Longitudinal energy-saving boiler with rotating fire grate

A furnace grate, vertical type technology, applied in the direction of furnace grate, rotary grate, rocking grate, etc., can solve the problems of energy waste, influence heat, simple structure, etc., to avoid burns, reduce energy waste, The effect of improving the safety of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

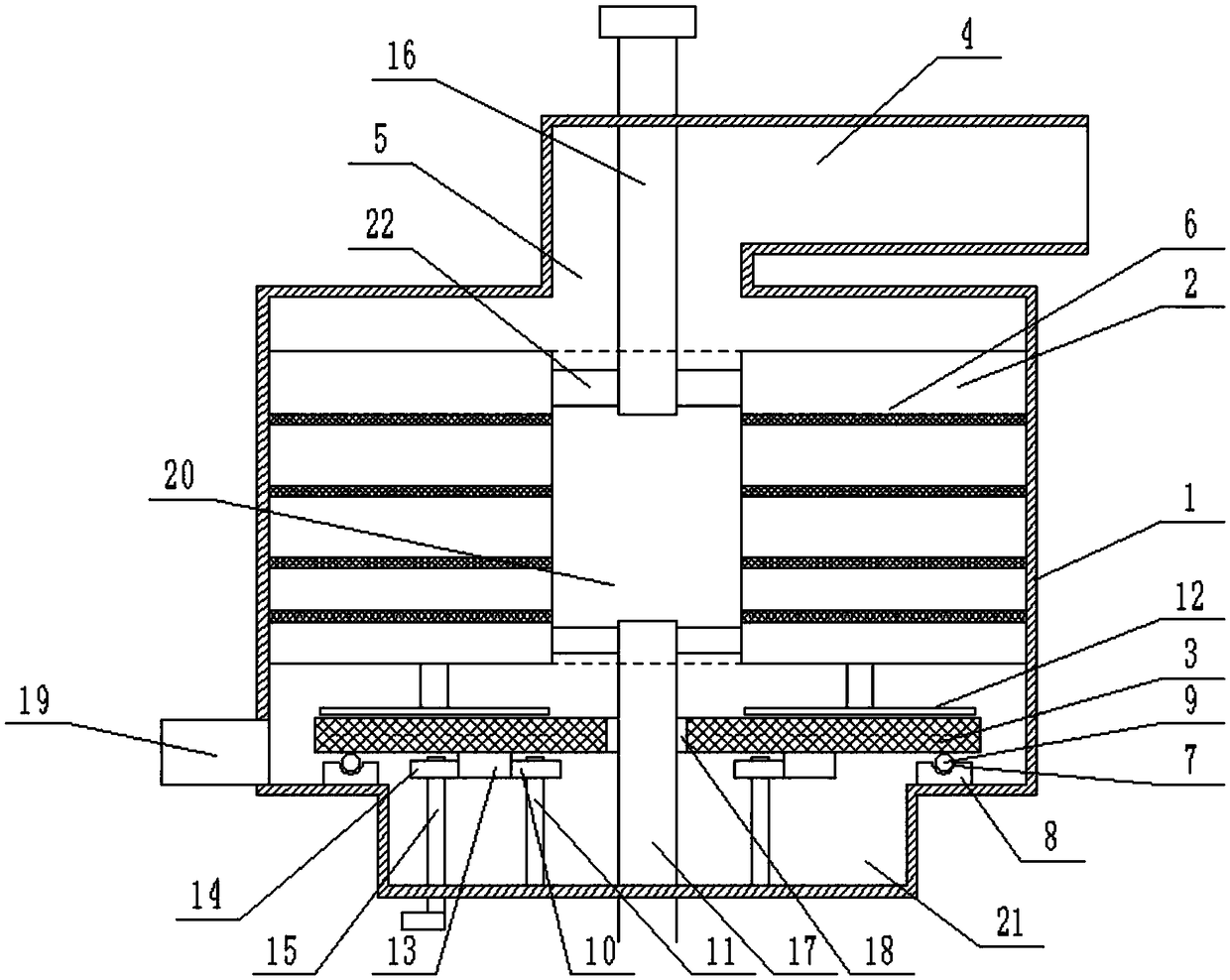

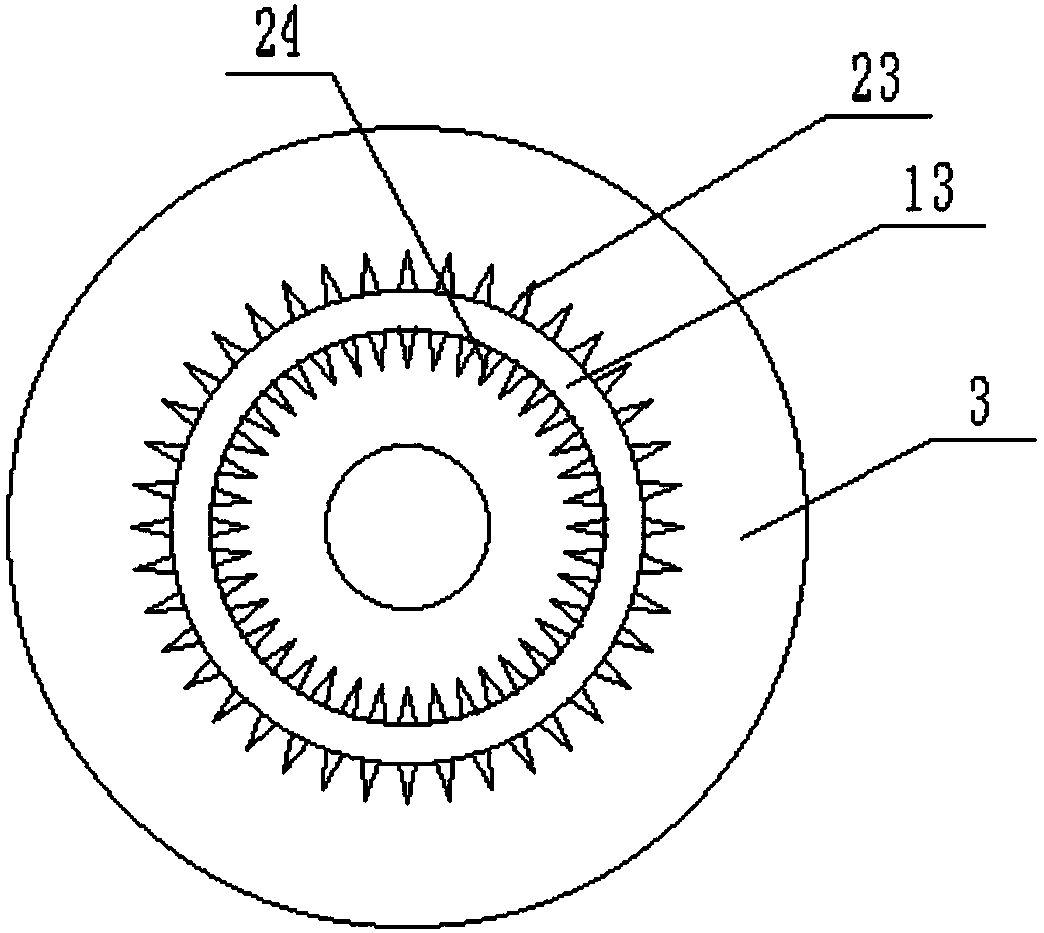

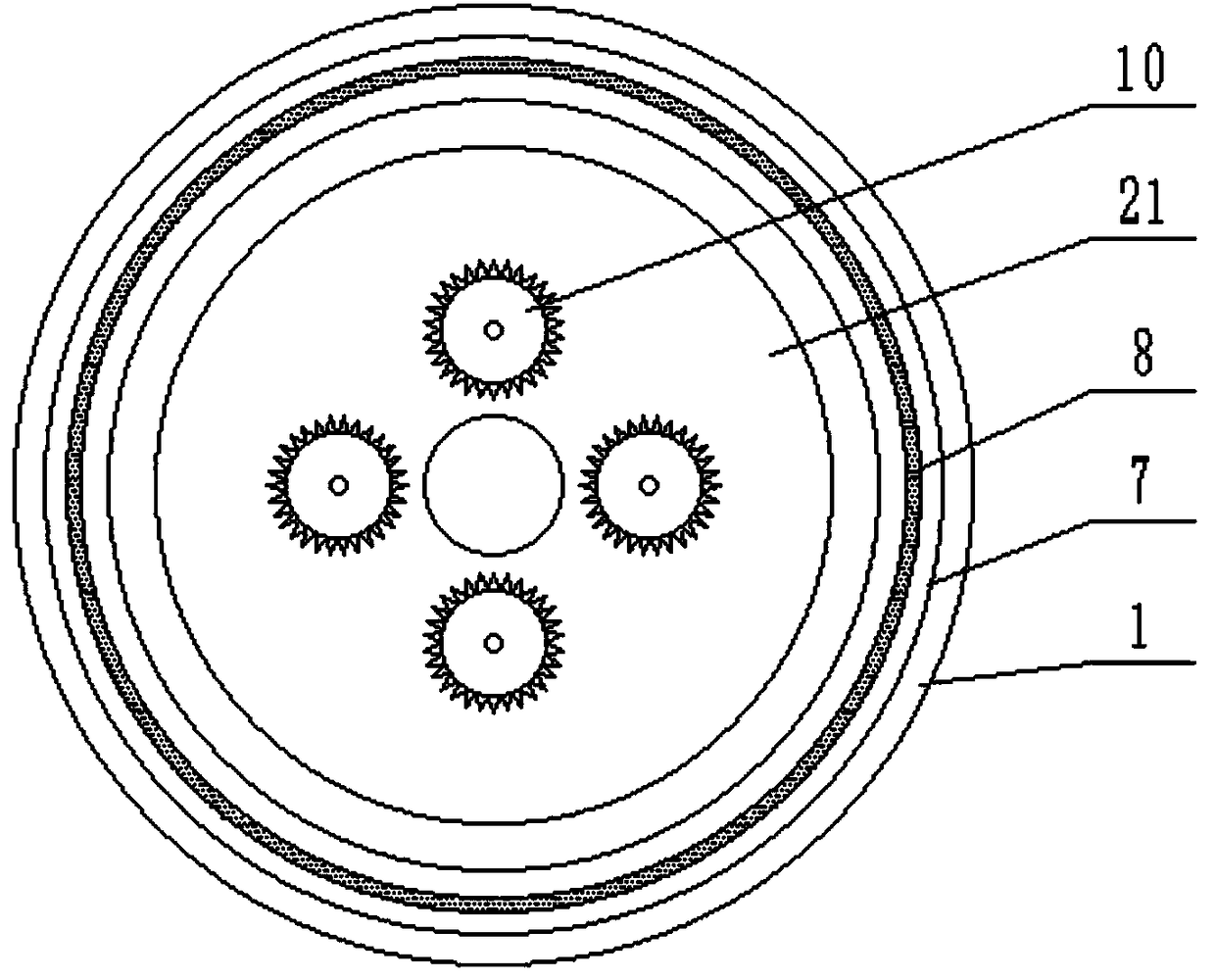

[0017] Please refer to the figure, in the embodiment of the present invention, a vertical energy-saving boiler with a rotating grate includes a furnace body 1, a water jacket 2, a furnace grate 3, a chimney 4 and a smoke exhaust port 5; the furnace grate 3 Located in the furnace body 1, a supporting rotating device is fixed on the lower side of the furnace grate 3, the supporting rotating device includes a lower steel ball groove 7, a lower fixing block 8, and steel balls 9, and the lower fixing block 8 is fixed on the furnace At the bottom of the body 1, the lower fixed block 8 is distributed in a ring, and the upper surface of the lower fixed block 8 is provided with a downwardly recessed lower steel ball groove 7, and several steel balls 9 are placed in the lower steel ball groove 7. The furnace grate 3 is located on the steel ball 9 and is supported by the steel ball 9 to facilitate the rotation of the furnace grate 3; a downwardly recessed collection tank 21 is provided at...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap