Driving lever gathering type Carthamus tinctorius harvester

A harvester and safflower technology, applied to harvesters, agricultural machinery and implements, cutters, etc., can solve problems such as low efficiency and high noise, and achieve the effect of reducing labor force and improving harvesting efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

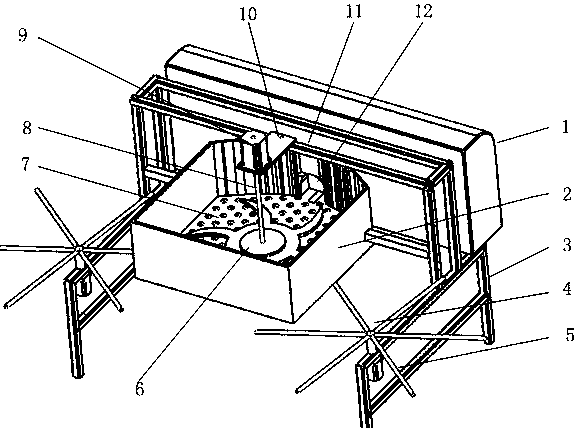

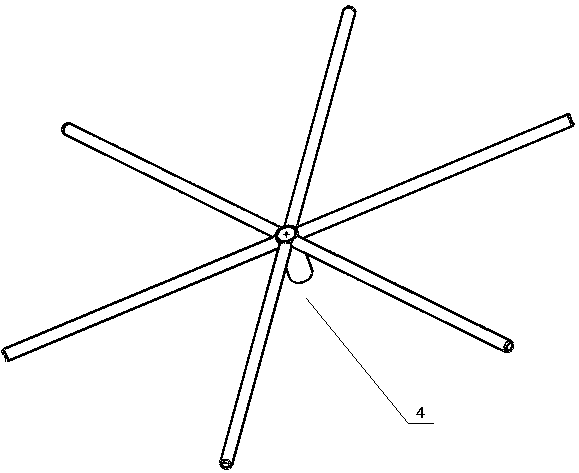

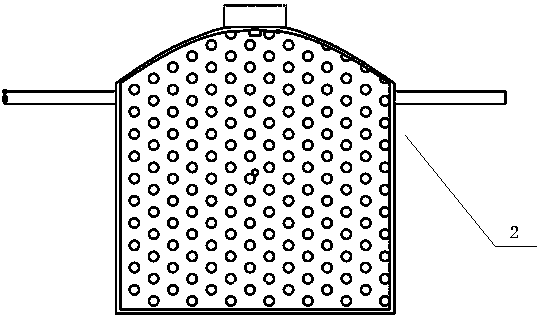

[0017] A lever gathering type safflower harvester comprises a frame, a picking device, a lever device, and an air-suction collecting device. Such as figure 1 As shown, the safflower filament picking device is installed on the front end of the frame (3), and the air suction collecting device is installed on the rear top of the frame (3). The picking device is characterized in that it consists of a grooved disc (2) with a circular hole (7), a high-speed stepping motor (9), a coupling (8), and a blade-shaped cutter (6) , the blade-shaped cutter (6) is installed on the grooved disc (2), and the whole is fixed on the frame through the connecting column. The circular hole (7) described here is designed by the size of the safflower curd, which should be less than its curd diameter, in order to prevent damage to the curd. The lever device is characterized in that it has six cylindrical levers (4), and the collecting device is characterized in that it includes a conveying pipe (12), ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com