Internal drive type spherical tire and driving method thereof

A spherical tire and internal drive technology, which is applied in the direction of connection with control/drive circuits, power devices, electric components, etc., can solve the problems that spherical tires cannot adapt to modern productivity, the external structure design of spherical tires is complicated, and the development is slow.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

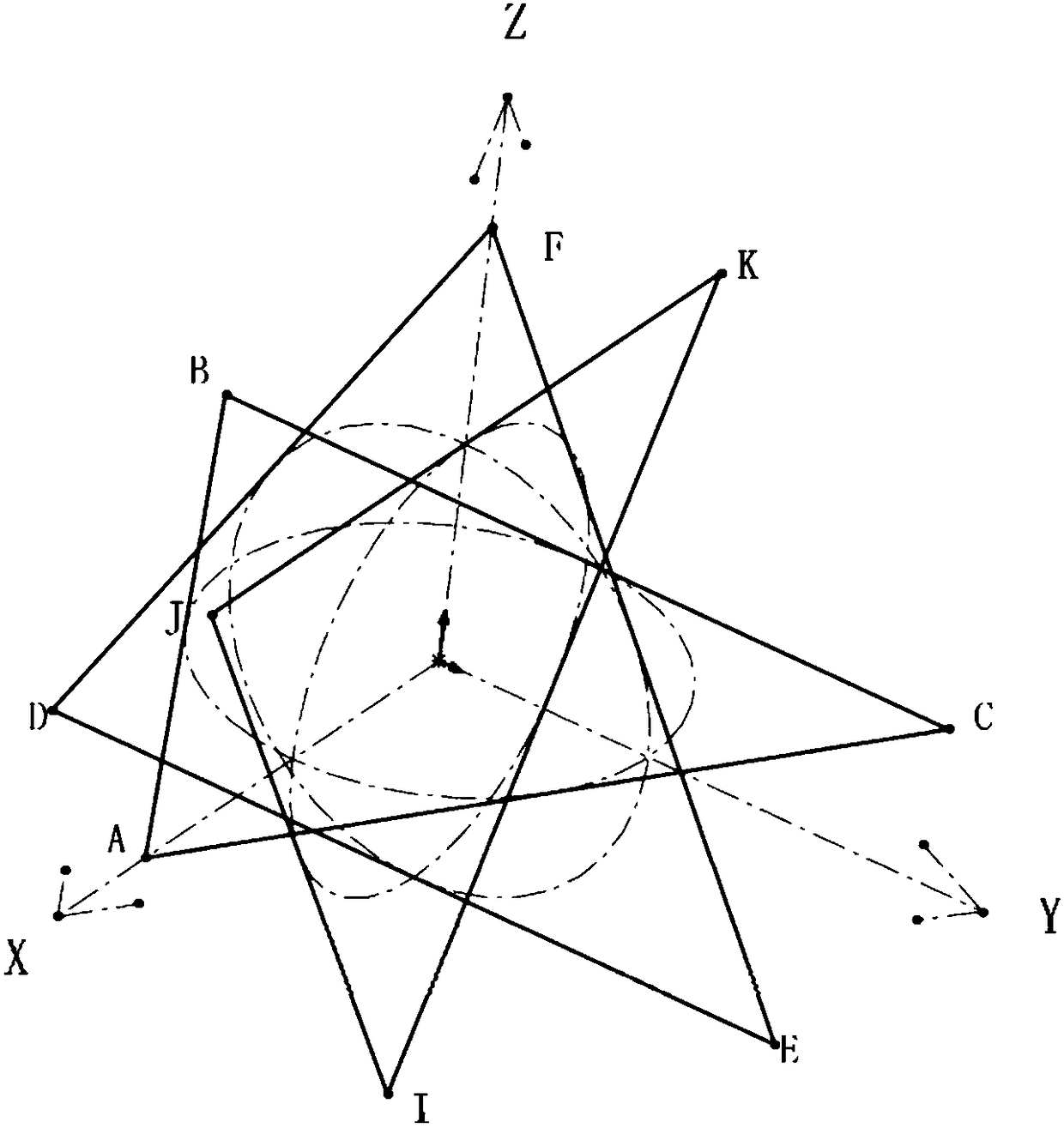

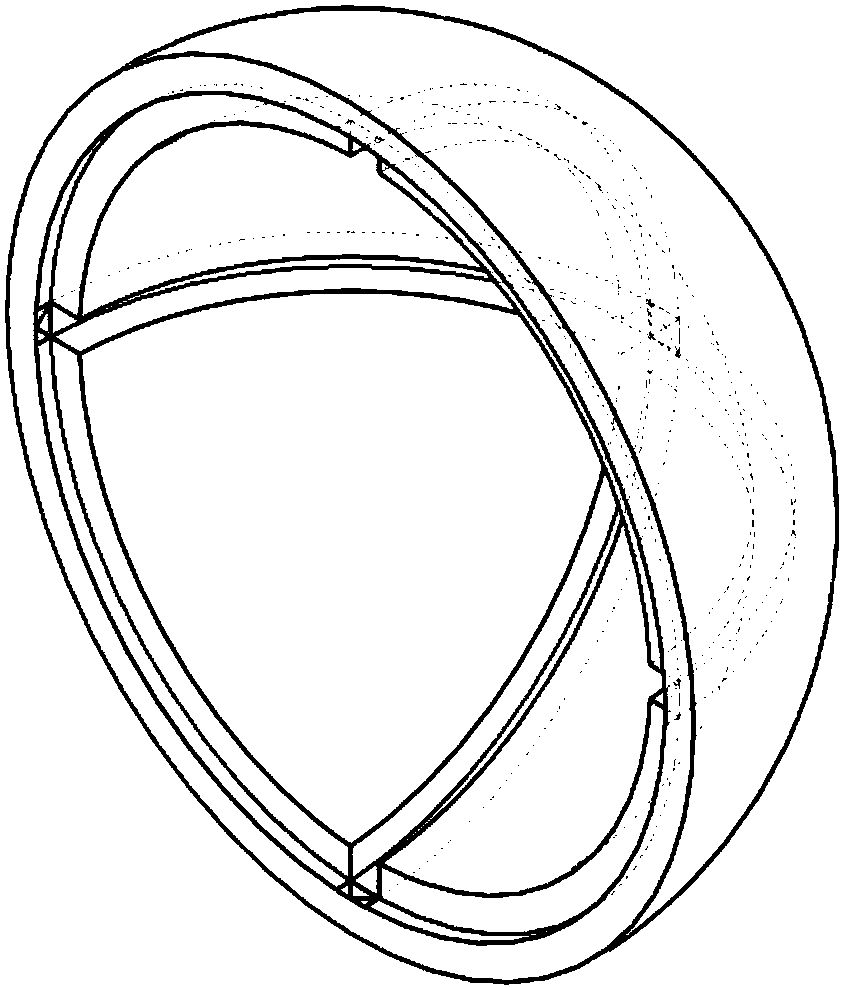

[0037] This embodiment discloses an inner-driven spherical tire comprising an outer sphere, an inner sphere, a first set of three-phase windings, a second set of three-phase windings, a first power supply and a second power supply; both the inner sphere and the outer sphere are hollow spheres , the inner sphere is arranged inside the outer sphere and the two are in a movable connection relationship, and the centers of the outer sphere and the inner sphere are the same.

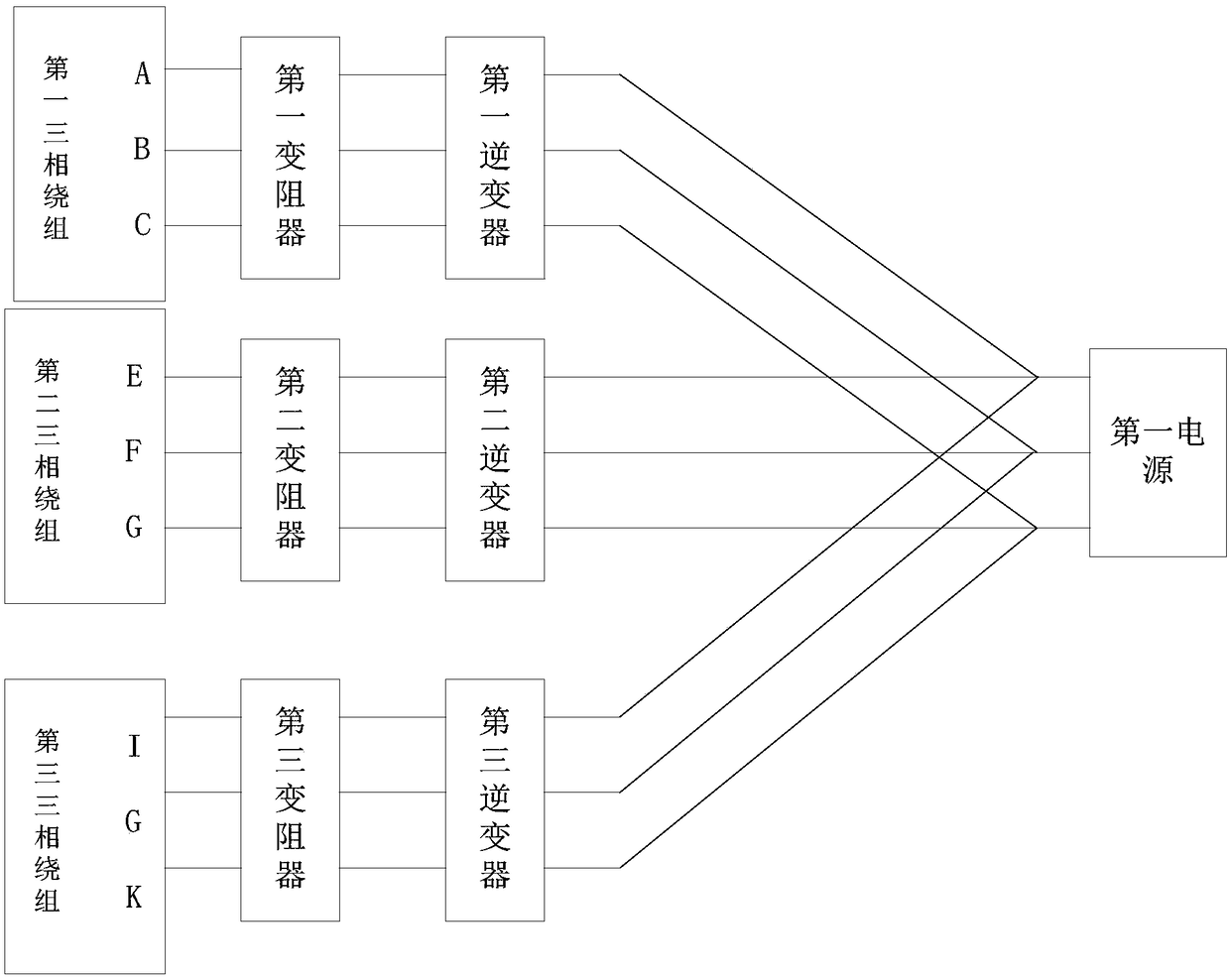

[0038] In this embodiment, the first group of three-phase windings includes three three-phase windings, which are respectively the first three-phase winding, the second three-phase winding and the third three-phase winding; the first three-phase winding, the second three-phase winding The first three-phase winding, the second three-phase winding, and the third three-phase winding are all connected to the first power supply, and the current is provided by the first power supply ; The first power supply is arran...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com