Roller shaft crusher and mated tool bit thereof

A pulverizer and roller technology, which is applied to the field of roller pulverizers and their supporting cutter heads, can solve the problems of easy falling off of cutter heads and affect production, and achieve the effects of convenient observation and adjustment, prolonging service life and novel structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

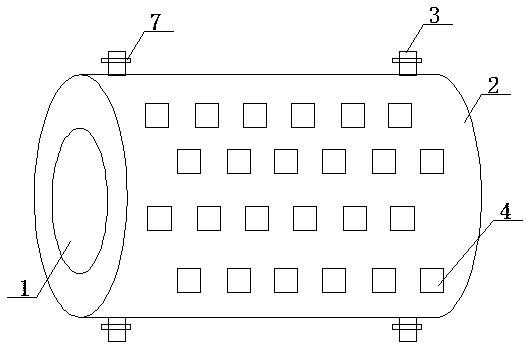

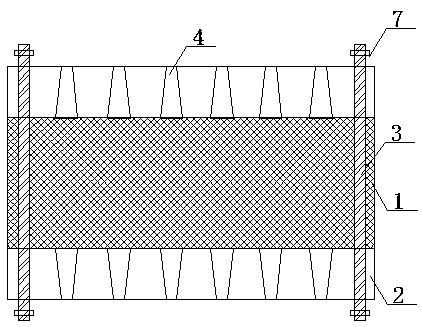

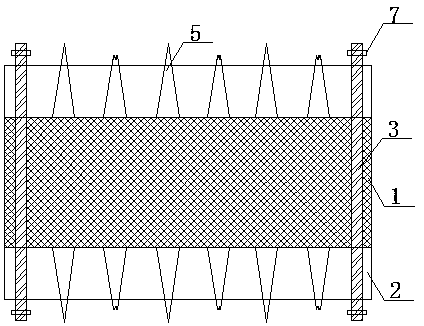

[0024] Such as Figure 1-5 As shown, a roller pulverizer includes an inner roller 1 and an outer roller 2, the outer roller 2 is arranged outside the inner roller 1, the diameter of the inner roller 1 is equal to the inner diameter of the outer roller 2, and the inner roller 1 and the two ends of the outer roller shaft 2 are plugged together through the inner column pins 3 respectively, the two ends of the inner column pins 3 are respectively provided with outer column pins 7, and the outer roller shaft 2 is axially provided with at least three rows of openings 4, There are at least three openings 4 in each row, and each opening 4 is evenly distributed on the outer roller shaft 2. The cross section of the opening 4 along the radial direction of the outer roller shaft 2 is trapezoidal. Each opening 4 is provided with a cutter head 5, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com