Freeze dryer and defrosting circulation system applied to freeze dryer

A freeze-drying machine and circulating pipeline technology, which is applied in drying, drying solid materials, and dry goods processing, etc., can solve the problem of inconvenient loading of freeze-drying machines, and achieve the effects of easy disassembly, easy loading and easy installation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

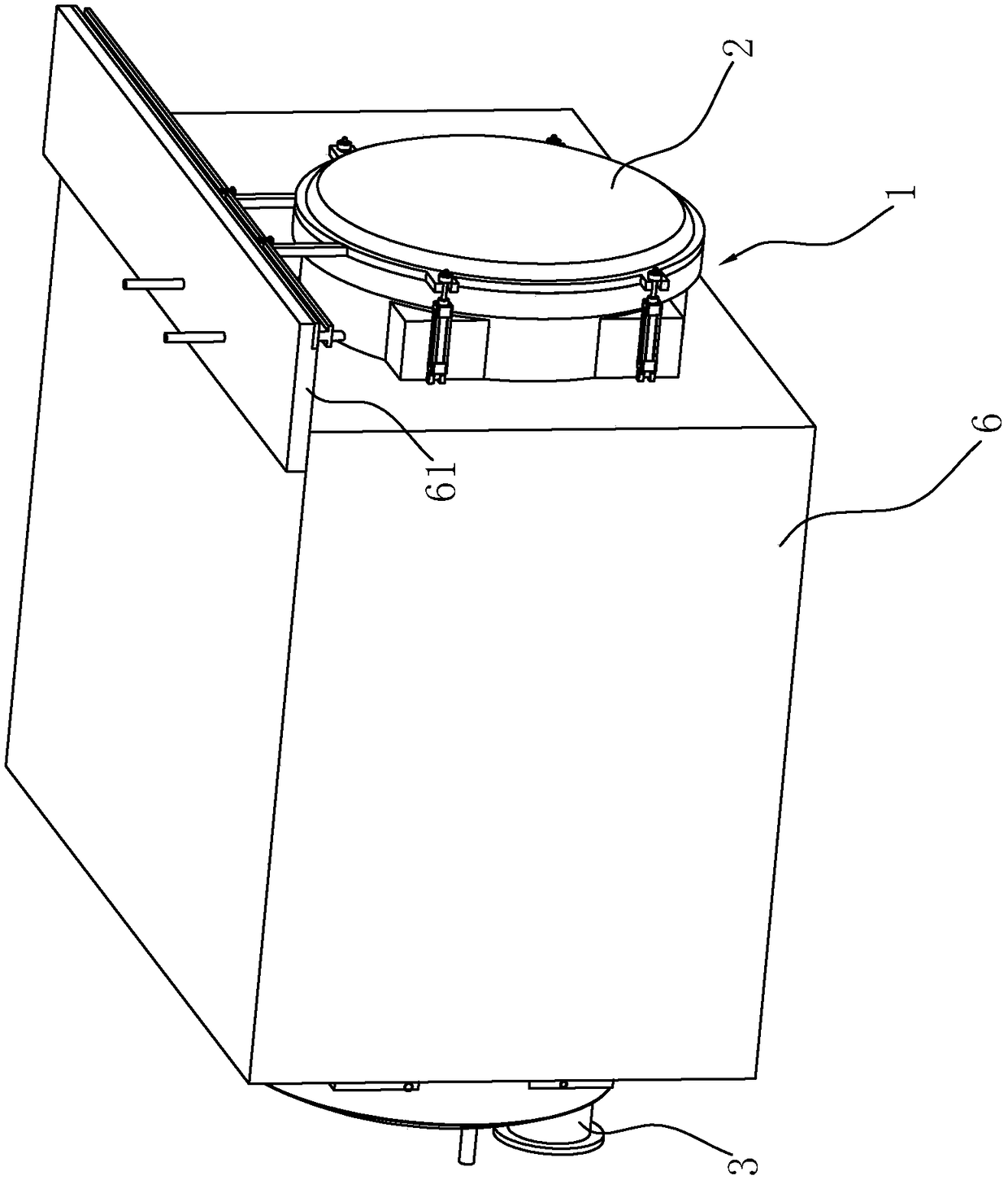

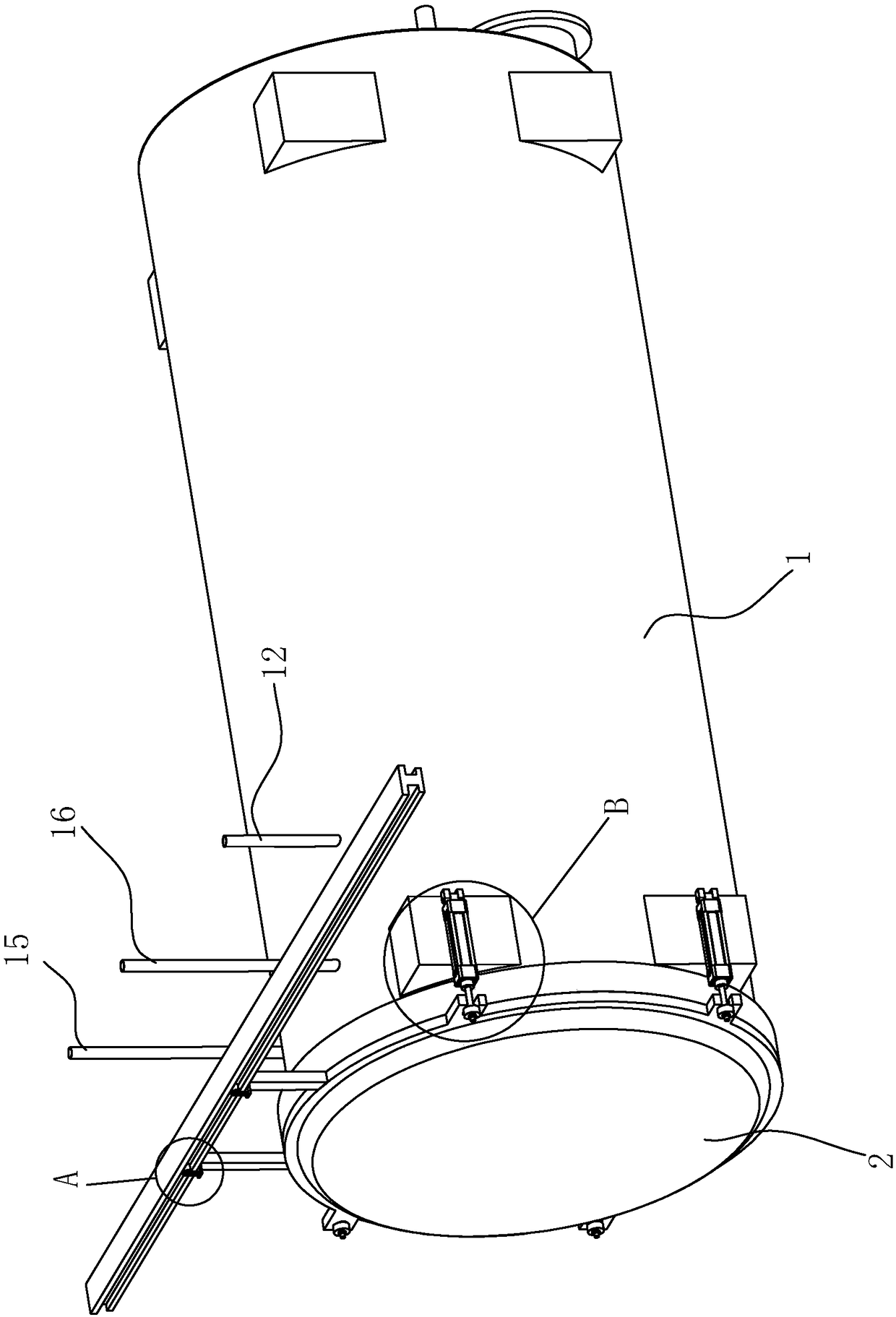

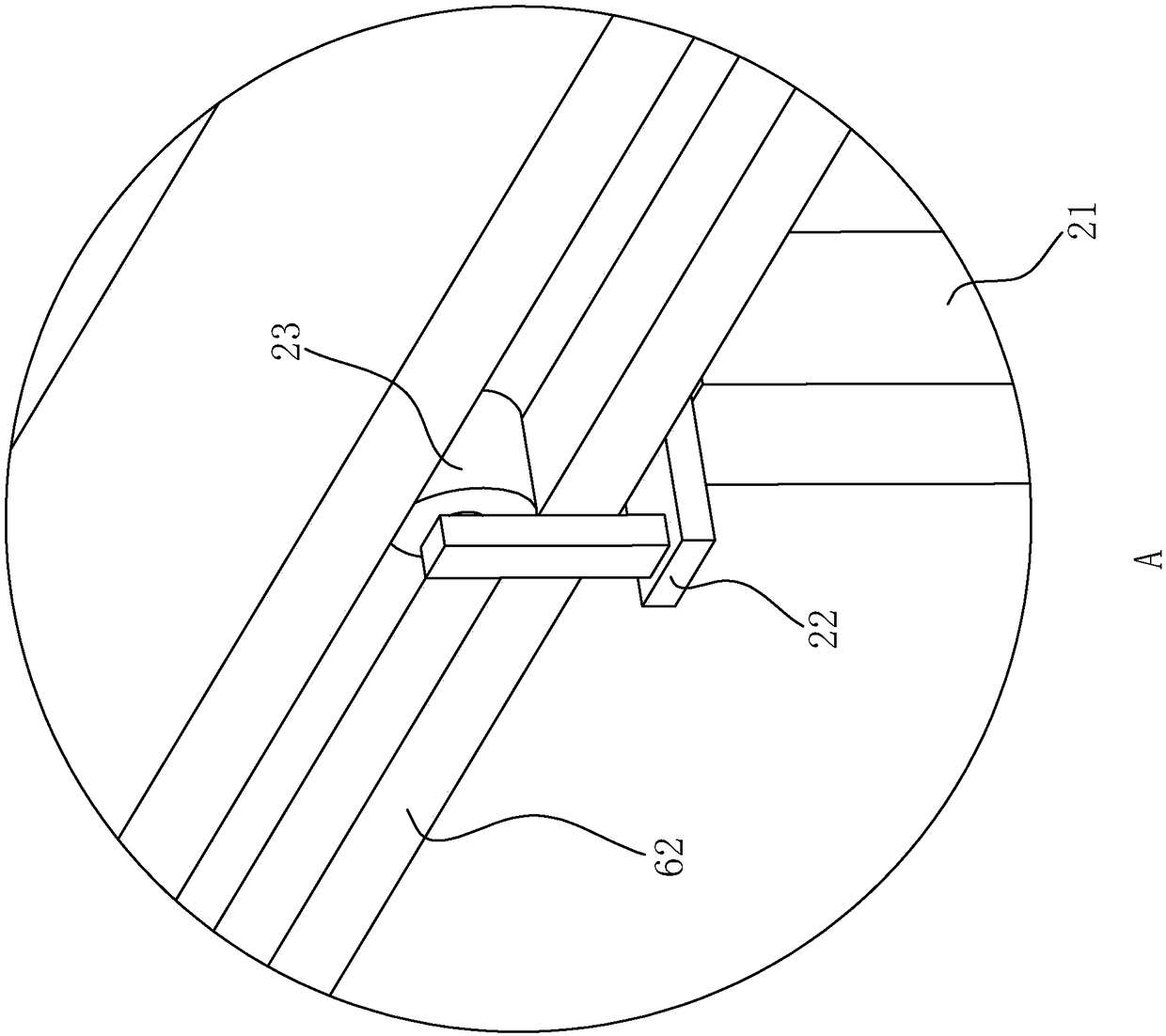

[0040] Embodiment 1: a kind of lyophilizer, such as figure 1 with Figure 5As shown, it includes a freeze dryer cylinder 1, a feed door 2 arranged at one end of the freeze dryer cylinder 1, and a water outlet 3 arranged at the other end of the freeze dryer cylinder 1, and the water outlet 3 is hinged with a water outlet; The freeze dryer cylinder 1 is provided with an ice-melting chamber and an ice-collecting chamber in sequence from the feed door 2 to the water outlet 3, and a partition 11 is arranged between the ice-melting chamber and the ice-collecting chamber, and the partition 11 and the freeze-drying machine cylinder The inner wall of the body 1 is fixedly connected, and a through hole connecting the ice-melting chamber and the ice-collecting chamber is opened on the partition 11; the side wall of the ice-melting chamber is connected with a vacuum tube 12 (such as figure 2 As shown), a vacuum pump is connected to the end of the vacuum tube 12 away from the ice-melting...

Embodiment 2

[0050] Embodiment 2: a kind of defrosting cycle system for the above-mentioned freeze dryer, such as Figure 10 As shown, it includes an ice-melting tank 8 arranged at the water outlet 3 of the lyophilizer cylinder 1, a heating circulation pipeline 9 connected to the air inlet pipe 15 and the air outlet pipe 16 on the lyophilizer cylinder 1, and a spray pipe 52 extends out of the ice-melting circulation pipeline 10 connected to one end of the lyophilizer cylinder 1; the heating circulation pipeline 9 is connected to the ice-melting circulation pipeline 10 through a plate heat exchanger 1001; the heating circulation pipeline 9 is connected to an air intake A check valve 92 is provided between the channel 91 , the inlet channel 91 and the plate heat exchanger 1001 , and an outlet channel 93 is connected between the check valve 92 and the plate heat exchanger 1001 .

[0051] One end of the ice-melting circulation pipeline 10 is arranged in the ice-melting tank 8, and the ice-melt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com