Injection mold for producing sewage treatment pipe

A technology for producing sewage and injection molds, applied in the field of molds, can solve the problems of increasing the structural size of the mold, the space in the middle is not fully utilized, and the cost of single mold manufacturing of the mold is increased. The effect of reducing the cost of single-piece manufacturing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

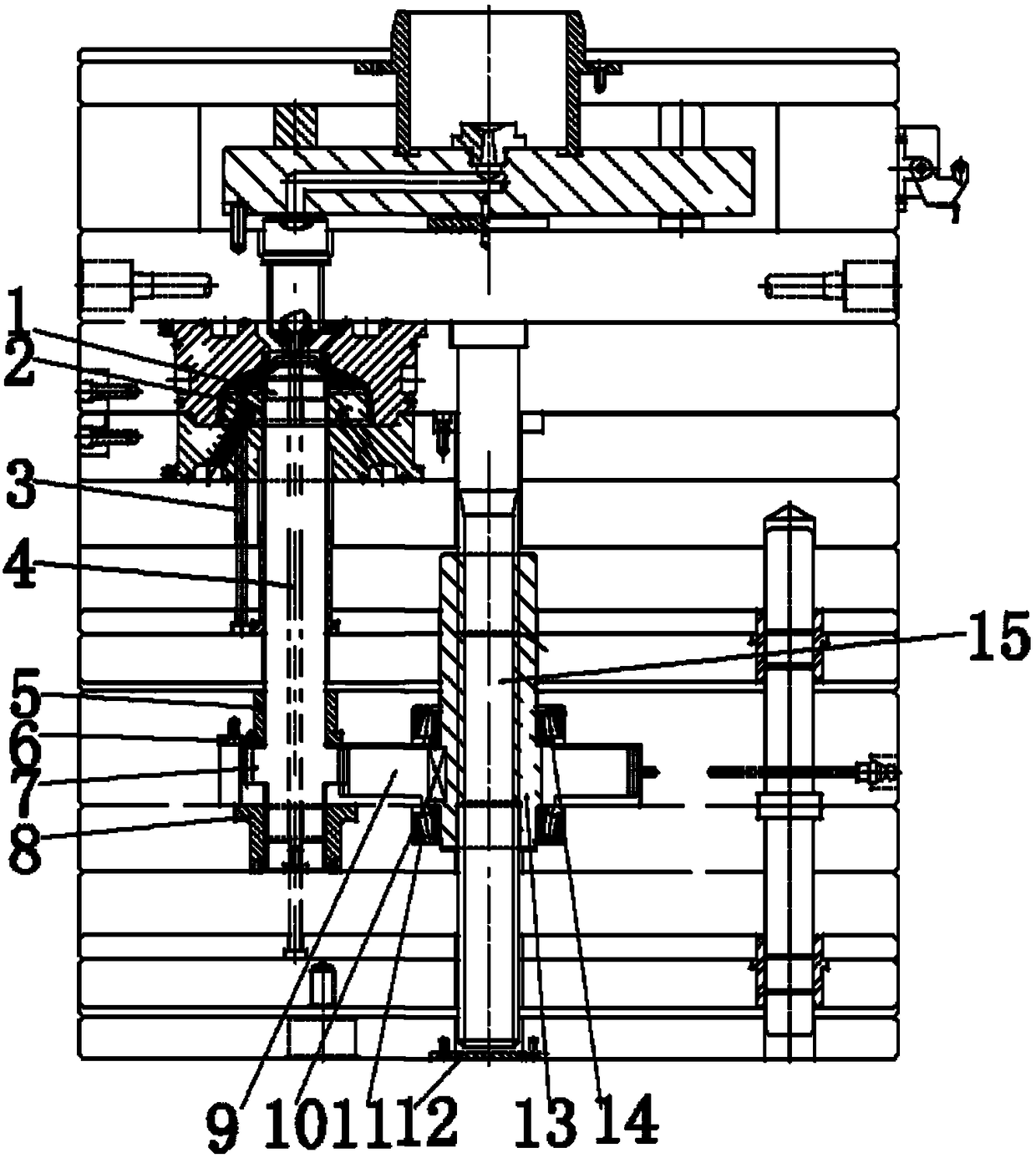

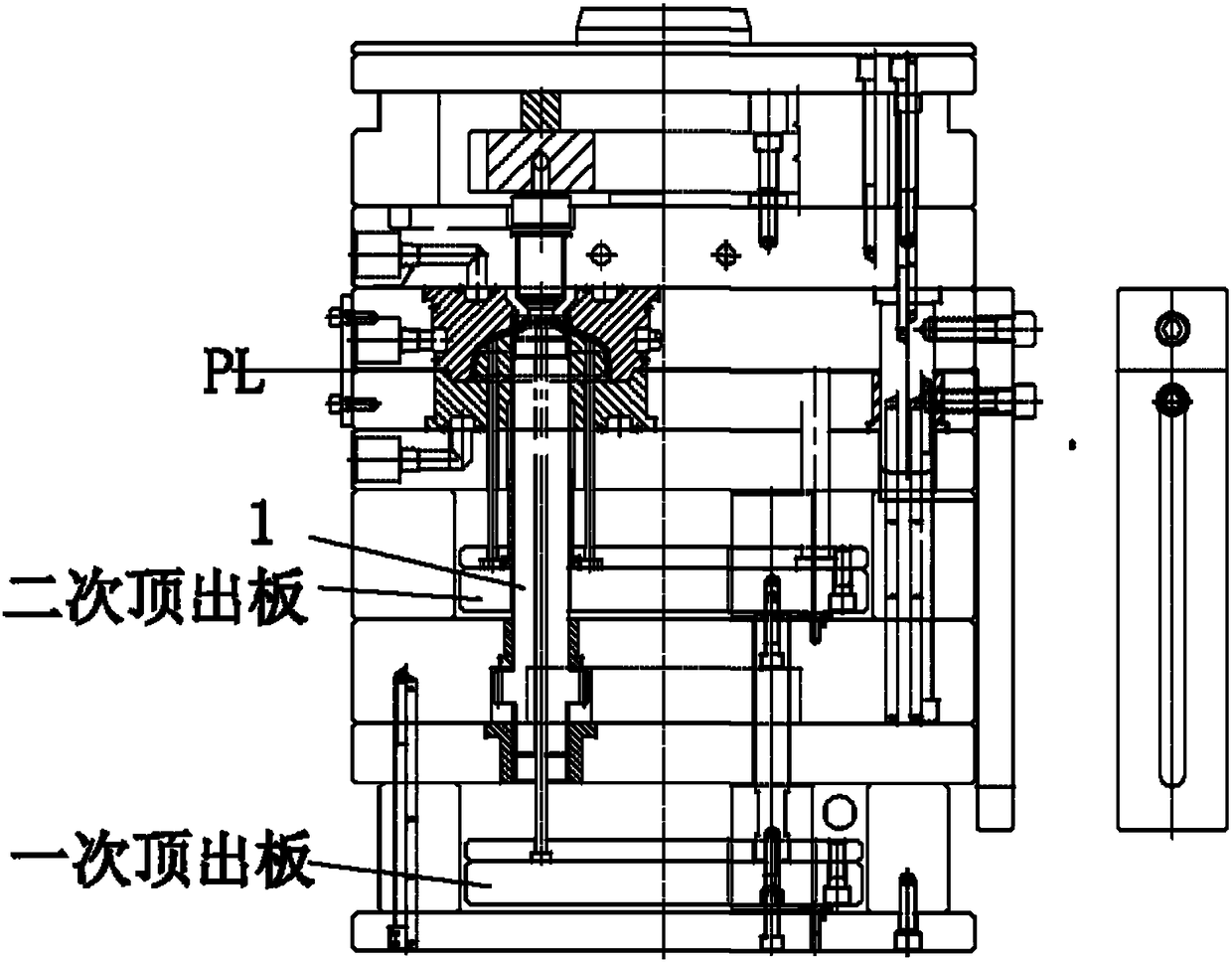

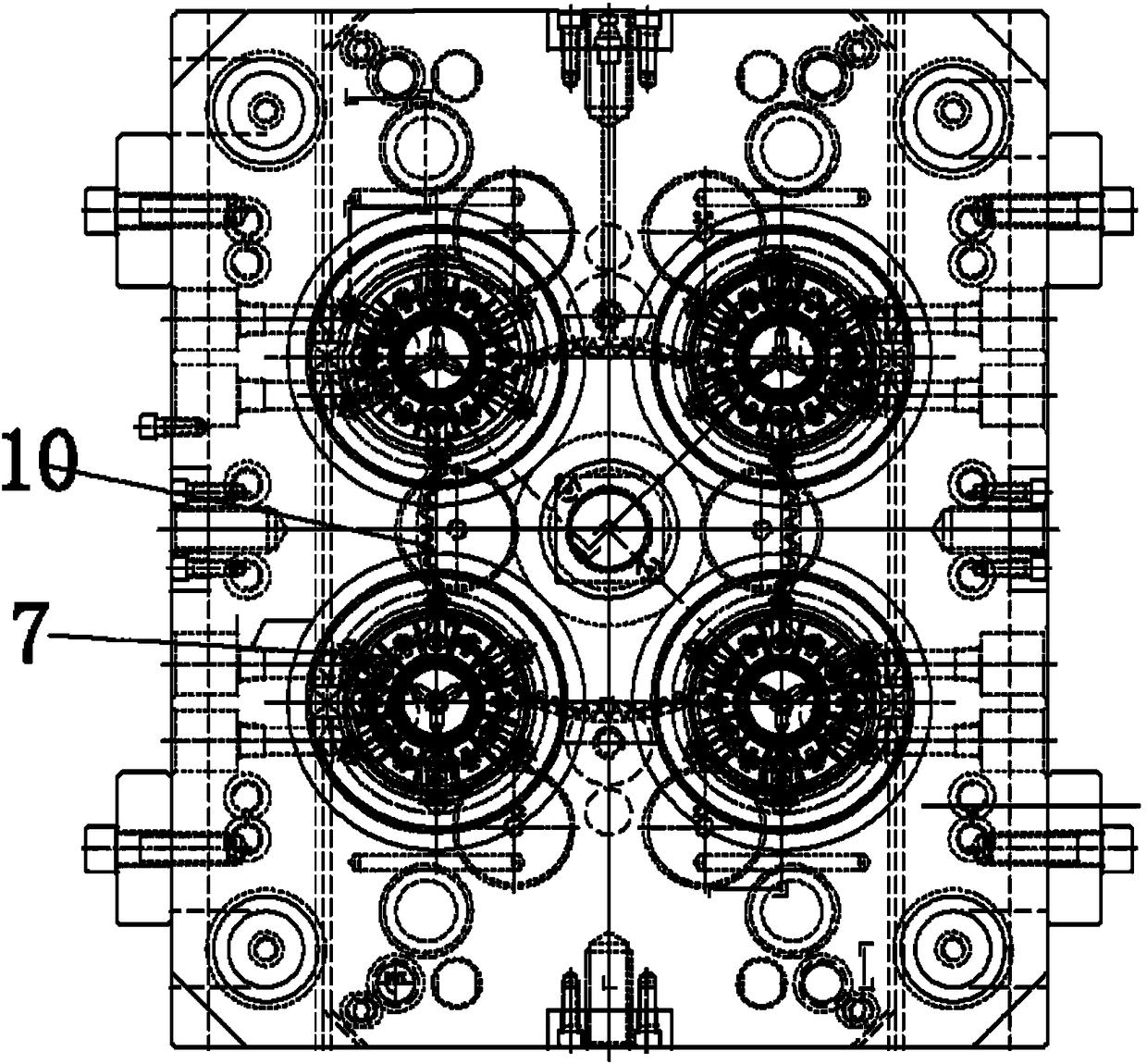

[0017] Figure 1-4 Shown is the relevant explanatory figure of the present invention; The specific embodiment is, as figure 1 , figure 2 , image 3 , Figure 4 As shown, an injection mold for producing sewage treatment pipes includes a central worm-driven gear unthreading mechanism, which includes a central threaded core 1, an inner edge ejector pusher 2, an auxiliary ejector needle 3, an ejector Material ejector rod 4, upper rotating sleeve 5, rotating sleeve fixing plate 6, threaded core gear 7, lower threaded sleeve 8, worm sleeve driving gear 9, gear key 10, lower bearing 11, ground cover 12, worm sleeve 13, Upper bearing 14, central drive worm 15.

[0018] The threaded core rotating assembly of the mechanism includes a central threaded core 1, an inner edge ejector push tube 2, an auxiliary ejector pin 3, a stripping ejector rod 4, an upper rotating sleeve 5, a rotating sleeve fixing plate 6, and a threaded core Gear 7, lower threaded sleeve 8, worm sleeve drive gea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com