Method for determining adhesion failure of output contactor of direct-current charging pile

A technology for outputting contactors and DC charging piles, which is applied in the direction of circuit breaker testing, etc., can solve problems such as waste of resources, personal safety hazards, contactor closing adhesion and opening adhesion, and achieve the effect of reducing hardware costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described below in conjunction with the embodiments.

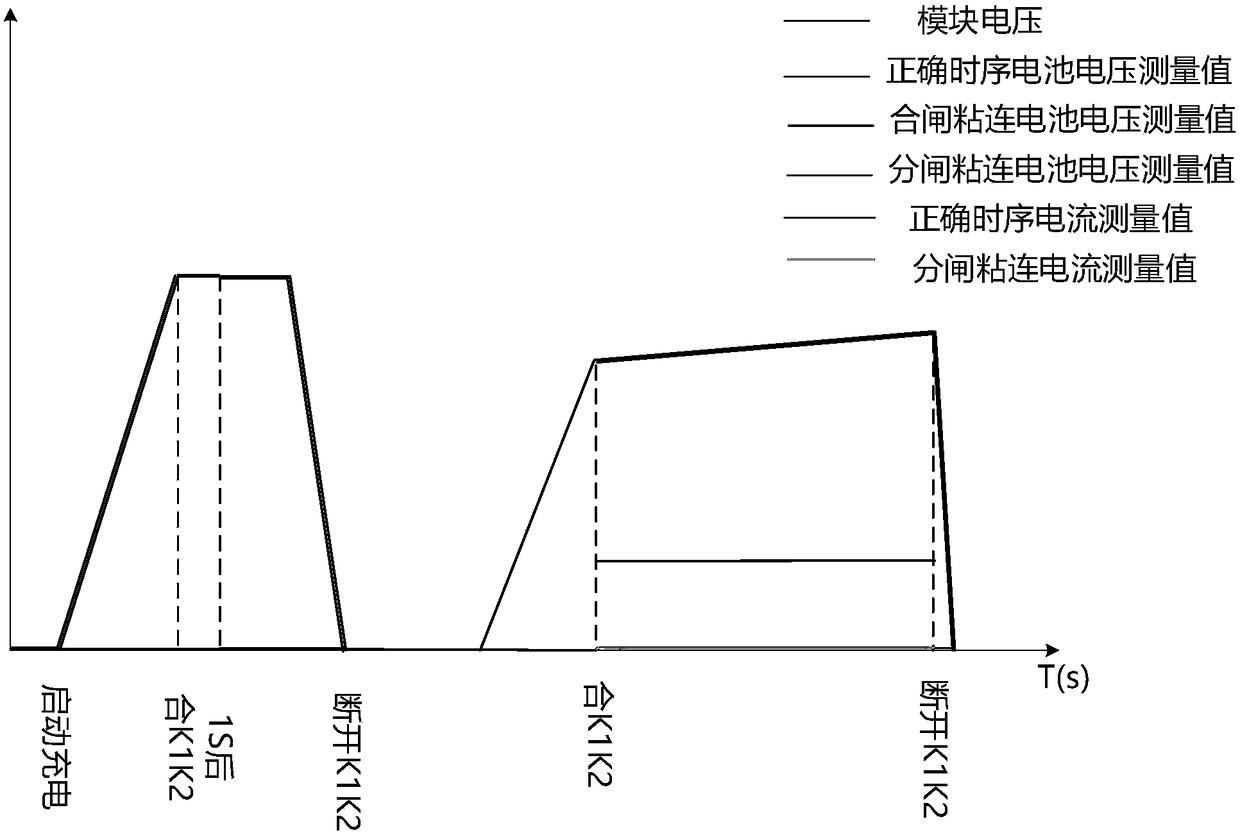

[0036] A method for judging the adhesion fault of the output contactor of a DC charging pile, there are three cases, before charging, during charging, and after charging.

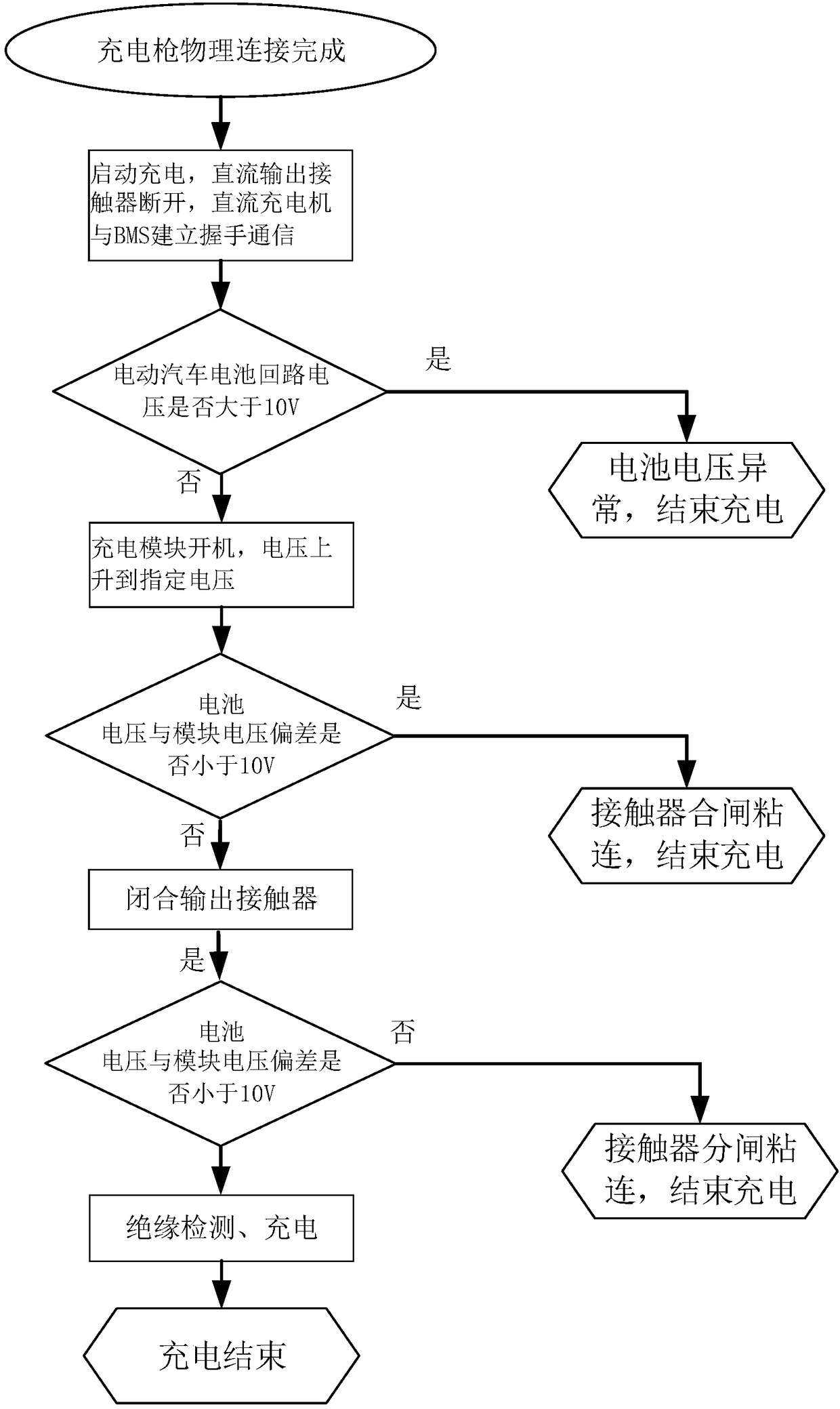

[0037] like image 3 As shown in the figure, a method for judging the adhesion fault of the output contactor of a DC charging pile, before charging, includes the following steps:

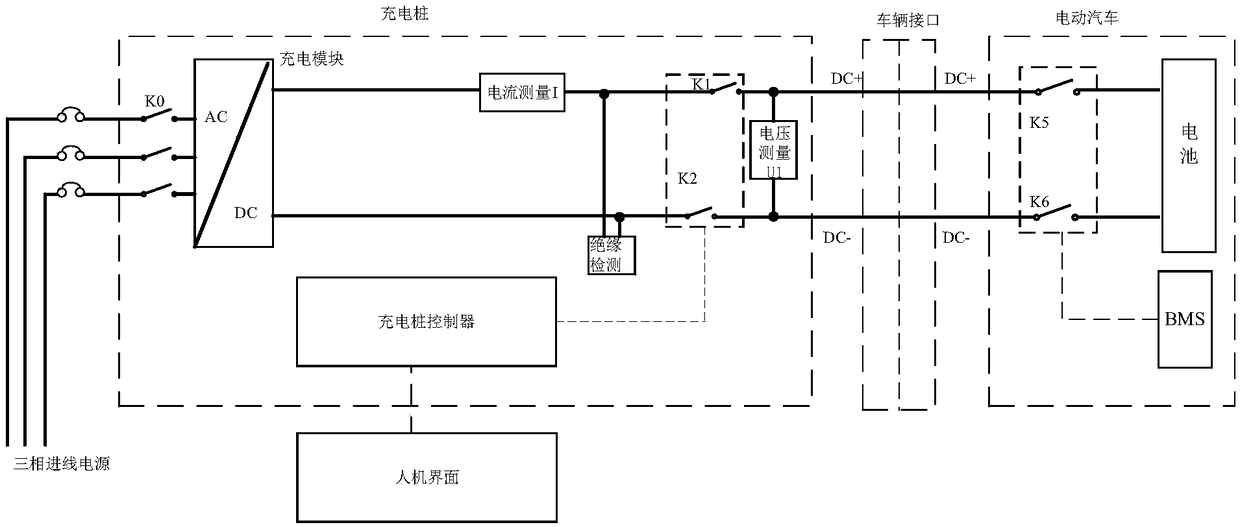

[0038] A1, if figure 1 As shown, the DC output contactor of the DC charging pile adopts the type without feedback node, which saves costs.

[0039] A2. The DC charging gun is inserted into the charging port of the electric vehicle, and the physical connection is intact; the electric vehicle and the charging pile must meet the five 2015 national standards for the charging interface and communication protocol.

[0040] A3. Start charging, the DC output contactor of the charging pile is disconnected, and the charging pile establish...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com