Vacuum explosion chamber with static side buffer and direct current circuit breaker

A technology of vacuum interrupter and static side contacts, which is applied in the field of high voltage devices, can solve the problems of reduced service life and extra impact force of opening, and achieve the effects of improving service life, reducing contact deformation and avoiding damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

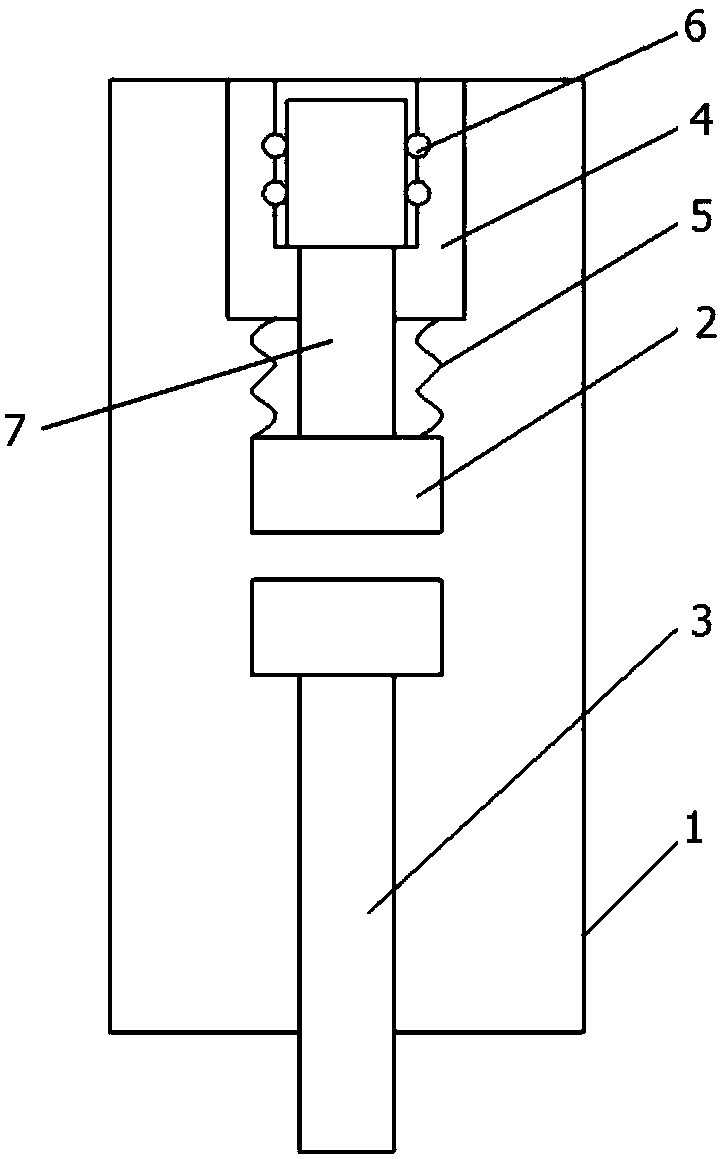

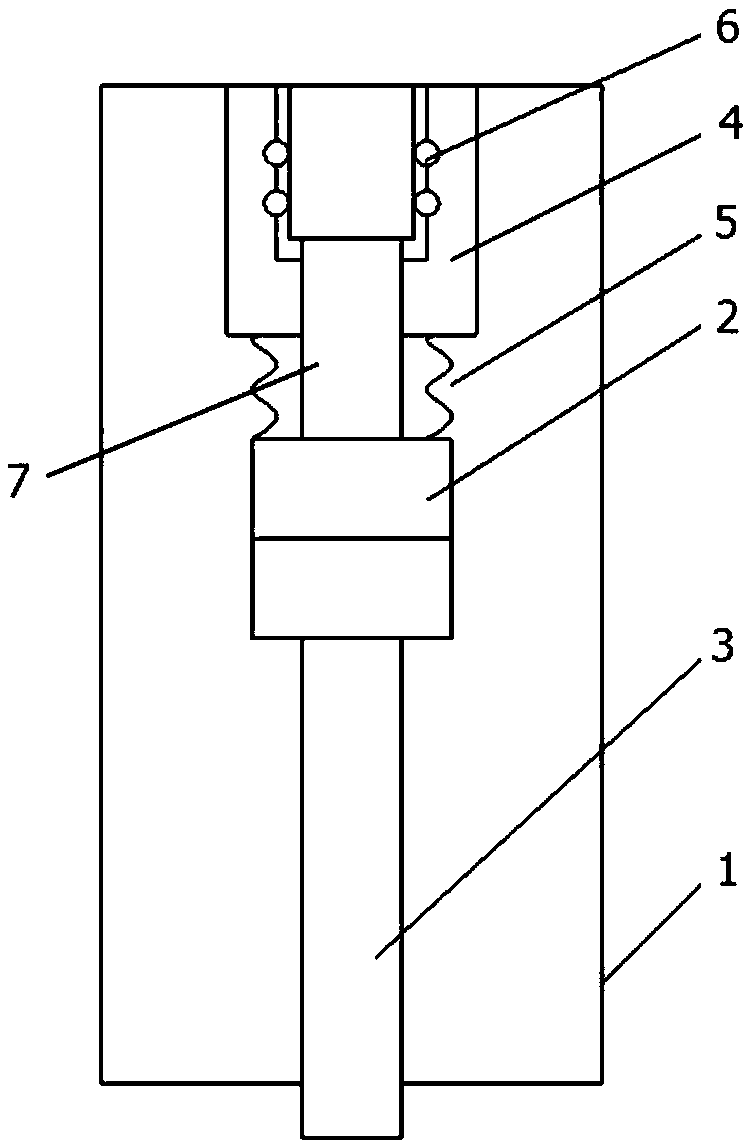

Embodiment 1

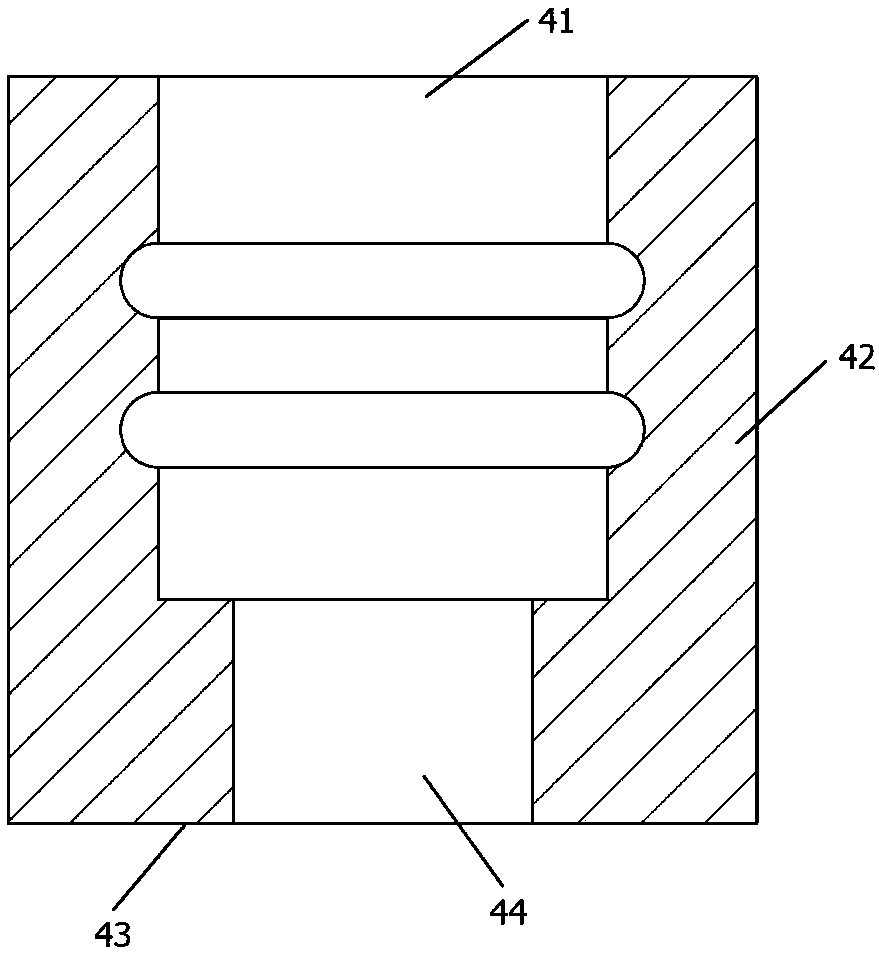

[0030] Example one, as image 3 and 4 As shown, the cross section of the conductive block 4 is a U-shaped structure, of course, it can also be other shapes, such as square, trapezoid, etc., including an opening 41, a side wall 42 and a bottom surface 43, the opening 41 is connected to the housing 1, and the bottom surface The center of 43 is provided with a through hole 44. The static conductive rod 7 has a T-shaped structure as a whole, including a vertical portion 71 and a horizontal portion 72. One end of the vertical portion 71 is connected to the static side contact, and the other end passes through the through hole. 44 is connected with the horizontal part 72, the horizontal part 72 is connected with the side wall 42 through the conductive contact fingers 6, the diameter of the through hole is larger than the diameter of the vertical part and smaller than the diameter of the horizontal part, so that the horizontal part 72 is easy to be stuck between the two holes of the ...

Embodiment 2

[0031] Example two, as Figure 7 and 8 As shown, the cross section of the conductive block 4 is a U-shaped structure, including an opening 41, a side wall 42 and a bottom surface 43, the opening 41 is connected with the housing 1, and a through hole 44 is provided in the center of the bottom surface 43. The static conductive rod 7 The other end of the static conductive rod 7 is provided with a long waist hole 73 along the length direction, the side wall 42 of the conductive block 4 is provided with a first through hole 45, the other end of the static conductive rod 7 and the side wall of the conductive block 4 also pass through the cylindrical pin 8. The long waist hole 73 is connected to the first through hole 45 , the closing stopper is set at the top of the long waist hole 73 , and the opening stopper is set at the top of the long waist hole 73 . In this way, the static conducting rod 7 It is not necessary to adopt a T-shaped structure, and a straight rod shape can also be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com