An installation method of long-span space truss

A space truss and installation method technology, applied in the processing of building materials, construction, building construction, etc., can solve the problems of large-scale machinery and equipment that cannot be constructed, the overall span is large, and the weight is increased, so as to improve installation efficiency and reduce transportation procedures , the effect of improving the degree of safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

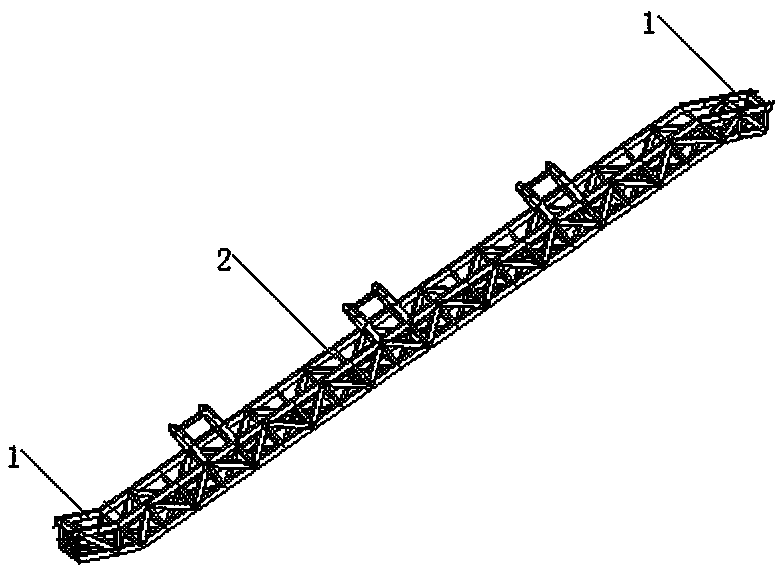

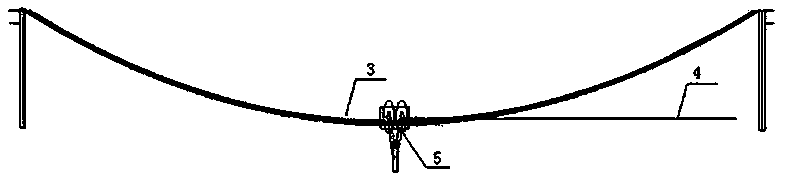

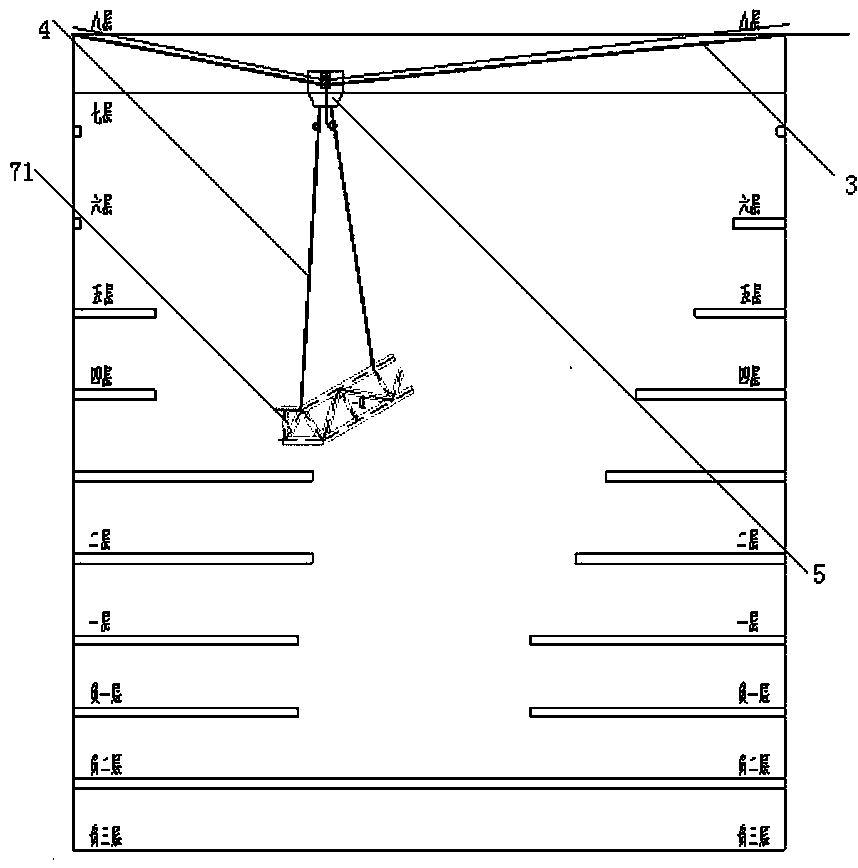

[0051] The large-span space truss in this embodiment is the 23.2-meter truss of Jinjue Vientiane Trestle Bridge, such as figure 1 As shown, the large-span space truss is formed by two horizontally connected installation and fixing sections 1 at the front and rear, and an inclined extension section 2 in the middle. Its span is 48 meters and the length of the truss is 54 meters. Installed indoors on the third to seventh floors, the single-product truss is 46 tons, and the upper and lower chords of the truss are welded box girders; the installation methods of the truss include construction preparation, embedded parts construction, construction cable installation, pulley system installation, rolling There are eight processes of lifting system installation, component placement, truss aerial assembly and completion acceptance.

[0052] Since the five processes of construction preparation, embedded parts construction, pulley system installation, winch system installation and completi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com