Ground fracture expansion simulation device and use method thereof

A technology of crack propagation and simulated ground, applied in the field of geotechnical engineering, can solve the problems of single type of basement fault and no consideration of boundary effects, etc., and achieve the effect of breaking through boundary effects, considering multiple factors, and simple operation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

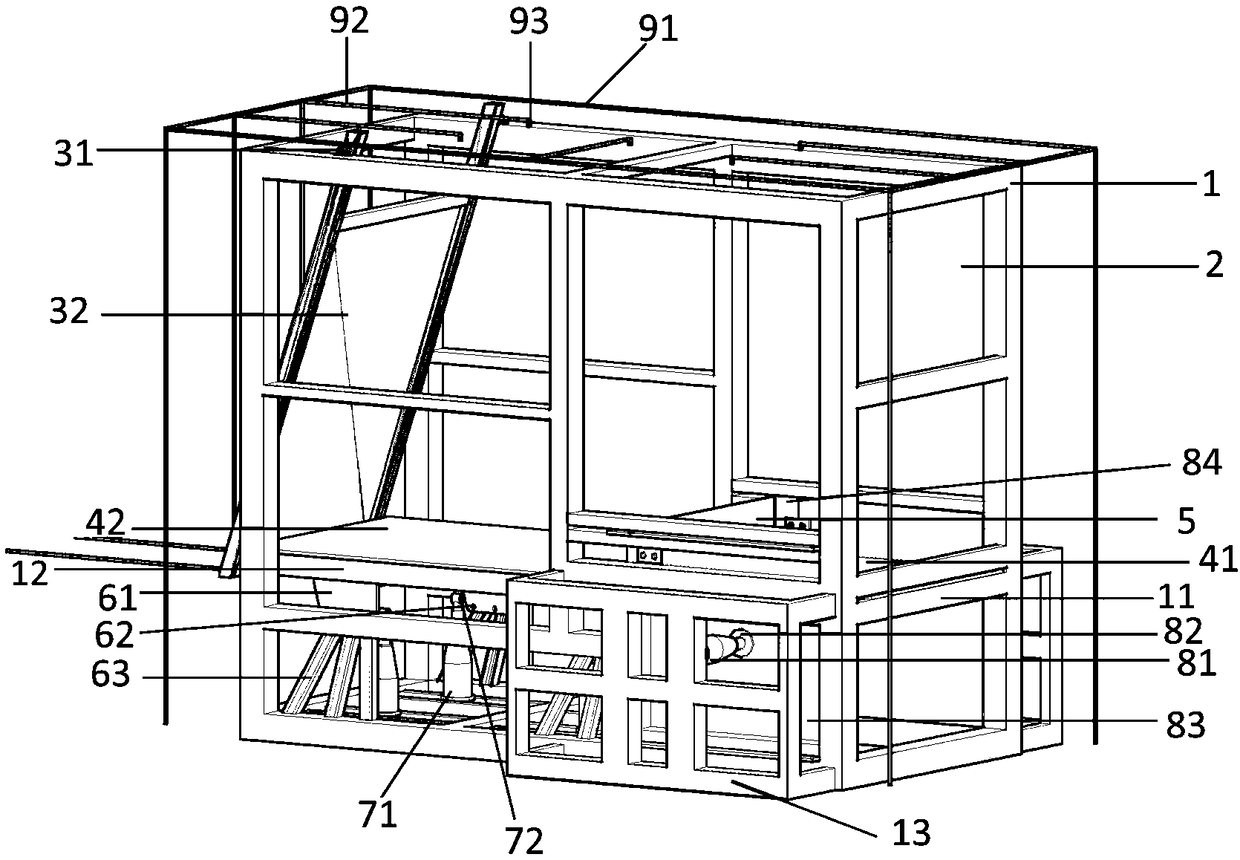

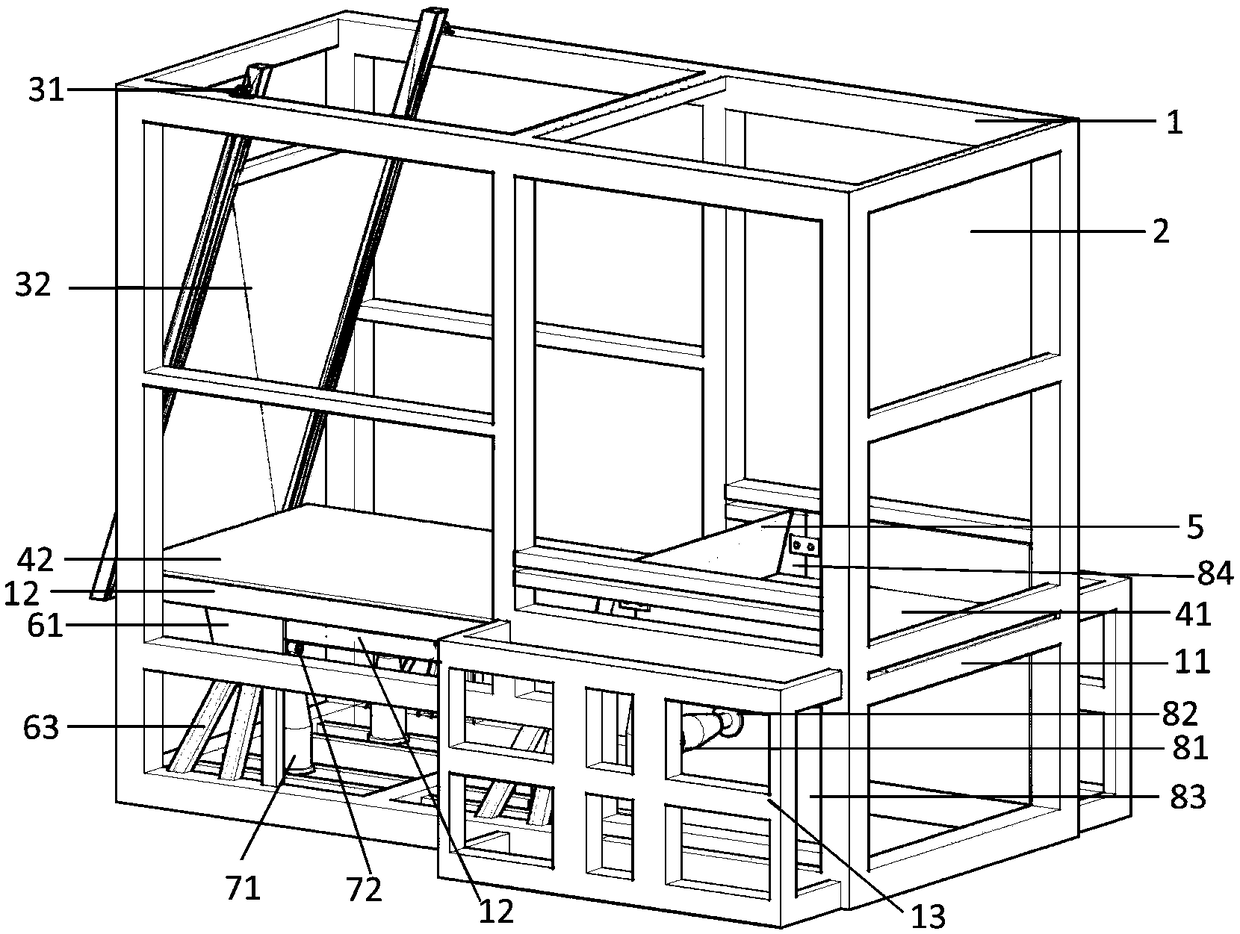

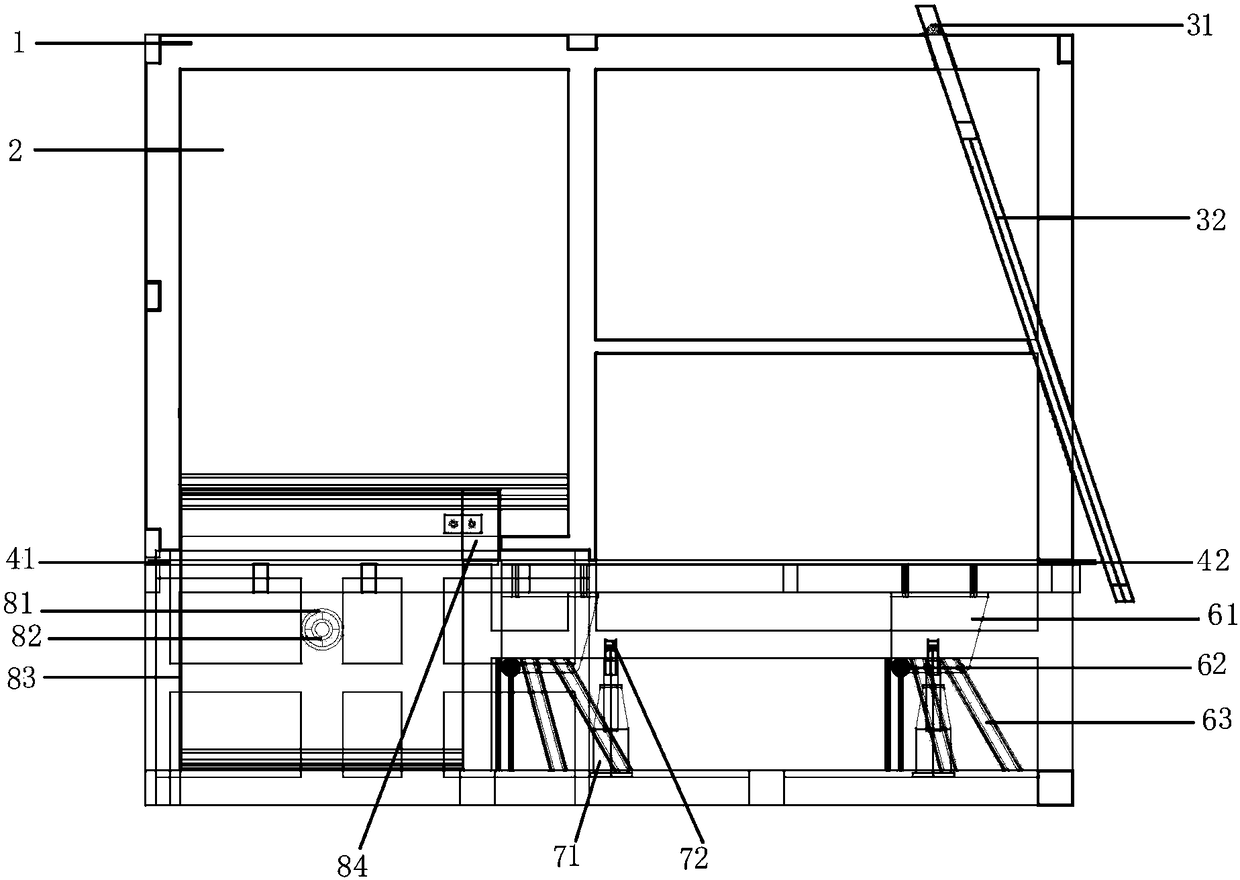

[0058] Working condition 1 (such as figure 1 ) implementation plan: ① Adjust the side wall loading device: No. 2 side wall steel plate with an installation angle of 90° (see Figure 7), and move the side wall steel plate to make it close to the frame to avoid its influence on the normal fault movement. holes and fixed with screws to simulate a normal fault with a dip angle of 90°. ③Adjust the inclination angle of the movable baffle: fix the position of the bearing in the screw hole closest to the baffle, and connect the baffle to the bearing with screws to ensure that the inclination angle of the baffle is also 90°, which ensures the consistency between the model boundary conditions and the actual boundary conditions resemblance. ④Install a smooth thin steel sheet with a thickness of 3mm between the support plate of the upper wall and the lower wall, and adjust the inclination angle of the thin steel plate to 90°, which is consistent with the inclination angle of the incline...

Embodiment 2

[0060] Working condition 2 implementation plan: ①Adjust the side wall loading device: install the No. 2 side wall steel plate with an angle of 75°, and move the side wall steel plate to make it close to the frame to avoid its influence on the movement of the normal fault. ②Adjust the tilt angle device : Insert one end of the guide rail roller into the inclined groove guide rail with an inclination angle of 75°, and the other end passes through the guide hole of the angle steel and fix it with screws to simulate a normal fault with an inclination angle of 75°. ③Adjust the inclination angle of the movable baffle: fix the position of the bearing in the pair of screw holes in the middle, and connect the baffle and the bearing with screws to ensure that the inclination angle of the baffle is also 75°, which ensures that the boundary conditions of the model are similar to the actual boundary conditions. ④ Install a 3mm thick mica sheet between the upper plate and the lower plate supp...

Embodiment 3

[0062] Implementation plan for working condition 3: ①Adjust side wall loading device: No. 2 side wall steel plate with an installation angle of 60° (see Figure 8 ), and move the side wall steel plate to make it close to the frame, so as to avoid its influence on the reverse fault movement. holes and fixed with screws to simulate a fault with a dip angle of 60°. ③Adjust the inclination angle of the movable baffle: fix the position of the bearing in the screw hole farthest from the baffle, and connect the baffle to the bearing with screws to ensure that the inclination angle of the baffle is also 60°, which ensures the boundary conditions of the model and the actual boundary conditions similar to. ④Install a smooth thin steel sheet with a thickness of 3mm between the support plate of the upper wall and the lower wall, and adjust the inclination angle of the thin steel plate to 60°, which is consistent with the inclination angle of the inclined groove guide rail and the baffle ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com