Dry-hanging connection system and construction method for architectural decorative panels

A technology of architectural decoration and connection system, which is applied in the field of building exterior wall decoration, which can solve the problems of safety accidents, heavy stress on grooves, and easy cracking, and achieve the effects of saving space, reducing weight, and saving keel materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

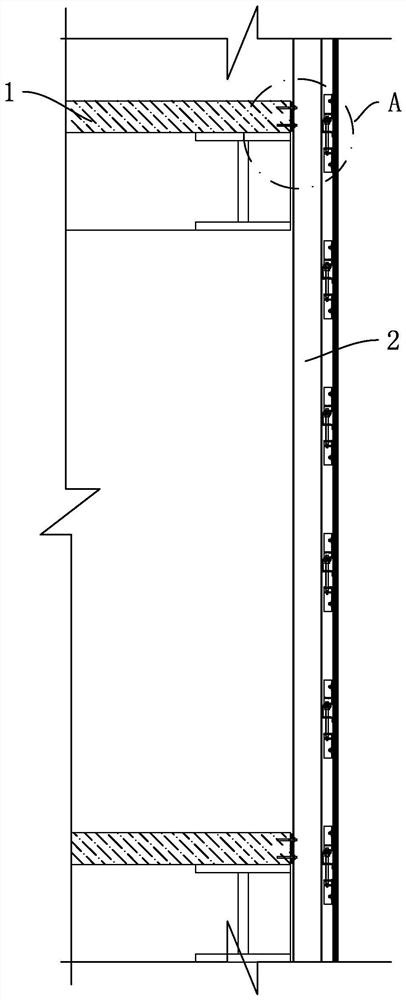

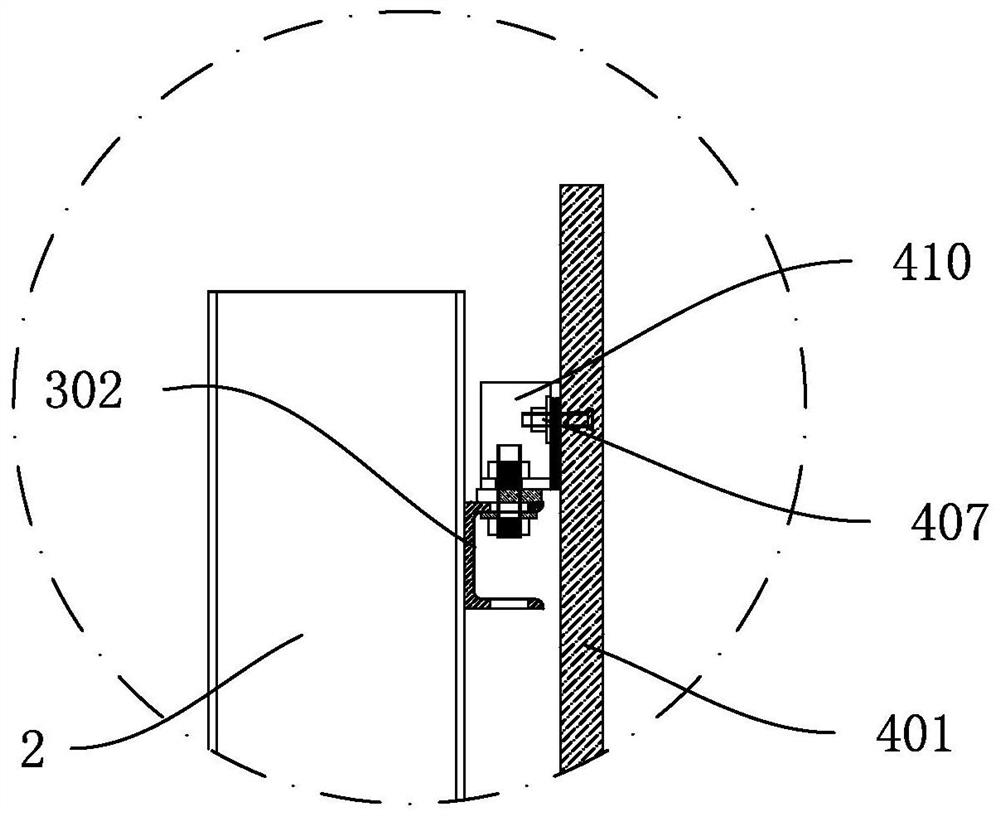

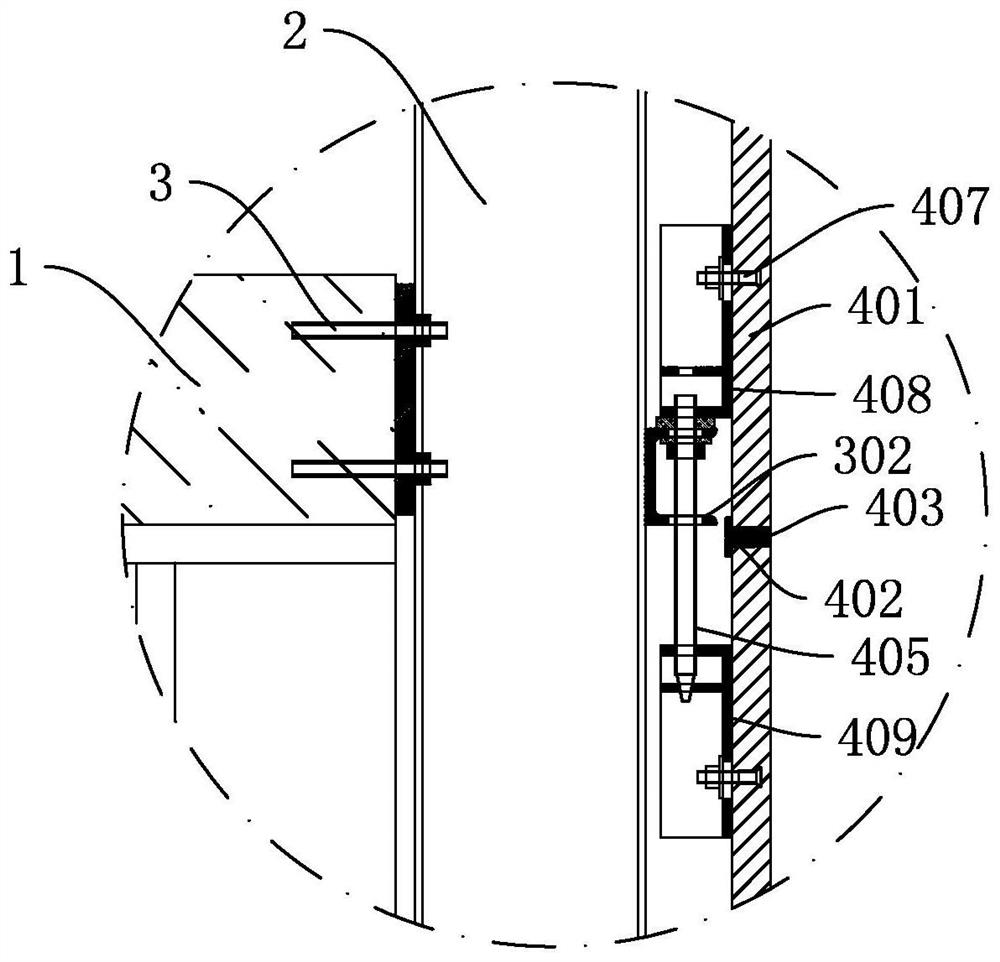

[0086] Such as Figure 1-3 As shown, a dry-hanging connection system for building decorative panels includes seven horizontally placed and parallel dry-hanging keels 302 and a decorative panel layer formed by splicing 18 decorative panels 401 of 6×3. Each decorative panel 401 are all dry-hanged connected together by dry-hanging connectors and the dry-hanging keel 302 adjacent to the inner side thereof.

[0087] It also includes 4 vertical keels 2 placed vertically and parallel to each other. The vertical keels 2 are positioned at the rear side of the dry hanging keel 302 and fixed together with the inside of the dry hanging keel 302. The vertical keel 2 passes through the vertical The keel fixing bolts 3 are fixed together with the outer end face of the building floor 1.

[0088] The upper part of the back of each decorative plate 401 is provided with two left and right symmetrical dry-hanging expansion bolt installation holes, and the upper part of the back of each decorativ...

Embodiment 2

[0101] A dry-hanging connection system for architectural decorative boards, the difference from Embodiment 1 is that the installation holes of the dry-hanging expansion bolts are replaced with bolt through holes, and the decorative board 401 passes through the through-hole bolt 411 of the decorative board 401 and the first back bolt. The dry-hanging connector 408 , the second back bolt dry-hanging connector 409 or the third back-bolt dry-hanging connector 410 are fixed together; the decorative board 401 is a cement fiber board.

[0102] Among them, the top connection nodes such as Figure 35 shown.

Embodiment 3

[0104] Such as Figure 37 As shown, a dry-hanging connection system for building decorative boards differs from Embodiment 1 in that: the inner side of each row of decorative boards 401 is provided with two upper and lower dry-hanging keels 302, and each decorative board 401 passes through The 2 dry-hanging expansion bolts 407 on the upper part are fixed with the backs of the 3rd back-bolt dry-hanging connectors 410 of the 2 upper rows, and the 2 dry-hanging expansion bolts 407 of the lower row and the 3rd of the 2 lower rows are fixed together. The back side of the back bolt dry hanging connector 410 is fixed together; the bottom surface of the third back bolt dry hanging connector 410 on the top of each decorative plate 401 is connected with the upper dry hanging keel 302 by bolts; the lower part of each decorative plate 401 The bottom surface of the third back bolt dry-hanging connector 410 and the lower dry-hanging keel 302 are connected together by bolts;

[0105] The la...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com