Emulsion and powder microsphere injection device and method

A technology of injection device and microspheres, which is used in earth-moving drilling, production of fluids, wellbore/well components, etc., can solve the problems of easy agglomeration, difficult dispersion, and difficulty of powder microspheres, and achieves a high degree of automation and control process. simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention is described in detail below in conjunction with accompanying drawing and specific embodiment:

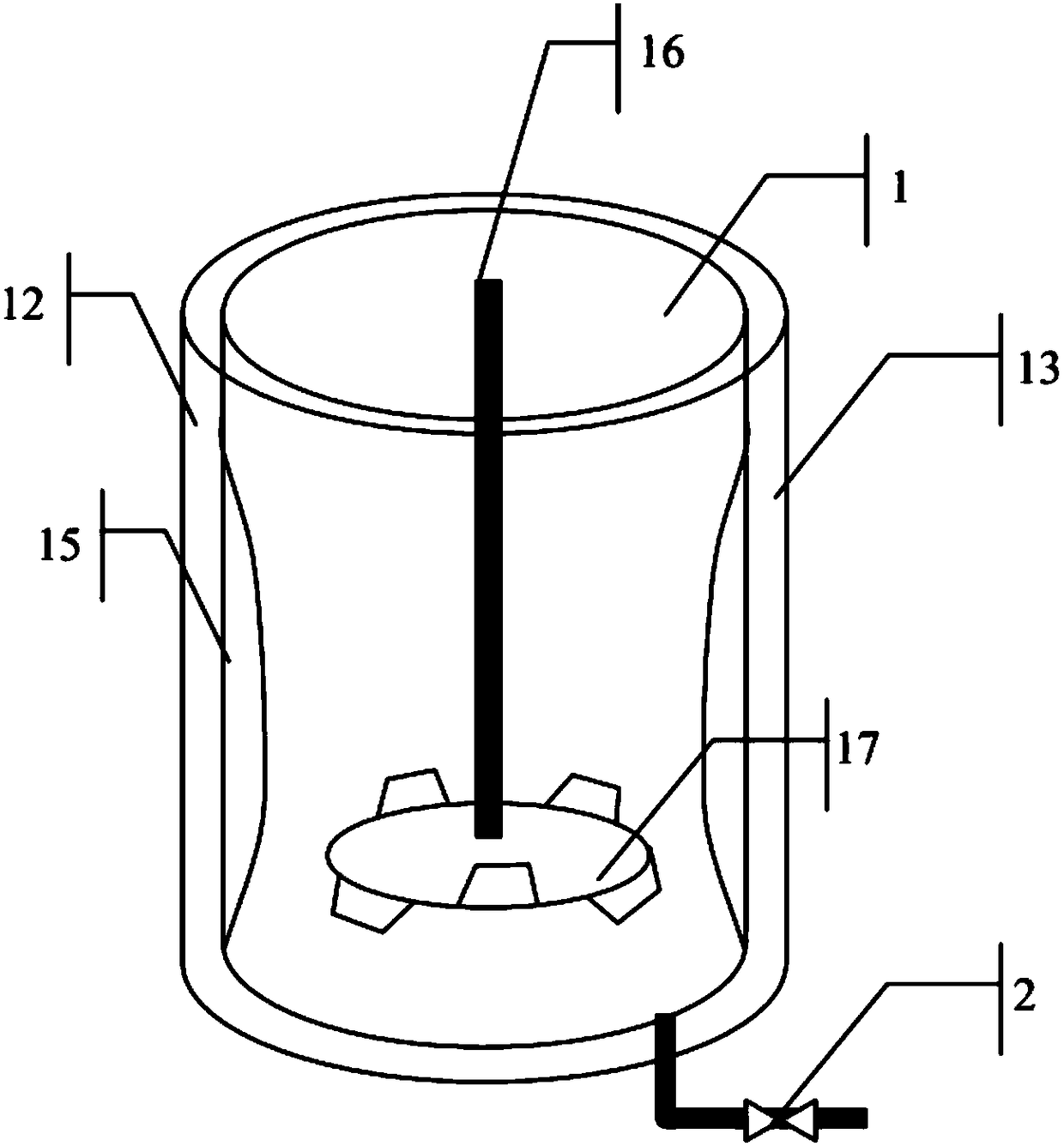

[0032] Such as Figure 1 to Figure 4 As shown, the present invention mainly consists of an injection unit and a liquid storage and dispensing unit.

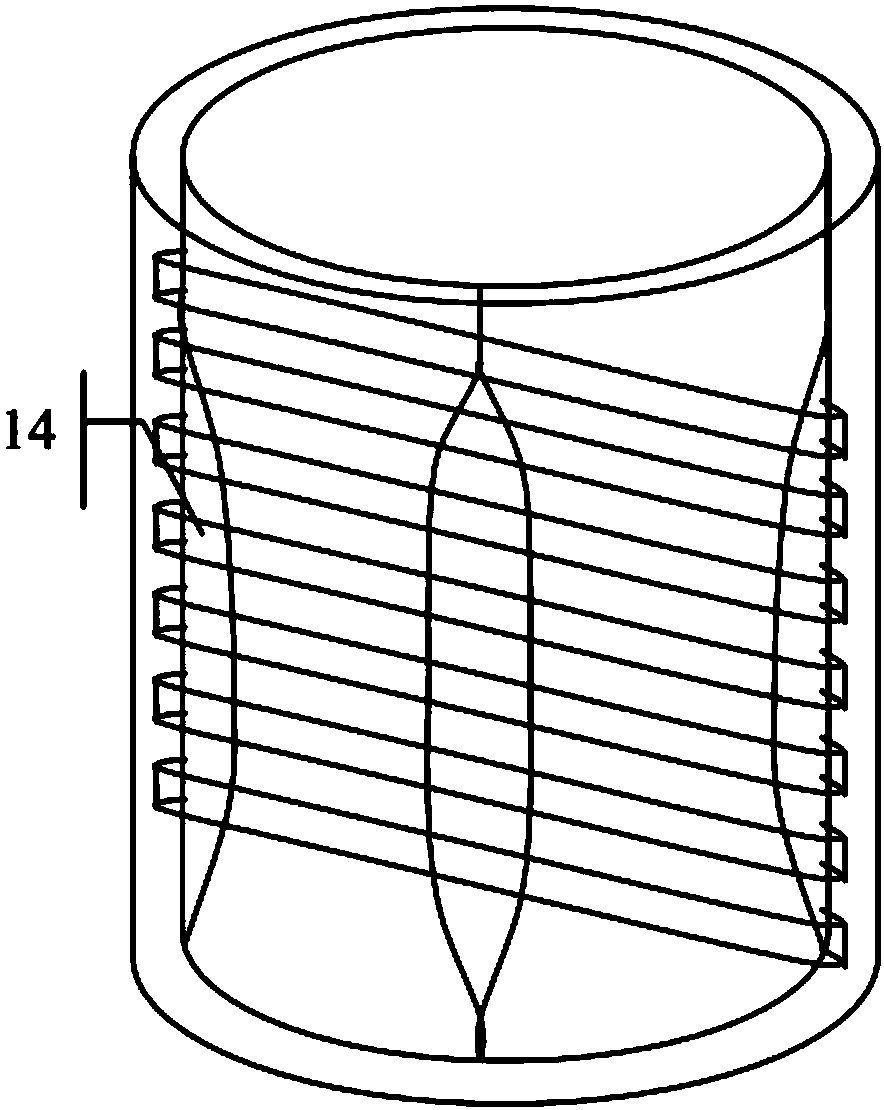

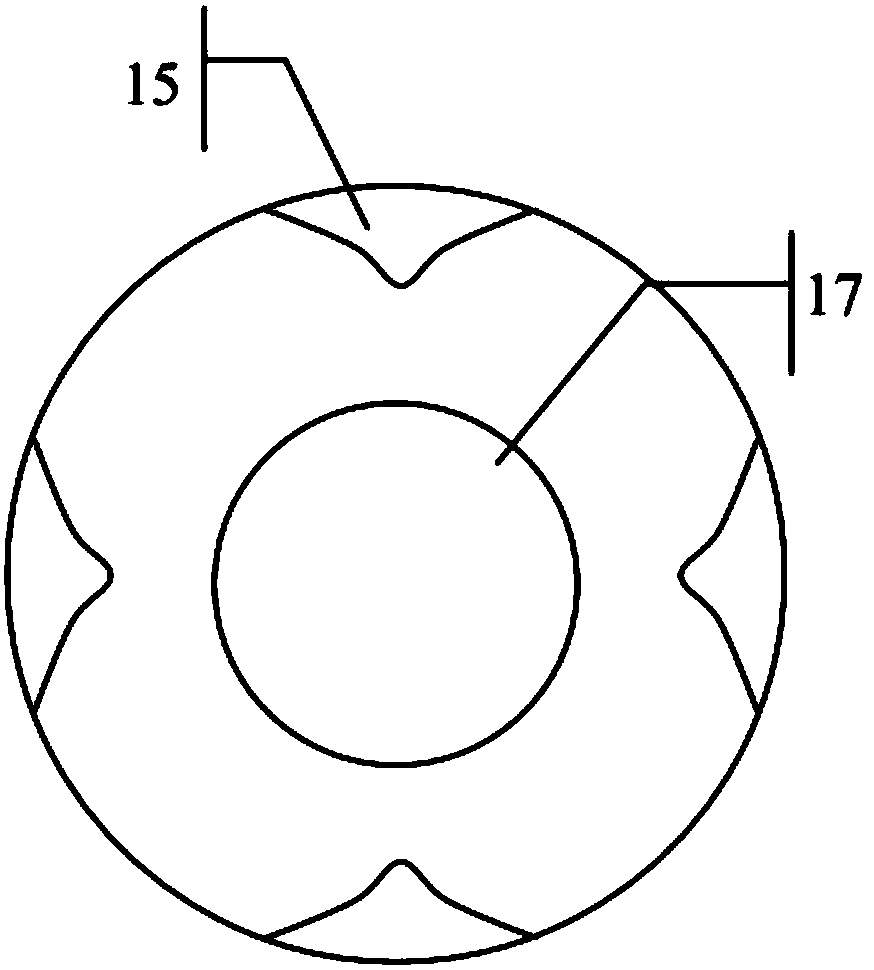

[0033] Such as Figure 1 to Figure 3 As shown, the liquid storage and dispensing unit includes a liquid storage tank. The liquid storage tank has a three-layer structure, which is an inner tank 1, an insulating layer 12 and an outer shell 13 from the inside to the outside. On the outer wall of the inner tank 1, heating cables 14 are evenly wound and distributed, and the heating cables 14 are connected to the control cabinet 9 through electric wires. The inner wall of the inner tank 1 has four spoilers 15, which are evenly distributed at 90°, which can increase the turbulence of the liquid in the tank and improve the dispersion effect. The inside of the inner tank 1 is provided with a dispersing disc 17...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com