Brickwork structure wall-breaking and hole-forming pre-jacking recovery construction method

A technology of pre-roofing and masonry structure by breaking a wall, opening a hole, and applying it in the direction of building construction, building maintenance, and construction, etc. Restoring load transfer paths, ensuring structural safety, and ensuring the effectiveness of tight connections

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

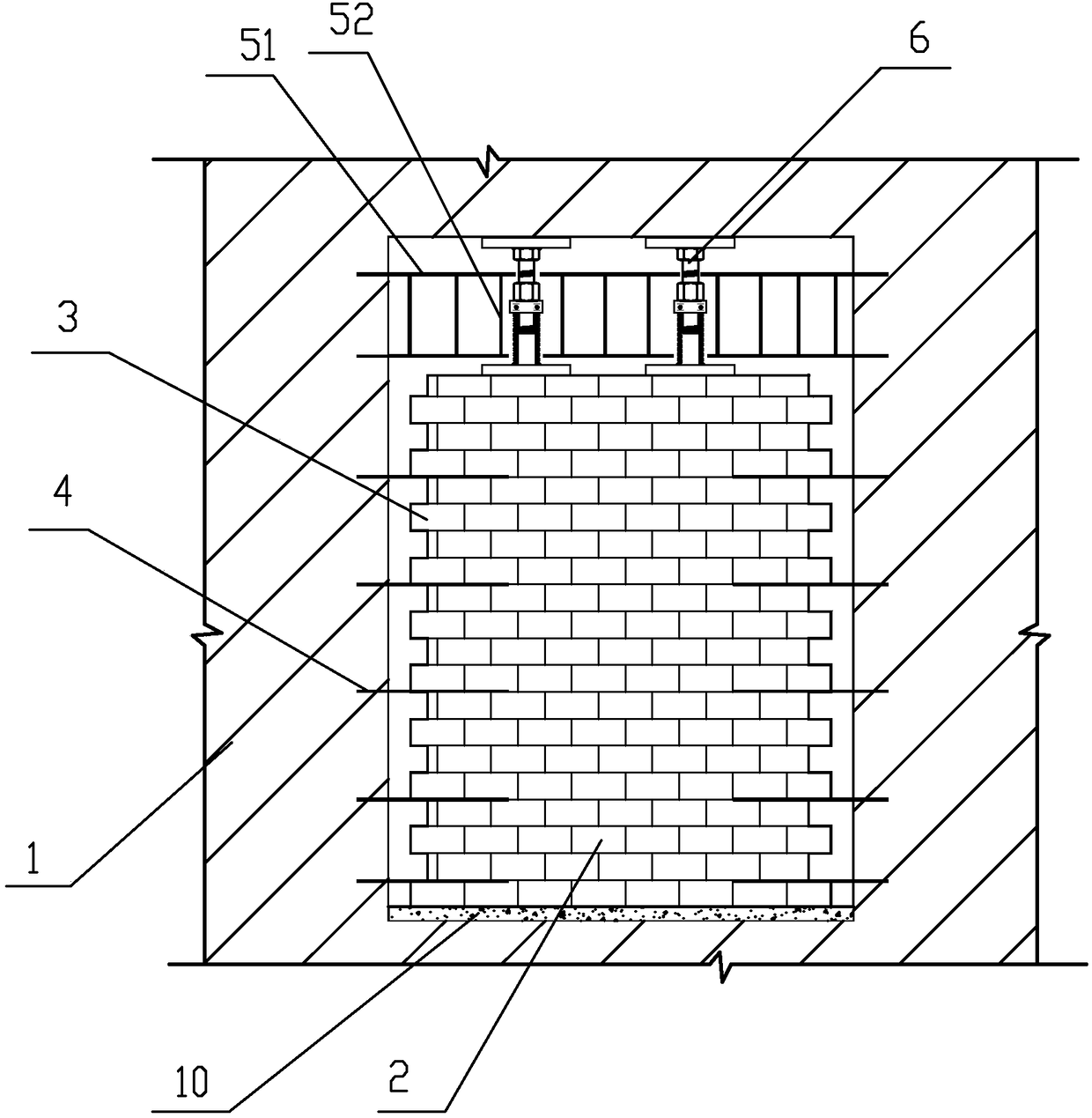

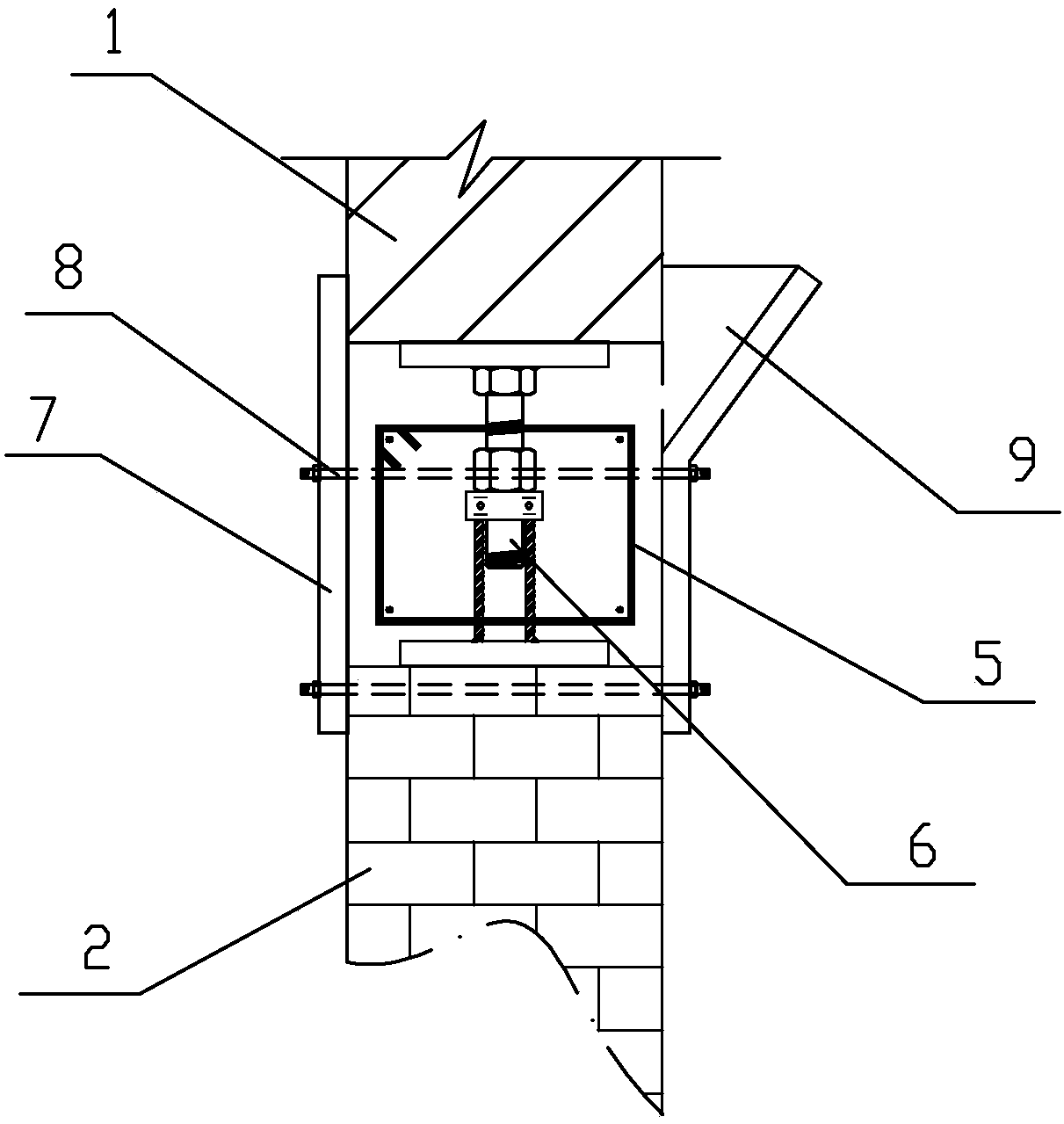

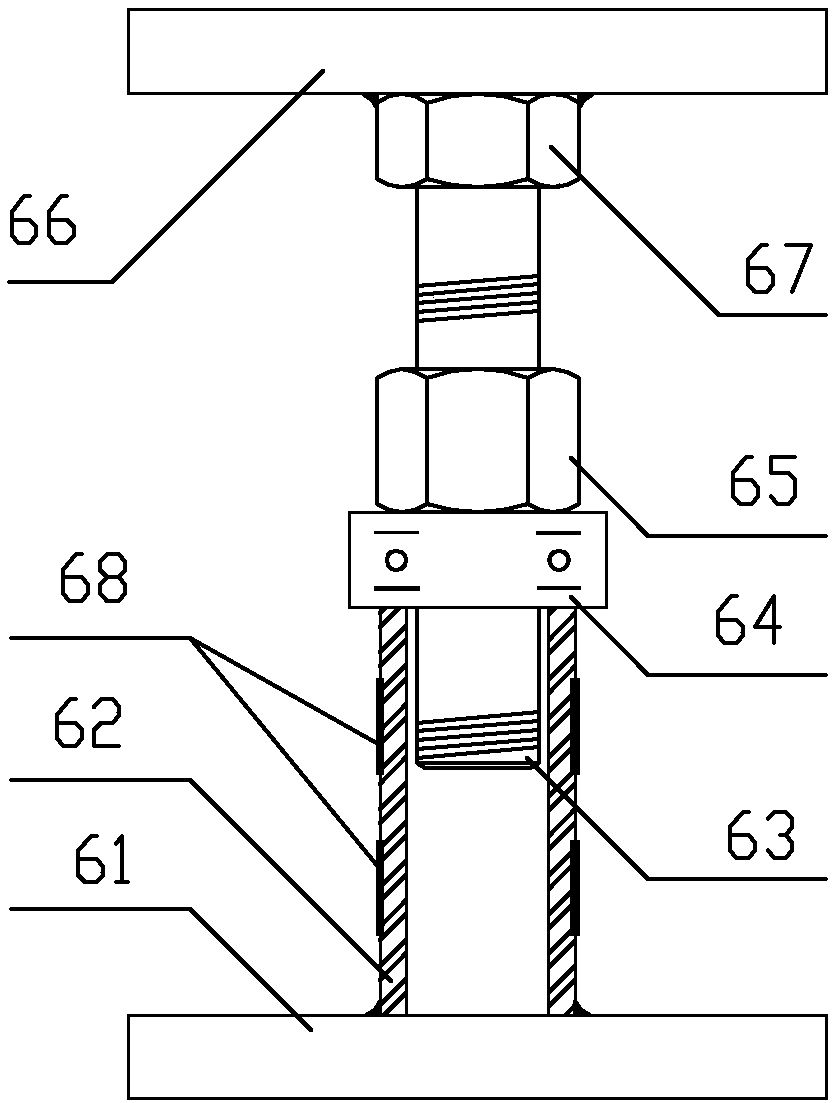

[0046] Embodiment: A kind of masonry structure broken wall opening pre-roof restoration construction method of this embodiment includes the following steps:

[0047] First of all, preparatory work before construction, such as Figure 4 As shown, by establishing the BIM structure model 11, the number of embedded controllable unloaders required for each opening and the predetermined loading value are determined. The specific steps include:

[0048](a) Establish a BIM structural model: collect the as-built drawings of the building to be reinforced, and conduct actual measurement and review of the length, width, height and axis dimensions of the building; Measure the position and size of the opening; measure and count the width, length and position of all wall cracks13 and floor cracks, and number the cracks; establish a complete BIM structural model of the building;

[0049] (b) On-site sampling of the blocks used in the load-bearing wall 14, and sent to the laboratory for mater...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com