Packaging structure of remote sensor and packaging method thereof

A technology of packaging structure and packaging method, which is applied in the fields of electric solid-state devices, semiconductor devices, semiconductor/solid-state device manufacturing, etc., and can solve the problems of short sensing distance of long-distance sensors and reduced sensing accuracy of chips

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

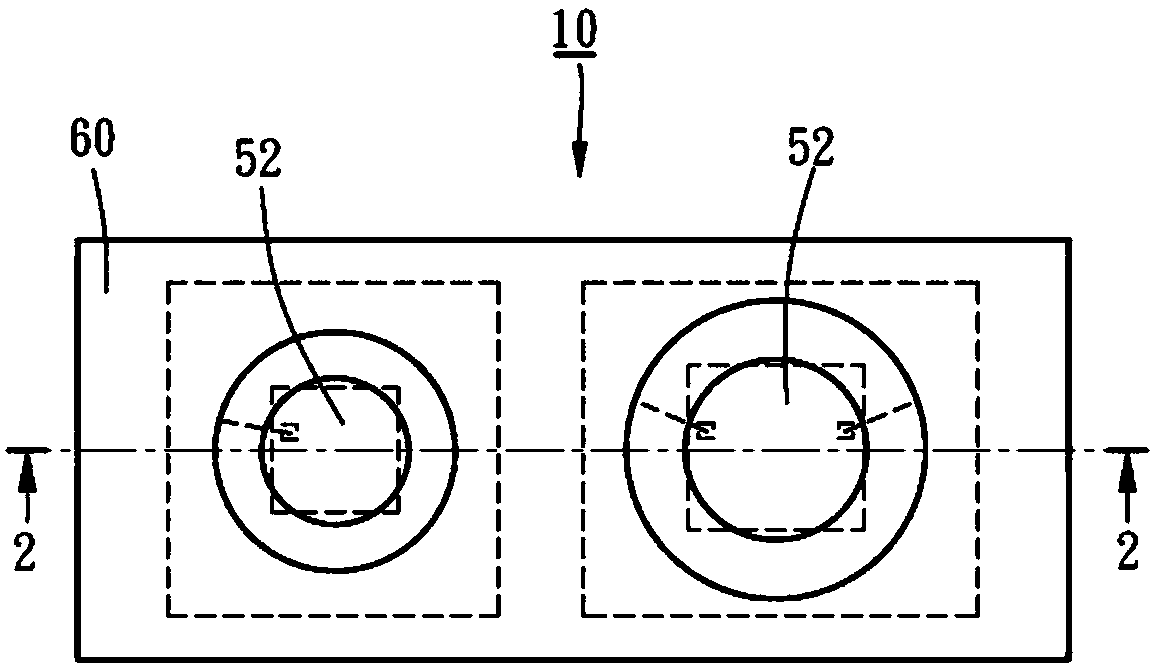

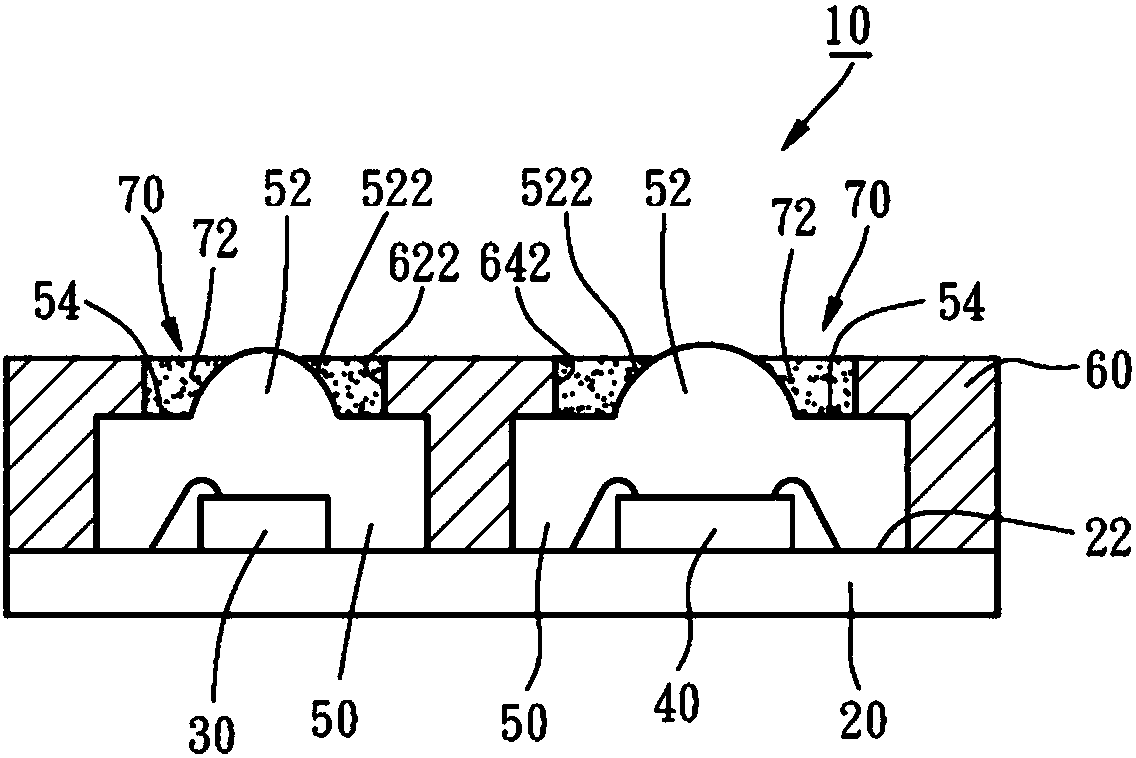

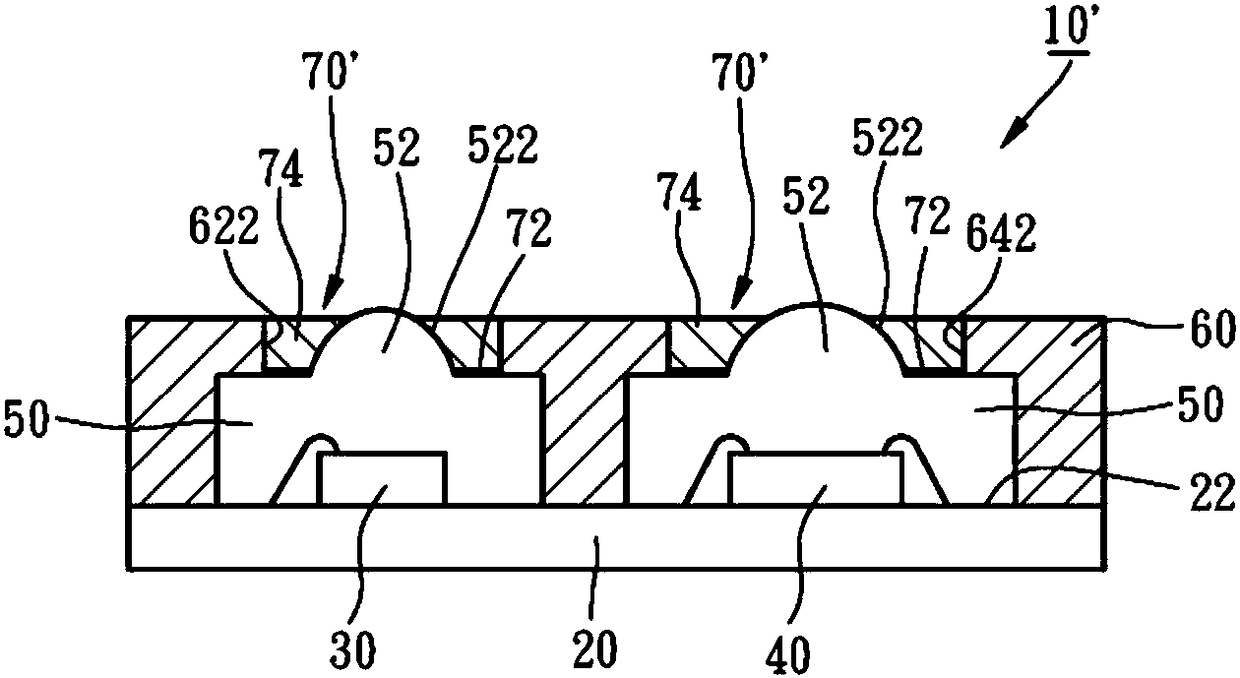

[0035] Please refer to attached image Figure 1~2 The package structure 10 of the remote sensor provided by the first preferred embodiment of the present invention includes a substrate 20, a light-emitting chip 30, a sensing chip 40, two encapsulants 50, a cover 60 and two shielding means 70.

[0036] The substrate 20 has a bearing surface 22, and the substrate 20 can be a printed circuit board (commonly known as PCB), a bismaleimide triazine substrate (commonly known as BT), a glass fiber substrate (commonly known as FR4) or a direct copper clad substrate (commonly known as DBC). ) but not limited thereto, whereby the production cost of the substrate 20 is lower.

[0037] The light-emitting chip 30 is disposed on the carrying surface 22 and electrically connected to the substrate 20 through a wire bonding process. In this preferred embodiment, the light-emitting chip 30 is an LED chip and can be used to emit light.

[0038] The sensing chip 40 is disposed on the carrying su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com