Fabricated building quality management system

A quality management, prefabricated technology, applied in the direction of collaborative operation devices, electromagnetic radiation induction, instruments, etc., can solve problems affecting construction progress, difficult to query, project quality impact, etc., to reduce safety accidents, avoid data inconsistency, improve The effect of quality management efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

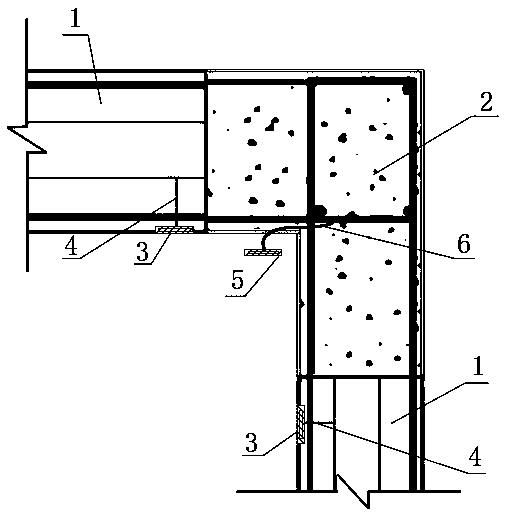

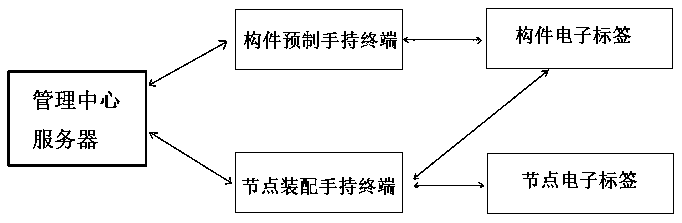

[0023] see figure 1 and figure 2 , a prefabricated building quality management system, including component electronic tags pre-embedded in building components 1, node electronic tags set at component nodes 2, management center server, component prefabricated handheld terminals and node assembly handheld terminals, said Both the component prefabricated handheld terminal and the node assembly handheld terminal include a battery, a tag reader, a microprocessor, a display screen, a wireless transmission device and a memory, and the component electronic tags and node electronic tags are non-contact automatic read-write electronic tags, The component prefabricated handheld terminal can read and write data on the component electronic tag, and the node assembly handheld terminal can read and write data on the node electroni...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com