Injection mold for continuous injection molding of products of different shapes and machining method thereof

A technology for injection molds and products, applied in the field of injection molding machines, can solve the problems of increasing the management workload of injection molds, waste of production costs, etc., and achieve the effects of reasonable structure design, reduction of production costs, and high processing efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further explained below in conjunction with the accompanying drawings and specific embodiments.

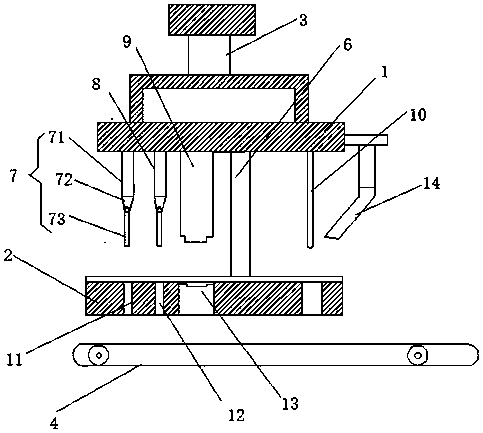

[0015] Such as figure 1 Shown is an injection mold for continuous injection of products of different shapes, an upper mold base 1, a lower mold base 2 and a mold clamping cylinder 3, the upper mold base 1 is connected to the mold clamping cylinder 3, and the lower mold base 2 is provided with Horizontal conveying guide rail 4, the middle position on the upper mold base 1 is fixedly provided with intermediate guide column 6, and the left side of intermediate guide column 6 is provided with punching thimble one 7, punching thimble two 8 and stamping punch 9, and intermediate guide column 6 The right side is provided with a bending thimble 10, and the lower mold base 2 is provided with an injection flow channel 21, and the injection flow channel 21 is provided with thimbles corresponding to the positions of the punching thimble 1 7 and the punchin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com