Water-based blackening low-foaming composite wetting agent for synthetic leather and application of composite wetting agent

A technology of synthetic leather and wetting agent, applied in coatings, polyurea/polyurethane coatings, etc., can solve the problems of poor wetting of leather surface, easy to appear bright spots, etc., achieve low wetting problems, improve blackness, spread good performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] The general structural formula of the raw materials used in all embodiments is the same, and is all made up of polyether modified organosilicon, decynediol polyoxyethylene ether surfactant and fatty alcohol polyoxyethylene ether phosphate surfactant; The formulation of the wet agent is shown in Table 4, and the raw materials involved are shown in Tables 1-3.

[0045] In the present invention, the polyether-modified silicone is defined as component I, the decynediol polyoxyethylene ether surfactant is defined as component II, and the fatty alcohol polyoxyethylene ether phosphate surfactant is defined as component III.

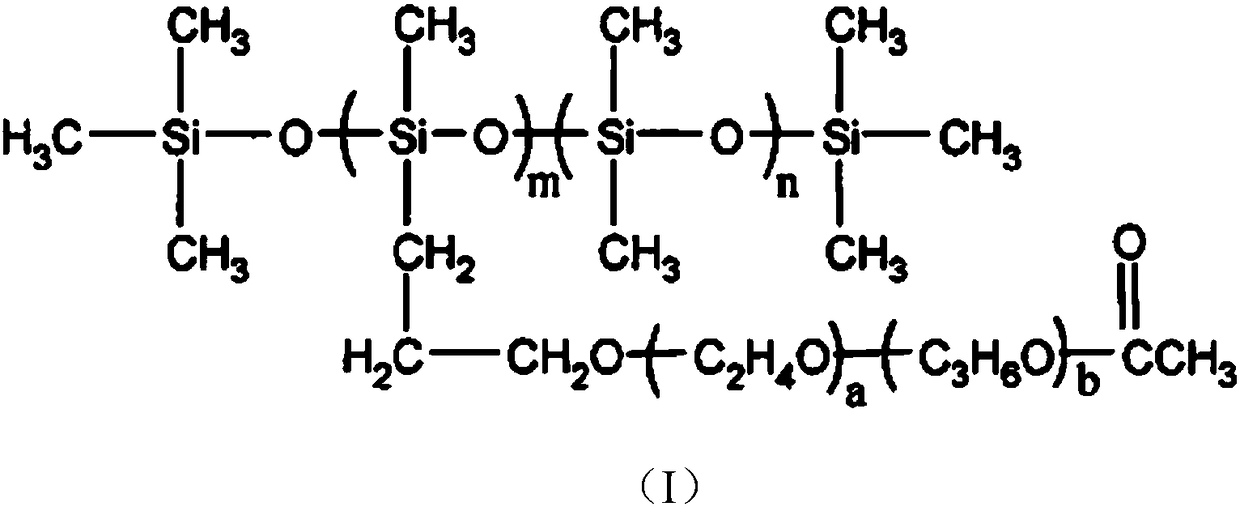

[0046] The general structural formula of the polyether modified silicone used is:

[0047]

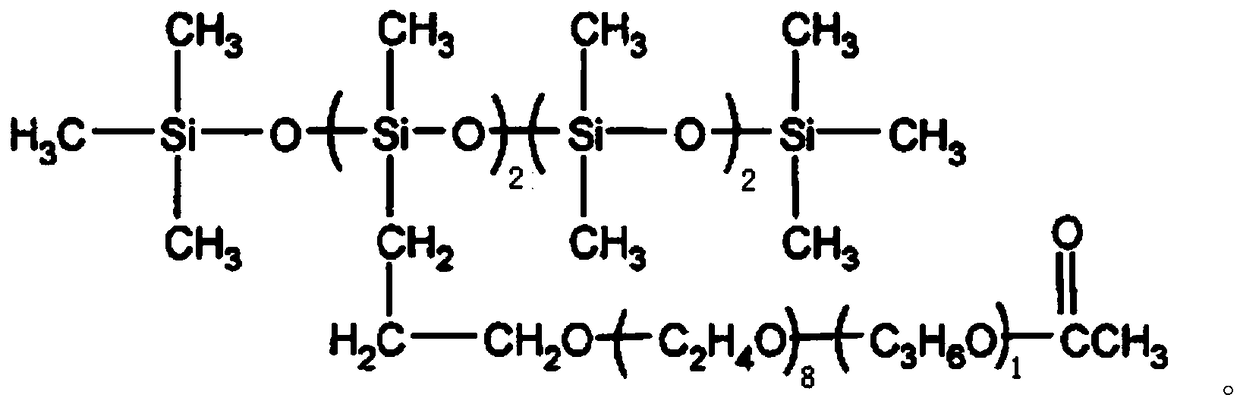

[0048]Table 1 - Chemical Structure of Component I Polyether Modified Silicone

[0049]

[0050]

[0051] The structural general formula of used decynediol polyoxyethylene ether surfactant:

[0052]

[0053] Table 2-Chemical Structure of Component II ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com