Highly-efficient polyether-modified sulfamate water-reducing agent, and preparation method and application thereof

A technology of sulfamate and high-efficiency water reducer, which is applied in the field of polyether modified sulfamate high-efficiency water reducer, can solve the problems of no change of water reducer, high dosage, large collapse loss, etc. Dispersion retention performance, effect of improving dispersion performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

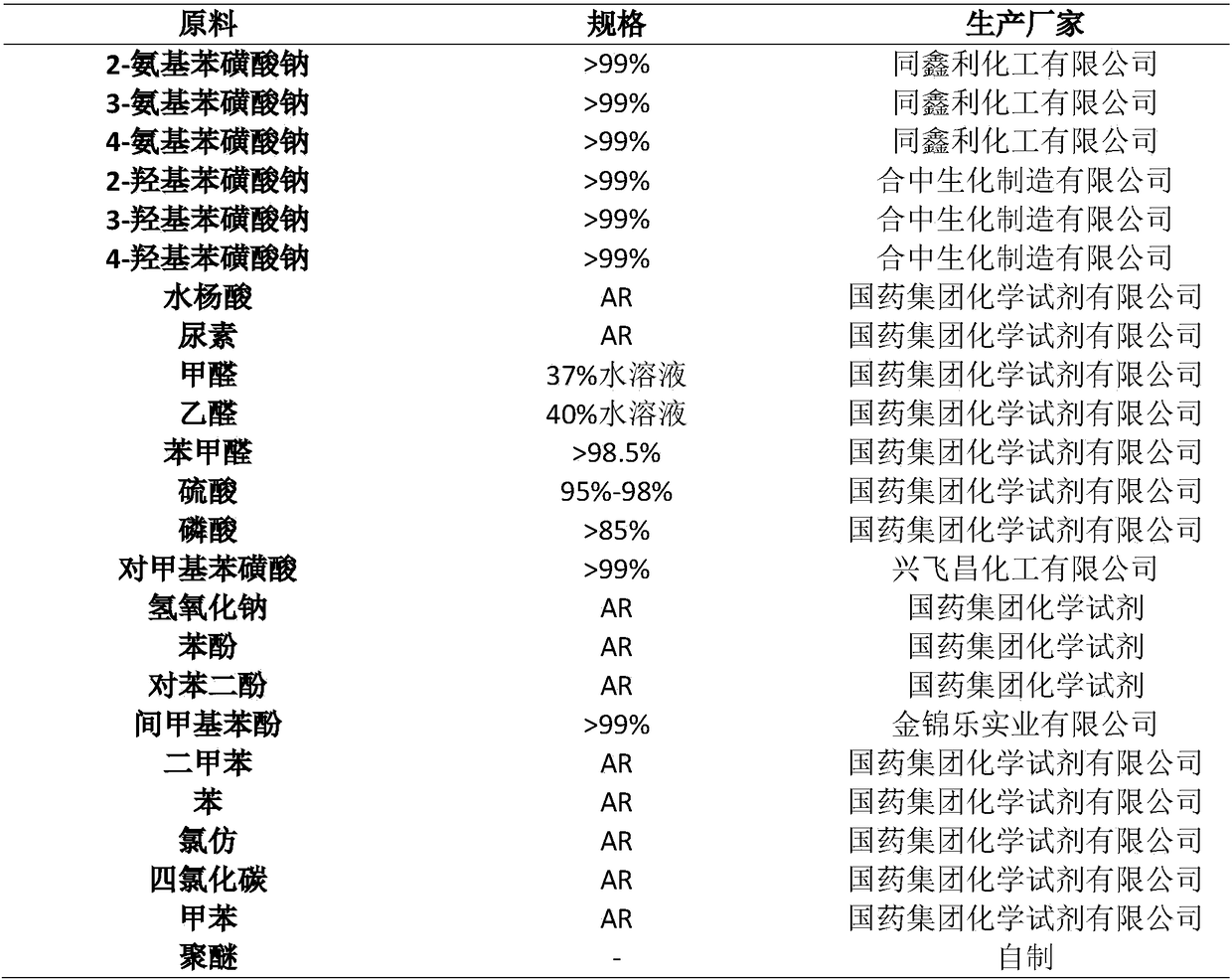

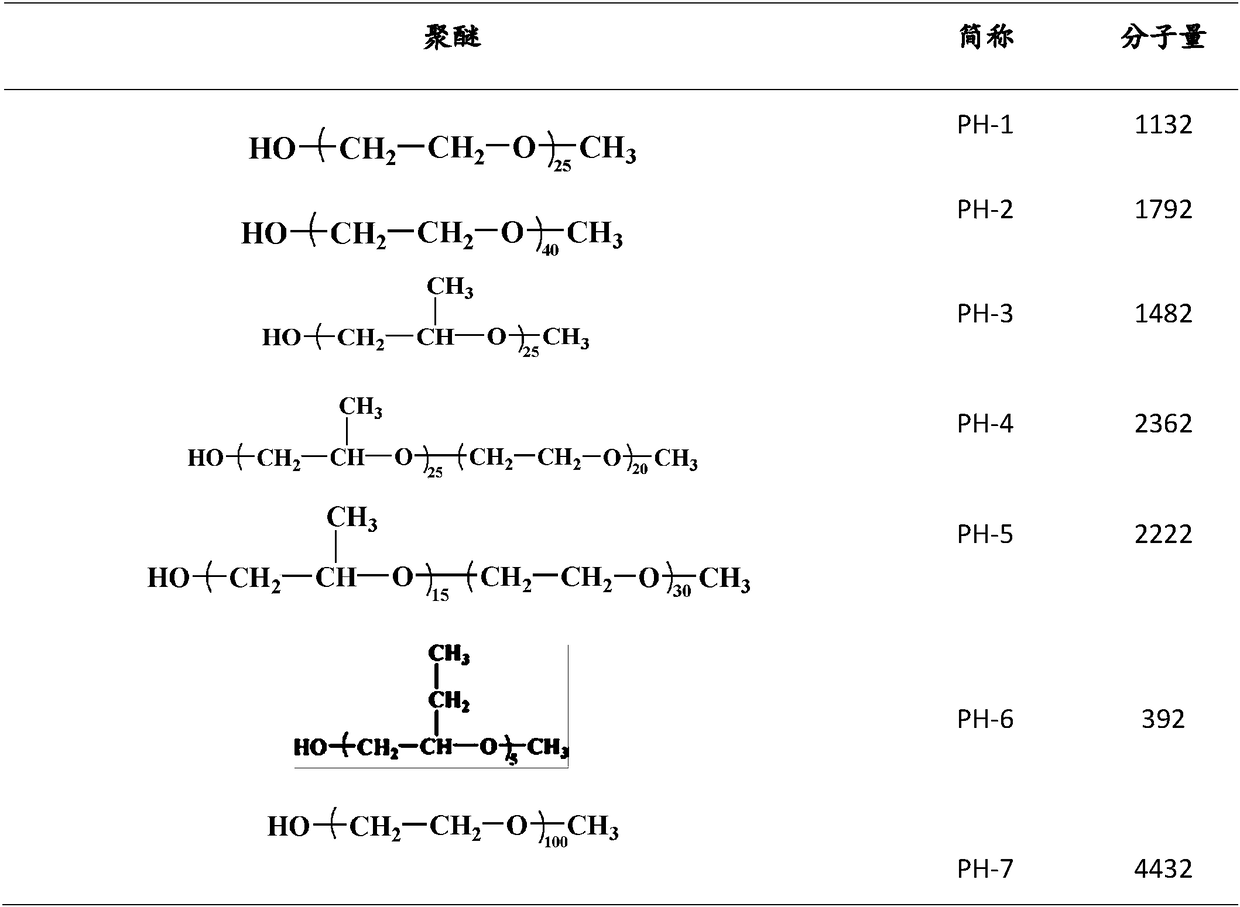

[0055] Weigh 0.08mol sodium 4-aminobenzenesulfonate and 0.02mol sodium 4-hydroxybenzenesulfonate, place them in a 500mL three-neck flask equipped with a stirring paddle and a reflux condenser, add 0.1mol polyether PH-1, 0.1mol water Salicylic acid, 0.1mol urea, and 0.12mol phenol were heated up to 80°C to dissolve them all, and 20.6g of concentrated sulfuric acid (10wt% of the total amount of monomers) was added while stirring, and 0.52mol of formaldehyde was added dropwise within 20 minutes. React at 90°C for 5 hours to obtain the molecular backbone of the sulfamate superplasticizer. Then add 60g of xylene into the flask, slowly add 10g of concentrated sulfuric acid, install a water separator, raise the temperature to 130°C, and perform the esterification reaction for 4 hours. After no water evaporates, turn off the stirring and heating, stop the reaction, and recover the fraction Aqueous xylene in the water container. After the reaction was completed, it was neutralized wit...

Embodiment 2

[0057] Weigh 0.09mol sodium 4-aminobenzenesulfonate and 0.01mol sodium 4-hydroxybenzenesulfonate, place them in a 500mL three-necked flask equipped with a stirring paddle and a reflux condenser, add 0.08mol polyether PH-2, 0.1mol salicylic acid , 0.01mol urea and 0.19mol hydroquinone, be warmed up to 85 ℃ and make it all dissolve, add vitriol oil 11.73g (5wt% of monomer total amount) while stirring, after slowly adding 0.504mol formaldehyde dropwise in 20min, in React at a constant temperature of 90°C for 4 hours to obtain the molecular backbone of the sulfamate superplasticizer. Then add 60g of toluene to the flask, slowly add 20g of p-toluenesulfonic acid, install a water separator, raise the temperature to 120°C, and carry out the esterification reaction for 5 hours. After no water evaporates, stop the reaction and recover the water-carrying agent toluene . After the reaction was completed, it was neutralized with 30% NaOH solution, and 250 g of water was added to obtain a...

Embodiment 3

[0059] Weigh 0.048mol sodium 4-aminobenzenesulfonate, 0.032mol sodium 2-aminobenzenesulfonate, and 0.04mol sodium 4-hydroxybenzenesulfonate, place them in a 500mL three-necked flask equipped with a stirring paddle and a reflux condenser, and add 0.05 mol polyether PH-3, 0.1mol salicylic acid, 0.1mol urea and 0.1mol phenol, be heated up to 100 ℃ and make it all dissolve, add 28.4g p-toluenesulfonic acid (15wt% of monomer total amount) while stirring ), slowly add 0.52mol formaldehyde dropwise within 20min, and react at a constant temperature of 110°C for 5h to obtain the molecular backbone of the sulfamate superplasticizer. Then add 50g of benzene in the flask, slowly add 10g of phosphoric acid (mass fraction greater than 85%), install a water separator, raise the temperature to 120°C, and perform the esterification reaction for 4 hours. After no water evaporates, stop the reaction and recover the water agent benzene. After the reaction was completed, it was neutralized with N...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap