includes a surface layer 11 , a barrier layer 12 and a transition layer 13 with a total thickness of 71 μm; the lower ...

Embodiment 2

[0031] This embodiment provides a cover film applied on the moisture absorbent, the cover film is arranged on the blister tray 4, and the material of the blister tray is PVC. The cover film includes an upper film 1 and a lower film 3, the lower film is provided with a vent hole 33, an easy-peelable layer 2 is arranged between the upper film 1 and the lower film 3, and the peeling force between the easy-peelable layer 2 and the upper film 1 is greater than The peeling force between the easy-peelable layer 2 and the lower film 3, tearing the upper film 1, and when the upper film 1 and the lower film 3 are separated, the easy-peelable layer 2 adheres to the upper film 1, exposing the vent holes on the lower film 3 33 , the content of the blister tray 4 can absorb gas through the vent hole 33 .

[0032] The upper film 1 in this embodiment includes a surface layer 11 , a barrier layer 12 and a transition layer 13 with a total thickness of 74 μm; the lower film includes a heat-seali...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com