Touch sensing module and production method thereof and touch display panel provided with touch sensing module

A touch sensing and module technology, which is applied in the input/output process of data processing, instruments, electrical and digital data processing, etc., can solve the problems of complex process, and achieve the effect of simplifying the process, saving costs, and good visual effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

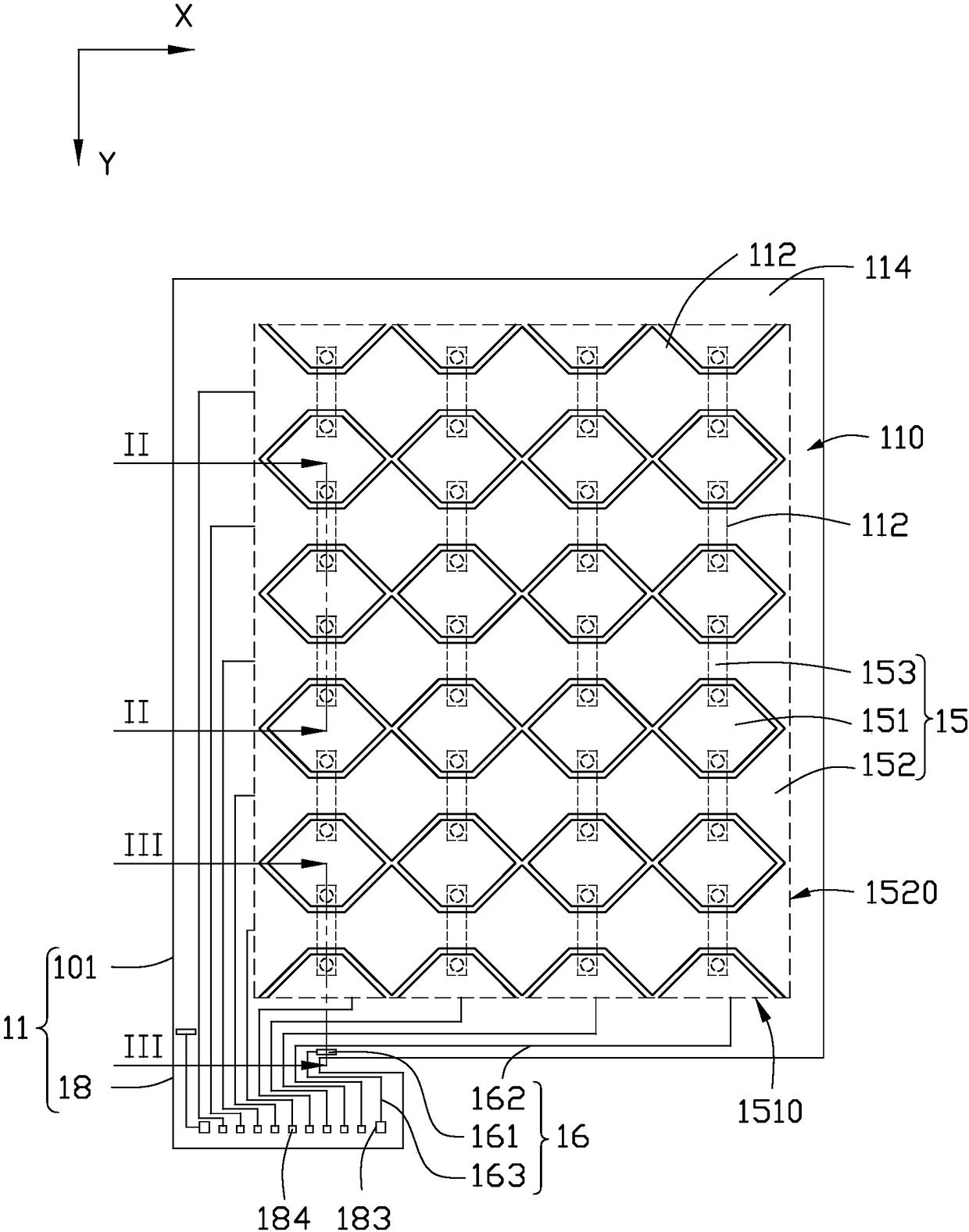

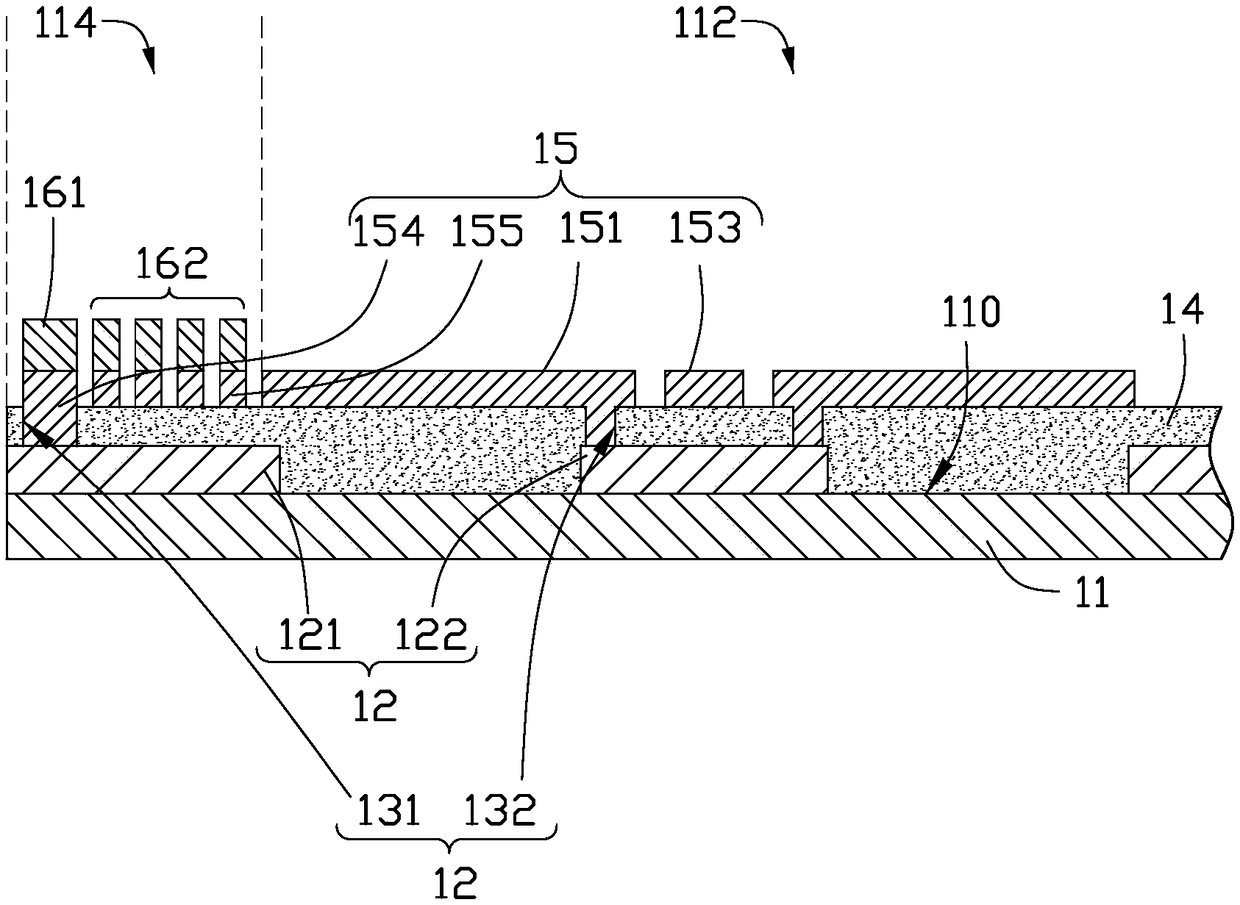

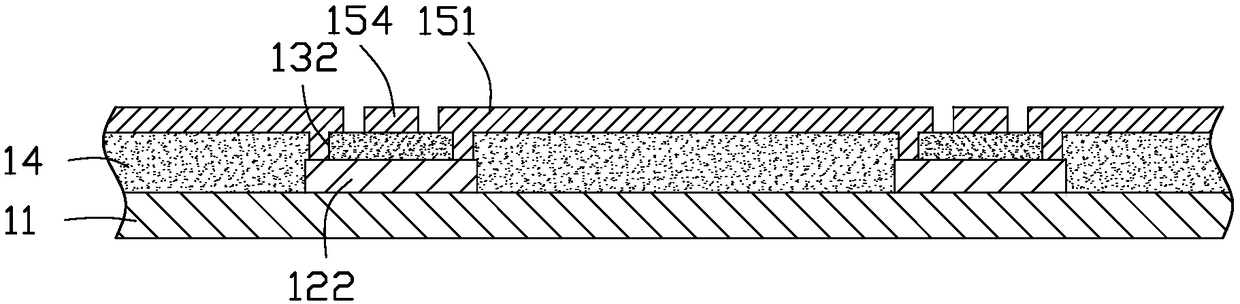

[0028] Such as Figure 1 to Figure 3 As shown, the touch sensing module 10 of the first embodiment of the present invention includes a substrate 11 , a first same-layer structure 12 , a second same-layer structure 15 , wires 16 , an insulating layer 14 and via holes 13 .

[0029] The substrate 11 is the carrier base of the touch sensing module 10, the first same-layer structure 12, the second same-layer structure 15, the wires 16, the insulating layer 14 and the conductors of the touch sensing module 10. The through hole 13 is disposed on the substrate 11 . The substrate 11 can be a flexible material or a non-flexible material. In this embodiment, the substrate 11 is a flexible material, which has flexibility, so that the touch sensing module 10 can be applied to a curved display device or a flexible display device. The material of the substrate 11 can be organic, such as polycarbonate (Polycarbonate, PC), polyimide (Polyimide, PI), polyethylene naphthalate (Polyethylene nap...

no. 2 example

[0043] see Figures 4a to 4g , is a schematic diagram of the steps of the manufacturing method of the touch sensing module provided by the specific embodiment of the present invention. It should be noted that the manufacturing method of the touch sensing module of the present invention is not limited to the order of the following steps, and in other implementations, the manufacturing method of the touch sensing module of this embodiment may only include the following Some of the steps, or parts of the steps, may be deleted.

[0044] Combine below Figures 4a to 4g The manufacturing method of the touch sensing module provided by the specific embodiment of the present invention is introduced in detail.

[0045] The manufacturing method of the touch sensing module 10 in a preferred embodiment of the present invention includes the following steps:

[0046] Step 1: Provide a substrate, and form an opaque first conductive material layer A by vapor deposition on one side of the su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com