A kind of polypropylene-based composite material and preparation method thereof

A composite material, polypropylene-based technology, applied in the field of polypropylene-based composite materials and their preparation, can solve the problems of low grafting rate, uncontrollable internal reaction, complex system, etc. Large-scale industrial production, the effect of simple and convenient preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

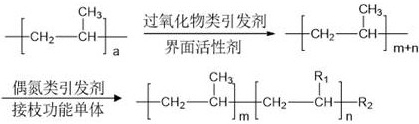

Method used

Image

Examples

Embodiment 1

[0066] Preparation of maleic anhydride grafted polypropylene compatibilizer (marked as A):

[0067] Add 100 g of polypropylene powder (brand PP-H-GD320), 20 g of benzoyl peroxide, and 150 ml of xylene as a surfactant into the reactor replaced by high-purity nitrogen, first raise the temperature to 80°C and swell for 1 h, then Adjust the temperature to 100°C for degradation for 1 hour to obtain high-fluidity polypropylene powder, then add 10 g of azobisisobutyronitrile and 15 g of maleic anhydride into the above-mentioned reactor containing high-fluidity polypropylene, and adjust The temperature was raised to 80°C for 5 h. After the reaction, the obtained sample was separated and purified with acetone and dried by suction filtration;

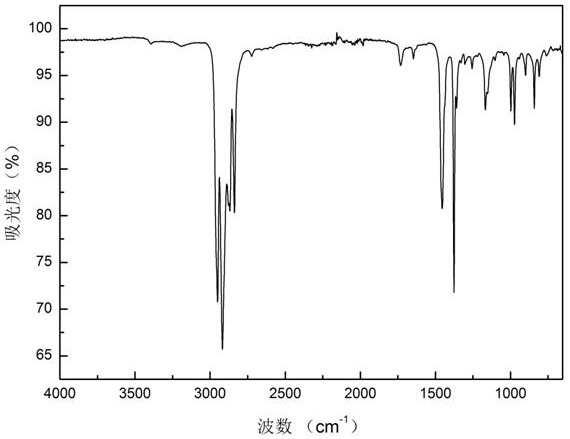

[0068] Through melt flow index measurement, the melt flow index of gained polypropylene compatibilizer is 56 g / 10 min, figure 1 It is the infrared absorption spectrum of the maleic anhydride grafted polypropylene compatibilizer, from which it ca...

Embodiment 2

[0070] Preparation of glycidyl methacrylate grafted polypropylene compatibilizer (labeled B):

[0071] Add 100 g of polypropylene (grade PP-H-GD320), 10 g of di-tert-butyl peroxide, and 150 ml of xylene as a surfactant into the reactor, first raise the temperature to 60°C and swell for 1 hour, then adjust the temperature to 80°C Perform degradation for 2 hours to obtain high-fluidity polypropylene, then add 15 g of azobisisoheptanonitrile and 100 ml of glycidyl methacrylate into the above-mentioned reactor containing high-fluidity polypropylene, and adjust the temperature to 90°C for reaction After 3 h, the obtained sample was separated and purified with acetone and dried by suction filtration.

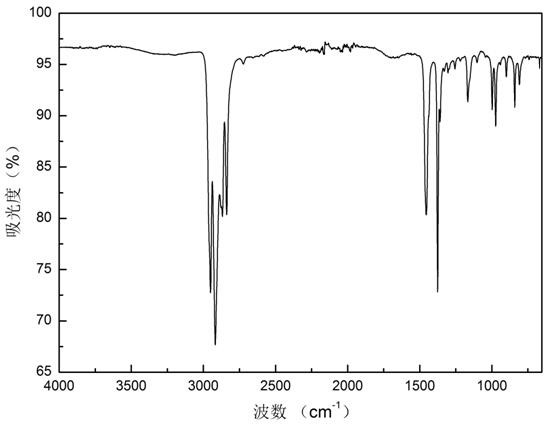

[0072] According to the melt flow index measurement, the melt flow index of the obtained polypropylene compatibilizer was 82 g / 10 min. figure 2 It is the infrared absorption spectrum of glycidyl methacrylate grafted polypropylene compatibilizer, from which it can be observed that gl...

Embodiment 3

[0074] Preparation of maleic anhydride grafted polypropylene compatibilizer (marked as C):

[0075] Add 100 g of polypropylene (grade PP-H-GD320), 15 g of di-tert-butyl peroxide, and 30 ml of n-hexane as a surfactant into the reactor, first raise the temperature to 80°C and swell for 1 hour, then adjust the temperature to 90°C Perform degradation for 3 hours to obtain high-fluidity polypropylene, then add 8 g of azobisisoheptanonitrile and 50 g of maleic anhydride into the above-mentioned reactor containing high-fluidity polypropylene, and adjust the temperature to 90 ° C for 6 h, After the reaction, the obtained sample was separated and purified with acetone and dried by suction filtration.

[0076] The melt flow index was measured by the melt flow index, and the melt flow index of the obtained polypropylene compatibilizer was 97g / 10 min, and the maleic anhydride grafting rate was further determined to be 1.06%.

[0077] Preparation Technology of Polypropylene-Based Composit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com