Environment-friendly bare concrete and preparation method thereof

A fair-faced concrete, environmentally friendly technology, applied in the field of concrete, can solve the problems of air bubbles and chromatic aberration, achieve the effect of bright and uniform color, improve appearance and reduce chromatic aberration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

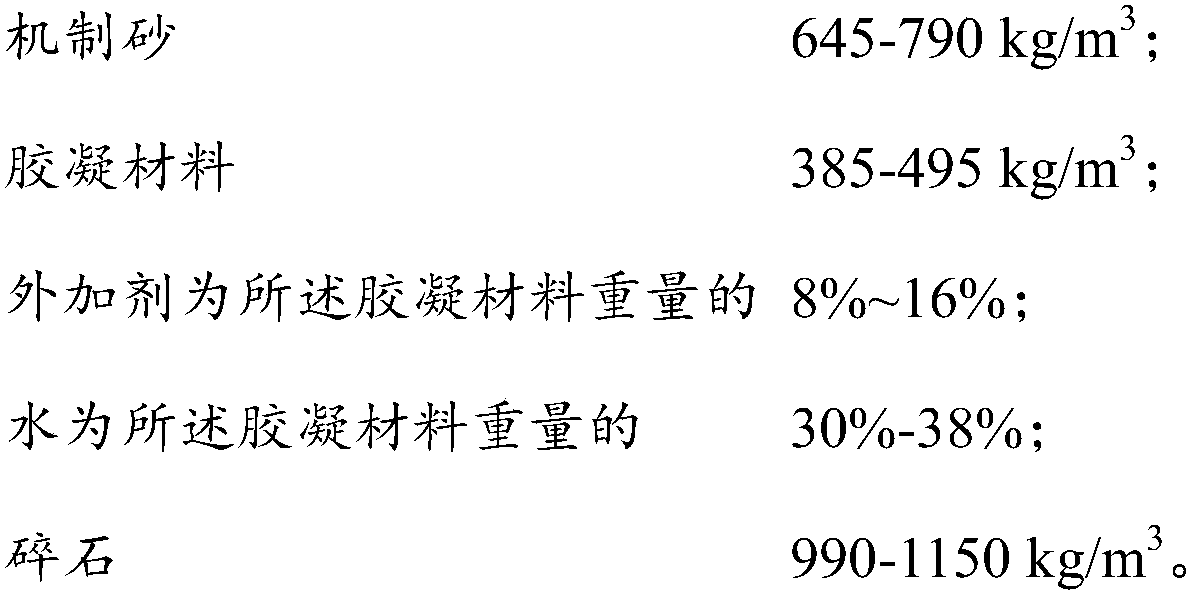

[0020] An environment-friendly fair-faced concrete, including machine-made sand, cementitious material, admixture, water and gravel. Weigh the raw materials according to the weight ratio of the following components: machine-made sand 731kg / m 3 , cement 249kg / m 3 , Mineral powder 184kg / m 3 , silicon powder 18.6kg / m 3 With fine microbeads 28.4kg / m 3 , gravel 1032kg / m 3 , Polycarboxylate superplasticizer 5.6kg / m 3 , water 149kg / m 3 .

[0021] The preparation method of environment-friendly fair-faced concrete is as follows:

[0022] 1) According to the relevant requirements of fair-faced concrete and the relevant specifications of concrete design, determine the mix ratio of environment-friendly clear-water concrete described in this embodiment, wherein:

[0023] Machine-made sand 731kg / m 3 , cement 249kg / m 3 , Mineral powder 184kg / m 3 , silicon powder 18.6kg / m 3 With fine microbeads 28.4kg / m 3 , gravel 1032kg / m 3 , Polycarboxylate superplasticizer 5.6kg / m 3 , water ...

Embodiment 2

[0029] An environment-friendly fair-faced concrete, including tunnel slag, cementitious material, admixture, water and gravel. Weigh raw materials according to the following component weight ratio: tunnel slag 724kg / m 3 , Cement 335kg / m 3 , mineral powder 98kg / m 3 , silicon powder 13.8kg / m 3 With fine microbeads 33.2kg / m 3 ; Gravel 1059kg / m 3 ;Composite water reducer 5.9kg / m 3 , of which polycarboxylate superplasticizer 5.37kg / m 3 , defoamer 0.06kg / m 3 , air-entraining agent 0.18kg / m 3 , tackifier 0.29kg / m 3 ; Water 146kg / m 3 .

[0030] The preparation method of present embodiment environment-friendly type fair-faced concrete is as follows:

[0031] 1) According to the relevant requirements of fair-faced concrete and the relevant specifications of concrete design, the mix ratio of the environment-friendly clear-water concrete described in this embodiment is determined, wherein the tunnel slag is 724kg / m 3 , Cement 335kg / m 3 , mineral powder 98kg / m 3 , silicon pow...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| power level | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com