Hexagonal battery piece assembly

A battery sheet and hexagonal technology, applied in the direction of electrical components, circuits, photovoltaic power generation, etc., can solve the problems of waste materials, achieve strong market competitiveness, reduce the cost of packaging materials, and increase the effect of effective power generation area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, so that the advantages and features of the present invention can be more easily understood by those skilled in the art, so as to define the protection scope of the present invention more clearly.

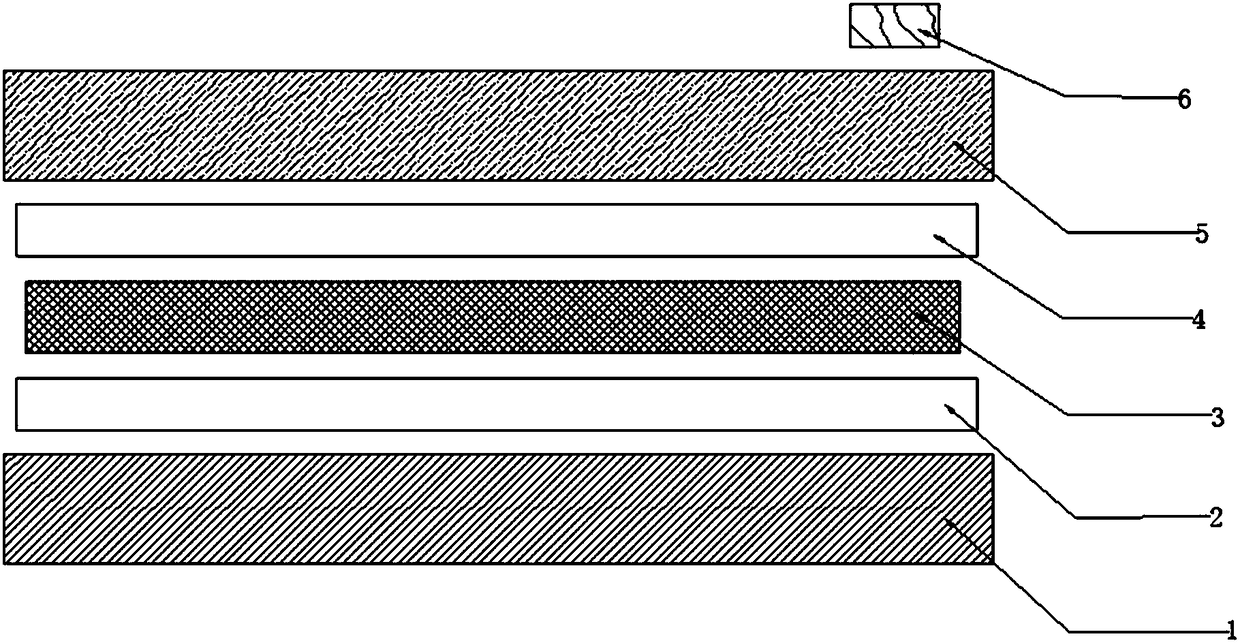

[0023] The hexagonal cell assembly includes a cell module 3 sandwiched between the front glass 1 and the back plate 5, and the cell module 3 is connected to the front glass 1 and the back plate 5 through the front adhesive film 2 and the back adhesive film 4 respectively. bonding. The front glass 1 is patterned glass coated with an anti-reflection film and is located on the light-receiving side of the cell to prevent the cell module 3 from being damaged by water vapor erosion or other natural disasters. The backboard 5 is a backboard with low water permeability.

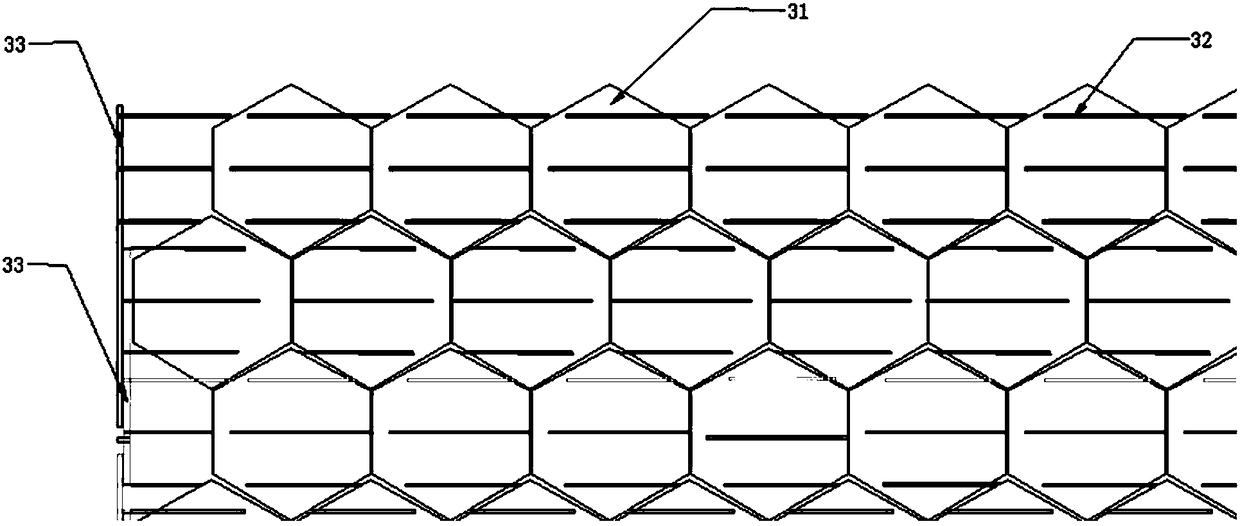

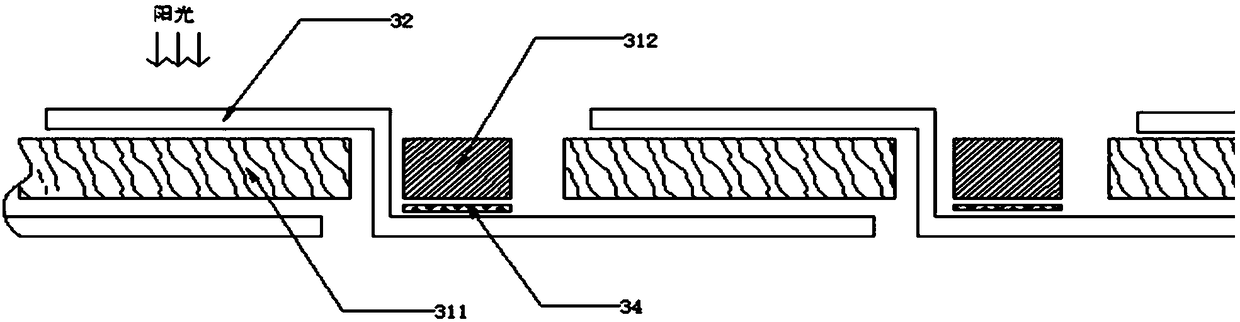

[0024] The cell module 3 is an important part of power generation and internal tra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com